experience with cokeless melting furnace

advertisement

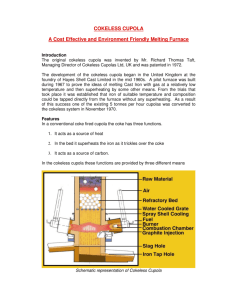

EXPERIENCE WITH COKELESS MELTING FURNACE By Dr. B K Basak, Executive Director Wesman Engineering Co. Pvt. Ltd. Introduction Today the Indian Iron Foundries mostly use Coke Fired Cupola for obtaining the necessary molten metal. From environmental point of view it is not at all a desirable situation for various reasons. 1. SPM level of 150 Mg / NM3 is difficult to achieve. The flue coming out of the cupola need filtration / treatment before releasing to the atmosphere. The wet process used for this purpose would necessitate treatment of water used in the process. 2. For 1 MT of Molten Iron, 374.4 Kg of CO2 generated which very much detrimental from environmental point of view as it adds to the Green House effect. 3. Besides above it emits CO, SO2, and NOX, which have adverse effect on the environment. Besides above, from economic and commercial point of view also there are problems with the Coke melting process. Problems with Coke availability and price India does not have enough reserve of good quality coking coal and is compelled to import the same from other countries. We would have to play in the hands of the exporter countries. The situation would become more serious when the exporter countries are our competitors in the world casting market. This phenomenon is obvious from the recent stiff price hike of imported Low Ash Metallurgical coke. Better Alternative – Cokeless Furnace The Cokeless Furnace, as the name suggest, does not use coke as fuel. Instead it uses liquid or gaseous fuels suitable for the purpose. The original cokeless cupola, also known as EcoMelt furnace, was invented by Mr. Richard Thomas Taft, Managing Director of Cokeless Cupolas Ltd, UK between 1967 and 1970 at their family foundry Hayes Shell Cast Limited. This was patented in 1972. Piped Natural Gas is becoming available at various locations throughout the country from indigenous sources. To take advantage of the availability of natural gas, Cokeless furnace should be used extensively. This will reduce the melting cost substantially. Where Natural gas is not available, other gaseous fuels like LPG, Propane or Coal bed methane may be used. When the cokeless furnace was invented in UK, the availability of coke, quality of coke and the environment issues were not so much of problems in those days. But today, all these issues are very important and in that context, it is quite evident that for our country, the cokeless furnace is the right product at the right time. As the name suggests, EcoMelt is both Eco-friendly and Economic in operation. Features of EcoMelt In a conventional coke fired cupola the coke has three functions. It acts as a source of heat, superheats the iron as it trickles over the coke and acts as a source of carbon. All these functions are mutually dependent and, therefore, difficult to control. In the Cokeless EcoMelt Furnace these functions are provided by three different means, which are explained with respect to the cross-sectional schematic (fig. 1) of the furnace as follows. Fig. 1 Schematic representation of EcoMelt 1. Heat is provided by the burners, which can be fired with a variety of fuels such as natural gas, diesel oil, propane or other suitable fuels. Burners must of short flame design. Special Burners (fig 2) have been developed for this purpose. Fig. 2 High velocity short flame Burner 2. Superheating is done by the specially developed spheres (fig. 3) that form the refractory bed. Water-cooled grate consisting of specially designed steel tubes, which may be coated with refractory, supports the Spheres. The metal is superheated as it trickles over the red-hot spheres. Fig. 3 Refractory Spheres 3. As there is no carbon pickup in the EcoMelt, this is added either by continual injection into the well of the EcoMelt by means of an injector. The rate of injection can be controlled. Carbon may, better, be added in an electric furnace. Advantages: a) Coke not required: India does not have reserve of good quality coking coal. We have to import coke from other countries. Use of Gas / Oil fired EcoMelt will eliminate the use of coke. Gas is becoming available at various locations through out the country. To take advantage of the availability of natural gas in many parts of the country, EcoMelt should be used extensively. The EcoMelt can also be fired with LPG, or Light Diesel Oil. b) No / Low Pollution The Gas fired EcoMelt for Iron melting was developed over 30 years ago and a comment passed about its performance in the early days is still very appropriate and probably more relevant, particularly in view of today’s stringent pollution norms. The comment was “What does not come out the top is more important than the metal from the bottom”. Fig. 4 EcoMelt top showing no emission during melting There is an increasing worldwide awareness of the impact that many processes can have on the environment. This is certainly true for foundries in India where the cost of meeting new regulations is significant. Undoubtedly, a conventional coke cupola does cause a lot of pollution as mentioned earlier. If the Coke cupola was converted to Gas fired EcoMelt