Warranty Policies and Procedures

advertisement

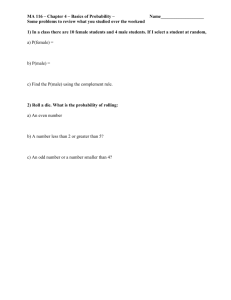

Warranty Policies and Procedures Frymaster, a member of the Commercial Food Equipment Service Association, recommends using CFESA Certified Technicians. 24-Hour Service Hotline 1-800-551-8633 *8195917* MAY 09 TABLE OF CONTENTS Warranty Procedures and Submittal 4 Warranty Submittal (Completing the CEFSA Form) 8 Proof of Installation & Serial Numbers 10 Mandatory Return Parts List 11 Warranty Invoice Status 12 Start-Ups 13 Length of Coverage – Standard Warranty 16 Length of Coverage – McDonald’s 18 Length of Coverage – McDonald’s LOV Fryer 20 Length of Coverage – Burger King 25 Length of Coverage – Hardee’s 26 Length of Coverage – YUM 27 Miscellaneous Warranty 28 Standard Labor Time Allowance 30 What The Warranty Does Not Cover 39 Tidbits of Information 40 Warranty Policy 41 Dean Standard Warranty 42 Dean Model Number Identification 43 Dean Serial Numbers 44 G-1 THIS PAGE INTENTIONALLY LEFT BLANK G-2 WARRANTY This department manages and provides information concerning the Frymaster warranty. Warranty invoice lookup available at www.frymaster.com. Evelyn Sutton Warranty & Parts Manager 318-219-7126 Patty Sepulvado Parts Coordinator 318-219-7127 Siobhan Jenkins Warranty Coordinator 318-219-1730 Eva Williams Parts Clerk 318-219-7128 G-3 Kelly Winters Warranty Asst 318-219-1729 WARRANTY PROCEDURES AND SUBMITTAL Tools to use to help with invoice submittals. ¾ Service Bulletins ¾ Service Policy Manual ¾ Warranty Claims Procedures ¾ Standard Labor Time Chart ¾ Internet Warranty Online entry is available and checks are in place to ensure correct information is submitted. To submit a warranty claim, go to www.frymaster.com, click on Service, click on Warranty Invoice Search, enter customer ID and password. Fill in warranty information. When complete, click on submit. This is the preferred method of submittal, as the process is selfcorrecting, faster and more cost effective than mailed paperwork. Accurate invoices submitted online also get preferential treatment. They are processed for payment before invoices received in the mail. If claims are sent by mail, they must be submitted on a CFESA form, and be computer-generated or typed. No handwritten claim will be accepted Send all claims to: FRYMASTER WARRANTY DEPARTMENT ¾ 8700 Line Avenue, Dock C, Shreveport, Louisiana 71106. DO NOT SEND TO CAMPUS DRIVE unless authorized by Frymaster personnel. When sending claims, please: ¾ Batch claims ¾ Do not fold ¾ Mail in a large envelope Claims that require parts to be sent back should be packaged with the part. This includes all computers, controllers, DOA parts and parts on the mandatory return list. Please no staples (except frypot claims) because optic scanning is performed. Rubber bands and paper clips are acceptable. Claims must be dark enough to scan. The only paperwork needed to process your warranty claim is the white copy of the (CFESA) form. G-4 Work orders do not have to be sent, although it is a good idea to send them to provide additional information. If you do not send the work order, please keep it until claim has been paid. A copy of the work order may be required to make a decision for payment. Sub-agent work orders do not have to be sent but must be held until the claim is paid. The Warranty Department will correct and pay invoices with mathematical errors. Any changes or adjustments will be made and a “note” will be added to the credit memo with an explanation of what was done. All warranty claims must be submitted within 60 days after the warranty work is completed. Failure to submit warranty claims within the 60 days will result in claims being discounted. (See discount structure on page 6) When completing the claim form, all areas must be filled in and must have the correct information. Labor time and mileage should be broken down in the correct section. Parts should be in parts section. Have your account number recorded in the “Service Company” section of the CFESA form. If for any reason parts are