New playhouse based on square root 2principle

advertisement

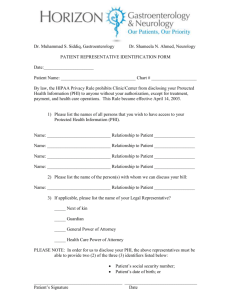

News magazine about engineering, environmental science and economics. No. 13, May 2006 New playhouse based on square root principle 2 African lake a ticking bomb New supermaterial for tunnels News magazine about engineering, environmental science and economics. No. 13, May 2006 New playhouse based on square root principle 2 New supermaterial for tunnels cowifeature – International news magazine about engineering, environmental science and economics. cowifeature is published in Danish and English and distributed to clients, business partners and employees Editors John Jørgensen (editor-in-chief), jhj@cowi.dk Christina Tækker, cht@cowi.dk Susanne Junge, sgn@cowi.dk Lotte Lykke Pedersen, llp@cowi.dk Translation LanguageWire Design & layout Josina W. Bergsøe, jwb@cowi.dk Patrick Andresén, pca@cowi.dk Hanne Bjørn Nielsen, hbn@cowi.dk Editorial input closed on 24 April 2006. Reproduction is permitted with appropriate source references. Print run 13,000 Production: Schultz Grafisk ISSN 1600-6186 New, sustainable wastewater treatment technology will draw tourists back to paradise island 30 fe Sa African lake a ticking bomb Picking up the pieces on Phi Phi ty pa ys off Se a bla t be of ck b lt alar o m t th echn xes to s and em p o os logies the list t va that lue g for m ive oney 14 Published by COWI A /S Parallelvej 2, DK-2800 Kongens Lyngby Tel +45 45 97 22 11 Fax +45 45 97 22 12 www.cowi.com Cover New playhouse taking shape. Photo: Stig Stasig COWI is a leading northern European consulting group. We provide stateof-the-art services within the fields of engineering, environmental science and economics with due consideration for the environment and society. COWI is a leader within its fields because cowi’s 3300 employees are leaders within theirs. 28 New gateway Tall towers are changing the skyline of Bahrain Gas for power production At 485 metres deep, Lake Kivu is one of the deepest lakes in the world. On the lakebed, bacteria breaks down organic material into methane gas and carbon dioxide. Every year about 120-250 million m³ of natural gas are formed – enough to produce around 100 MW of power. It is estimated that the lake contains 50 billion m³ of methane. Like shaking champagne An eruption in the lake could possibly be triggered by a combination of excessive quantities of gas in the water combined with an extraneous impact – such as a large quantity of lava flowing to the bottom of the lake. Such an eruption would be comparable to a well-shaken bottle of champagne. A broad stream of water saturated with gas would shoot about 80 metres up into the air, releasing the gas into the atmosphere and probably asphyxiating all life within a wide radius. This is what happened in Cameroon in 1986 when Lake Nyos, which is much smaller than Lake Kivu, witnessed a similar eruption that killed over 1,700 people. African lake is a ticking bomb High-technology project aims to bring gas-filled lake in Rwanda under control and convert the gas into energy. Farreaching perspectives for Rwanda’s economy and environment By Eva Isager The gas is washed out of the water A platform on the lake will collect the gas, clean and compress it and send the resulting natural gas onshore, where a power plant will convert it in to energy for delivery to the national electricity supply company. The technology for collecting the gas is novel, whereas the technology of cleaning is essentially that used in the process of purifying polluted air. Lake water full of gas and carbon dioxide is piped from the lakebed up to the surface, where a vessel separates the gas from the water and carbon dioxide. The carbon dioxide is then partially returned to the lake. Lake Kivu, on the border between Rwanda and The Democratic Republic of Congo in Central Africa, is one of the most dangerous lakes in the world. It is also considered among the most beautiful lakes in all of Africa, surrounded by green hills, fields and virgin forest. The danger presented by the 2,400 km² lake is concealed under the almost perpetually becalmed surface. The lakebed produces methane gas and carbon dioxide in such enormous quantities that it is in all probability only a question of time before an eruption occurs and releases the choking gas. The result would be a human catastrophe. In a worst-case scenario, all inhabitants of this densely populated area could be at risk of losing their lives. Illu : Me tio n s tr a ar m diaf Converting gas to energy But for the time being, at least, the local population can breathe easily. A high-tech project currently under way will not only extract the gas, but also reduce the risk of eruption. The gas will be converted into energy in such quantities as to render this impoverished nation self-sufficient – and reduce energy costs by up to 80 per cent into the bargain. Today Rwanda’s power plants run on imported diesel, which is a pollutant. A reduction in the consumption of International news magazine from cowi • 5 diesel and oil would benefit the environment and increase currency reserves. “Lake Kivu is a ticking bomb, but it is not too late to render it harmless. We expect another 100 years to elapse before any eruption occurs, which gives us time to plan what action to take,” explains COWI project manager Mogens Winkler, who is acting as consultant for the World Bank, which is representing the project’s seven international lenders. COWI is assisting a joint venture between the Rwandan government and the Finnish-Dutch-Norwegian company Dane Associates to extract the gas. COWI’S responsibilities include ensuring that security, the stability of the lake and environmental conditions in connection with the project are optimal. Perpetual production process Project manager Paul A. Nickson from International Finance Corporation under the World Bank is positively enthused about the project: “It is a first-rate project with far-reaching perspectives. We are negating the risk of a catastrophe in the area and helping Rwanda get back on its feet. Not to mention the environmental gain,” says Paul A. Nickson. The first phase of the project has a price tag of about DKK 500 million. The longer-term aim is to extract the same volume of gas that is constantly being formed at A high-tech project is currently under way to extract gas from Lake Kivu, Rwanda. Photo: Scanpix A power plant will extract the gas from Lake Kivu and convert it into power that will be supplied to the national electricity company. The power can be used to supply electricity to private homes and factories. Illustration: Mediafarm the 485-metre deep lakebed – and in so doing establish a sort of perpetual production process. Later in the year it is planned to start up a test plant in the lake to facilitate ongoing measurements of the lake to assess its continued stability. Does the potential danger increase if lava from nearby volcanoes flows into the bottom of the lake? And what if an earthquake strikes the area? At present very little is known, even by experts in these fields. @ Project manager Mogens Winkler, mwi@cowi.dk http://perso.wanadoo.fr/mhalb/kivu/eg/eg_ 1a_lac.htm 35$!. Facts about Lake Kivu: Lake Kivu is situated in Central Africa on the border between The Democratic Republic of Congo and Rwanda. Lake Kivu flows into the River Ruizi and south into Lake Tanganyka 5'!.$! $2#/.'/ +%.9! 2 7!.$! ,AKE 6ICTORIA ,AKE+IVU "52 5.$) 4!.:!.)! 6 • International news magazine from cowi International news magazine from cowi • 7 “The two-stage process can convert bio fuels such as straw, wood chips or briquettes into a combustible gas,” explains cowi project manager Jens Dall Bentzen. Photo: Tao Lytzen Fuel cells have potential to be the energy technology By Gitte Roe Eriksen of the future “In the search for new energy technologies to meet future consumption, fuel cells present an attractive opportunity given the many benefits to be gained from using them,” says Jan Pieter Ouweltjes of the Dutch energy research centre ECN. He is project partner in the EU’S “Biocellus” project, where Indec, part of ECN, is providing fuel cell and gas purification equipment to test the fuel cell on biomass gasifiers in Europe. COWI and the Technical University of Denmark are the Danish participants in Biocellus, and the fuel cell will be tested on a pilot gasification plant at the university. Danish participation in the project is receiving support from the EU and the Danish Energy Authority. From lawnmowers to cars Basically, a fuel cell is a small electrochemical power plant that produces power from the input of air and gas such as hydrogen, reformed natural gas or other sources of energy. They produce significant quantities of power relative to the amount of gas used to ‘feed’ them. And they