Shell & Tube HX Design: Taborek Method

advertisement

Shell and tube HX – Taborek-method

See course thermal installations + Wolverine engineering data book III

Taborek-method

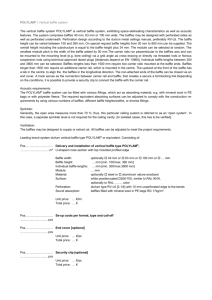

Valid for single-phase shell-side flows of S&T HXs with single segmental baffles (TEMA E-shell)

Bundle and shell geometries

Lbi: inlet baffle spacing

Lbo: outlet baffle spacing

Lbc: central baffle spacing

Dotl: outer tube limit diameter

Dctl: centreline tube limit diameter

Dt: outside diameter of tubes

o Dctl = Dotl – Dt

Ds: shell internal diameter

Lbch: baffle cut height

Bc: baffle cut = (Lbch/Ds)*100%

Lbb: diametral clearance between shell internal diameter and tube limit diameter

o If Dotl is not known:

Lbb assumed = 9.525 mm (3/8 inch) for Ds < 300 mm

Lbb assumed = 12.7 mm (1/2 inch) for 300 < Ds < 1000 mm

Lbb assumed = 15.875 mm (5/8 inch) for Ds > 1000 mm

Lsb: diametral clearance between shell internal diameter and the diameter of the baffle Db

o If Lsb is not known:

Lsb = 2.0 mm for Ds < 400 mm (15.75 inch)

Lsb = 1.6 + 0.004*Ds for Ds > 400 mm (15.75 inch)

Ltb: If the diametral clearance between the baffle holes and the outside of the tube is not

known, the maximum TEMA value can be assumed 0.794 mm (1/32 inch) or a smaller value

in the range from 0.397 mm (1/64 inch) to 0.794 mm.

Configuration

The pitch between the pipes is minimum 1.25*Dt.

The type of configuration depends on the fluid on the shell side:

Pitch configuration

Triangular

Triangular

Square

Square

Angle

30°

60°

90°

45°

Shell fluid

Clean

Clean

Fouled

Fouled

Flow regime

All

Not often used

Turbulent

Laminar

Ltp: tube pitch (= distance centre-to-centre between tubes in the bundle)

Lpp: pitch parallel to the flow direction

Lpn: pitch normal to the flow direction

The simple estimation for fixed tubesheets for single tubepass units without any tubes

removed in the nozzle entrance and exit areas:

2

0.7854 𝐷𝑐𝑡𝑙

2

𝐶𝑙 𝐿𝑡𝑝

o

Number of tubes 𝑁𝑡𝑡 =

o

Constant Cl = 1.0 for square (90°) and rotated square tube (45°) layouts and Cl =

0.866 for triangular (30°) tube layouts

For multiple tubepasses fewer tubes will be used than this expression

o

Compactness triangular

Square 90° best heat transfer for turbulent flow + maintenance

Convection coefficient shell side - hs

hs = hid Jc Jl Jb Jr Js J

Jc Jl Jb Jr Js J≈ 0.6 for a classical S&T HX

with:

hid = convection coefficient for ideal case of complete cross flow over the tube stack

o

𝑚̇

𝑚

o

2⁄3

𝜆𝑠

)

𝑝,𝑠 𝜇𝑠

ℎ𝑖𝑑 = 𝑗𝑖 𝑐𝑝,𝑠 (𝑆 𝑠) (𝑐

𝑗𝑖 = Colburn j-factor for an ideal tube stack

𝑎

1.33

𝐷𝑡

o

𝑎

𝑗𝑖 = 𝑎1 ( 𝐿𝑡𝑝 ) 𝑅𝑒𝑠 2

𝑎=

𝑎3

𝑎

1+0.14𝑅𝑒𝑠 4

𝐷 𝑚̇

𝑅𝑒𝑠 = 𝜇𝑡 𝑆 𝑠

𝑠 𝑚

o

o

𝑚̇𝑠 = mass flow shell side

𝑆𝑚 = cross section in the centre of the shell for cross flow between two baffles.

𝐷𝑐𝑡𝑙

𝑆𝑚 = 𝐿𝑏𝑐 [𝐿𝑏𝑏 + 𝐿

𝐿𝑡𝑝,𝑒𝑓𝑓 = 𝐿𝑡𝑝 for 30° and 90° tube layouts and 𝐿𝑡𝑝,𝑒𝑓𝑓 = 0.707𝐿𝑡𝑝 for 45°

staggered layouts

𝑡𝑝,𝑒𝑓𝑓

(𝐿𝑡𝑝 − 𝐷𝑡 )]

𝐿𝑡𝑝

𝐿𝑡𝑝 − 𝐷𝑡

Lbc

o 𝑐𝑝,𝑠 = specific heat at shell side at MEAN bulk fluid temperature

o 𝜇𝑠 = the dynamic viscosity at MEAN bulk fluid temperature

o 𝜆𝑠 = thermal conductivity fluid at MEAN bulk fluid temperature

Baffle cut correction factor Jc (typical 0.65 – 1.175)

o Jc = 0.55 + 0.72*Fc

o Fc = 1 – 2*Fw

𝜃

𝑐𝑡𝑙

𝐹𝑤 = 360

−

𝑠𝑖𝑛𝜃𝑐𝑡𝑙

2𝜋

(fraction of the cross sectional area occupied by the

window)

𝐷

𝐵

𝑐

𝜃𝑐𝑡𝑙 = 2𝑐𝑜𝑠 −1 {𝐷 𝑠 [1 − 2 (100

)]} (angle of the baffle cut relative to the

𝑐𝑡𝑙

centreline of the HX [°]) (valid for Bc of 15% to 45%)

