Sensory Analysis of Chocolate Liquor

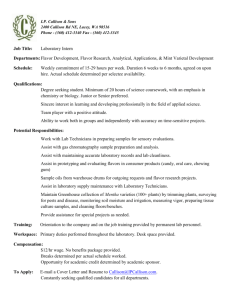

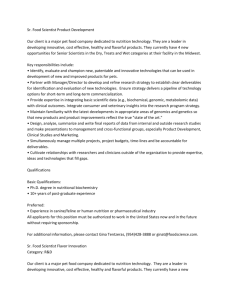

advertisement

Sensory Analysis of Chocolate Liquor Written by Stacy Reed Flavor is the most important organoleptic property of a food: if food didn’t taste good, people wouldn’t eat it. Human beings use all five senses to perceive flavor, and the most important sense used to describe the flavor of a food is taste. The basic sense of taste uses receptor cells, which are located within our tongue’s taste buds and are able to perceive all five basic tastes. The scientific disciplines of sensory science and flavor chemistry use experimental design and the human senses to aid businesses in making educated decisions about their products; therefore, it is important that a food manufacturer—such as a confectioner—strives to control all variability in their raw materials and processes, so that they may produce finished products with consistent flavor. Sensory testing in the form of daily tastings of both semi-processed and finished product can assure manufacturers that their products meet specific flavor requirements. Cocoa beans from the tree Theobroma cacao are a very complex raw ingredient used to make the chocolate liquor used in chocolate and for cocoa powder manufacturing. The complexity of the cocoa bean’s flavor mystifies chocolate manufacturers and flavor chemists still today. Currently, more than 500 flavor compounds have been identified from cocoa products, and identifying the source of each of these flavors is a science in itself. Each lot of cocoa beans should be evaluated for flavor prior to processing because the reproducibility of consistent flavor may vary greatly from lot to lot. A confectioner should never take for granted that their cocoa beans have been harvested, transported, and processed precisely the same as they always have been in the past; therefore, manufacturers have to be able to adapt and adjust formulations to avoid undesirable changes in the flavor profile of their finished products, which makes chocolate and cocoa powder manufacturing somewhat of an art. WHAT AFFECTS THE FLAVOR OF COCOA BEANS AND CHOCOLATE LIQUOR? The flavor of the cocoa bean and its liquefied state—known as chocolate liquor—can be dissected based upon origin practices, shipping/storage environment, and processing conditions. At origin, the growing season, weather during harvest and farming practices can all affect the quality of cocoa beans. It is believed that Safra (main crop, or approximately October through April) produces a better quality bean than the Temporao (mid-crop, or approximately May through September). Mid-crop tends to produce beans with higher mold levels, and the beans tend to be smaller, lower in fat and of lower flavor quality versus main crop beans; thus, chocolate manufacturers prefer beans grown during the main crop season. The weather during crop seasons can also affect bean quality and flavor. For example, In West Africa, Harmattan Season occurs during main-crop (November through March/April), in which a trade wind blows from the North, resulting in cold night temperatures; and therefore, it is a known post-harvest practice that bean fermentation should be longer in order to produce quality beans, and farmers that don’t practice this method bring beans of poor color and flavor quality to market. On the farm, practices before and post-harvest are very important for bean flavor. Cacao trees grow best in deep soil of neutral to acidic pH with proper drainage. Also, the type and age of the cacao plant, along with post-harvest fermentation and drying practices all weigh heavily on bean value. Three main cacao bean types exist: Forastero, Criollo, and a hybrid of the formers, Trinitario. The Forastero plants from Brazil and West Africa produce what is known as bulk beans, which are violet in color and come from smooth pods. Bulk beans are produced in larger volumes and tend to have a more robust cocoa impact. Criollos (White beans – lack anthocyanins), Trinitarios, and Nacional (a Forastero variety known as Arriba, found only in Ecuador) are known as flavor beans: these plants produce lower volumes, but have indistinguishable aromatic flavors for making chocolate. Examples of flavor beans are: Venezuela, Arriba, Trinidad, Grenada, and Java. Post-harvest practices, such as the length and manner by which cocoa beans are fermented and dried, can all affect the flavor precursors in the beans. Storage and shipping environments need to be clean and free from odors to ensure the beans are received at the manufacturer just as if they were coming directly from the farm. Once beans are received at a