November - The Monty

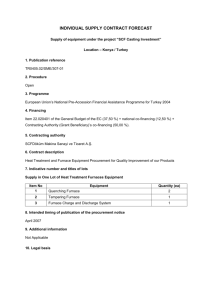

advertisement