Mechanics of Materials Course Presentation

advertisement

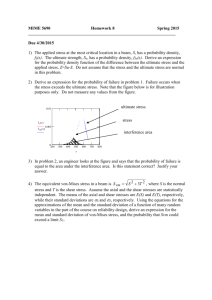

INTRODUCTION TO MECHANICS OF MATERIALS (INGE 4019) Pablo G. Caceres-Valencia (B.Sc., Ph.D., U.K.) Assessment The course will be assessed in the following manner: 1st Exam 25% 2nd Exam 30% Quizzes* 30% Others** 15% (*) (*) Date due WebCT or Moodle Quizzes and Pop‐Quizzes (max‐6). Missed quizzes will be graded with zero. Lack of access to WebCT or Moodle is not an excuse for not submitting your answers. (**) Class participation and Attendance. After the third missed class, one point will be deducted in the final grade for each missed class (up to 15 points). GENERAL INFORMATION Course Number INGE 4019 Course Title Introduction to Mechanics of Materials Credit Hours 4 Instructor Dr. Pablo G. Caceres-Valencia Office Lucchetti L-212, Extension 2358 Office Hours M-W from 9-12am and 1-3pm e-mail pcaceres@me.uprm.edu Web-site http://academic.uprm.edu/pcaceres Grades Final Grade Range 100 – 90 89 – 80 79 – 70 69 – 60 59 ‐ 0 Final Letter Grade A B C D F Attendance Attendance and participation in the lecture are compulsory and will be considered in the grading. Students should bring calculators, rulers, pen and pencils to be used during the lectures. Students are expected to keep up with the assigned reading and be prepared to answer questions on these readings during lecture and for the pop‐ quizzes. Please refer to the Bulletin of Information for Undergraduate Studies for the Department and Campus Policies. Tentative Dates Monday Wednesday Monday Wednesday 08/12 Introduction 08/17 Mech.Prop. 08/19 Linear Elasticity 08/24 Axial Loads 08/26 Axial Loads 08/31 Statically Indetermined 09/02 Thermal Effects Tuesday 09/07 Stresses on Inclined Planes 09/09 Stress Concentration 09/14 Torsion 09/16 Thin Walled Tubes 09/21 1st Exam 09/23 Holiday 09/28 Shear and Bending 09/30 Shear and Bending 10/05 Principal Stresses 10/07 Mohr’s Circle 10/12 Holiday 10/14 Triaxial Stresses 10/19 Plane Stresses 10/21 Plane Stresses 10/26 Hooke’s Law 10/28 Plane Strain 11/02 Plane Strain 11/04 Elasticity 11/09 Combined Loadings 11/11 Holiday 11/16 Combined Loadings 11/18 2nd Exam 11/23 Combined Loadings 11/25 Deflection of Beams 11/30 Deflection of Beams 12/02 Deflection of Beams Outcomes Upon the completion of the course the student should be able to: • Calculate the principal stresses and strains in a loaded component • Solve problems using stress transformation and Mohr’s circle • Apply Hooke’s law for plane stress and plane strain • Calculate stresses in thin walled spherical or cylindrical pressure vessels • Calculate the stresses produced by combined axial, bending and torsional loads Exams All exams will be conducted during lecture periods on the specified dates. There will be no final exam. Neatness and order will be taking into consideration in the grading of the exams. Up to ten points can be deducted for the lack of neatness and order. You must bring calculators, class notes and blank pages to the exams. Texbooks James M. Gere and Barry J. Goodno, Mechanics of Materials, 7th Edition, Cengage Learning. My lecture notes are available in the web at http://academic.uprm.edu/pcaceres See syllabus of the course for recommended books. Review of Statics Mechanics of materials is a branch of mechanics that develops relationships between the external loads applied to a deformable body and the intensity of internal forces acting within the body as well as the deformations of the body. Equations of equilibrium (i.e., statics) are mathematical expressions of vector relationships showing that for a body not to translate or move along a path then ΣF = 0 . For a body not to rotate, ΣM = 0. Stress Stress has