Toward a Theory of Continuous Improvement and the Learning Curve

advertisement

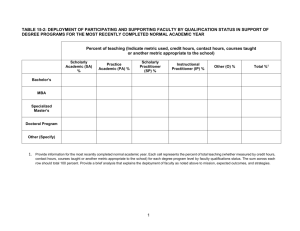

Toward a Theory of Continuous Improvement and the Learning Curve Author(s): Willard I. Zangwill and Paul B. Kantor Source: Management Science, Vol. 44, No. 7, (Jul., 1998), pp. 910-920 Published by: INFORMS Stable URL: http://www.jstor.org/stable/2634506 Accessed: 16/06/2008 13:59 Your use of the JSTOR archive indicates your acceptance of JSTOR's Terms and Conditions of Use, available at http://www.jstor.org/page/info/about/policies/terms.jsp. JSTOR's Terms and Conditions of Use provides, in part, that unless you have obtained prior permission, you may not download an entire issue of a journal or multiple copies of articles, and you may use content in the JSTOR archive only for your personal, non-commercial use. Please contact the publisher regarding any further use of this work. Publisher contact information may be obtained at http://www.jstor.org/action/showPublisher?publisherCode=informs. Each copy of any part of a JSTOR transmission must contain the same copyright notice that appears on the screen or printed page of such transmission. JSTOR is a not-for-profit organization founded in 1995 to build trusted digital archives for scholarship. We enable the scholarly community to preserve their work and the materials they rely upon, and to build a common research platform that promotes the discovery and use of these resources. For more information about JSTOR, please contact support@jstor.org. http://www.jstor.org Toward a of Theory Improvement and the Continuous Learning Curve Willard I. Zangwill * Paul B. Kantor GraduateSchoolof Business, 1101 East 58th Street, University of Chicago,Chicago,Illinois 60637 Tantalus,Inc. and RUTCOR,Rutgers University,New Brunswick,New Jersey08903 ontinuous improvement (CI) unceasingly strives to improve the performance of production service firms. The learning curve (LC) provides a means to observe and track that tand improvement. At present, however, the concepts of CI are abstract and imprecise and the rationale underpinning the LC is obscure. For managers to improve processes effectively, they need a more scientific theory of CI and the LC. This paper begins to develop such a theory. Our approach is based on learning cycles, that is, in each period management takes an action to improve the process, observes the results, and thereby learns how to improve the process further over time. This analysis suggests a differential equation that not only characterizes continuous improvement but also reveals how learning might occur in the learning curve. This differential equation might help management to evaluate the effectiveness of various procedures and to improve and enhance industrial processes more quickly. (ContinuousImprovement; Improvement; Learning;LearningCycle;LearningCurve;LearningTheory;ManagementEffectiveness; Quality;TotalQualityManagement;ValueAdded;Deming;Lotka;Volterra) C 1. Introduction Continuous improvement (CI) is an array of powerful techniques that has produced substantial improvements in numerous companies and organizations. CI provides perhaps the most central and universal component of TQM (total quality management) which itself has helped many companies achieve high quality and productivity. Despite the clear effectiveness of CI, however, no scientific theory exists to guide its application or to systematically improve the concepts of CI themselves. This paper attempts to begin development of such a theory. The approach presented may assist management to enhance industrial processes more quickly because it reorients the fundamental paradigm used to achieve improvement. Right at the start this paper connects the concept of continuous improvement with the concept of the learning curve (LC). This makes sense because in the industrial context CI and the LC are different, yet are symbiotic. The LC forecasts how fast future costs will drop as more of an item is produced. But it does not suggest how to reduce costs nor how to reduce them faster. CI, on the other hand, identifies what improvement to make, and how to do that better and faster. In this sense, CI removes some of the obscurity behind the LC and can help management improve the LC's rate of learning. The theory this paper develops for CI is then equally applicable to the LC. This paper also exposes and attacks a serious problem with the LC. At present, to determine the amount of learning (process improvement) management generally uses the total cost method. That is, management examines the total cost in one period compared with the total cost in the next period. But that approach, as we will see, often produces significant statistical errors. This paper suggests that a superior approach may be to monitor the amount of cost reduction directly. The direct method does not compare total costs, but only examines the few aspects of the process that have been changed. Because the direct method generally substantially reduces the (rather large) error of the present method, it often significantly improves the value of both the LC and CI. 0025-1909/ 98/4407/ 0910$05.00 910 MANAGEMENTSCIENCE/VOl. 44, No. 7, July 1998 Copyright X) 1998, Institute for Operations Research and the Management Sciences ZANGWILL AND KANTOR Towarda Theoryof ContinuousImprovementand the LearningCurve To analyze and understand the improvement process this paper employs the fundamental notion of the learning cycle. Specifically, in each period management attempts various strategies to make improvements. At the end of the period management observes how effective these strategies were. That information is then employed to develop