Baffle leakage correction factor Jl (typical 0.7 – 1)

o 𝐽𝑙 = 0.44(1 − 𝑟𝑠 ) + [1 − 0.44(1 − 𝑟𝑠 )]𝑒 −2.2𝑟𝑙𝑚

𝑆𝑠𝑏

𝑆𝑠𝑏 +𝑆𝑡𝑏

𝑆 +𝑆

𝑟𝑙𝑚 = 𝑠𝑏𝑆 𝑡𝑏

𝑚

𝑟𝑠 =

Shell-to-baffle leakage area 𝑆𝑠𝑏 = 0.00436𝐷𝑠 𝐿𝑠𝑏 (360 − 𝜃𝑑𝑠 )

Tube-to-baffle hole leakage area for 𝑁𝑡𝑡 (1 − 𝐹𝑤 ) tube holes 𝑆𝑡𝑏 =

𝜋

{ 4 [(𝐷𝑡 + 𝐿𝑡𝑏 )2 − 𝐷𝑡2 ]} 𝑁𝑡𝑡 (1 − 𝐹𝑤 )

Cross-flow

𝐷𝑐𝑡𝑙

(𝐿𝑡𝑝

𝐿𝑡𝑝,𝑒𝑓𝑓

area at

the

bundle

centreline

𝑆𝑚 = 𝐿𝑏𝑐 [𝐿𝑏𝑏 +

− 𝐷𝑡 )]

o

𝐿𝑠𝑏 = diametral shell to baffle clearance

o

𝑐

𝜃𝑑𝑠 = 2𝑐𝑜𝑠 −1 [1 − 2 (100

)]

o

𝐿𝑡𝑝,𝑒𝑓𝑓 = 𝐿𝑡𝑝 for 30° and 90° tube layouts and 𝐿𝑡𝑝,𝑒𝑓𝑓 =

0.707𝐿𝑡𝑝 for 45° staggered layouts

𝐵

Bundle bypass correction factor Jb

3

o

o

𝐽𝑏 = 𝑒 −𝐶𝑏ℎ 𝐹𝑠𝑏𝑝 (1− √2𝑟𝑠𝑠 )

𝐶𝑏ℎ = 1.35 for laminar flow (Re ≤ 100); 𝐶𝑏ℎ = 1.25 for transition and turbulent flows

(Re > 100)

o

𝐹𝑠𝑏𝑝 = 𝑆 𝑏 = ration of bypass to crossflow area

𝑆

𝑚

𝑆𝑏 = 𝐿𝑏𝑐 ⌊(𝐷𝑠 − 𝐷𝑜𝑡𝑙 ) + 𝐿𝑝𝑙 ⌋

𝐿𝑝𝑙 = width of the bypass lane between tubes

for no pass partition lane or for such a lane normal to the flow

direction 𝐿𝑝𝑙 = 0

for a pass transition lane parallel to the flow direction 𝐿𝑝𝑙 =

1

(𝑎𝑐𝑡𝑢𝑎𝑙

2

o

𝑟𝑠𝑠 =

𝑁𝑠𝑠

𝑁𝑡𝑐𝑐

𝑑𝑖𝑚𝑒𝑛𝑠𝑖𝑜𝑛 𝑜𝑓 𝑡ℎ𝑒 𝑙𝑎𝑛𝑒) or assumed 𝐿𝑝𝑙 = 𝐷𝑡

= ration of number of sealing strips passed by the flow to the number of

tube rows crossed between baffle tips in one baffle section.

𝐷

𝐵

𝑐

𝑁𝑡𝑐𝑐 = 𝐿 𝑠 [1 − 2 (100

)]

𝑝𝑝

𝐿𝑝𝑝 = 0.866 𝐿𝑡𝑝 for 30° layout; 𝐿𝑝𝑝 = 𝐿𝑡𝑝 for 90° layout and 𝐿𝑝𝑝 =

0.707 𝐿𝑡𝑝 for 45° layout

o The expression has a maximum of 𝐽𝑏 = 1 at 𝑟𝑠𝑠 ≥ 1⁄2

Unequal baffle spacing correction factor Js

o For Lbi = Lbc = Lbo Js = 1

o

Else 𝐽𝑠 =

(𝑁𝑏 −1)+(𝐿𝑏𝑖 ⁄𝐿𝑏𝑐)1−𝑛 +(𝐿𝑏𝑜 ⁄𝐿𝑏𝑐 )1−𝑛

(𝑁𝑏 −1)+(𝐿𝑏𝑖 ⁄𝐿𝑏𝑐 )+(𝐿𝑏𝑜 ⁄𝐿𝑏𝑐 )

n = 0.6 for turbulent flow and n = 1/3 for laminar flow

Nb = number of baffle compartments determined from the effective tube

length and the baffle spacings.

Laminar flow correction factor Jr

o No necessary here (only for Re ≤ 100) Jr = 1

Wall viscosity correction factor J

𝜇𝑠

)

𝜇𝑠,𝑤

0.14

o

𝐽𝜇 = (

o

For gasses no correction factor!

o

𝜇𝑠,𝑤 via a first guess value of 𝑇̅𝑤 =

Effective tube length Lta

𝐴0 = 𝜋𝐷𝑡 𝐿𝑡𝑎 𝑁𝑡𝑡

𝑏

𝑓𝑖 = 𝑏1 (

o

1.33

𝑃𝑇

𝑑𝑢

𝑏=

𝑏

) 𝑅𝑒𝑠 2

𝑏3

𝑏

1+0.14𝑅𝑒𝑠 4

𝑇̅𝑐 +𝑇̅ℎ

2