two components, one acting perpendicular to the plane of the area and the other acting parallel to the area. Mathematically, the former component is expressed as a normal stress which is the intensity of the internal force acting normal to an incremental area such that: where +σ = tensile stress = "pulling" stress and -σ = compressive stress = "pushing“ stress. The latter component is expressed as a shear stress which is the intensity of the internal force acting tangent to an incremental area such that: COMPRESSION (*squeezing) -ve TENSION (*stretching) +ve Prismatic bar in tension: (a) free-body diagram of a segment of the bar, (b) segment of the bar before loading, (c) segment of the bar after loading, and (d) normal stresses in the bar. Prismatic bar = Section does not change in the length of the bar Normal Stress and Normal Strain σ= ε= P = stress A δ L = normal- strain 2P P = σ= 2A A ε= δ L P σ= A 2δ δ ε= = 2L L Uniform Normal Stress Stresses are constant over the cross sectional area. Uniform stress distribution in a prismatic bar: (a) axial forces P, and (b) cross section of the bar. To have uniform stresses (tension or compression) over the cross-section area (A), the axial force must act along the centroid. xδA ∫ x= A yδA ∫ y= A ©2001 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learning™ is a trademark used herein under license. Does the material resist the applied force? What is the relationship between the stress applied and the deformation? Tensile Testing • The sample is pulled slowly • The sample deforms and then fails • The load and the deformation are measured Force Extension or change in length E = 29 × 10− 6 psi D = 1.07 in. d = 0.618 in. Determine the deformation of the steel rod shown under the given loads. • Apply free-body analysis to each component to determine internal forces, P1 = 60 × 103 lb P2 = −15 × 103 lb P3 = 30 × 103 lb • Evaluate total deflection, Pi Li 1 ⎛ P1L1 P2 L2 P3 L3 ⎞ ⎟⎟ = ⎜⎜ + + A E E A A A i i i ⎝ 1 2 3 ⎠ δ =∑ ( ) ( ) ( ) ⎡ 60 × 103 12 − 15 × 103 12 30 × 103 16 ⎤ = + + ⎥ 6⎢ 0.9 0.9 0.3 29 × 10 ⎣⎢ ⎦⎥ 1 = 75.9 × 10−3 in. L1 = L2 = 12 in. L3 = 16 in. A1 = A2 = 0.9 in 2 A3 = 0.3 in 2 δ = 75.9 ×10−3 in. Find the stresses and strains: (a) Change in length of the pipe (b) Lateral strain (c) Increase in outer and inner diameters (d) Increase in wall thickness (*tearing) Normal stress (σ) : the subscript identifies the face on which the stress acts. Tension is positive and compression is negative. σx σ xx Shear stress (τ) : it has two subscripts. The first subscript denotes the face on which the stress acts. The second subscript denotes the direction on that face. A shear stress is positive if it acts on a positive face and positive direction or if it acts in a negative face and negative direction. τ xy 3D From equilibrium principles: τxy = τyx , τxz = τzx , τzy = τyz TORSION (*twisting) BENDING (*flexure) M σM Mc = I For 2-D: ΣFx = ma x Where αz is the angular acceleration ΣFy = ma y ΣM z = I zα z Moment of a Force about an axis Free body Diagram Change the steel for aluminum. A steel strut S serving as a brace for a boat hoist transmits a compressive force P to the deck of a pier. Bearing pad in shear. Elastomer with Modulus of Rigidity Ge The connection shown in the figure consists of five steel plates, each 2.5mm thick, to be joined by a single bolt. Determine the required diameter of the bolt if the allowable bearing stress, σb, is 180.0MPa and the allowable shear stress, τallow, is 45.0MPa? FBD Determine the allowable load P based on the following four considerations. Two-bar truss ABC supporting a sign of weight W. Determine the required cross-sectional area of bar AB and the required diameter of the pin at support C