Sensing and Sensors: Acoustic Sensors

advertisement

Sensing and Sensors: Acoustic Sensors

version 1.1

MediaRobotics Lab, January 2008

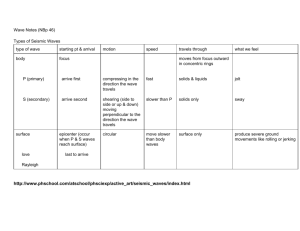

Background: sound waves

Sound waves are created by alternate compression and expansion of solids, liquids or

gases at certain frequencies.

Longitudinal mechanical waves: oscillation in the direction of wave propagation

'Sound' are longitudinal mechanical waves between 20 and 20khz, based only on our

own hearing abilities / limitations... Mechanical waves below 20hz. Are perceived by

dogs and called Infrasound by humans.

Check your hearing and your audio equipment here:

http://www.audiocheck.net/audiotests_frequencychecklow.php

References:

Fraden: Handbook of Modern Sensors

Drafts, Acoustic Wave Sensors

Buff, SAW Sensors

Cady. Piezoelectricity: An Introduction to the Theory and Applications

of Electromechanical Phenomena in Crystals.

The Speed of Sound

The speed of sound depends on the medium through which the waves are passing, and

is often quoted as a fundamental property of the material. In general, the speed of sound

is proportional to the square root of the ratio of the elastic modulus (stiffness) of the

medium to its density. Those physical properties and the speed of sound change with

ambient conditions.

For example, the speed of sound in gases depends on temperature. In air at sea level,

the speed of sound is approximately 343 m/s, in water 1482 m/s, and in steel about

5960 m/s (at 20 °C). The speed of sound is also slightly sensitive (a second-order effect)

to the sound amplitude, which means that there are nonlinear propagation effects, such

as the production of harmonics and mixed tones not present in the original sound.

http://en.wikipedia.org/wiki/Sound

Sound as an waveform can be described in terms of its energy and the

frequencies it can be decomposed into

sound wave of a human voice

in the time domain

Signals are converted from time or space domain to the frequency domain usually

through the Fourier transform. The Fourier transform(s) describe a decomposition of a

function in terms of a sum of sinusoidal functions (basis functions) of different

frequencies that can be recombined to obtain the original function.

The Fourier transform and its various derivatives form an important part of the art and

science of digital signal processing (more on this later in the course).

S(t) =

50mV . sin (2 pi 1000 t + pi/2) +

100mV . sin (2 pi 2000 t + 0 ) +

100mV . sin (2 pi 3000 t + 0 ) + ..... + ....

http://www.4p8.com/eric.brasseur/fouren.html

Human voice signal (5 seconds) and the corresponding frequency componets

http://en.wikipedia.org/wiki/Frequency_spectrum

Power spectrum of a human whistle versus a human (male) voice

Sound as a qualitative measure is often described as having the following components

"Music components":

* Pitch

* Timbre

* Harmonics

* Loudness

* Rhythm

"Sound envelope components":

* Attack

* Sustain

* Decay

The pitch of a sound is determined by the frequency of the sound.

* low (bass) - sounds of thunder and gunshots

* midrange - a telephone ringing

* high (treble) - small bells and cymbals

Timbre is that unique combination of fundamental frequency, harmonics, and overtones

that gives each voice, musical instrument, and sound effect its unique coloring and

character.

The harmonic of a wave is a component frequency of the signal that is an integer multiple

of the fundamental frequency.

1f

2f

3f

4f

440 Hz

880 Hz

1320 Hz

1760 Hz

fundamental frequency

first overtone

second overtone

third overtone

first harmonic

second harmonic

third harmonic

fourth harmonic

Rhythm is a recurring sound that alternates between strong and weak elements

Envelope of a sound

peak

loudness

[dB]

time [seconds]

attack

sustain

decay

Loudness, a subjective measure, is not equivalent to objective measures of sound

pressure such as decibels or intensity. Research suggests that the human auditory system

integrates intensity over a 600-1000 ms window.

The abstraction of loudness is sound intensity. Like several other physical properties (light

and noise) sound intensity is measured in decibel, a logarithmic scaling. The decibel scale

linearizes a physical value in which exponential changes of magnitude are perceived by

humans as being more or less linearly related; a doubling of actual intensity causes

perceived intensity to always increase by roughly the same amount, irrespective of the

original intensity level.

sound intensity is described by convention in Decibels : β=10 log10 P1/ P0

where the unit of β is the decibel (dB) and p0=10−12 W / m2 , the 'sound threshold'

Example: 30dB is the ratio between a base sound and a sound 1000 times more intensive

10 log10 1000W /1 W =30dB

Here some notable sound levels

Threshold of hearing

heavy traffic

Niagara Falls

threshold of pain

hydraulic press at 1m

0dB (β = 0)

80 dB

85 dB

120dB

130dB

Microphones

Microphone: acoustic sensors for air waves in the audible range

Hydrophone: acoustic sensor for liquid waves

microphone / hydrophone are pressure sensors with a wide dynamic range...

A microphone / hydrophone is a pressure transducer, adapted for the transduction of sound /

liquid waves.

All microphones / hydrophones have a moving diaphragm and a displacement tranducer that

converts this motion into an electric signal.

Microphones / hydrophones differ by :

sensitivity, direction characteristics, frequency bandwidth, dynamic range

condensor microphones / capacitive microphones

background: capacitance, charge and voltage across two conducting plates a distance d apart

area A

+

+

+

+

+

+

+

+

+

+

+

+

voltage V

-

distance d

+q

-q

V = q∗d /em∗e0∗A

em: material constant

e0: permitivity constant

−12C2

8.8542∗10

/ Nm

2

A capacitive microphone linearly converts a distance between plates into an electric voltage.