there would be no visible emission (fig. 4), there would be no Sulphur emissions and the amount of carbon emissions are approximately 1/6 that of coke operation. There is less than 2 % carbon monoxide in the waste gas. There will still be some dust emissions contained in the charge but these can be readily removed if required. Depending on the regulations, there can be a considerable saving in capital cost as well as savings in running cost. In short there is a dramatic reduction in pollution level with the SPM level being well within the Indian pollution limit of 150mg/CuM. Actual installation in India has been monitored for the emission level. SPM level has been found to be only 29 and 42, against the allowable norm of 150 max, with and without wet cap respectively. SO2 level has been found to be 60 mg / NM3 with wet cap against the allowable norm of 300 mg/NM3. At these low pollution levels, the EcoMelt is the best solution for eliminating the pollution problem faced by Indian foundries. Also in absence of Coke, dust and dirt problems are minimized in the foundry providing cleaner working environment. c) Other Advantages Once a cupola has been converted to EcoMelt, the foundry would be in a position to produce ductile iron and some graded iron without the need for an electric furnace. As this is a considerable growth area in India, it would offer the foundry an additional advantage over its competitors who were still using a conventional coke cupola. The foundry industry in India is rapidly expanding and many foundries have adopted electric melting, particularly for the production of ductile iron. For these foundries where expansion is being considered, the capital investment of installing a Gas / Oil fired EcoMelt could well be considerably less than adding additional electric furnaces. Liquid metal could be transferred from the EcoMelt to the existing electric furnaces where they would be used for superheating and recarburising the metal instead of purely melting. The existing electric capacity would be more than sufficient for any expansion as less than 100 kW hrs per tonne are required for superheating and recarburising whereas generally more than 650 kW hrs per tonne are required for electric melting. Melting at low temperature in a cupola consumes comparatively less power. On the other hand superheating the molten metal in induction furnace consumes much less power. Therefore duplexing – melting at low temperature in Cupola / EcoMelt and super heating in electric furnace, would consume much less combined power compared to that while melting at high temperature in Cupola or in Induction furnace alone. d) It also reduces Melting Cost Tapping temperature has the main influence on economics, which depends mainly on bed height. This influences the melting rate, which also effects the gas consumption. With the unit melter operating at 1450 deg C, natural gas would be consumed at around 85 cu m per tonne with a typical sphere consumption of around 2.5 %. In the duplex operation gas consumption can be down to 60 cu m per tonne with sphere consumption as low as 1.5 %. No two foundries are alike and there will be variations in charge make up, tapping temperature, final analysis required and the method of manufacture can also influence metal requirements. It may be noted that the duplex operation gives highest saving. Although the price of coke, fuel and electric rates may vary from location to location, it is clear that the cokeless system can offer considerable economic benefits. OBSERVATIONS Melting Parameters The study was made in a Foundry at Agra where the first Indian Cokeless Furnace has been installed with financial aid from CTI, a USA organisation who sanctioned some money for protecting the Tajmahal form various emissions. This foundry operates on Natural Gas, supplied from Mathura Refinery, instead of Coke which is ban in the Taj trapezium area. The natural gas has a calorific value of 8500 K Cal / N M3. The foundry makes CI castings – mainly Electric Motor body. They do not produce Ductile Iron. Therefore the furnace was operated as unit melter. For reducing cost of raw material, the Foundry uses two grades of pigs. One cheaper quality (Pig Iron B) and the other (Pig Iron A) containing comparatively more carbon and Silicon. The furnace was charged with the “charge mix” every six minutes, which amounts to ten charges an hour. The capacity of the furnace being 3 MT per hour, each batch of charge mix contained 300 Kg of metal. The mix was as follows. Pig Iron A (with 4.4% carbon and 2.25% silicon) Pig Iron B (with 4.1% carbon and 1.87% silicon) Foundry return (with 3.6% carbon and 1.9% silicon) Limestone - 50 Kg -175 Kg - 75 Kg - 6 Kg (2%) To start with, when the furnace was cold, a bed of refractory spheres was made over the water-cooled grate bars to a depth of about 600 mm. This required 65 numbers of spheres weighing about 228 Kg. However, during the course of melting, one sphere with each charge was added after few initial charges. The burners (3 numbers) were then lighted up and the bed of refractory spheres were pre-heated to red hot temperature, as shown in the figure 5 This took little more than one hour. The furnace was then loaded with charge with 10 charge mixes. Molten metal was tapped after Ten minutes of charging. Fig. 5 Red-hot bed of refractory spheres The operating parameters are as follows. 