are efficient in all sizes of plants – big and small. “Fuel cells can be used in countless applications, from lawnmowers to cars and even in buildings, where they can supply both power and heating – in a highly decentralised energy system,” explains COWI project manager Jens Dall Bentzen. In addition to the many opportunities afforded by fuel cells in terms of power output, there are also important environmental advantages. The cells are noiseless, emit no sulphur dioxide (SO2) and only very little nitrogen oxide (NOX). The only waste product is water. Challenges waiting in line However, we are still at a very early stage of development. Jens Dall Bentzen explains: “Fuel cells are costly to make, degenerate over time and are susceptible to impurities. Quite simply, they die if the gas being fed into the cell is in any way impure. So there are many challenges that need to be addressed.” In the Netherlands there is a firm belief that fuel cells are the thing of the future. “In the course of the next decade we will see a major breakthrough in the use of fuel cells,“ predicts Jan Pieter Ouweltjes. “The initial results are very promising and therefore we are expecting good results from the next phase, where a real fuel cell based system will be connected to a gasification plant.” Fuel cells for use in private homes Eight Danish companies headed by Danfoss have joined forces to establish a demonstration project for micro heat and power systems based on Danish fuel cells. The aim of the project is to bring fuel cells into private homes as a source of heat and power. COWI has assisted Danfoss in preparing and organising the project and with completing applications for public funding. The entire project is expected to run for seven years. In the initial phase of the project, the industrial parties will construct a firstgeneration plant. In subsequent phases, when the plants are to be placed, COWI’S role will be to act as the link between the industrial companies and the users. 8 • International news magazine from cowi The best plant Biocellus will test the fuel cell on five different biomass gasifiers in Europe. “The Technical University of Denmark has been approached to host the long-term testing for the entire project, as it has the best biomass gasification plant available,“ explains project manager Jens Dall Bentzen. Waste heat with no wastage The Technical University of Denmark has a so-called twostage gasification process in operation. For many years COWI has enjoyed close collaboration with the university’s researchers on the development, upscaling and optimising of this process. Head of gasification activities at the Technical University of Denmark, Ulrik Henriksen, says: “The two-stage process can convert bio fuels such as straw, wood chips or briquettes into a combustible gas. The gas from the two-stage process is characterised by extremely low tar content and high hydrogen content, which is ideal for optimum fuel cell performance.” “The fuel cells to be used in the test are so-called SOFC cells, which operate at high temperatures. Waste heat from the fuel cells can be used in the gasification process, and with an SOFC fuel cell we can achieve a very high electrical efficiency of about 50%.” @ Project manager Jens Dall Bentzen, jdb@cowi.dk New supermaterial for tunnels Concrete mixed with steel fibres each measuring no more than 47 mm in length gives a new, robust building material that is about to be put to the test in the bored district heating tunnel 30 metres below ground level in Copenhagen By Eva Isager Deep underground in Copenhagen – so far down that the metro runs above it – a boring machine is about to begin drilling in readiness for laying a four-kilometre long district heating main. The boring work will begin near Amagerværket south of Copenhagen city centre, run beneath the royal residence of Amalienborg and close to the landmark Frederik’s Church, popularly called the Marble Church, and terminate beneath the Nørrebro quarter on the north side of the city. This will be the largest civil engineering project in Copenhagen since the city’s metro, but the people of Copenhagen will hardly be aware of the activity beneath their feet. It was precisely to minimise disruption to the city’s citizens and traffic that it was decided to lay the district heating main in a bored tunnel deep underground, rather than dig it down close to the surface. Work on the tunnel 30 metres underground is technically very demanding, but it means that disruption to traffic can be avoided and also presents an opportunity to put the new building material to the test. Instead of traditional reinforced concrete, for the first time in Denmark a construction project is to utilise steel fibre reinforced concrete elements in the shape of curved slabs lining the inner surface of the tunnel. Ring girder reinforcement work in progress on the district heating tunnel 22 metres underground. Photos: Henrik Pyndt Sørensen be under sustained pressure. Therefore just 35 kg of steel fibre per cubic metre of concrete is sufficient to withstand anything the elements are subjected to during transportation and construction. If this technology had been known when Denmark’s Great Belt tunnel was constructed, steel fibre reinforcement would very likely have been the preferred solution. And it will certainly make an obvious choice for the next stage of Copenhagen’s metro expansion.” COWI is designing and supervising the tunnel construction for Copenhagen Energy and is the first consultant in Scandinavia to use steel fibre reinforced elements. Withstands high temperatures Despite their modest size – 47 mm in length and 0.8 mm in diameter – steel fibres can certainly compete District heating tunnel Copenhagen Energy is constructing the new district heating tunnel in Copenhagen as part of its modernisation plans for the production of district heating. Much of the production is being moved from the old plants at H.C. Ørstedsværket and Svanemølleværket to Amagerværket, which will render production more economical and environmentally friendly than at present. The boring work commences in July 2006 and the last stretch of tunnel should be in use by spring 2009. Initially it will transport both district heating water and steam, and will be built so that the steam system can later be converted to a water system. New technology “Steel fibre reinforced concrete elements are really the optimal solution for tunnels,” claims COWI’S project team comprising project manager Morten Faurschou, Carola Edvardsen, Thomas Kasper and Jens Nymann. “When you construct a tunnel in soft earth close to the surface, tension can occur in the liner and therefore the steel fibres have to be supplemented with traditional reinforcement – or the volume of fibre has to be significantly increased. But in this particular case the tunnel is being laid deep and consequently the liner will International news magazine from cowi • 11 Copenhagen Harbour 3,000-tonne prizewinner Amalienborg Palace There is steel in the door handles, structural elements, ceilings and bridges. The 3,000 tonnes of steel which were used to build Copenhagen’s Flintholm Station have made the structure unique. The station was awarded the prestigious European Steel Design Awards 2005. The steel made it possible to accomplish a building with both large spans and a slimline look. This is clearly visible from the steel bridges that span almost 29 metres and the 5,000 square metre glass roof that seemingly floats above Flintholm Station. Photo: Morten Larsen @ Project manager Erling M. Bødker, emb@cowi.dk 30 metres underground Black box will reduce traffic accidents s tr a tio n: i ll uvi ld Consultants must ensure that the water table is not lowered, as this could cause damage to buildings founded on timber piles Illu Water table The temperature in the steam pipe can reach 3oo°C District heating main Clay and filler Service trolley for tunnel maintenance access Limestone The steel pipes will be lowered into the shaft It is small and black and no bigger than a couple of cigarette packets. The black box, as we know it from aircraft, has for the first time in Denmark been tested in a slightly different format in minibuses. cowi has recently completed a pilot project for Denmark’s Road Safety and Transport Agency to determine if the black box can help reduce traffic accidents. The black box stores such data as the speed of the bus, how hard it brakes and whether the bus driver uses his indicator lights – and results suggest that bus drivers take more care on the ens : Siem Photo roads with a black box installed on the dashboard. @ with traditional steel reinforcement. First and foremost, these tiny fibres save society massive amounts of money. They are cheaper to produce than steel bars and do not corrode – the cause of concrete spalling – which also means reduced maintenance costs. This makes the steel fibre solution especially well suited to the district heating tunnel and the more demanding climatic conditions resulting from the tunnel’s internal temperature of 50-60 °C, caused by the 300°C steam passing through it to supply the district heating. Calculations from scratch The steel fibre reinforced concrete elements have only been used twice before in tunnels in Europe: in a test section of a tunnel in the Netherlands in 1998 and in a tunnel project in England in 2002-2003. The tunnel in England is shorter than the one in Copenhagen, but the experience has been so positive that the people of Copenhagen will soon have the new building material in use beneath their feet. Given that steel fibre reinforcement is such a new material, there are not yet any standards showing how the material performs under pressure and tension etc. Therefore COWI has had to make all calculations from scratch. It was also necessary to carry out regular testing in Germany and Denmark of both the strength of the reinforced concrete and the durability of the rubber water stop intended to prevent groundwater from seeping in between the elements – a critical point given the high temperatures. @ Project manager Morten Faurschou, mnf@cowi.dk Denmark gets Europe’s most modern mill 250,000 tons of flour per year. This is how much Europe’s most modern mill will produce on completion in three years’ time in Vejle Harbour. Food manufacturer Cerealia Danmark A/S is investing DKK 400 million in the mill, which will produce flour for the Danish market. This is the first new mill to be built in Denmark in modern times, and it will be connected to the existing one in Vejle. cowi is responsible for all disciplines of the project. @ Pho to: Sca npix Chief project manager Knud Eigil Kruse, kek@cowi.dk Project manager Per Tybjerg Aldrich, pea@cowi.dk Diploma for green environment in Vietnam The provincial government in Phu Tho in Vietnam has honoured a recently completed Danida-financed project headed by cowi’s Morten Jørgensen. Among other things, the project has shown the authorities and citizens of Viet Tri City, 75 km west of Hanoi, how to deal with hazardous waste, plant more trees, take care of the aquatic environment and improve sanitary conditions in the city’s marketplaces. cowi has been involved in developing methods and assisted in implementing environmental projects. @ Project manager Morten Jørgensen, mjo@cowi.dk Ph 12 • International news magazine from cowi International news magazine from cowi • 13 ot o: Sc an pi x ca to: S Pho Seat belt alarms and black boxes give most safety for money npix Increased safety for trucks and lorries In addition to increased safety in cars, cowi has also identified the safety improvements in trucks and lorries that give the best cost-benefit ratio – listed here in order of priority: 1 Retro-fitting of blind spot mirrors. Obligatory on new lorries and trucks in all countries, and in Denmark and some other countries also obligatory on older trucks and lorries. 2 Reflectors on the sides and rear to reduce the risk of collision. Not obligatory. 3 Crosspieces on the underside to reduce the risk of other road users ending under the vehicle in the event of a collision. Not obligatory, but widely in use on the front and rear of trucks and lorries. 4 Soft front. A so-called crash absorber that reduces the risk of damage and injury in the event of a collision. Not obligatory. The advantages of installing safety technologies in cars outweigh the costs, a new eu survey carried out by cowi shows By Gitte Roe Eriksen Seat belt reminders and event and accident data recorders that can show the speed of a car and the actions taken by a driver in accident situations top the list of vehicle safety equipment. And there is further potential in alcolocks, electronic stability control (ESC) and intelligent speed adaptation, according to the results of an economic cost-benefit assessment carried out by COWI on behalf of the EU to determine which technologies ‘give the most value for money’. At the bottom of this list are basics like intelligent adaptive cruise control and automatic tyre pressure monitoring equipment. Of the 21 safety technologies assessed, 17 are for use in passenger cars and 4 in trucks. The analysis shows that the benefits – in the form of fewer fatalities and injuries – will in the vast majority of cases far outweigh the costs of installing the technology in vehicles. COWI team leader Thomas Odgaard points out: “While the analysis does not provide definitive final results, the figures nevertheless indicate the extent of usefulness of the technology.” Top 5 – the safest eu countries In 2002 the five safest countries to drive in, measured by the number of fatalities per million inhabitants, were: Malta: 40 United Kingdom: 60 Netherlands: 61 Sweden: 62 Finland: 80 In 2002 Denmark reported 83 fatalities per million inhabitants. Top 5 – the most dangerous eu countries In 2002 the five most dangerous countries to drive in, measured by the number of fatalities per million inhabitants, were: Latvia: 225 Lithuania: 205 Greece: 171 Estonia: 159 Portugal: 158 The figures give an indication of accident risk in each eu country. Values based on exposure, i.e. travelled kilometres, are not available. Apart from the human cost, the socio-economic costs run to DKK 1700 billion annually. Given these alarming statistics, the EU has set itself the goal of halving the number of road fatalities by the year 2010, in part through the use of passive and active safety equipment in vehicles. outweigh the costs. However, for some technologies it was not possible to carry out the analysis in its entirety, as these technologies are still in the test phase or under development. Although this does not mean that they are not effective or suitable as safety equipment, because they could well prove to be.” Focus on electronics The 21 technologies range from familiar, documented technologies such as seat belt reminders and the use of blind spot mirrors in trucks to more sophisticated technology such as event and accident data recorders, intelligent speed adaptation and electronic stability control. The latter is among the technologies that car producers are setting great store in and where there is significant potential for the development of new components. Thomas Odgaard explains: “With very many of the 21 technologies that we have analysed, the benefits far Demand for safety Countries beyond the EU, too, are looking at ways to improve safety in cars. And motorists themselves are increasingly weighing safety measures when deciding which car to buy. “Clearly this constitutes a competitive parameter that car producers are already working on. And all the indications are that it will take on even more importance in the future. Normally, new technologies first appear in more expensive cars and later they become standard in other classes of cars,” says Morten Klintø Hansen, traffic safety expert with COWI. @ Team leader Thomas Odgaard, tod@cowi.dk Would reduce fatalities by half In 2001, over 50,000 people lost their lives and millions were injured as a result of road accidents in Europe. 14 • International news magazine from cowi International news magazine from cowi • 15 Safety equipment for the car Seat belt reminder tops the list With the help of economic cost-benefit assessments, a team of cowi economists and engineers has determined which technologies are most beneficial relative to the cost of installing them in vehicles. Of the 21 technologies analysed, it was possible to carry out cost-benefit assessments for 13 of them. Technology 10. eCall A system that immediately phones the emergency services if the vehicle is involved in an accident. The system automatically sends road coordinates so that emergency services can quickly reach the right location. Available in a number of variations in several makes of cars. Of the 21 technologies assessed by cowi, 17 can be installed in private cars 15. Improved seats and headrests Whiplash injuries can be reduced through enhanced design of seats and headrests. The system can be developed to actively adapt to accident situations by, for example, automatically reverting the seat to an upright position and tightening the seatbelt. Also provides protection from other types of injury. Benefit in relation to cost Major benefits Seat belt reminder 8 (times greater benefit than cost) 7 Almost 4 Event and accident data recorder ESC Retro-fitting of blind spot mirrors Intelligent speed adaptation Alcohol ignition interlocks Almost 4 3 3 Significant benefits Conspicuity marking Under-run protection Daytime running lights Lane departure warning 2½ 2½ Almost 2 Almost 2 5. Alcolock In best law-abiding style, you blow into the alcolock to show if you are in a fit state to drive. The car does not start before you have blown into the alcolock. However, it is only 100% effective if the driver continues to blow into it at regular intervals to guard against drinking while driving. In Denmark, about 25% of accidents resulting in fatalities involve alcohol. 