Basic PID Control

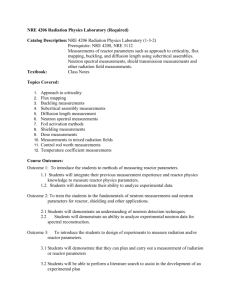

advertisement