sent to you at no charge by the service department, we still need part numbers. A correct model and serial number. THIS IS A MUST! Installation date – THIS IS A MUST -Fryer install date. Warranty is based on install date. On-line claims cannot be submitted without this information. Labor time should be based on the time chart provided by Frymaster. There is a copy in this book and also in your service policy manual. If excess time is needed, call our Service Department for an authorization number. Authorizations are numbers, not names! Total mileage over 100 miles or travel over 2 hours will NOT be paid without authorization. Two trips still require an authorization if over the 100 miles, two hours. NO EXCEPTIONS. All freight charges must have an authorization for payment. number, not a name. Again, a No authorization number will be given after warranty claim has been submitted to Frymaster or after warranty claim has been paid. G-5 Computer claims – All defective computers must be returned to Frymaster. Claims will not be paid without the computer. The old and new computer serial numbers must be listed on the CFESA form. Paperwork and computers should be sent together unless submitting claims on line. When submitting computer claims online, submit the claim and send the computer with a copy of the claim. Send to: Frymaster Warranty Department, 8700 Line Avenue, Dock C, Shreveport, La. 71106. Frypot Claims: We no longer require old frypot tags to be sent back. VERY IMPORTANT: The old frypot serial number must match up with the fryer listed on the warranty claim. Failure to have the correct frypot serial number will result in non-payment. Please hold frypot tag or frypot until claim has been paid. Complete Frypot:: Frypots manufactured with “400” stainless steel must be returned to the factory for testing. The frypot can be tested with a magnet; if the magnet sticks, frypot must be returned to the factory for testing. Serial number tags should not be cut out of a “400” material frypot, the frypot has to be tested for leaks by QA. Frypot cannot be tested with a hole in the pot. Claims for frypots with tags cut out will not be paid. For either of the above claims, the new-frypot number, old-frypot number, model and serial number of the fryer must be listed on the CFESA. Also list the install date and dates of service. Any authorization numbers given pertaining to frypot serial numbers must be given by the Warranty Department VERY IMPORTANT: Please make sure all information is on the warranty claim and in the correct section when it is submitted. Once a claim has been processed, it will not be reopened for an additional credit due to omissions. If there is anything out of the ordinary that we need to know to process a claim, please include that information in Section 1 of the Warranty Service Report (CFESA). G-6 WARRANTY PROCESSING Effective August 2006 – Any claims that are submitted past the 60 day deadline are subject to late submittal deduction. 90 Days 120 Days 150 Days 180 Days 210 Days Invoice less 10% Invoice less 20% Invoice less 30% Invoice less 50% Zero Consideration G-7 WARRANTY SUBMITTAL-COMPLETING THE CFESA FORM 1. 2. 3. 4. 5. Date and invoice number (upper right hand corner of form) Manufacturer: Frymaster LLC Authorization number (if you have one) FASC name, address, phone number and contact person Your account number (found on any of your invoices) Section 1 6. Customer name, store number, address and a correct customer phone number, including the area code. 7. Model and serial number of the equipment. 8. We need the following information where applicable: • Voltage, Supply Volts • Phase, Amp reading • Type of gas • W/C pressure 9. Reported complaint: An exact explanation and details of the customer’s complaint must be provided. Unit not working is not acceptable. 10. Probable Cause: Explanation of what is wrong with the equipment and what caused the problem. 