8. Intelligent adaptive cruise control (ACC) A car can be programmed in advance to run at a predetermined speed. The system can also maintain a given distance to the vehicle in front. An electronic control unit automatically brakes or accelerates the car as required. 1. Seat belt reminder Controls if the driver and passengers have fastened their seatbelts. Failure to do so triggers an alarm, either visually on the dashboard or by emitting a sound. Today about 80 per cent of all motorists and passengers use seatbelts when sitting in the front seat of the car, but only half of car passengers use seatbelts in the back seat. 17. ISOFIX A standard for securing baby chairs that utilises a click system. Installed in many makes of car. Benefits not justified by costs Adaptive cruise control Almost ½ Tyre pressure monitoring Almost 0.05 Difficult to categorise eCall 9. Tyre pressure monitoring Sensors in each tyre valve monitor the tyre pressure and warn the driver if it is too low. Between almost 0.5-2 s tr Illu 11. Collision warning system With the help of a radar-activated light or sound signal, this system warns the driver when other vehicles are pulling over in front of the car or if the vehicle in front is reducing speed. Can be developed to make the car able to “think for itself”; in other words, avoid collisions by braking or taking avoiding action. 13. Improved vehicle compatibility Soft bonnets and hoods reduce injury to pedestrians on impact with the vehicle. Serve as a kind of cushion that absorbs the impact of a collision. 16 • International news magazine from cowi 6. Daytime running lights In many cars the lights switch on automatically when the ignition key is turned on. In a number of countries, driving with the lights on at all times is required by law. o ati n: f dia Me ar m 3. ESC Electronic stability control. Prevents the car from veering off the road. For instance, if the driver overdoes a manoeuvre ESC will intervene in the brake system, motor and steering to ensure that he does not lose control of the car. Volvo and Saab have ESC in all new models. A system that is becoming increasingly widespread. 7. LDWS Lane Departure Warning System. Infrared sensors under the bumper register if the vehicle comes too close to the edge or centre lines. The driver is warned by means of a sound, or the seat vibrates if the vehicle is veering off the road or into the path of approaching traffic. Already standard in several makes of car. 16. Brake measurement devices Automatically tests that the brakes are working. 14. Brake assistant systems Enhanced automatic braking in the event of accidents. Surveys show that female drivers in particular do not brake hard enough and consequently do not fully utilise the car’s braking ability in accident situations. 4. Intelligent speed adaptation (ISA) A computer in the car performs automatic speed adaptation in relation to the speed limit in force for the stretch of road on which you are driving. The system can be based either on a GPS combined with digital map in the car or road signs that transmit a signal to the car. If the speed is too high, the driver is warned by means of a flashing light or a voice message informing him of the correct speed. The speeder can also be set to provide resistance, so that maintaining too high a speed will require extra pressure. It would also be possible to install more advanced systems with the ability to modify speed levels to the prevailing road conditions – wet, slippery, etc. road surface – and density of traffic. 12. Fatigue detectors Sensors in the dashboard monitor the driver’s eyes while driving. The system registers if the driver’s eyes start to blink slowly or close for longer periods at a time. An alarm emits a sound signal to keep the driver awake. Currently under development. 2. Event and accident data recorders Records speeds and other data for use in the event of an accident. Has a preventive effect and can also help to prove guilt or innocence in the event of accidents. In Iceland, tests have been carried out with mail vans – and here the black box was found to have a pronounced preventive effect. International news magazine from cowi • 17 The last steel girder, 85 m in length, has been installed in the Danish Royal Theatre’s new playhouse. And so this highly distinctive building is beginning to take shape near Kvæsthusbroen bridge in Copenhagen 140 tonne steel girder erected in a single operation Photo: Stig Stasig Read about Copenhagen’s new architectonic attraction on pages 18-26 The outermost lattice girder of the playhouse is almost in place. On completion, the girders will form an architectonic pattern throughout the entire building. Photos: Stig Stasig The construction moves In order to create the feeling that the entire top floor seems almost to be suspended above the rest of the building, the roof has a very large free span. The biggest freely suspended cantilever, at the corner of the playhouse, is 26 metres – the equivalent of a seven-floor building. The construction is similar to the roof of Copenhagen’s new Opera House, which can be seen on the other side of the harbour. ng e floati from th e the n a m g receiv The fla ready to irder. crane is long lattice g e tr e m 85 By Christina Tækker Scandinavia’s biggest floating crane, known as Samson, comes chugging through the mist. A massive orange and blue colossus, it sails slowly through Copenhagen Harbour hauling its heavy load: a 140tonne lattice girder suspended on two strong hooks. The monotonous sound of the motor suddenly ceases as the floating crane reaches the Danish Royal Theatre’s playhouse at Kvæsthusbroen bridge over Copenhagen harbour. Slowly the giant crane turns in the water while the flagman, Head of department Rene M. Kræmer (left) and project manager Kim Bundgaard watch for the floating crane. feet planted solidly on what will eventually be the foyer of the new theatre, shouts orders as he guides the 85 metre long steel girder into place the length of the playhouse. Precision manoeuvring is imperative. The girder must be laid in steel frames high above the ground to form the top floor of the playhouse, which is being built on a number of long steel girders. For the first time in Denmark, 85-metre long steel girders are being installed from the water. The girders have been welded together in quarters in Latvia, and then transported to the B&W dockyard close to the playhouse site in Copenhagen harbour for final assembly. Installation takes about eight hours per girder. And so this highly distinctive building is beginning to take shape. Suspended in the air “It is very unusual to install such massive steel girders in a single operation,” comments COWI head of department René M. Kræmer, “and I don’t think it has ever been done before But the difference is that the cantilever on the playhouse is designed to support the canteen, wardrobes and meeting rooms. The top floor is so solidly dimensioned that the staff of the Royal Theatre can party until dawn if they wish in the freely suspended canteen. To compensate for the heavy load, the end of the grey steel lattice above the water has been raised about 10 cm. But by the time the building is completed, the structure will have settled and the entire floor will be level. “The dimensions are outsized and the construction moves more than is normal in civil engineering,” explains COWI project manager Kim Bundgaard. “The grey steel lattices have been made with a built-in skew – because when they are subject to the full pressure of the roof, they will level out. You can compare it to the pylons of Denmark’s Great Belt Bridge. They were also installed slightly skewed – deliberately so, I might add. Because the subsequent load exerted by the bridge girders caused them to recede and stand straight.” @ Project manager Kim Bundgaard, kbu@cowi.dk See video of the Playhouse steel girders being installed at www.cowi.com The floating crane set off in the dead of night, when the gusting winds of the previous day had finally eased. from the water. The size and span of the girders stand comparison with those of a bridge. On completion of the construction, the free span will be of such dimensions that the girders will appear to be suspended in the air with no supporting structure.” The steel girders, which will support the actors’ canteen and wardrobe, form a prominent part of the building. By day people will clearly see the pattern formed by the long