The coordination of investment in systems of complementary assets

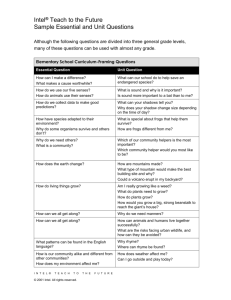

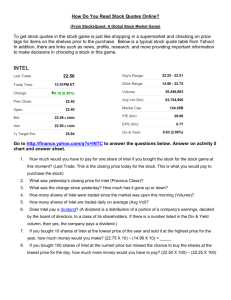

advertisement