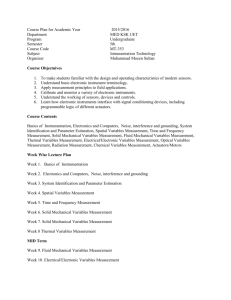

ENG438

advertisement

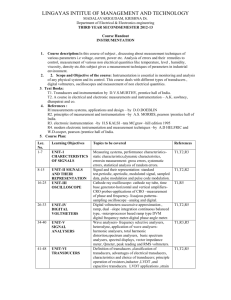

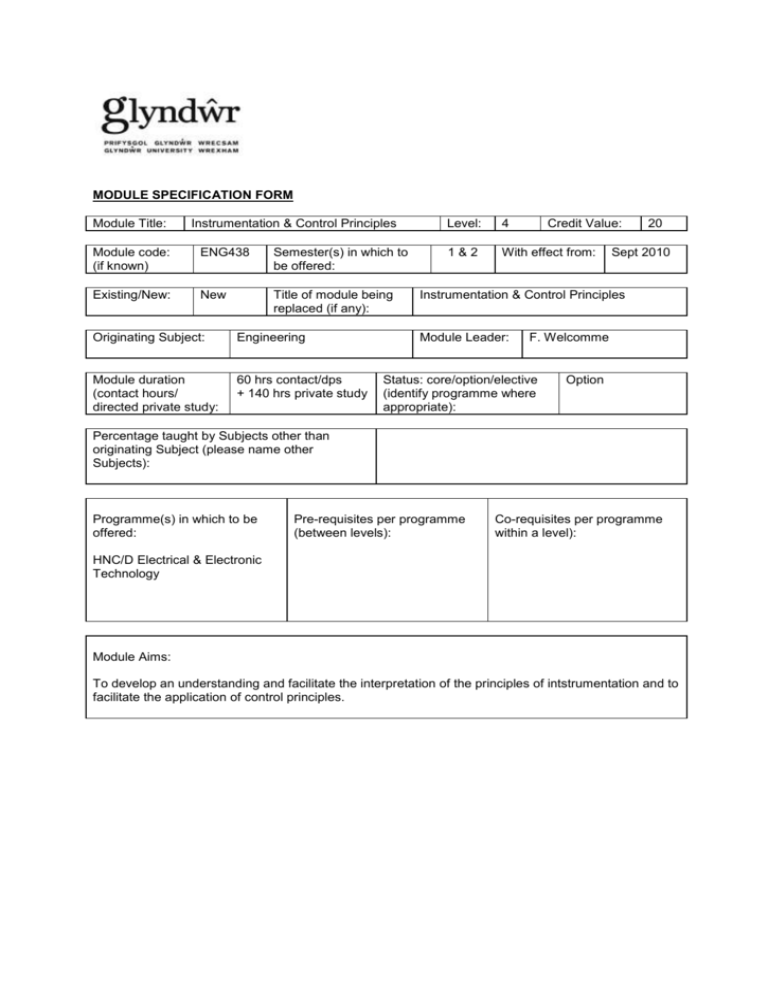

MODULE SPECIFICATION FORM Module Title: Instrumentation & Control Principles Module code: (if known) ENG438 Semester(s) in which to be offered: Existing/New: New Title of module being replaced (if any): Originating Subject: Engineering Module duration (contact hours/ directed private study: 60 hrs contact/dps + 140 hrs private study Level: 4 Credit Value: 1&2 With effect from: 20 Sept 2010 Instrumentation & Control Principles Module Leader: F. Welcomme Status: core/option/elective (identify programme where appropriate): Option Percentage taught by Subjects other than originating Subject (please name other Subjects): Programme(s) in which to be offered: Pre-requisites per programme (between levels): Co-requisites per programme within a level): HNC/D Electrical & Electronic Technology Module Aims: To develop an understanding and facilitate the interpretation of the principles of intstrumentation and to facilitate the application of control principles. Expected Learning Outcomes Knowledge and Understanding: At the end of this module the student should be able to: 1. Investigate the operation of contempory sensors/transducers/transmitters used inprocess measurement systems. 2. Investigate process control systems & controllers. 3. Investigate the use of regulating units. Transferable/Key Skills and other attributes: · Problem solving · Managing self · Working with others Assessment: please indicate the type(s) of assessment (eg examination, oral, coursework, project) and the weighting of each (%). Details of indicative assessment should also be included. Assessment number (use as appropriate) Assessment One: Assessment Two: Assessment Three: Type of assessment Weighting Practical Exercise to demonstrate understanding of accuracy, repeatability, error, etc. Outcome 1 Written Assignment covering knowledge of process controllers, system technology, tuning & representation. Outcome 2 Practical Exercise/write up for process controllers. Outcome 3 30% 40% Duration (if exam) Word count (if coursework) 1500 30% Learning and Teaching Strategies: Interactive classes, structured assignments and exercises in a laboratory environment. Syllabus outline: 1. Instrumentation systems: System terminology, sensors/transducers, transmitters/signal converters, transmission medium. 2. Process control & system controllers: Need for process control, quality, safety, consistency of product. Process controller terminology, deviation, range, span, control effect, set point, process variable, one-off control, two step control, measured variable, bumpless transfer, process variable tracking, integral, derivative, proportional. System terminology, distance velocity lags, multiple transfer lags, capacity, resistance, dead time, reaction rate, open loop closed loop. Tuning, Zeiger Nichols, continuing cycle, reaction curve. System representations, P & I diagrams, wiring diagrams, constructing and using diagrams. 3. Regulating units: Terminology, body, trim, plug guide and seat, valve, bonnet, packing gland, yoke, actuator. Regulating units. Dampers, power cylinders, louvers, valve positioners. Bibliography Essential Reading: Instrumentation & Process Measurement. Bolton. Butterworth-Heinemann. 2001 2 nd edition.