better strategies for the next period. In one learning cycle, for example, management might change the software parameters on a machine, see if production improves, and if so, change the software parameters on all similar machines. Learning cycles and their inherent feedback and adaptation capabilities seem fundamental to maintaining rapid, long term improvement. This paper presents five postulates that seem to underlie certain types of industrial learning and that give rise to a differential equation that seems to describe that learning. The differential equation introduces to the LC and CI literature the Lotka-Volterra approach of predators and prey. Here the prey are the errors, wastes, and other inefficiencies that impair the operations of the process. The predators are management, because they are attempting to eradicate the inefficiencies in order improve the system. The predictor-prey approach often produces interesting results, and it does so in our case also because the differential equation naturally produces three types of solutions. Two are well-known learning curves: the exponential and the power law. The third solution, however, is new in this arena and might be a new type of learning curve. The new solution can be more fundamental than the others, as (1) it seems to depict the complete elimination of unnecessary work, and (2) the other two solution forms can be built up from this new form. First, the paper reviews CI, a battery of procedures known to boost efficiency, often dramatically. Next the LC is examined as a historical antecedent that provides a quantitative basis for CI. Finally, the paper develops the differential equation and explore its implications. 2. Historical Review Continuous Improvement The management approach called "continuous improvement" raises the efficiency of many processes and systems and is closely integrated with total quality management, just-in-time, and kaizen (largely equivalent to MANAGEMENTSCIENCE/Vol. 44, No. 7, July 1998 CI). Imai (1991) states that ". . . kaizen can increase productivity by 30, 60, or even 100 percent or more without major capital investment." Harmon and Peterson (1990) echo this view and ". . . expect improvement of 50 to 90 percent and more." Schonberger (1986) cites improvement by factors of 5, 10, or even 20 in manufacturing cycle time. Two Origins of Continuous Improvement: Toyota and Statistical Reasoning. CI traces its origins to two major historical trends, both dating from about 1950. The first occurred at Toyota, where Tiichi Ohno and Shigeo Shingo conceived the just-in-time (JIT)production system (also called kanban, Japanese production, lean production) and catalyzed a production revolution of a magnitude similar to that of Henry Ford a generation earlier. JITpioneered the disciplined and organized methodology that produced the impressive efficiency gains just cited. As one example of how this is accomplished, Toyota employees conduct systematic analyses to improve the way that they do their jobs, and they do this every week (Adler 1991). The second trend underpinning CI is the quality movement and statistical reasoning, conceived in the 1920s by Shewhart. Its contemporary renaissance is often traced to W. Edwards Deming's 1950 lectures to Japanese executives, during which he highlighted the importance of data collection and of Shewhart's Plan-DoCheck-Act (PDCA) cycle (a statement in the learning cycle approach taken in this paper). The Legacy of Cost Analysis: The Learning Curve The historical predecessor of our analysis of CI is the learning curve, which monitors and forecasts improvement by a quantitative approach. We take the viewpoint that what drives continuous improvement is some sort of underlying learning. The LC contributes a simple mathematical relationship between some metric (performance measure)-such as the cost, quality, or cycle time of producing an item-and a firm's experience in producing that item. The resulting curve of the metric very often follows some standard form, often a power law. This form of mathematical description (unlike what will be developed below) has no parameters explicitly representing the policies and procedures of management. 911 ZANGWILL AND KANTOR Towarda Theoryof ContinuousImprovementand the LearningCurve Let C(q) be the cost (or other metric) of manufacturing the qth item in a series and C(1) be the cost of producing the first one. Then for p, the parameter of learning, the classical power law becomes C(q) = C(l)q-P. (1) Time (t) is often substituted for the quantity produced (q). The LC has been widely employed in nearly all industries (see Dutton and Thomas 1982 and Dutton et al. 1984). Its typical use is to forecast the cost of producing the item in the future. Because the LC is so important, attempts have been made to place the learning curve on theoretical foundations.' While these analyses propose reasons why the empirically observed learning curve might occur, they do not suggest practical procedures by which management might systematically accelerate the learning. Mishina (1987) punctuates this point by noting that the causes of learning are not clear and that "black boxes" seem to lurk behind the curve. The result is a "dumb" learning curve that simply records learning, where the learning just happens, driven by an unknown "natural economic phenomenon." Indeed, traditional LC theory provides no organized way for management to improve the slope of the LC so that learning (improvement in cost or other metric) occurs faster. Adding Learning Cycles to the Learning Curve What is missing from the traditional LC theory and would help make the learning occur faster are the concepts of CI