11. Action Taken: Explain what action was taken, what parts were defective, all of the information that tells what was done to fix the problem. Section 2 12. Service technician’s name 13. Exact date of installation – Month, Date, Year 14. Number of trips 15. Labor and travel hours and mileage 16. Your labor rate and extended amounts 17. Sub agent handling (if applicable) 18. Total this section Section 3 19. Quantity of parts replaced 20. Frymaster part numbers only 21. Description of parts 22. List price of parts 23. Extended price list (this should also be the net price) 24. Frypot and computer serial numbers (old and new) 25. Add total parts replaced 26. Parts handling 27. Freight amount (where applicable) 28. Total of parts sections 29. Total of parts section and labor section 30. Name of person completing this form G-8 CFESA FORM 30 G-9 PROOF OF INSTALLATION If your Serial Number begins in the year 1997; i.e., 9702______ And your install date was in the year 1999; i.e., 9912__ (two years later) Then you need proof of purchase and install date. Units that have not been installed within three manufacturing date are not covered under warranty years of their SERIAL NUMBERS Like model numbers, serial numbers provide important details when you are searching for troubleshooting assistance, replacement components, and warranty information. With the serial number, Frymaster’s call center can identify: the model, options, warranty status, who the unit was sold to, and the month, day and year a unit was produced. Here is a breakdown of a sample serial number as they are now: 9501FM0054 95 year of manufacture, 01 month of manufacture, FM Family Model, 0054, Sequential number of fryers built Before December of 1987, the serial number designation was different. 85A43416B 85 year of manufacture, A month of manufacture, 43416 Sequential number of fryers built B, Family Model G-10 MANDATORY RETURN PARTS LIST All ASA’s must return the parts identified in the Mandatory Return Parts List to the Frymaster Dean factory at the time the warranty claim is submitted. Warranty claims involving these parts will not be processed until the parts have been received at the Frymaster Dean factory. No return authorization is required for mandatory return parts. Most parts are computers. Other parts are associated with quality concerns. All computers/controllers under warranty, even if they are not listed on the Mandatory Return must be returned. For an up-to-date Mandatory Return Parts List please go to Frymaster Dean’s web site on the internet. www.frymaster.com Click on Service Click on Home Service Click on On-Line Literature Click on Mandatory Return Parts, here you will find an up-to-date Mandatory Return Parts List. When the list changes, a notification will be e-mailed to Warranty Administrators and Service Managers. Please share with appropriate people in your company. OTHER PARTS REPLACED Tag all parts with pertinent information and hold for sixty (60) days. We will at times request warranty parts to be returned to Frymaster. A notice will be faxed notifying you of parts needed. DOA PARTS (Dead on Arrival) A DOA unit is a unit that fails within the first 14 days from installation. Any parts replaced within the 14 days must be sent to the factory for evaluation and/or testing. A DOA tag should be attached to the part and sent to Frymaster with the warranty claim (CFESA). DOA tags are available upon request, part number 819-5855. Warranty Claims that require parts to be returned to the factory are subject to non-payment if parts are not available for return. G-11 WARRANTY INVOICE STATUS All warranty invoices submitted to the factory can be viewed via the Internet at www.frymaster.com. A user ID and Password are required. It is recommended the website be checked regularly to confirm that all invoices have been received. If any invoices are not listed on the website 15 working days after being sent, please resend or call the warranty department to discuss, 800-551-8633. Invoices are listed on the Internet in 1 of 3 ways. RECEIVED: Indicates that the invoice is being processed and is to be paid. Once a claim is paid, your invoice