processing facility, the manufacturer’s equipment and processing parameters can also affect a chocolate liquor’s flavor. HOW CHOCOLATE LIQUOR IS PROCESSED The product of grinding cocoa nibs to a final fat content between 50-60% is known as chocolate liquor or cocoa mass (21CFR163.111). The manufacture of chocolate liquor is an intricate process of: cleaning the cocoa beans, nib and shell separation (micronization thru winnowing), alkalization (dutching), heat treatment (roasting), grinding to a desired particle size, and the standardization of the products fat. Four key points exist during this process in which the flavor of the liquor is vulnerable to change. The first key point is the cleanliness of the cleaning and separation operations: if cleaning and separation is not optimized for the specific bean type, debris and broken beans can make their way into the liquor. The second key point is alkalization: should a manufacturer choose to alkalize the liquor, an increase in fudge type flavors can be achieved. The degree of roast is the third point of flavor modification, but this is considered the most influential flavor development portion of the entire process, so it is discussed in much greater detail at a later point in this literature. The fourth key point exists during fat standardization, in which a practice known as liquor treatment (or conching) may be used to drive off volatiles and acidic flavors by heating and agitation. WHY MANUFACTURERS SHOULD TASTE CHOCOLATE LIQUOR It is essential for a chocolate manufacturer to taste their chocolate liquor daily to ensure that it always tastes consistent, as this liquor is being used for chocolate manufacture either internally by the manufacturer or externally by a customer. The sensory analysis of chocolate liquor can be a difficult feat due to all the factors that may affect its quality, and this important, complicated analysis for consistent sensory properties is the reason why sensory departments play a huge role in today’s food industry. A statistical analysis of sensory results can aid a confectioner in making educated business decisions about their products and processes. All sensory panels should occur first thing in the morning so that the panelists have a fresh focus and can concentrate on the task at hand. Early morning panels may be difficult in a production driven setting, but picking a time slot early in the day is still encouraged. The panel area should be free of noise and aroma, and panelists should not eat, smoke, or drink coffee one hour prior to the panel. Panelists should not participate in sensory evaluation if they are feeling ill or are pregnant, as these situations can impair judgment due to aliments and hormonal changes. In order to minimize bias, panelists should evaluate the products given to them individually without facial expressions, and discussion should be limited to after the completion of the tasting. HOW AND WHAT TO TASTE FOR WHEN TASTING CHOCOLATE LIQUOR Chocolate liquor should be tasted in a warmed liquid state (40-60°C) to aid in the release of volatile flavors and aromas, as well as making gritty texture—an undesirable trait resulting from unwanted moisture absorption—more apparent. Also, Chocolate liquor should remain unsweetened to avoid the unintentional masking of off-notes or flavor defects. To begin evaluation panelists should take the warm chocolate liquor and, using the bottom of a spoon, paint their tongue with it. Panelists can choose to expectorate the liquor after the evaluation if they so desire. Samples should be lined up and tasted from left to right, and should be arranged from least flavorful to most flavorful. In between liquor samples, the mouth’s pallet should be cleansed with room temperature water and unsalted saltine crackers to rid the taste buds of the previous sample’s flavor. Panelists should wait one to five minutes between samples to allow their pallet to refresh. Only a maximum of three liquor samples should be evaluated per session to ensure the panelists’ taste buds do not get exhausted. To ensure panelists remain calibrated after their initial training on the proper flavor attributes of chocolate liquor, the group should be tested once every month using a blind control and a failure flavor/ offnote sample. The type of sensory panel for this test—descriptive or difference—is up to the sensory coordinator to choose, and should be based upon the typical objectives of their standard testing. The flavor attributes found in chocolate liquor can be categorized based on: drying and storage, fermentation, degree of roast, improper storage and handling, and other miscellaneous flavor notes. A chocolate liquor flavor