and in particular the notion of the learning cycle. Under the learning cycle, as noted, in each period management attempts strategies to decrease the costs (or other metric) and if the strategy is successful adopts it. The example cited about improvement at Toyota il'An excellent review of the learning curve is given by Muth (1986), who also suggests his own model based on the statistical theory of extremes. Other work reviewed in Kantor and Zangwill (1991) includes Roberts' (1983) and Sahal's (1942) probabilistic models, Venezia's (1985) optimization model, and Levy's (1965) component-based model. More recently, Argote et al. (1990) stressed the role of forgetting in learning, while Camm et al. (1993) noted that forgetting might be explained by variations in production rate. Adler and Clark (1991), for data from an electronics equipment firm, identify engineering changes and work force training as important inputs to learning. 912 lustrates how that firm applies this learning cycle concept weekly. To apply the learning cycle notion to the LC requires that management determine whether the strategies it uses in a period (cycle) really help to reduce the cost. The "obvious" way to determine this information is to subtract the total cost of making the item at the end of the period from the total cost at the end of the previous period. The amount of improvement is thus AC(q) = C(q) - C(q - 1). (2) 3. Problems with Identifying the Improvement Although calculating Equation (2) appears straightforward, it is not, because as Bohn (1991) stresses, the usual cost data are extremely noisy.2 To illustrate, suppose the cost in a period is 100 with an error of ?+10(standard deviation of 10). Let the cost in the next period be 95 with an error of ?10. Using basic subtraction, the resulting cost improvement is 5. That result, however, generally is not correct. First consider the common case where the distributions of the errors are normal and independent. Then the improvement is 5 ? 14. Here, although the initial error was about 10 percent, after the subtraction to calculate the improvement, the error has ballooned to 280 percent. Next consider a most auspicious case when the errors have a correlation of 0.5. The error is still a sizable ?10, meaning that the amount of improvement would have a 200-percent error. Moreover, these examples are not anomalies. An extremely large error will nearly always result because the subtraction involves two large numbers that are similar in value. When it is measured as a difference, the value of the real improvement is almost anyone's guess. The large error in the traditional approach makes it difficult to identify statistically significant relationships among variables-a problem that may help explain why there has been little progress in determining an underlying understanding of CI and LC. 2 For particular techniques to analyze the data see Box and Tiao "In- tervention Analysis with Applications to Economic and Environmental Problems," J. AmericanStatisticalAssociation,70 (1975), 70-79. MANAGEMENTSCIENCE/Vol. 44, No. 7, July 1998 ZANGWILL AND KANTOR Towarda Theoryof ContinuousImprovementand the LearningCurve Analysis of Errors To analyze the cause of the errors, note that the total cost (or other metric) of producing an item is actually the sum of the costs of numerous small activities, say a,, . .., an, each with its own random variation. These small activities might be: entering sales data, billing, contacting clients, training, telephoning, heat etc. Assuming n = 100 activities, the total cost in the period t - 1 (using time instead of cumulative quantity made) can be written C(t - 1) = a, + a2+ a3 + + aloo Suppose that during period t management attempts to reduce the cost of some activities. Let bi denote the cost of those particular activities at the end of the period. If management works on two activities during the period, the cost of activity i = 1, 2 is cut from ai to bi. Since management does not work on any of the other activities, their costs should be unchanged except for random disturbances. Let those costs at the end of period t be designated a*, ... , a 0o.The total cost in period t is thus C(t) = b, + b2 + a3*+ + a*00 Calculating the improvement, AC, from Equation (2), AC(t) = C(t) - C(t - 1) = [a, + a2 + a3 + * * * + a100] + (3) + a*o]. -[b,+ b2 + a3* Using the approach of subtracting total costs (Equation (2)) the improvement calculated includes the errors of 200 cost estimates. Some observers have suggested that the error might be reduced by taking a long series of observations. But that approach does not help because it takes too much time to obtain the data, perhaps quite a few learning cycles. Our goal is to obtain information quickly so we can rapidly learn how to make better improvements. To overcome some of these error difficulties, we propose to measure the amount of cost improvement by looking only at the activities improved. In the above example, since only two of the 100 activities were changed, we can calculate the improvement using the equation Since this equation has the errors of only four terms to contend with, the error is substantially reduced.3 Example Of Obtaining Data But how can we obtain the data needed for Equation (4)? To illustrate this, suppose for action 1 management moves machine A next to machine B, eliminating the need to forklift the material from A to B. Say management estimates the cost of the forklifting as $2. Moving machine A next to B then should cut $2 from the cost of making the item. Consequently, the quantity a, - b = $2. As a second action during the period, suppose management revises the software on their enterprise resource planning