girders through the glass façades of the top floor. And in the evening the roof will appear as a belt of light right around the playhouse. Facts about the Danish Royal Theatre’s playhouse In October 2002 in open competition, COWI landed the contract to provide engineering consultancy services for the new playhouse, due for completion in 2008. The building will house a large auditorium with 650 seats, a smaller auditorium with 275 seats, and a restaurant and café. Owner: Ministry of Culture. Architect: Boje Lundgaard & Lene Tranberg Arkitekter A/S. It requires great concentration to install the 140 tonne lattice girder in the dark. New playhouse based on square root 2 principle Architect Henrik Schmidt in front of the playhouse which is taking shape. Photo: Stig Stasig By Eva Isager What will happen at the point on the apron where the lines cross? Wait and see, smiles the architect. Perhaps the evening’s performance will be imbued with a special energy Applying the square root 2 principle, a line cuts through the Playhouse along the edge of the quay. Another line goes through the stage tower and the large auditorium. The lines cross at the apron, illustrates architect Henrik Schmidt. Photo: Stig Stasig balconies of the main auditorium and the It is almost verging on the inconceivable to foyer filled with life.” think that by the end of February 2008 the curtain is due to rise on opening night at Respect for the surroundings the Danish Royal Theatre’s new playhouse The building will be abuzz with activity – right here where today there is a jumble virtually round the clock. From one side of concrete and boarding and muddied you will be able to peep in through the workmen aplenty. But even though the window chinks in the wall and see some of main auditorium and the rest of the playthe preparations under way for the house at Kvæsthusmolen on Copenhagen’s evening performance. The square, glassquayside presently resembles a chaotic construction site, it does not take too much enclosed top floor, taut between the big steel lattice imagination to “We wanted to provide the optimal girders, houses picture how the conditions for … the encounter facilities for new building actors and adminwill enhance the between audience and play” istration, includtheatre experiing the canteen and rehearsal rooms with ence for audiences. Before they even take their stunning views out over the water. In their seats in the auditorium. the evening, life on the top floor and the The interplay between the playhouse three stages will form a fulcrum of activity. and the harbour space is central to this Total audience capacity for the three massive project, valued at DKK 750 milstages is about 1,100 seats, of which 650 are lion. The new national stage will project in the main auditorium, which will have about 50 metres out into the harbour cavern-like qualities with a relatively short entrance. On completion, audiences will be seated in what is now the actual harbour distance between actors and audience. Henrik Schmidt describes the architecentrance, while the actors will be where tural concept behind the playhouse: the edge of the quay currently runs. But “It all started with the location. We for architect Henrik Schmidt from the firm wanted to create a building in harmony of architects Lundgaard & Tranberg, the with its surroundings and with the spaprincipal architect behind the playhouse, ciousness of the harbour. Not a big, flashy the drama begins outside the building for building, but one at a deferential distance theatregoers and others: to the axis formed by the Royal residence “Access is via a massive timbered promof Amalienborg and the new Opera House, enade, a sort of boardwalk suspended out and the background buildings on the landover the water on skewed piles a la Venice,” explains Henrik Schmidt. “The promenade ward side. For instance, the view to the water from the square of Skt. Annæ Plads runs right around the building and the remains unimpeded.” architectonic drama continues in the “The solution was a large brick building glass-facaded foyer, which is surrounded with three main elements in the form of a by water on three sides. You will be able promenade, stage construction and the to see right in to the rough brick walls, large top floor. The building has all the the broad stairways leading up to the basic functions that go into keeping the machinery of theatre functioning, and tailoring a playhouse for the Danish Royal Theatre has been an amazingly exhilarating experience. We wanted to provide the optimal conditions for what, in essence, this is all about – the encounter between audience and play.” Invisible lines The playhouse is in harmony with the neighbouring buildings – and with itself. Important to achieving architectural harmony is the mathematics of the project, or to be more precise the square root 2 principle. The entire composition and position of the building on the ground embodies this principle, which serves as a guideline for determining the distance between the various parts of the building. The architect’s drawings show the building dissected by lines that divide the building into rectangles. The sides of the rectangles are in the ratio of 1:1.414 to each other. The square root 2 is equal to 1.414 – hence the designation. One line cuts through the building along the edge of the quay while another goes down through the middle of the stage tower and the main auditorium, with the two lines crossing each other at the apron which, depending on the performance taking place, will be used either by the actors, for additional rows of seating or as part of the orchestra pit. And what happens at that point? Wait and see. If you are really paying attention you will notice something, smiles Henrik Schmidt. An energy, perhaps, that makes its presence felt through the performance … @ Project manager Kim Bundgaard, kbu@cowi.dk International news magazine from cowi • 23 A well-composed COWI group. From Left: Gustav Lanng Madsen, Jens Mellergaard, Bernt Wangy, Thanh Quoc Nguyen, Kim Rasmussen and Kim Bundgaard. Photo: Stig Stasig Unusual framework Photo: Scanpix Photo: Morten Larsen Audiences heat the new playhouse Body heat from the audiences and water from Copenhagen Harbour are used to heat and cool the playhouse. The heat from the strong projector lights and from the audience attending the previous evening’s performance is used to heat the changing rooms, offices and foyer. This is done by extracting the heat from the auditorium and storing it in liquid form for use as floor heating the following day. This is one of the first Danish projects to use thermo-active concrete constructions, which utilise a combined heating and cooling system consisting of plastic pipes moulded into the concrete floor and ceiling. The playhouse is receiving eu support for its energy systems. New fire regulations have allowed for an open and more flexible building. With function-based fire regulations, an unusual framework can be created for the playhouse without compromising fire precautions. The large auditorium is designed with more seating per row than is allowed by the standard fire regulations. Safety measures in the event of fire are instead documented by means of comprehensive calculations and evacuation analyses. These analyses are optimised to accurately reflect the fire risk and consequently only those fire precaution measures that will actually make a difference need be implemented. Model photo: Boje Lundgaard & Lene Tranberg Arkitekter A/S Six men and a playhouse Playhouse built on piles A mass of tilted piles. It looks as if the playhouse is built on Venetian piles. But beneath the surface of the water a row of piles bored into the limestone floor of the harbour supports the promenade built around the playhouse. The piles represented a construction challenge for the consultants and the 24 • International news magazine from cowi Almost a Mediterranean feel contractor, who had to take into account the old berthing structures driven into the earth, a 132kV cable from Copenhagen Energy that traverses the harbour basin, and a diversity of soil conditions such as moraine, meltwater deposits, limestone and flint. Prior to performances and during intermissions, theatregoers will congregate in the playhouse’s glass-enclosed foyer with its nine-metre high ceiling. The foyer is also open to the public, so that families just out for a Sunday afternoon stroll will also be able to enjoy a cup of coffee in the café. From here you can enjoy a wonderful view over the water that surrounds the foyer on three sides. And when the weather allows, there will be outdoor tables near the south-facing entrance. By Eva Isager There they stand in the unfinished rehearsal room, trying to look rough and tough at the request of the photographer. But