wheel (see Figure 1) has been complied for use as a reference for tasting and training on chocolate liquor sensory analysis. FERMENTATION FLAVORS Fermentation is a multi-stage reaction process that utilizes yeasts and bacteria to create key flavor precursors and color changes in cocoa beans through fermenting and liquefying the sugars and mucilage surrounding the beans after pod removal. The first stage of fermentation is an anaerobic reaction which takes place over 2436 hours; during this stage, sugars are turned into ethanol by the action of anaerobic yeasts lowering the pH of the cocoa bean. The second and third phases of the fermentation reaction occur between 48-96 hours in the presence of oxygen. The second phase happens when lactic acid bacteria oxidize sugar and organic acids into lactic acid. Lastly, the third phase occurs when an exothermic reaction takes place under heat (45-50°C) using acetic acid bacteria oxidizing ethanol to acetic acid. The amount of fermentation required for optimal flavor precursor varies by bean type: Forastero’s require 5-7 days; Criollo’s require 1-3 days; and Hybrids require approximately 3-5 days. Common fermentation practices on farms are to ferment beans in either piles covered with banana leaves or stored in wooden boxes. Proper bean fermentation is evident by the lack of low fermentation flavors caused by methyxanthines and polyphenols (which cause astringency and bitterness), and bean color will also be a violet or violet/brown. An excellent reference of well-fermented beans is the West African Ghana bean. If a bean has not under gone a proper fermentation period they will be a slate/grey color and low fermentation flavors will be strong in liquor made from the beans. An example of poorly fermented beans would be Sulawesi or unfermented beans such as Sanchez. Cocoa bean color changes take place due to the disappearance of polyphenols such as purple cyanidin glycosides in the pigments of the beans. When proper fermentation is complete, beans typically should be brown in color and contain fissuring, and the amount of polyphenols should also have decreased from ~ 20% to ~5%.—a polyphenol content of 10% is considered substandard fermentation. Under fermented beans will lack the appropriate amount of flavor precursors to achieve high-quality cocoa flavors upon further processing Low Fermentation Flavor Attributes When fermentation is not carried out for the appropriate amount of time the following flavors can result: Astringency* – the constriction or shrinking of mouth tissues resulting in the perception of a dry or fuzzy feeling in the mouth. A reference for astringency is the sensation on the tongue given by: drinking a solution of cocoa powder in water, chewing celery, or eating red grapes. Bitterness* – The taste stimulated by substances such as, but not limited to, quinine or caffeine. A reference for bitterness is the flavor of a 0.1% caffeine water solution expectorated. Grassy/Green – The aromatic characteristic of freshly cut grass or the general descriptor for green vegetation. A reference for a green vegetation flavor note is the aroma of cis-3-hexenol. *Note that panelists can tend to confuse astringency and bitterness, so it is important to remind them that astringency is a sensation and bitterness is a basic taste. When panelists are initially trained they should go through a basic tastes screening process, and if a panelist cannot taste bitter, they may have a genetic disposition as a bitter “nontaster”. High Fermentation Flavor Attributes Extended fermentation causes a sharp rise in the bean’s pH and the formation of ammonia, causing what some consider unfavorable high fermentation flavor notes. The color of the beans will also begin to darken beyond Brown; this drastic change in bean flavor and color can symbolize the beginning of spoilage. When fermentation is too long, the following flavors can result: Acetic** – A fermentation flavor characterized by the aromatic of distilled white vinegar. A reference for acetic is the flavor of a 10% vinegar (acetic acid) water solution. Cheesy-general – The aromatic associated with indistinguishable acidic cheese. A reference for cheesy-general is the flavor of cheddar cheese spread. Fermented fruit/Winey – The aromatic reminiscent of the non-descript fruit note in red wine. A reference is the flavor of Communion Wine in a 5% vinegar solution. Putrid – The characteristic aromatic of rotten fruit. Putrid is an unpleasant flavor associated with end products of alcoholic and bacterial fermentations. A reference for putrid is the flavor of a 50:50 red wine vinegar water solution. Sour **– The basic taste stimulated by acids. During