system. Suppose that reduces the scrap and defect rates, thereby cutting $7 from the cost of making the item. Hence a2 - b2= $7. Whenever several individual improvements are made, their sum is assumed be to the total improvement made. Recasting Equation (4) AC(t) = a, - b, + a2- b2= $8, (5) for a cost reduction of $8. While this $8 value undoubtedly has some error, it is likely to be a small fraction of the error produced by subtracting the total costs as in Equation (3). This is because the errors of only a very few terms accumulate in Equation (5), but Equation (3) bears the error of 200 terms (assuming 100 small activities). This approach of looking directly at the actions improved makes certain assumptions. For instance, the improvements made should not interact, and also the improvements made should not cause any decreased effectiveness in other parts of the process. In practice, these assumptions should be checked by inspection and careful monitoring, and when necessary some or all of the additional terms in Equation (3) might have to be included. Also, the cost improvement of an activity should be easily obtained. In general that can be done by measuring the relevant operational factors before and after the change, for instance, the reductions in time, scrap, rework, labor, machine time, and so on. In most cases obtaining the amount of improvement 3In fact, if activities 1 and 2 were improved by different methods, we AC(t) = (a, - b1) + (a2 - b2). MANAGEMENTSCIENCE/Vol. 44, No. 7, July 1998 (4) would look at each difference separately. 913 ZANGWILL AND KANTOR Towarda Theoryof ContinuousImprovementand the LearningCurve directly is easy and inexpensive and requires minimal data collection (Hands-On, How-To, Kaizen and JIT 1992). Unless the situation is highly unusual, only a few of the terms in Equation (3) will be needed. 4. Psychological Learning Theory Since learning and improvement-the central issues here-are human endeavors, psychological learning theory may be relevant to the model to be developed. Newell and Rosenbloom (1981) noted that the power law of learning (Equation (2)) empirically fit a number of psychological learning situations. They also suggest, however, the importance of the exponential, where for a parameter r, the exponential law has the form M(q) = M(O) exp(-rq). (6) (Here we use M(q) to unmistakably depict a general metric, not necessarily cost.) The exponential's use in human learning is strongly justified from a theoretical viewpoint. Mazur and Hastie (1978) comment, "For more than two decades psychologists have relied on exponential equations more than any others . . ." and "reliance on the exponential has not declined. . ." Exponential Laws and Industrial Improvement The exponential law is also well-known in industrial learning situations. Levy's (1965) LC model uses the exponential, as does the analysis by Schneiderman (1988). Muth (1986) has also noted departures from the power law and cites several other forms that have appeared in the literature. A particularly interesting application of the exponential law was made at Analog Devices (see Schneiderman 1988 and Stata 1989) when they discovered that many of their important business processes followed an exponential (or half-life law, as they called it). Such processes included on time delivery, outgoing defect levels, lead time, manufacturing cycle time, process defect level, yield, and time to market. Management then used these half-life curves to promote the elimination of problems and to enhance the rate of improvement. Relative to the industrial and the psychological learning theory literature, the classical power law, Equation (2), and the exponential, Equation (6), seem to be the two curves in most widespread use. 914 5. The Differential Equation Postulates The differential equation is founded upon five postulates. POSTULATE Ia. For any given metric, M, and process, the process can be operatedso that it achieves its optimum performancelevel, denotedby Z*, as measuredby that metric. Also, (Ib): managementcan estimateZ*. Given any process and the available equipment, labor, and other resources, we postulate that management can estimate an optimal way (ideal, best) to operate the process. The value of the metric when the process is operating at an optimum is denoted as Z*. Depending upon the metric Z might, for example, depict the fastest time to make the product, or the lowest cost. The Optimal Value Z* Has Different Definitions Like its sister term, "quality," the optimal value Z* is difficult to define precisely. Depending on the application, management can estimate Z* by extrapolation or in a variety of ways (Zangwill 1993), such as: 1. Benchmark.Management can study the performance of similar systems or processes at the best firms in the world. Management then sets the goal, Z *, so that the system would then be operating at least as well as the best such process. 