the only rough stuff around here are the large concrete surfaces of the playhouse, where six of COWI’S budding engineers have been working together for so long and got to know each other so well in the process. Gustav Lanng Madsen, Thanh Quoc Nguyen, Bernt Wangy, Jens Mellergaard and a couple of Kims called Bundgaard and Rasmussen are all between 30 and 38 years of age. They all have engineering backgrounds and make up the main part of the COWI team that is working on design, follow-up and inspection of the playhouse construction at Kvæsthusbroen in Copenhagen harbour. In the initial stages their more seasoned colleagues worked on the design, but at a relatively early stage the younger team took over. After a couple of minutes in the company of the six young engineers, you automatically start laughing. There is a chemistry between them that is hard to put into words. Take equal parts professional camaraderie and seriousness, mix in a good portion of fun and games and sprinkle liberally in an all-male environment, and you might begin to get the idea. Female on the way “Our jargon and humour…” begins Bernt Wangy, before Gustav Lanng Madsen cuts in: “…is so downright childish.” The laughter echoes around the concrete room. Bernt Wangy tries again: “OK, we also have in common the tremendous energy we put into our work here. We want to show that we can do a good job, and perhaps that is more important for us than for our more seasoned colleagues.” The other five nod their assent. Kim Bundgaard emphasises the dynamism and creativity of the team: “The architects and the staff of the Royal Theatre who are here on-site are also creative and about the same age as us, which makes it easier for us to talk to one another.” “Would we like to have a female in the group? Yes, please! A female will actually be joining us soon, and we are really not a coarse bunch, so as long as she can go along with the jargon…” smiles Gustav Lanng Madsen. “On completion of the design phase we will no longer be together so much, so that should make it a little easier for her,” adds Bernt Wangy wryly. Different type of project For several members of the group, being involved in the construction of the playhouse is something very special. Thanh Quoc Nguyen is one of them: “To date I have worked on this project for two years and it is very different from other projects because so many things have to come together in a synthesis – plus it is such an important building for the city of Copenhagen. This is the kind of project that makes working for COWI so interesting.” International news magazine from cowi • 25 Large-scale Model photo: Lundgaard and Tranberg/cowi Playhouse in 3d Because of the complexity of the construction, cowi decided to utilise 3d design. In collaboration with the architect, cowi computer-modelled the entire auditorium. Using 3d makes it easier for the owner and non-technicians to understand the drawings and see what the finished result will look like. With 3d you can sketch the projected dimensions, which come over more clearly than just a line would, and show space requirements for cable racks etc., thus minimising the risk of error. construction of low-energy housing Four city communities are ambassadors for energy-wise solutions in a large-scale eu project By Christina Tækker Solar collectors, solar cells, wind turbines, biomass plants and heat pumps. Many different solutions will be trialled in the so-called ECOCity project under the EU Commission’s CONCERTO programme when a series of low-energy ECObuildings are supplied with energy in Helsingborg (Sweden), Elsinore (Denmark), Trondheim (Norway) and Tudela (Spain) over the next five years. The CONCERTO initiative is probably the greatest integrated venture the EU Commission has instituted in the field of energy. Designer bricks The playhouse is being built with bricks of a kind never before seen in Denmark. The firm of architects Lundgaard & Tranberg had them developed by a brickworks in southern Jutland to give the playhouse a distinctive, contemporary brick finish that, while stylish, still merges with the surrounding old buildings and warehouses. The bricks are slimmer and longer than normal – just over half a metre in length – and have been made in a range of slaty nuances: grey-beige, grey-mauve and grey-green. The bricks will be used for both internal and external walls. The background shows some of the different bricks considered for use in the project. Photo: Stig Stasig Photo: Scanpix Natural sound The inner walls are broken up into sections that are offset in relation to each other and clad with special bricks. The ceiling also has different sections and angles, and the seats absorb the same amount of sound regardless of whether the auditorium is half empty or completely full. This innovative concept is an inventive approach to providing the large playhouse auditorium with superb room acoustics. The actors will be able to perform without the usual small microphones and still be clearly heard throughout the auditorium. Nor will performances be marred by extraneous noise. During the initial round, nine integrated projects have been set in motion, ECO-City being one of the first. The energy component of the ECO-City project accounts for more than DKK 200 million, which the EU is subsidising to the tune of DKK 85 million. Setting an operating precedent “The ECO-City project will set a precedent for ways of operating more energy-efficiently in future at municipal level and will promote lowenergy building to meet the new requirements set out in building regulations in accordance with the EU Building Directive EPBD. The purpose is to develop and demonstrate solutions that not only cut energy consumption on the demand side but also make it possible to switch to more environmentally friendly forms of energy sources,” says project manager Reto M. Hummelshøj from COWI, head of the ECO-City consortium comprising 22 partners. The ECO-City project includes a total of 2,400 m2 of solar collectors, 4,000 m2 of solar cells, 5 MW wind turbines, a 5.75 MW biomassfuelled heating plant, 1,050 low-energy homes and refurbishment of another 477 homes, as well as underground cold storage, interseasonal storage of waste and investigating the biogas supply for public transport, energy measuring equipment and systematic energy savings in public buildings. @ Project manager Reto M. Hummelshøj, rmh@cowi.dk By 2010 the eu aims to be producing 22 per cent of generated electricity from solar power, wind power and other renewable sources of energy. Photo: Scanpix 26 • International news magazine from cowi International news magazine from cowi • 27 Pearl Towers comprise two 50-storey towers and a 40-storey tower. Photo: Courtesy AL Hamad Construction and Development Company New gateway to Bahrain Pearl Towers with the landmark Pearl roundabout in the foreground. Photo: Courtesy AL Hamad Construction and Development Company Two 53-storey twin towers, a 12-storey Harbour House and a 7-storey Financial Mall complex are changing the skyline of Bahrain. cowi Almoayed Gulf has been appointed to a number of prestigious high-rise projects in Bahrain Edited by Christina Tækker A new gateway to Bahrain is taking shape. The historic landmark of Bab Al Bahrain – or Gateway to Bahrain – links the traditional trading history of Bahrain’s Souq with the Bahrain Financial Harbour. From the gateway of Bab Al Bahrain, an avenue connects the old Bahrain to the new, welcoming modern traders into the financial heart of Bahrain to take part in the region’s prosperity. Here the biggest construction work ever in the history of Bahrain has begun. At the centre of Bahrain Financial Harbour, the Bahrain Financial Centre when completed will comprise two 53-storey towers, a 12storey Harbour House and a 7-storey Financial Mall complex. The complex will house the Bahrain stock exchange within the mall and will be complemented by extensive car parking facilities. COWI Almoayed Gulf has been appointed to a number of prestigious high-rise projects in Bahrain. In addition to structural design review and structural supervision of Phase I of the Bahrain Financial Harbour, the work includes the structural design and supervision of Abraj Al Lulu (Pearl of the Gulf), as well as the structural design of the BIIC building, which also forms part of the Bahrain Financial Harbour. Face the challenges of the 21st century The Bahrain Financial Harbour Development project was designed by Ahmed Janahi Architects, whose vision has largely spurred Bahrain to open the floodgates for the development of Bahrain to face the challenges of the 21st century. The Financial Centre is the first phase of the Bahrain Financial Harbour Development project. The first phase of the project comprising the two high-rise towers, the Financial