fermentation sour flavors peak and begin to tail off. A reference for sour is the flavor of 0.08% citric acid/water solution. Straw – The aromatic associated with dried grain stalks. A reference for straw is the aroma of straw or unfiltered, unflavored cigarettes. Yeasty – The aromatic associated with yeast and yeast-containing products. A reference for yeasty is the aroma of bread yeast hydrated in hot water. ** Panelists must learn the difference between acetic and sour flavors. Acetic is a fermented flavor and sour is a flavor due to the presence of acids. To demonstrate fermentation and how flavor changes, have panelists taste White grape juice vs. White wine. DRYING AND STORAGE FLAVORS After fermentation, cocoa beans are dried. The drying period length depends upon what kind of weather the country of origin is having during post-harvest. Drying aids the bean in: lowering the moisture (~6-8%), increasing the pH, enzymatic action changing the color (brown color), loosening the shell, and lowering astringency (helps build flavor precursors). Drying can occur by natural or mechanical means. Natural sun drying—such as on mats—is preferred, but the length of time, labor, and weather all dictate if natural drying is actually used; for example, if a country of origin has a wet or highly humid season, high moisture can affect bean flavor and lead to mold growth. Many countries—Brazil, for one—use mechanical drying methods such as fires to dry beans. Mechanical driers, while fast, can lead to the untimely loss of enzymes from high temperatures, broken beans due to brittleness and off flavors; and this is why Brazilian beans sometimes have a smokey offflavor. Following the drying process, beans are transported to market to be sold and then shipped for processing. The conditions (temperature and humidity) in which the beans are stored can contribute flavor notes such as musty and meaty decay flavor notes. Natural drying and storage conditions have the potential to add the following flavors: Musty – The aromatic of items stored under highly humid conditions (damp basements, molds). Moldy beans have been found to contain high levels of carbonyls, resulting in this musty off-note. Musty flavors can be caused by mold growth in beans because of high moisture within the bean or due to moist storage conditions. A musty/moldy reference is the flavor of Brie cheese rind. Meaty – The aromatic reminiscent of cooked red meat, often thought to be a decay note. A reference for meaty is the flavor of boiled beef. Mechanical drying and storage conditions have the potential to add the following flavors: Petroleum-like – The characteristic aromatic associated with petroleum-based distillates, this flavor is thought to be absorbed into the bean when dried using gasoline fueled driers. A petroleum reference is the flavor of petroleum jelly (eg. Vaseline®) Smokey – The aromatic associated with wood smoke, which results from the improper drying of beans by fire. Not to be confused with hammy flavor, a reference for smokey is the aroma of Chipotle Pepper powder. Sulfury-rubber – The sulfur-like aromatic associated with rubber tires, this flavor note is thought to be absorbed into the bean when either rubber tires are thrown onto a drying fire or when beans are placed next to rubber-containing products when transported or stored. A reference for sulfury-rubber is the aroma of allyl furoate. PROCESSING FLAVORS Roasting is thought to be the first point in the manufacture of chocolate products in which the manufacturer truly has control of manipulating the product’s flavor. Manufacturers are able to change a product’s flavor based on the degree of roast they choose. Roasting is a process that can take up to 1 hour per batch for nibs and 120 min for whole beans and, based on preference and taste, can reach temperatures anywhere from 110-150°C (varies per degree of roast and per manufacturer). Roasting is important for microbiological reduction and flavor development. Flavors develop by the Maillard reaction during roasting. The Maillard reaction occurs between reducing sugars such as glucose and fructose in cocoa beans and amino acids, and aids in the development of chemical compounds such as phenyl acetaldehyde, isovaleraldehyde, isopentanal, and pyrazines in cocoa nibs, all which are important for a good cacao impact. It is also known that the presence of certain amino acids from fermentation helps cocoa flavor development; those amino acids are: leucine, alanine, phenylalanine, and tyrosine. The degree at which a manufacturer chooses to roast a product is their preference. Low roast conditions are favored in Europe because of the acidic low bitter character