2. TechnologicalEntitlement.The system may be evaluated by engineers to determine its performance if it were operating optimally, with no wastes, defects, or problems of any kind. Management then establishes this performance level as the goal to strive for, Z*. This definition for Z* has been widely utilized at firms like Alcoa (Zangwill 1993). EXAMPLE. To illustrate the entitlement approach for determining Z*, consider a process for handling a sales order, and let the metric be cycle time. Suppose the process takes three weeks, during which there are three major steps: the order itself must be checked for accuracy, the customer's credit must be checked, and an order must be placed for the material required to make the item. During this process the order must be transferred to each of the three different offices that do the respective steps (see figure 1). In this case Z*, the minimum cycle time for this process, is determined by the "real" work. If, for example, MANAGEMENTSCIENCE/Vol. 44, No. 7, July 1998 ZANGWILL AND KANTOR Towarda Theoryof ContinuousImprovementand the LearningCurve Figure1 Processinga SalesOrder CHECK ORDER CHECK CREDIT ORDER MATERIAL (1/2HR) (1/2HR) (1/2HR) THREE WEEKS each of the steps takes about a half hour of someone's time, Z* is 1.5 hours. During the rest of the time (three weeks, less 1.5 hours), the sales order is being sent from office to office or sits on someone's desk (or in the memory of some computer). These latter activities are examples of NVA, or waste, when no productive work is being done while the sales order ages. In an ideal process they would not exist. Reaching the Performance Goal With some training, management can usually decide upon the optimal point, Z*. Moreover, it is usually not necessary to know Z* accurately, because the actual operation of the system is usually so far away from Z* that a sizable error in Z* has little managerial import. For instance, in the above example, it makes little difference if Z * is 1.5 hours or 3 hours, since what must be attacked is the cycle time of three weeks. As the system operates closer to Z*, management can revise the estimate of Z*. The usual challenge facing management is not how to estimate Z*, but how to improve the system so that it operates close to performance level Z*. POSTULATEII. Other things being equal,for any metric M(q), the rate of improvement is proportional to the nonvalue-added(NVA) componentof the metric,N(q). Specifically, M(q) = (otherfactors) x N(q) Further,specifythe NVA as N(q) = M(q) - Z*. (7) In common parlance NVA is frequently construed as any workthat does not contribute value to the final customer. For mathematical precision, however, we define NVA as in Equation 7, so that NVA is any "work" not required by the ideal operating process Z*. In particular, if M(q) is the current performance level, then M(q) Z* represents the amount of metric that remains to be MANAGEMENTSCIENCE/Vol. 44, No. 7, July 1998 removed before the process will operate optimally. In actual practice the common usage of NVA and our definition are almost identical. Typically, NVA includes rework, waiting, changes, delays, erroneous information, defects, wastes, preparation time, transportation, idle time, and inspection. Also, NVA would be the work in making any items not sold. Postulate II can thus be interpreted as follows: If M(q) - Z* is large, there are many opportunities to improve, so the rate of improvement should be large. Conversely, if M(q) - Z is small, there are few opportunities and the rate of improvement should be small. III. The rate of improvementis proportional to the effectivenessof managementin a Volterra-Lotkaform. POSTULATE In the 1920s Lotka and, separately, Volterra (see Murray 1989) suggested an equation describing populations of predators and prey. As a simple instance, wolves prey on moose. Over a wide range of conditions, the rate of elimination of moose over time (- dS / dt) will be proportional to: (1) the number of moose S(t), as the opportunities for each wolf are proportional to the number of moose; (2) the number of wolves W(t), as the moose population will decline in proportion to how many wolves are preying upon them. This analysis led Lotka and Volterra to the multiplicative relationship: dS / dt = -aW(t)S(t). In the present context, the "prey" is the nonvalue added component of the metric, N(q) = M(q) - Z*. That represents the errors, extra work and waste that management wants to get rid of. The "predator" is the management, or more precisely the effectivenessof management's effort to improvethe process. Let E(q) denote that effectiveness of management in making improvements after q items are made. Consequently, we may rewrite the Lotka and Volterra observations4 as the rate of improvement in the metric is proportional to 4 See also Fine and Porteus (1989), who express improvement as a random variable that is a fraction of the amount left to improve. 915 ZANGWILL AND KANTOR Towarda Theoryof ContinuousImprovementand the LearningCurve (i) the effectiveness of management, E(q), and (ii) the amount of metric left to eliminate, N(q). 6. The Continuous Improvement Equation The postulates combine to produce our continuous improvement differential equation. Assuming that low values of the metric are "better," and noting that Z* is a constant, - dN / dq = rate of improvement in the metric. (8) Following Postulate III, we then have for c a coefficient of proportionality: dN/dq = -cE(q)N(q). (9) To measure improvement in any practical application, express Equation (9) in finite differences: /N/ Aq = -cE(q)N(q). (10) These forms, Equation (9) and also Equation (10), are the "continuous improvement differential (or finite difference) equation" (CIDE). 