Mall complex and the Harbour House was procured on a design and build 28 • International news magazine from cowi basis. Al-Hamad Construction, a Sharjah based construction company, won the contract, valued at approximately USD 193 million out of a total USD 1.3 billion for the entire Bahrain Financial Harbour project. The first phase of the project is expected to be completed by March 2007. Craig Oldfield, COWI Almoayed Gulf, senior project manager for the structural works, says: “The main towers were topped out in January 2006, a little ahead of schedule – they are now the tallest buildings in Bahrain!” Abraj Al Lulu residential project As a result of its work on the Bahrain Financial Harbour project, COWI Almoayed Gulf was requested to prepare the structural design and structural supervision of the prestigious Abraj Al Lulu residential project, developed by the Dadabai Corporation. The residential project, located in the heart of Manama near the landmark Pearl Roundabout, will comprise three multi-storey residential towers – two 50-storey towers and one 40-storey tower. The towers will house car parking facilities as well as leisure facilities. Valued at approximately USD 220 million, the project is expected to be completed by the end of 2007. In addition, the BIIC building with its 23 storeys and a total height of 94 m is an equally prestigious building, although smaller in scale, situated within the Commercial East of the Financial Harbour Development project. COWI Almoayed Gulf is responsible for the structural design of the building, the construction of which recently started on-site. @ Senior project manager Craig Oldfield, cagco@batelco.com.bh International news magazine from cowi • 29 The tsunami swept a holiday paradise into the sea. Now new sustainable wastewater treatment technology will draw the tourists back to Koh Phi Phi Picking up the pieces on Phi Phi Infrastructure destroyed Today, Witchuda Jantharo’s hotel – Phi Phi Hotel – is again open for business, while other houses and hotels still lie in ruins. The tsunami also caused extensive damage to the island’s water and wastewater systems. Even before this latest disaster, the wastewater situation had been proving a plague to residents and tourists alike. Punkham Kittithornkul, mayor of Koh Phi Phi, explains that the island has only old septic tanks made of concrete for processing wastewater from toilets, kitchens and bathrooms. When the tanks overflow or spring leaks, the wastewater seeps out into the street or down into the groundwater – the same water that is pumped up to provide supplies to the island’s hotels and houses. Or it forms stagnant puddles that attract mosquitoes. And in the rainy season the groundwater level rises and toilets cannot be flushed. The government had previously installed a central wastewater treatment plant on the island, but it was never put to use. It was prohibitively costly to operate, in places the sewer pipes were turned the wrong way and very few houses were connected to the main collectors. In Thailand, residents are not legally required to connect to main collectors. And the actual Photos: Mikkel Rye Christensen By Mikkel Rye Christensen For Witchuda Jantharo and the other hotel owners on the Thai island of Koh Phi Phi, Boxing Day 2004 was a cruel, dreadful day. Just after breakfast, the tsunami swept ashore and within minutes their livelihoods and their businesses were reduced to wreckage washing out to sea – a scene of devastation that was repeated all along Thailand’s west coast and throughout the southern islands. Witchuda Jantharo recounts how the massive wave struck them from two sides. Koh Phi Phi resembles a butterfly in flight, with wooded hills on each ‘wing’ connected by a sandy isthmus rimmed by beaches where almost all the island’s hotels and houses are located. On that fateful day, most of the buildings were washed away. As people ran for their lives, the huge deluge of water transformed this idyllic tourist paradise into a scene of death and destruction. Hotel owner Witchuda Jantharo leafs through COWI’S proposed new master plan for Koh Phi Phi Don. The petals of the butterfly filter are made tight with large membranes. The membranes are delivered in rolls and welded together. wastewater treatment plant – which consisted of a number of open ponds containing foul-smelling wastewater – was located among the island’s many bungalows and consequently right under the noses of the tourists, recounts COWI project manager Carsten Laugesen. Paradise reconstructed Supported by Danish disaster relief, the local authorities assisted by COWI are introducing a completely new technology on Koh Phi Phi that is the result of the whole issue of wastewater management having been thoroughly thought through: “We are connecting private residences, commercial premises and hotels, installing septic tanks, oil and grease separators, laying new pipes, and building pumping stations that channel all wastewater flow to the new, constructed wetland via closed, odourfree systems,” explains COWI engineer Henrik Lynghus. He is part of a specialist team working on the assignment together with Hans Brix, lecturer at the Department of Biological Sciences at Aarhus University, Ejlif Mikkelsen from the municipality of Viborg and Dr. Thammarat of the Asian Institute of Technology. @ Project manager Carsten Laugesen, carsten@hlaugesen.com International news magazine from cowi • 31 Photo: Bablu Virinder Singh Danish aid to tsunami-devastated Thailand Wastewater treatment tailored to the tropics In January 2005, DANIDA and then Danish Minister for Development Bertel Haarder gave DKK 20 million towards rebuilding the tsunami-devastated regions along Thailand’s west coast. The disaster relief was channelled through existing projects. COWI, together with the Danish Embassy in Bangkok, administered DKK 10 million for the reconstruction of drains and sewers, piping and wastewater treatment plants. The work is taking place on the tropical island of Koh Phi Phi, Patong Beach on Phuket and the towns of Ban Nam Khem and Baan Pru Teau in Phang Nga province. In addition to this amount, the CODI organisation has received DKK 7 million towards helping local communities in the affected areas, while the remaining DKK 3 million is earmarked for restoring nature reserves that were devastated by the tsunami. The new wastewater treatment plant on Koh Phi Phi utilises natural processes, is odourless - and designed like a butterfly By Mikkel Rye Christensen #().! - 9! . - ! 2 ,!/3 4(!),!.$ 6)%4.!- #!-"/$)! B 2R5U. %NI) " - ! , ! 9 3 ) ! "ANGKOK +OH0HI0HI 32 • International news magazine from cowi Carsten Laugesen adds: “At only modest cost to cover the expenses of operating the wastewater treatment plant, recycled wastewater can be supplied for uses such as watering gardens and flowers. You will note, too, that we on the island actually don’t call it a wastewater treatment plant but a water purification plant, which places the focus on the end-product.” Then there is the question of energy. Many wastewater treatment plants in Thailand do not work because the municipalities cannot afford the electricity bills. Therefore the pumps for Koh Phi Phi’s new wastewater treatment plant will run on solar energy, explains Carsten Laugesen. “In addition, to regulate the water in the filters we are using a so-called siphon – a kind of ‘pull and release’ mechanism – that releases the wastewater into the plant at regular intervals,” adds Henrik Lynghus. “This gives a marked increase in purification efficiency. In fact, the whole system is automatic and virtually cost -free to operate.” 