of the resulting chocolate. Low roasts are known to preserve the fruitiness of some bean varieties, whereas, medium roasts (110-140°C) are a favorite in the U.S. because cacao can be optimized using these processing conditions. High roasts (>140°C) are typically used for blending due to their imbalances and high carbon burnt flavors. The flavor profiles per roast are graphically represented in a spider chart in Figure 2. Figure 2: Flavor Profile for Ivory Coast Beans Per Roast Condition Cocoa Astringent Bitter Low Roast Earthy Acid Medium Roast High Roast Nutty Burnt Fruity The method of roasting can change the flavors generated in cocoa beans. Manufacturers can roast either the whole bean (continuous process) or solely the cocoa nib (batch process). In industry today, one will usually see nibs roasted in order to achieve the micro reduction and uniform heating that manufacturer’s desire, but this is all based on manufacturers’ processes and preference. Whole bean roasting can be used to achieve unique flavors, but contamination is a factor if proper micro reduction is not achieved due to the bean not being properly sterilized. Whole bean roasting can lead to burnt flavors due to the increased temperatures needed to accomplish the proper micro kill. Beans can also be roasted by wet or dry roasting cycles, and wet roasting aids in volatilizing unwanted offflavors and killing microbiological risks. Other than the non-enzymatic browning Maillard reaction that occurs during roasting, confectioners can choose to manipulate the product’s color and flavor prior to roasting using an alkalization (or dutching) process. Through the use of water, heat, and alkalizing agents, the cocoa nibs’ natural acids and acetic and lactic acids from fermentation are neutralized to pH of ~ 6.0, which changes the natural acidic and astringent taste of cocoa products. Low Roast Flavor Attributes Fruity – The aromatic reminiscent of fruit. A reference was provided earlier. A reference is the flavor of Communion Wine in a 5% vinegar solution. Floral – The aromatic associated with a mixture of fresh cut flowers. A reference for floral is the aroma of linalool, a terpene alcohol substance naturally found in flowers and spices. Sour – The taste stimulated by acids. A reference was provided earlier. A reference for sour is the flavor of 0.08% citric acid/water solution. Green/Grassy – The aromatic characteristic of freshly cut grass or the general descriptor for green vegetation. A reference for a green vegetation flavor note is the aroma of cis-3-hexenol. High Roast Flavor Attributes High roast flavors are present when beans or nibs are roasted to an extreme degree, and may result in the following flavors: Ash – The aromatic associated with food items that have been burnt to the point where all carbon has been removed and only white material remains. A reference for ash is the aroma of ashes. Carbon – The aromatic associated with food items that have been blackened by heat treatment (not roasted, toasted or ash). A reference for carbon is the flavor of blackened pretzels. Sulfur compounds can develop when a product is subjected to excessive processing conditions. The following attributes found in chocolate liquor are examples: Sulfury-rubber – The sulfur-like aromatic associated with rubber tires. A reference for a distinctive rubber aroma is the aroma of allyl furoate. Sulfury-skunky – The sulfur-like aromatic associated with the odor emitted by a skunk. A chemical reference for the odor of a skunk is the aroma of 2mercaptopropionic acid. Improper Storage and Handling Flavor Attributes Improper storage and handling of cocoa beans during transit and manufacturing operations can lead to broken beans and off flavors if debris remains within the liquor operation. Offflavors such as: ash, nutty-general, earthy, and woody can result in the liquor if debris is not separated efficiently from the beans or if beans are stored improperly and flavors are absorbed into the product. Ash – The aromatic associated with food items that have been burnt to the point where all carbon has been removed and only white material remains. A reference for ash is the aroma of ashes. Nutty-general – The aromatic associated with indistinguishable nuts, this flavor is attributed to peanuts or peanut shells coming into contact with cocoa beans. A reference for nutty-general is the flavor of mixed nuts. Earthy – The aromatic associated with topsoil, this flavor has been found to increase in the last reaming beans in a silo due to the accumulation of dirt and debris. An earthy off-flavor can be very unpleasant and should be rejected when present at high levels. A reference for earthy is