10.2 VILLAGE AND SMALL INDUSTRIES

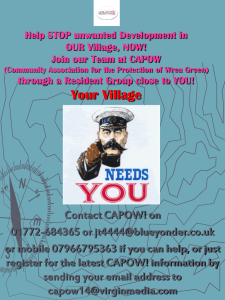

advertisement