0 The wastewater treatment plant on Koh Phi Phi consists of a siphon-driven inlet tank, three types of planted subsurface flow constructed wetlands (gravel filters), a surface flow constructed wetland, a polishing pond and a storage tank for reuse purposes. The main treatment process takes place in the gravel filters. Three different sizes of crushed stone, all shipped to Koh Phi Phi from the mainland, are used in the gravel filters. The treatment utilises natural processes: when the wastewater passes through the filter, a layer of bacteria on the aggregate devours the pollutants in the wastewater. “Constructed wetlands and the polishing pond function well in the tropics, in part because of the high temperatures, which give optimal conditions for the microorganisms that break down the pollutants in the wastewater. The temperature on Koh Phi Phi is 28°-32°C all year round,” explains COWI engineer Henrik Lynghus. Ecologically operated wastewater treatment plant Tourist consumption of water is straining reserves on the island. The mayor points out that about 2,000 people live on Koh Phi Phi, and prior to the tsunami about one million tourists visited the island each year. And they all had to share 12 km² of land and 6000 m³ of water from the reservoir. Recycling of wastewater is the obvious solution. Project manager Carsten Laugesen considers it a waste to simply release wastewater into the sea. The wastewater treatment plant has the capacity to treat 400 m³ of water daily, which he plans to supply to the island’s hotels and restaurants. The butterfly filter It is a condition that the wastewater treatment plant must not be an eyesore and must be odour-free. Therefore the plant and piping is being laid underground. Koh Phi Phi is a small island, so we cannot avoid siting the treatment plant close to the tourist bungalows – on the only piece of land owned by the local authorities. The underground gravel filter will be concealed by a landscaped park complete with flowers, pavilions and paths. The crowning glory of the treatment plant is its design, innovatively depicting a flower and a butterfly, with wastewater inflow through the petals and outflow through the butterfly’s antennae. “Tourists cannot avoid passing the treatment plant. Therefore the architecture must be sustainable. The solution is both functional and pleasing to the eye. The island of Koh Phi Phi is shaped like a butterfly and boasts many species of flora, which we have taken as our source of inspiration,” says Carsten Laugesen. Inexpensive and sustainable In Denmark we have costly high-tech wastewater treatment plants. But the small municipalities in Thailand are not geared for such solutions, and the technology has to be modified to local capacity. “There is no tradition here of treating wastewater,” Carsten Laugesen points out. “So when we approach them to explain the concept, there are two things they want to know: will it smell, and what will it look like? And if they don’t get a quick and good answer, then it’s no thank you and out the door.” The new wastewater treatment plant is formed like a flower and a butterfly, with wastewater inflow through the petals and outflow through the butterfly’s antennae. Graphics: CD-WMA He goes on to explain that wastewater treatment plant operations will need to generate money if the system is to become sustainable. On Koh Phi Phi, fees will be collected for the reused water. Furthermore, Danida has provided a five-year operation and maintenance budget for the municipality worth 500,000 baht (about DKK 95,000) a year. This money will enable the municipality to maintain the treatment plant and make whatever modifications may be necessary on the advice of COWI. The total cost of the plant is 28 million baht (about DKK 3.5 million) – cheap compared to previous plants, which cost the Thai government about five to ten times more. Towards the future “Phi Phi is interesting for several reasons. The treatment plant offers an innovative solution – nature-based, odour-free and pleasing to the eye – and with the right mix of technologies, we are looking at the future of wastewater management in tropical countries,” says Carsten Laugesen. Hotel owner Witchuda Jantharo and mayor Punkham Kittithornkul have high expectations of the new treatment plant – as does the rest of the island’s population. At a public hearing, all 150 delegates voted in favour of COWI’S proposals on behalf of the entire population of Koh Phi Phi. @ Project manager Carsten Laugesen, carsten@hlaugesen.com International news magazine from cowi • 33 This bridge, linking Copenhagen’s Islands Brygge and Fisketorvet, is more underplayed than other footbridges and in daylight appears reduced to a thin line. Model photo: Dissing + Weitling New, elegant bridge des igns for towns and cities In the last decade a number of unique footbridges have appeared in Danish towns and cities, of which the most recent examples are the projected swing bridge across Copenhagen Harbour and an arched bridge in the Copenhagen suburb of Nørrebro. Today the aesthetics of bridge design are playing a greater role than ever before By Christina Tækker Purely functional and monumental footbridges are a thing of the past in Denmark. Today, bridges for pedestrians and cyclists are developed to be slim, light and well-designed. As with the projected swing bridge over Copenhagen Harbour, a couple of bridges just outside Copenhagen and most recently the Ågade arched bridge in Copenhagen , which will form part of the “green bicycle route” between the municipalities of Copenhagen and neighbouring Frederiksberg. The bridge across Ågade will follow the horizontal alignment of the 34 • International news magazine from cowi existing bicycle path and is being per- Need for a setting “In recent years we have entered ceived as a gateway to Copenhagen into a period where everything with its special, inclined arch. surrounding us should preferably The trend is clear: these bridges be designed or unique. Our homes reflect an era in which everything are increasingly for expressing our has to be stylish. Bridges have enidentity. And this has now extended tered our living rooms in the shape into the environment around us, of “coffee table” books featuring where we have become much more spectacular bridge design by leadconscious of our surroundings – ing firms of architects such as from bridges right down to the WilkinsonEyre and Spanish architect design of benches,” says architect Calatrava. Bridge owners have also Jesper Henriksen from the firm of become increasingly aware that architects Dissing + Weitling. bridges stand as a landmark and In recent years architects have signal that the visual environment experienced a growing demand for has been taken into account. architect-designed bridges around the world. Where previously bridge construction involved purely engineering, nowadays it often entails close interplay between architect and engineer. Today the majority of bridge projects kick off as a competition among architects, with the visual aspect of far greater importance than it used to be. Creative partnership With a creative partnership going back years, Dissing + Weitling and COWI – architect and engineer – have fashioned a partnership in which aesthetics, economics and technology form a synthesis. The field of work of engineers and architects overlaps and during a project they may test many different proposals and suggestions that start off as sketches filling reams of paper. From the engineer’s perspective, the new bridge projects involve a greater creative challenge. COWI project manager Ib Blom Andersen says: “Engineers are often a source of irritation to architects, as we have a tendency to kill off their ideas because the creative solutions they embrace prove impractical in reality. But the collaboration between Dissing + Weitling and COWI has culminated in a more creative way of working which has proven inspiring and challenging in terms of attaining a given goal that truly represents the best possible solution.” However, the team agrees there is a risk that runaway creativity can derail a project. There are any num- ber of examples of unnecessary pylons and stays which – on a smaller scale – serve no apparent purpose. In such cases the static, functional proportions become lost along the way. But at present the prospect of engineer and architect working together on future bridge projects involving even longer spans, higher pylons and other materials appears promising. Nor does it necessarily need to cost any extra, says Ib Blom Andersen: “There is a tendency to believe that large-scale architecture is costly. But this is not necessarily the case. The challenge is to accomplish something beautiful that is also economically feasible.” @ Project manager Ib Blom Andersen, iba@cowi.dk With its lightweight appearance in comparison to the arch, Copenhagen’s Ågade footbridge will stand in contrast to the solid buildings typical of the area,” says architect Jesper Henriksen from the firm of architects Dissing + Weitling. Model photo: Dissing + Weitling International news magazine from cowi • 35 Denmark receiving heavier rainfall Drip, drip, drip. The puddles get bigger and bigger. Heavy rainfall is becoming more frequent, and when it comes it is more intense. Over the last 25 years the heaviest rainfall has become 20-25 per cent heavier in Denmark, a new analysis carried out by cowi and dhi Water & Environment shows. “It surprises me that the rainfall has become so heavy. We are seeing the effects of climate change now which five years ago we thought would happen over the next 100 years or so,” says Karsten Arnbjerg, project manager at cowi. The extreme rainfall has implications for the capacity of sewer systems in the future, as well as for the way we develop our urban areas. One possible solution is to reserve special areas that can be flooded during heavy rains. @ Photo: Morten Larsen Project manager Karsten Arnbjerg, kar@cowi.dk