the flavor of a potato skin. Woody – The aromatic associated with the dried, dead, bark-removed wood that is burned during processing. A reference for woody is the flavor of a toothpick. Other Liquor Flavor Attributes The flavor attributes detailed in this category are listed under other or miscellaneous because they don’t clearly fall within the other attribute categories—the sources of quite a few of these attributes are still under speculation and have not been scientifically proven: Brown Fruit – The aromatic associated with indistinguishable fruit flavor found in sun-dried grapes and plums. A reference for brown fruit is the flavor of pureed prunes or raisins. Brown spice – The aromatic associated with nondescript brown spices. A brown spice flavor has been speculated to be caused by under-ripened beans that are high in free fatty acids. References used for brown spice are the aroma of pumpkin pie spice or toasted coconut. Cacao – The characteristic aromatic of roasted cocoa beans often described as chocolate essence, this flavor is dependent upon the bean type and the optimal length of fermentation for that bean. A reference for cacao is the chocolate impact of chocolate bars containing high cacao content. Cardboard – The aromatic associated with wet cardboard, this flavor is a stale note that can come through in liquor, and is related to age, packaging, or processing. A reference for cardboard is the aftertaste of 10 x sugar. Heated fat – The aromatic associated with fat that has been heated. A reference for heated fat is the flavor of potato chips cooked in cottonseed oil. Hammy – The aromatic of ham/meat notes, this attribute is believed to be due to the disproportionate fermentation of beans. A hammy flavor is believed to be impossible to remove, even by processing or blending. A reference for hammy is the flavor of cooked ham. Phenolic – Characteristic aromatic of phenol which can be found in disinfectants, Phenolic can be found in Malaysian beans and is thought to be caused by improper fermentation methods used in Malaysia. A reference for phenolic is the aroma of a band-aid. Panelists are instructed to taste chocolate liquor and specifically observe the levels of four key attributes: cacao, carbon, sour, and bitter. Panelists are also to ensure the liquor does not contain any unwanted off-notes. Once acceptable levels for each flavor are determined based on a control, a well-trained sensory panel can use their knowledge to test any chocolate liquor. The level of cacao, carbon, sour, and bitter will vary based upon bean origin, but flavor attributes that should cause any liquor to be rejected are: sulfury-rubber, sulfury-skunky, earthy, meaty, hammy, musty, petroleum-like, smokey, and phenolic. The presence of the aforementioned flavor attributes represents a defect in postharvest practices, improper storage and handling, or unacceptable processing conditions. HOW UNIQUE CAN CHOCOLATE FLAVOR BE AROUND THE WORLD? The flavor of cocoa beans grown within 20° of latitude on either side of the equator can be significantly different, thus expressing the flavor of its country of origin and the farming practices inherent to that geographical area. The major causes of variation between and within origins can be attributed to differences in bean varieties, country of origin, and postharvest methods. Even within the same country, different post-harvest treatments between regions can result in completely different flavors. An example of similar geographical areas where different fermentation post-harvest practices affect flavor are Hispaniola and Sanchez: both country’s beans originate from the Dominican Republic, but unfermented Sanchez beans are known for their little flavor and bitterness, whereas the well-fermented and dried Hispaniola beans tend to be more flavorful with winey, earthy, and even tobacco notes. Another good example of this is the different bean grades within Java. In Java you will find Java A (Criollio/Forastero Hybrid) and Java B (Forastero) bean varieties, but only Java A is what is generally thought of as Java, with beans that are light in color, acidic, and sometimes have fruity or nutty notes. A summary table of different origins, their bean variety, and the bean’s common flavor profiles can be found in Table 1; this table is not allinclusive of every bean variety that exists at every origin, but it is a good compilation. Also, the flavor profiles listed are generalizations of flavor notes you should find from that origin, but variations in profile from season to season and even lot to lot are always possible. The spider chart in Figure 4 more clearly shows some of the extreme differences in flavors