7. Monitoring the Effectiveness of CI In applying the CIDE to actual operations, the quantity Z*, being the ideal performance of the process, would be estimated early in the project. M(q) would also be known, since that is the value of the metric, say cost, after q items are processed. Further, c would be set to the scale of the data, so without loss of generality we can set c = 1. To apply the CIDE, thus, we need only determine the rate at which the metric improves, /M / Aq, as that will provide the effectiveness of management: E(q). Specifically, E(q) AMM/ (/qN(q)). Practical Importance of the CIDE Using the metric M(q) alone does not easily provide information about the effectiveness of an improvement technique. But the CIDE does, because it normalizes the improvement to account for the amount of metric left, N(q) = M(q) - Z. For example, suppose SPC is implemented on a specific machine and $3 per unit is saved, so AM1 = $3. Suppose that later, after more products are processed, a new incentive system motivates the workers to save $2 per item, so L\M2 = $2. Since $3 is larger than $2, it appears that installing SPC has a bigger impact than the new incentive system, and that SPC ought to be deployed through the entire operation before the incentive system is. But that might not be correct. The absolute amount of savings must be adjusted for the amount of NVA left, N(q). In particular, suppose, Ni(q) = $6 and N2(q) - $3. Then from the CIDE, since $2 / $3 is greater than $3 / $6, the incentive system is actually more effective. What is relevant here is the fraction of NVA cut, not the absolute amount cut. Without use of the CIDE, management might erroneously replicate a method that had been effective only because it was applied to a situation with a sizable value of N(t). The CIDE automatically adjusts for the NVA left and thereby produces an appropriately scaled measure of impact, the percentage of NVA cut. (11) During any period of interest, Aq is the number of items processed. (If we are examining how the metric improves from the time the 36th item is made until the 39th item is made, then /\q = 3.) Next we must estimate AM, or how much the metric changed during that interval. As discussed, direct ob- 916 servation is generally preferable to inference from some change in a grand total. With that done, E(q) is then known. In general, suppose that during different intervals of time a firm implements different CI techniques, such as SPC, moving the machine, improving maintenance, training, etc. Then for any specific CI technique implemented, E(q) expresses the corresponding effectiveness of CI. That information lets us identify which improvement effortsor techniquesare morepowerful. 8. Autonomous Solutions of the CIDE So far the CIDE has been given in general form. We now show that for simple dependencies of the E(q), effectiveness of management, on the current level of N(q), the CIDE can be solved explicitly. MANAGEMENTSCIENCE/Vol. 44, No. 7, July 1998 ZANGWILL AND KANTOR Towarda Theoryof ContinuousImprovementand the LearningCurve To motivate that expression, note that E(q) might depend upon the amount of known NVA in the process: N(q) = M(q) - Z*. On the one hand, when there is a compelling need to improve, such as a tight deadline, management might increase its effort toward the end. In this case, as M(q) - Z* gets small, E(q) increases. On the other hand, without special pressure, as the optimum point Z* is approached and little possible improvement remains, management might shift its attention away from this project to other more immediate needs. In this case, as M(q) - Z* gets small, E(q) decreases. Postulate IV subsumes both of these possibilities. Theeffectivenessof the CI effortdepends upon the amount of improvementremaining,accordingto a powerlaw. Specifically,for a parameter,K, and coefficientK, POSTULATE IV. (12) E(q) = KN(q)K. Equation (12) represents ways in which management can change the level of effort (effectiveness) it puts into this activity as improvement is accomplished. In particular, N(q) = M(q) - Z* is decreasing as improvements are being made. If the parameter K > 0, the effectiveness of management is decreasing, while K < 0 represents increasing effectiveness, and K = 0 is constant effectiveness of management. 9. Explicit Solutions of the CIDE Plugging Equation (12) into the CIDE Equation (10) we obtain dM/dq = -cK(M(q) - (13) Z*)K+l. Solutions Depending on the parameter, three solutions to Equation (13) result (Kantor and Zangwill 1996). If K > 0, the solution is a power law, which, as in Equation (1), is the classical form of production learning. Restoring the full value of the metric, M(q), the general form is: M(q) = (M(1) - Z*)(1 + qoff)P(q + qoff)-P + Z*. When the offset parameter qoff, which shifts the origin, is set to zero, the classical law results: M(q) = (M(1) - Z*)q-P + Z*, q ? 1. This law is often written with Z * = 0. MANAGEMENTSCIENCE/Vol. 44, No. 7, July 1998 (14) If K = 0, the solution is an exponentiallaw. M(q) = (M(O) - Z*) exp(-rq) + Z*. (15) Setting K < 0 generates a new class of solutions, which go to Z* at a finite amount of production qmax. We call this class the finiteform, since it seems to represent specific categories of NVA being (totally) eliminated from the process in a finite period of time. M(q) = (M(O) - Z*)(1 = Z* forq - q/qmax)d + Z* for q < 2 qmax. qmax (16) Empirical Evidence Certainly, the power law and the exponential are wellknown to reflect learning. More important, empirical testing confirmed that the new form, the finite, also seems to reflect industrial learning. Specifically, the three forms were tested on published data series from the quality progress literature. The data series subsumed metrics as diverse as "cost per keystroke" (for data entry) and "errors per invoice," and included various cycle time measures. For the 21 data series analyzed, the finite form fit the data best in 9 cases, and the power and exponential forms were each best in 6 cases. In sum, all three forms were empirically validated and were roughly equally good in fitting the learning and improvement data (See Kantor and Zangwill 1996). The empirical evidence for the three forms can be interpreted as preliminary support for the CIDE Equation (8) and for Equation (13). 