The device requires a source of electric charge (q) whose magnitude directly determines the

microphone sensitivity.

Many capacitive / condenser microphones are fabricated of silicon diaphragms that convert

the acoustic pressure of the sound wave into a (distance) displacement

Mechanical feedback:

improves the frequency

range of the microphone,

but reduces deflection ->

lower sensitivity

fiber-optic microphones

Preferable where capacitive measurements are impossible (inside a rocket engine)

Design: a single-mode temperature insensitive interferometer + reflective plate diaphragm.

The interferometer emits a laser beam that is used to detect the plate deflection which is

directly related to the acoustic pressure. The phase of the reflected light will vary and differ

from that of the (reflected reference light). Since both sensing and reference light travel in

the same light guide, they interfere resulting in light intensity modulation.

Such microphones can detect diaphragm movement in the order of 10−10 m

piezoelectric microphones

background: the piezoelectric effect

A piezoelectric crystal is a direct converter of mechanical stress to electric charge.

When compressed or pulled, a piezoelectric crystal will build up alternate charges on

opposite faces, thus acting like a capacitor with an applied voltage. A current

(piezoelectricity) can then be generated between the faces.

When subjected to an external voltage, the crystal will expand or contract accordingly.

1880 - 1882

The first experimental demonstration of a connection between macroscopic

piezoelectric phenomena and crystallographic structure was published in 1880 by

Pierre and Jacques Curie.

Their experiment consisted of a conclusive measurement of surface charges

appearing on specially prepared crystals (tourmaline, quartz, topaz, cane sugar {sic}

and Rochelle salt) subjected to mechanical stress. These results were obtained using

tinfoil, glue, wire, magnets and a jeweler's saw.

Other areas of scientific phenomenological experience that were noted around the

same time:

"contact electricity" (friction from static electricity)

"pyroelectricity" (electricity from crystals via heating)

http://www.designinfo.com/kistler/ref/tech_theory_text.htm

http://www.piezo.com/tech4history.html

http://www.piezomaterials.com/

http://www.nanophys.ethz.ch/members/baumgartner/Work/AFMBasics.html

Today piezoceramics are preferred as there specifications can be more

tightly controlled (and synthesized). Also, piezoceramics can operate up

to higher frequencies.

Typically, a piezoelectric disk with two electrodes serves as the input to a

high impedance amplifier. Incoming acoustic waves generate

mechanical stress in the disk and a corresponding piezoelectric current.

Electret microphones

An electret microphone is a permanently electrically polarized crystalline dielectric material. It

is an electrostatic transducer consisting of metalized electret and a backplate separated from

the diaphragm by an air gap.

Because the electret is permanently electrically polarized, there is an electric

field in the air gap. When an acoustic wave hits the device, the air gap is altered

(reduced):

V =s∗ds/e0 se∗s1

Fraden states (after a few derivations) that the sensitivity does not depend on the area

of the dielectric.

fr=1/ 2pi∗ po/ so∗M

M: mass of membrane

po: atmospheric pressure

so: effective thickness of membrane

This frequency should be set such that it is larger than the highest frequency to

which the microphone is expected to properly respond.

Electret microphones do not require a DC bias voltage for operation.

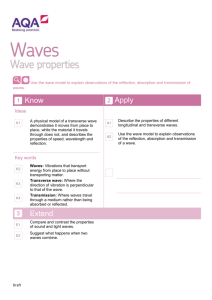

Acoustic wave sensors

Acoustic wave sensors are so named because their detection mechanism is a

mechanical, or acoustic, wave. As the acoustic wave propagates through or on

the surface of the material, any changes to the characteristics of the propagation

path affect the velocity and/or amplitude of the wave. Changes in velocity can be

monitored by measuring the frequency or phase characteristics of the sensor and

can then be correlated to the corresponding physical quantity being measured.

Virtually all acoustic wave devices and sensors use a piezoelectric material to

generate the acoustic wave. Piezoelectricity refers to the production of electrical

charges by the imposition of mechanical stress. The phenomenon is reciprocal.

Applying an appropriate electrical field to a piezoelectric material creates a

mechanical stress. Piezoelectric acoustic wave sensors apply an oscillating

electric field to create a mechanical wave, which propagates through the

substrate and is then converted back to an electric field for measurement.

Among the piezoelectic substrate materials that can be used for acoustic wave

sensors and devices, the most common are quartz (SiO2), lithium tantalate

(LiTaO3), and, to a lesser degree, lithium niobate (LiNbO3). An interesting

property of quartz is that it is possible to select the temperature dependence of

the material by the cut angle and the wave propagation direction.

The advantage of using acoustic

waves (vs electromagnetic waves) is

the slow speed of propagation (5

orders of magnitude slower). For the

same frequency, therefore, the

wavelength of the elastic wave is

100,000 times shorter than the

corresponding

electromagnetic

shortwave.

This allows for the fabrication of very

small sensors with frequencies into

the gigahertz range with very fast

response times.

Solid state acoustic detectors have

the electric circuit coupled to the

mechanical structure where the

waves propagate.

The sensor generally has two

(piezoelectric) transducers at each

end. One at the transmitting end

(generator) and one at the receiving

end (receiver) where the wave is

converted into an electric signal.

A typical acoustic wave device consists of two sets of interdigital transducers. One

transducer converts electric field energy into mechanical wave energy; the other converts

the mechanical energy back into an electric field.

Influence on SAW sensors

SOURCE:

W. Buff, SAW SENSORS FOR DIRECT AND REMOTE MEASUREMENT