between origins, such as the differences in the degree of cocoa flavor between Côte D’Ivoire and the other origins represented. Also noteworthy is Malaysia’s degree of acidity when compared to South American and African varieties: although the beans share the same genetic lines, the different fermentation practices amongst their origins results in completely different flavor profiles. Figure 4: Flavor Profile Intensities Per Bean Origin Cocoa Astringent Bitter Côte D'Ivoire Brazil Ecuador Malaysia Earthy Acid Java Venezuela Sanchez Nutty Burnt Fruity CONCLUSION When taking a step back and looking at the big picture, it is easy to see why sophisticated sciences such as sensory and flavor chemistry are needed to understand more about the flavor development and differences found in Theobroma cacao. One can also further understand why the creation of confections is quite a craft in itself. Thus, the confectionery industry must use sensory analysis on a daily basis to ensure the production of quality products, especially knowing that variation in ingredients and processing can and will occur. The commitment to customers is to make the best products possible, and, as manufacturers, to stand for nothing less than superior quality. Table 1 Origin Côte d'Ivoire São Tomé & Principe Ghana Nigeria Madagascar Venezuela Brazil Colombia Peru Ecuador (home of Arriba) Mexico (Tabasco) Panama Jamaica Dominican Republic (Sanchez) Dominican Republic (Hispaniola) Flavor Profile Good cocoa impact, low bitterness, low acid, fruity, nutty Good cocoa flavor, bitter, spicy, fruity, earthy Strong chocolate flavor Medium cacao, occasional off-notes Winey, putrid, citrus Mild chocolate, slightly bitter, distinct fruity notes (plum and cherry) Cocoa impact, bitter, acid, astringent (sometimes rubber, hammy, smokey), some fruitiness, no nutty notes (fermented in boxes and artificial drying) Fruity, bitter, cacao Slightly bitter and fruity Balanced profile, low chocolate, floral, fruity, grass, earthy notes (partially fermented) Low chocolate, strong acid, low fruitiness (can be both fermented and unfermented) Moderate chocolate, acidic, fruit and nut notes (mechanically dried or sun dried, poor fermentation) Fruity Costa Rica Trinidad & Tobago Grenada Low cacao, flavorless, bitter (unfermented) Winey, earthy, can have tobacco notes (improved drying and six day fermentation) Fruity, balanced cocoa flavor (mechanically dried or sun dried, poor fermentation) High cacao, nutty and winey notes, aromatic Chocolate, fruity, floral, grassy, woody Indonesia Low chocolate, acidic, fruity Sulawesi High bitter, low sour, low cacao, astringent Java Mild, bland profile, acid, low cacao, light color Papua New Guinea Variable strong acid, floral, mild, nutty Low to medium cacao, medium to high acidity, astringent (due to fermentation level) phenolic Malaysian Bean Type Forastero Forastero Forastero hybrids Forastero hybrids Criollo Criollo "Porcelana" Forastero Trinitario and Criollo Forastero Forastero (Nacional) Criollo/Forastero hybrids Forastero Forastero Criollo/Forastero hybrids Criollo/Forastero hybrids Forastero Trinitario (birthplace) Trinitario Criollo/Forastero hybrids Criollo/Forastero hybrids Criollo/Forastero hybrids Hybrids/pure Criollo and Forastero Forastero hybrids References Afoakwa, E.O., Paterson, A., Fowler, M., and Ryan, A. 2008. ‘Flavor Formation and Character in Cocoa and Chocolate: A Critical Review’, Critical Reviews in Food Science and Nutrition, 48: 9, 840-857. Ardhana, M.M., and Fleet, G.H., 2003. The microbial ecology of cocoa bean fermentations in Indonesia., 86: 87-99. Chocolate Liquor. 21CFR163.111. Revised as of April 1, 2009. Cook, R., and Meursing, E. Chocolate Production and Use. 1982. Guittard, G. 2009. Cocoa Bean Types and Characteristics. 63rd PMCA Production Conference. 1-4. Hanneman, E. The Origins and Character of Cocoa Beans. The Manufacturing Confectioner. ___: 53-56, 2000. Meilgaard, M., Civille, G., and B.T. Carr. Sensory Evaluation Techniques 3rd ed. 1999. Potts, R. Sensory Evaluation of Chocolate. The Manufacturing Confectioner. 63-70, 2002. Reineccius, G. Flavor Chemistry and Technology. 2nd Ed. 2006. Seguine, E. S. Factors Influencing the Taste, Selection and Specification of Chocolate. The Manufacturing Confectioner. 72-77, 1988. Urbanski, J.J. Chocolate Flavor/Origins and Descriptions. The Manufacturing Confectioner. 72 (11): 69-81, 1992. Urbanski, J.J. Dark Chocolate: What Affects the Flavor? 55th PMCA Production Conference. 152-157, 2001. Wood, G., and Lass, R., Cocoa 4th ed. 1985. Woodling, S. et al. Natural Selection and Molecular Evolution in PTC, a Bitter-Taste Receptor Gene. Am. J. Hum. Genet. 74: 637-646, 2004.