10. Interpretationof the Three Families of Solutions Since all three solution forms of the CIDE seem useful, let us examine them in more detail. Power Law and Exponential Forms of Learning In the LC literature the classical form is the power law, Equation (14). However, as mentioned, other equation forms have also appeared in the literature, most notably the exponential form, Equation (15). Managerial Application of the Exponential From a managerial viewpoint, the exponential is a very attractive choice because it is memoryless. The other forms are more cumbersome because they require 917 ZANGWILL AND KANTOR Towarda Theoryof ContinuousImprovementand the LearningCurve specification of a starting point, a shift q0ff,or an ending point qmax. To apply the exponential management needs merely to articulate the goal of achieving a given percentage improvement per unit time. Hewlett-Packard states goals this way. At Analog Devices, Schneiderman (1988) introduced the exponential, and it is discussed as part of that firm' strategy by Stata (1989). Motorola also employs the exponential in forming goals (Smith and Zangwill 1988). The proprietary data we obtained from Motorola, while not conclusive, indicate that exponential improvement was holding for several factors-of-2 improvement. As a means for management to establish improvement goals, the exponential seems the form of choice. total defect events (quality), it is the sum of all defect events occurring in all activities of the production process, and Mi is the number of defects contributed by the ith activity. If M(q) is the cost to make an item, then the terms Mi (q) represent the cost of the numerous activities in the process. For multiplicative metrics, such as the yield in wafer production, the logarithmic transform leads to additivity. Exponentials Sum to Power Law Utilizing Postulate V, the exponential and the power law become intimately related. The power law of improvement can be represented by a sum of exponentials, or in the limit, as the integral of exponentials. (1? Finite Forms The finite form (Equation (16)) has not previously appeared in either the learning curve or CI literature. With the exponential or power models NVA vanishes only asymptotically. The finite form, however, goes to zero in finite experience or time, and this seems to happen in practice. In manufacturing, for example, a just-intime system might eliminate certain inventory storage. Metric components associated with the storage, such as cost, time of storage, or defects occurring during storage, then totally disappear. Thus the finite form seems to describe the elimination of some step in the work process. q.in + )P(q qmin )-P 0 = (1 f + qnin)p 1 17() e-rqminrPe-rqdr. Equation (18) suggests that, at least in principle, the total metric M(q) could improve as a power law, while the component parts of that metric, Mi(q), improve as exponentials (see Kantor and Zangwill 1991). Finite Forms Approximate Exponential Forms It is also true is that the exponential can be approximated as a sum of finite forms (Kantor and Zangwill 1996). The exponential can be written as: e-rq (1 = - q/qmax)d q 11. Hierarchyof Solution Curves d Xqmaxr d+1 The three forms are not just solutions to the CIDE. They also seem to form a hierarchy describing the removal of NVA when viewed at different scales of detail. To explore this we introduce Postulate V. POSTULATE V. Additive Decompositionof Metric. The metricM(q) of a processcan be decomposedinto submetrics Mi(q), which are metricsfor steps of the process,and whose sum is the metricM(q). M(q) = , Mi(q). (17) This interpretation holds, with appropriate amendment, for the key metrics of cycle time, quality, and cost. For example, if M(q) represents total cycle time to complete a process, Mi(q) is the time to complete the ith step on the critical path for that process. If M(q) represents 918 (18) + 1) e ~mxq~.(19) -rqmaxdqmax The Hierarchy of Improvement Curves The three functional forms appear to compose a hierarchy. Sums of the finite form can well approximate the exponential form, and sums of exponentials can well approximate a power law. However, the reverse is not true, as such sums would require negative coefficients, which seems to make no sense. Since the finite form can generate the other two, but not conversely, the finite form seems the most fundamental. As mentioned, each finite term can be interpreted as the elimination of a category of NVA. Consequently, it might be that both the power law and the exponential are observed at high levels of aggregation when the underlying reality is that many small contributions to the metric are eliminated entirely. MANAGEMENTSCIENCE/Vol. 44, No. 7, July 1998 ZANGWILL AND KANTOR Towarda Theoryof ContinuousImprovementand the LearningCurve Perspective on the Three Forms As Feller (1940) noted, the power law is something of a catchall, because it provides a good fit for a variety of curves. When a power law is observed, we cannot ignore the possibility that, in reality, the data are the sum of other forms. This could largely explain the dominant role of the power law in the learning curve literature, where cost data are sums of hundreds or thousands of separate series of data. Specifically, even if the total metric, M(q), appears to follow a power law, the detailed source metrics, Mi(q), might not. They might be finite forms, depicting quantities of metric being eliminated. 