Unit Weight

advertisement

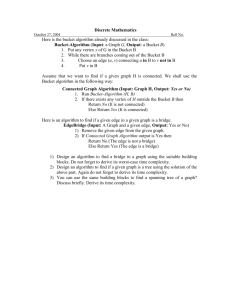

Unit Weight Unit Weight Significance and Use • Often used to determine bulk density values used in selecting proportions for concrete mixes • Also used for mass/volume relationships for conversions in purchase agreements • Also used annually for inventory control and verification 1 Unit Weight Definition • Unit Weight is the weight per unit volume of a material. Unit Weight = Weight of Material Volume of Material Example: U.W. = 103.2 lbs = 103.2 pcf 1 cf Loose Unit Weight 2 Loose Unit Weight Loose Unit Weight 3 Loose Unit Weight Loose Unit Weight 4 Dry Rodded Unit Weight Test Procedure • For nominal maximum size of 1½” (37.5 mm) or less, use rodding procedure. • For nominal maximum size greater than 1½” (37.5 mm), use jigging procedure. • Record weight of empty bucket (to the nearest 0.1 lbs or 0.05 kg). • Dry aggregate sample to a constant mass. • Fill bucket ⅓ full with dried aggregate. • Level surface with fingers. Dry Rodded Unit Weight Test Procedure 5 Dry Rodded Unit Weight Test Procedure Dry Rodded Unit Weight Test Procedure • Rod 1st aggregate layer. – Use 25 strokes of the tamping rod. – Evenly distribute the strokes over the surface. – Do not allow rod to strike bottom of bucket forcibly. • Fill bucket ⅔ full with dried aggregate. • Repeat leveling and rodding procedure. – Use more vigorous effort than on 1st layer, but – Do not cause tamping rod to penetrate to previous layer. 6 Dry Rodded Unit Weight Test Procedure Dry Rodded Unit Weight Test Procedure • Fill bucket to overflowing. • Repeat leveling and rodding procedure. • Level final aggregate surface with fingers or a straight edge. – Make any slight projections of larger pieces of aggregate approximately balance the larger voids in the surface. • Record weight of bucket and sample. • Calculate unit weight and % voids of dry rodded aggregate. 7 Dry Rodded Unit Weight Test Procedure Dry Rodded Unit Weight Test Procedure 8 Dry Rodded Unit Weight Test Procedure Dry Rodded Unit Weight Test Procedure 9 Dry Rodded Unit Weight Test Procedure Dry Rodded Unit Weight Test Procedure 10 Unit Weight Bucket Calibration • Volume of bucket must be calibrated at least once per year. – Place a thin layer of grease around the rim of the bucket to prevent water leakage. – Record combined weight of empty bucket and plate glass (to the nearest 0.1 lbs or 0.05 kg). Unit Weight Bucket Calibration • Bucket volume calibration, cont’d – Fill bucket with water and cover with plate glass. • Leave no bubbles or excess water. • Wipe off any overflow water. – Record combined weight of bucket, water, and plate glass (to the nearest 0.1 lbs or 0.05 kg). 11 Unit Weight Bucket Calibration • Bucket volume calibration, cont’d. – Record temperature of water (to the nearest 1 °F or 0.5 °C). – Use Table 1 to determine correct unit weight of water at the recorded temperature. – Calculate the volume of the bucket (same as volume of just the water). Unit Weight Bucket Calibration Table 1 Water Temperature, °F Unit Weight of Water, pcf 60 62.366 65 62.336 70 62.301 73.4 62.274 75 62.261 80 62.216 85 62.166 12 Unit Weight Bucket Calibration • Bucket volume calibration, cont’d. A = Weight of empty bucket + plate B = Weight of water‐filled bucket + plate C = Unit Weight of water at measured temperature Bucket Volume = B – A C Unit Weight Bucket Calibration • Example: – Weight of empty bucket + plate = 1.8 lbs – Weight of water‐filled bucket + plate = 34.2 lbs – Temperature of water in bucket = 70 °F • UW of water at 70 °F = 62.301 pcf (from Table 1) Bucket Volume = (34.2 lbs – 1.8 lbs) 62.301 pcf Bucket Volume = 0.52 cf 13 Adjusted Unit Weight % Moisture • Record weight of wet aggregate sample • Dry sample to a constant mass • Calculate %moisture of sample: – %Moisture = (Wet Wt. – Dry Wt.) x 100 Dry Wt. Adjusted Unit Weight % Moisture • Example: – Weight of wet sample = 125.0 lbs – Weight of dry sample = 117.9 lbs % M = (125.0 lbs – 117.9 lbs) x 100 117.9 lbs % Moisture = 6.0% 14 Adjusted Unit Weight % Moisture • Adjust the dry‐rodded unit weight for moisture • Example: – Dry‐rodded unit weight = 101.2 pcf – % Moisture = 6.0% – Adjusted U.W. = 101.2 pcf x 1.06 – Adjusted U.W. = 107.3 pcf 15