number, the amount paid, the date paid and the memo number are displayed alongside your warranty invoice number. REJECTED: Indicates the claim cannot be processed, as it does not meet Frymaster’s warranty provisions. A notice will be sent via fax informing you this claim will not be processed for payment. NEED INFO: Indicates that the invoice cannot be processed until further information has been provided. A notice will be sent via fax informing you of the information needed. Answers should be received by Frymaster within 30 days from the date you receive the fax. No answer to this fax could result in nonpayment. Responses to claims can be entered on the website – an e-mail is automatically sent to Frymaster with the answer. Answers can also be faxed to 318-688-2200. It is your responsibility to maintain your account and keep it up to date. If claims do not show up on the website as paid, received, rejected or need info within 15 working days from the date sent to Frymaster – you should check and make sure Frymaster got copies of the claims. Remember if we don’t have a copy, we don’t know the claim exists. Be diligent in checking the website for payments. G-12 START-UPS When filing a claim for a start-up, verify a start-up was purchased or that the customer qualifies for a start-up. When filing claims for a start-up, include CFESA and Start Up Form 8195689 –revised version 10/02 or 1/04. All serial numbers including the filter system number must be listed on the start up form and also on the CFESA claim. The companies listed below get automatic start up: APPLEBEE’S ARBY’S BACKYARD BURGER BAJA FRESH BOJANGLES BRINKERS CONCEPTS: • BOSTON MARKET • BRINKERS CONCEPT • BIG BOWL • CHILI’S • CORNER BAKERY • COZYMEL’S • MACARONI GRILL • MAGGIANO’S • ON THE BORDER • WILDFIRE BUFFALO WILD WINGS BURGER KING CAPTAIN D’S CARL’S JR. /CKE CARRABBA’S/OUTBACK CHECKER’S CHEESEBURGER IN PARADISE CHURCH’S CRACKER BARREL DAIRY QUEEN EL POLLO LOCO FATBURGER FIVE GUYS BURGERS AND FRIES GOLDEN CORRAL HARDEE’S/CKE HOOTER’S IHOP JACK IN THE BOX G-13 JOHNNY CARINO’S JOHNNY ROCKETS JOLLIBEES KRYSTAL LASALSA MCDONALD’S OUTBACK STEAKHOUSE PEI WEI P F CHANG’S PENN STATION POPEYE’S RALLY’S RED ROBIN RUBIO’S RUBY TUESDAY’S SHEETZ SONIC STEAK ESCAPE STEAK N SHAKE TACO BUENO WAL-MART WHITE CASTLE WORLD OF WINGS YUM • A&W • KFC • LONG JOHN SILVER’S • PIZZA HUT • TACO BELL • WINGSTREET The above start-up pay: 1-3 serial numbers - 90.00 4 or more serial numbers - 155.00 G-14 START-UP PROGRAM This start-up pays up to 155.00 per system and pays for fryers with filter systems manufactured beginning January 2, 2003. These are dealer-sold fryers and are paid the same as the chain start up program. GAS PASTA COOKER AND RETHERMALIZERS Start-up is paid on all Gas Pasta Cookers and Rethermalizers. 1 – 3 serial numbers – 90.00 4 or more serial numbers – 155.00 SINGLE UNIT START-UP Single Units Pay the same as a battery of fryers 1 – 3 serial numbers – 90.00 4 or more serial numbers – 155.00 When filing a start-up for single units on line, put the first serial number in the field for serial number, list the other serial numbers in Action Taken field. ECONOMY FRYERS Start-ups are not paid on economy fryers: GF14 or SR-series fryers. This includes chain accounts. For any restaurant not listed above, if start-up is in question, please contact the Frymaster Technical or Warranty Departments at 1-800-5518633. G-15 LENGTH OF COVERAGE STANDARD WARRANTY NOTE: ANY SR (SR42, ETC.) FRYERS INSTALLED IN ANY TYPE OF MOBILE/CONCESSION KITCHEN WILL NOT BE COVERED UNDER WARRANTY FRYPOTS – Frypots are warranted against manufacturing defect and/or weld seam failure. HIGH EFFICIENCY H50/H55 ¾ After May 1, 1998-all H50/H55 seven years, frypot assembly and labor ¾ Before May 1, 1998, one-year labor, frypot assembly - lifetime NON HIGH EFFICIENCY Example: MJCF, MJ45, MJ35, MJ47, J1C ¾ One year parts and labor ¾ Second and third year frypot assembly only ¾ After third year, lifetime on the bare pot ELECTRIC SPAGHETTI MAGIC AND FPTCF Example: 8SMS ¾ One year parts