13. Summary Lack of a quantitative theory for the learning curve and for the concepts of continuous improvement has inhibited their development and their application. We suggest that a powerful method to produce improvement / learning is repeated use of the learning cycle. During each learning cycle, management can observe what techniques are producing greater improvement and thus can learn how to improve processes faster and faster. The traditional way to obtain data for the learning cycle would be to subtract the total cost (or other metric) in one period from the total cost in the previous period. That technique, however, can introduce sizable errors, and we propose that it is often possible to reduce that error by measuring the individual improvements directly. The notion of the learning cycle allows us to propose the beginnings of a theory of continuous improvement / learning. This theory is based on a five postulates and leads to a differential equation describing the learning. This equation then leads us to three forms of the learning curve: the power law, the exponential, and the finite. With regard to the coexistence of power law and exponential forms of learning, the differential equation shows that these may belong to the same family as a new law of learning, the finite form. In industrial situations, the power and exponential laws might be sums of finite forms, suggesting that the finite law may be more basic. It is hoped that this theory will be tested through direct measurement of the elimination of NVA. Other MANAGEMENTSCIENCE/Vol. 44, No. 7, July 1998 tests might examine whether complex systems are governed by the finite form at the level of small component processes, by exponential forms at intermediate levels of aggregation, and by power laws at the highest aggregation levels.5 This work has been supported in part by the National Science Foundation program in Decision, Risk, and Management Sciences grant SES8821096 to Tantalus, Inc. The authors wish to thank Paul Noakes, Vice President of Motorola, Inc., for his help in obtaining data for this project. Professors Harry Roberts and Gary Eppen, Graduate School of Business, University of Chicago, contributed valuable advice. Moula Cherikh and Xiaomei Xu, of Tantalus, Inc., performed computer analyses. We acknowledge the thoughtful and persistent efforts of the editors and referees. 5 References Adler, P. S. and K. B. Clark, "Behind the Learning Curve: A Sketch of the Learning Process," ManagementSci., 37, 3 (1991), 267-281. , "NUMMI, Circa 1988," Department of Industrial Engineering and Engineering Management, report, Stanford University, Stanford, CA, June, 1991. Argote, L., S. Beckman, and D. Epple, "The Persistence and Transfer of Learning in Industrial Settings," Technical Report, Carnegie Mellon University, Pittsburgh, PA, 1990. Bohn, R., "Noise and Learning in Semiconductor Manufacturing," University of California report, San Diego CA, March, 1991. Camm, J. D., T. R. Gulledge, and N. K. Womer, "Forgetting: A Production Line Representation," presented at TIMS/ ORSA National Meeting, Chicago, IL, May (1993). Dutton, J. M. and A. Thomas, "Progress Functions and Production Dynamics," report, (Graduate School of Business Administration, New York University, New York, May, 1982). , and J. E. Butler, "The History of Progress Functions as a Managerial Technology," BusinessHistory Rev., 58, 2 (1984), 204233. Feller, W., "On the Logistic Law of Growth and Its Empirical Verifications in Biology," Acta Biotheoret.,5 (1940), 51-66. Fine, C. H. and E. L. Porteus, "Dynamic Process Improvement," Oper. Res., 37, 4 (1989), 580-591. "Hands-On, How-To, Kaizen and JIT,"Workshop, Kaizen Programs, University of Dayton, Dayton, OH, July 13-16, 1992. Harmon, R. L. and L. D. Peterson, Reinventingthe Factory,Free Press, New York, 1990. Imai, M., in (Kaizen Institute of America, 701 Dragon, Austin, TX). Kantor, P. B. and W. I. Zangwill, "Theory of the Learning Rate Budget," ManagementSci., March (1991), 315-330. and , "Studies of a Theory of Continuous Improvement," report, Rutgers University, New Brunswick, NJ, 1996. Levy, F. K., "Adaptation in the Production Process," ManagementSci., 11, 6 (1965), B136-B154. Mazur, J. E. and R. Hastie, "Learning as Accumulations: A Reexamination of the Learning Curve," PsychologicalBulletin, 85, 6 (1978), 1256-1274. 919 ZANGWILL AND KANTOR Towarda Theoryof ContinuousImprovementand the LearningCurve Mishina, K., "Behind the Flying Fortress Learning Curve," report, Harvard Business School, Cambridge, MA, 1987. Murray, J. D., MathematicalBiology, Springer-Verlag, Berlin 1989. Muth, J. F., "Search Theory and the Manufacturing Progress Function," ManagementSci., 32, 8 (1986), 948-962. Newell, A. and P. S. Rosenbloom, "Mechanisms of Skill Acquisition and the Law of Practice," Report, Department of Computer Science, Carnegie-Mellon University, Pittsburgh, PA, 1981. Roberts, P., "A Theory of the Learning Process," J. OperationalRes. Society,34 (1983), 71-79. Sahal, D., "A Theory of Progress Functions," InternationalInstitute of Management,Berlin, Germany, 1942. Schneiderman, A. M., "Setting Quality Goals," Quality Progress,April (1988), 51-57. Schonberger,R. J., WorldClassManufacturing, Free Press, New York,1986. Smith, B. and W. Zangwill, "Total Customer Satisfaction: The Motorola System," Report, Graduate School of Business, University of Chicago, Chicago, IL, 1988. Stata, R., "Organizational Learning-The Key to Management Innovation," Sloan ManagementRev., 30, 3 (1989), 63-74. Venezia, I., "On the Statistical Origins of the Learning Curve," EuropeanJ. Oper. Res., 19 (1985), 191-200. Wright, T. P., "Factors Affecting the Cost of Airplanes," J. Aeronautical Sci., 3 (1936), 122-128. Zangwill, W. I., "The Limits of Japanese Production Theory," Interfaces, 22, 5 (1992), 14-25. , Lightning Strategiesfor Innovation,Lexington, Division of Simon and Schuster, New York, 1993. Acceptedby RalphKatz;receivedNovember1993. This paperhas beenwith the author24 monthsfor 4 revisions. 920 MANAGEMENTSCIENCE/Vol. 44, No. 7, July 1998