1. Blow rate (air) 2. Air/Gas Ratio 3. Gas blow rate 4. Furnace pressure 5. Metal Temperature 5. Casting Quality 1800 Cum per Hr 10.5: 1 171 Cum per Hr 500 mm Max 1395 Deg C Max (in Ladle) (Photo no. ) All castings are acceptable. Carbon equivalent of molten metal was found to be 4.11 to 4.22. Carbon between 3.4 to 3.51 and Silicon from 1.77 to 1.87. (Fig. 6). Fig. 6 CE Meter showing the carbon equivalent, Carbon and Silicon % Pollution level To ascertain the level of various emissions a study of emission level was made by CTI, the USA organisation who gave financial aid to the Foundry as stated earlier. They engaged Environment Management group of National Productivity Council (NPC), an independent National body, Delhi for air pollution adequacy monitoring. The monitoring was done as per procedure prescribed by CPCB and US PBA (fig 7). The average of the observed figures are as follows. WITHOUT WET CAP Visible Emission Particulate Matter NONE 42 mg/ Nm3 WITH WET CAP NONE 29 mg/Nm3 OTHER OBSERVATIONS Carbon Dioxide: Sulphur Dioxide: 1% 59 mg / NM3 (with wet cap on) Fig. 7 NPC scientists seen while taking readings Discussion of the result Melting Temperature The Foundry produces Electric Motor Body castings with thin cooling fins. They require good fluidity of metal to have fault free casting with good impression of the cooling fins. They determined that they could achieve this with the pouring temperature of 1350 O C or above provided the carbon equivalent of molten metal would be 4 and above. Since the metal temperature in the ladle just after tapping was observed to be 1395 O C. and the carbon equivalent was observed to be 4.11 to 4.22 the melt was considered to be quite suitable for pouring. No attempt, therefore, was made to increase the molten metal temperature. With this molten metal they obtain very good casting without any rejection. Fuel Consumption As may be seen from the operating parameters, the gas blow rate was 171 CuM / Hour. The melting rate, as required by the foundry, was about 2.5 Tons per hour. Therefore Fuel consumption per Metric Ton was 68.4 CuM / Hour. This does not include the fuel spent for preheating the bed of sphere. 171 CuM of Gas was spent for pre-heating the spheres for one hour. If the furnace would run for 10 hours, which it does normally in most of the foundries, then this additional gas consumption per MT would become 171/ 25 ie 6.84 CuM per MT. Therefore, the total gas consumption per MT would be 68.4+ 6.84= 75.24 CuM. This figure would reduce for campaign more than 10 hours. The cokeless furnace - EcoMelt with shell cooling is suitable for 48 hours campaign. In such cases, the initial gas consumed for pre-heating the spheres for one hour would be distributed over 48 X 3 = 144 MT and the additional gas consumption would be 171/144 = 1.19 Cubic Mtr. The total gas consumption would be 68.4 + 1.19 = 69.6 approximately 70 Cubic Mtr per Metric Ton. Sphere Consumption The bed of sphere was prepared with 65 Spheres. During the melting process additional 21 spheres were added with the charge. 75 Kg of spheres were recovered which could be reused. Total of 86 (65+21) Spheres weighing 301 Kg were added. Considering the recovered spheres, the net amount of 226 Kg of spheres was consumed while melting 6.8 MT of metal. Therefore sphere consumption per MT is about 33 Kg ie 3.3% including preheating. Considering preheating time to be 1 hour, the melting time of 2.75 Hour is about 73 % of the total time of 3.75 hour. Therefore sphere consumption during melting may be assumed to be 0.73 X 226 = 165 Kg. Therefore sphere consumption during melting is 2.42%. With the increase of duration of campaign, this consumption would reduce substantially. Emission level As may be seen from the observations made by the NPC team, the level of particulate emission of 42 and 29 mg / NM3 with out and with the wet cap respectively are quite low compared to the allowable norm of 150 mg / NM3 as per Central (as well as West Bengal) Pollution Control Board of India (CPCB). At present there is no regulation regarding the other emissions in our country. However as per US PBA, SO2 level has to be within 300 mg / NM3. The observed figure of 59 mg / NM3 (with wet cap on) is much below the norm. For Carbon Monoxide also there is no norm as per CPCB. The observed level of 1% CO is many times lower than what is generally observed in a Coke Cupola. Carbon & Silicon loss Considering the quantity of two types of pigs and foundry return and the respective carbon content, the total amount of carbon in 300 Kg charge is 12.075 kg. This means carbon content of the metal charged is 4.025 %. The carbon contents in the tapped molten metal observed to be 3.4 to 3.51%, the average being 3.455 %. Therefore the carbon loss is 14.16%. In the same way the total amount of Silicon in the charge of 300 Kg is 5.7975 Kg, which amounts to 1.9325%. The observed Silicon in the tapped molten metal, as mentioned before, is 1.77 to 1.87 %, averaging 1.82%. Therefore, the Silicon loss is 5.82%.