and labor ¾ Ten year – pot only RETHERMALIZER, WATER BATH, GAS PASTA COOKER, ESW,EWBS Example: FBR18,ESW,EWBS,17EC,17ECS ¾ One year parts and labor ¾ Ten year – frypot assembly GF14, GF40, G18FB, GL18FB, GL24FB Example: GF14SD Model number will have SP or SD at the end ¾ One year – parts and labor ¾ Five year – S/S frypot only ELECTRIC UNITS Example: H/RE14, H/RE17, and H/RE22, E1721 ¾ One year – parts and labor ¾ Frypot only – lifetime COMPUTERS ¾ First year computer and labor SHORTENING DISPOSAL UNIT Example: SDU ¾ First 90 days – all parts and labor ¾ Between 90 days and one year, pump only G-16 PRODUCT HOLDING DEVICE Example: PHD ¾ One year parts and labor SINGLE BASKET DISPENSER Example: SINBAD ¾ One year parts and labor HEATED PASS THRU HPT ¾ One year parts and labor PORTABLE FILTER ¾ One year parts and labor PURCHASED REPLACEMENT PARTS/FRYPOTS/COMPUTERS ¾ Parts, 90 days, no labor ¾ Stainless Steel Frypots – 1 year, 90 day labor ¾ Computers, 1 year, no labor FENWAL THERMOSTATS ¾ Two years ¾ First year thermostat and labor ¾ Second year, thermostat only DROP-IN FRYERS-FRYMASTER ¾ 90 days all parts-no labor ¾ 2 years fenwal thermostat-no labor ¾ Lifetime on stainless steel frypot (for original owner) (International frypot warranties vary) G-17 LENGTH OF COVERAGE MCDONALD’S FRYPOTS – Frypots are warranted against manufacturing defect and/or weld seam failure. HIGH EFFICIENCY GAS ¾ Units installed December 1, 2003 and after Ten years parts and labor on frypot assembly. Components attached to the frypot, such as the high-limit, probe, gaskets, seals, igniters, and related fasteners, are also covered by the ten-year warranty if replacement is necessitated by the frypot replacement. Components that are not part of the frypot assembly, such as blower, gas valve, micro switches, doors, cabinetry, are not covered by the frypot warranty ¾ Units installed July 1, 2001 through November 30, 2003 Seven years parts and labor on frypot assembly. Components attached to the frypot, such as the high-limit, probe, gaskets, seals, igniters, and related fasteners, are also covered by the seven-year warranty if replacement is necessitated by the frypot replacement. Components that are not part of the frypot assembly, such as the blower, gas valve, microswitches, doors, and cabinetry, are not covered by the frypot warranty. ¾ Installed November 1 1994 through June 30, 2001 Seven years parts and labor on frypot assembly. ¾ Installed January 1989 through October 31, 1994 Lifetime on frypot assembly ¾ Installed before January 1989, five-year warranty on frypot assembly After fifth year 50% of list price for frypot assembly. ELECTRIC ¾ Units installed after December 1, 2003, ten years parts and labor ¾ Installed after January 1995 - seven year warranty parts and labor ¾ Units installed January 1, 1995 carry three-year warranty on elements. One year labor, second and third year part only ¾ Installed January 1989 through January 1995 - lifetime on pot, one year parts and labor ¾ Installed before January 1989 – After fifth year, 50% of list price for frypot PORTABLE FILER ¾ One year parts and labor G-18 COMPUTERS Original M2000 on a new fryer ¾ First year computer and labor ¾ Second year computer only ¾ Third year reduced cost -90.00Note: When a computer is replaced under warranty, the replaced computer only carries the remaining original fryer warranty. SHORTENING DISPOSAL UNIT Example: MSDU ¾ First thirty days parts and labor ¾ After thirty days, one year parts only, no labor UNIVERSAL HOLDING CABINET Example: UHC, UHC-P ¾ Two-year parts and labor ¾ All UHC Replacement parts carry a 90 day, no labor warranty HEATED LANDING ZONE Example: HLZ ¾ First year parts and labor ¾ Second year motor only, no labor VERTICAL TOASTER Example: VT ¾ One year parts and labor ¾ One year parts/labor warranty ¾ Second year motor only, no labor ¾ Replacement Oriental Motor has a one year warranty, no labor SINGLE BASKET DISPENSER Example: SINBAD ¾ One year parts and labor (Fuses are not covered) PURCHASED REPLACEMENT PARTS/FRYPOTS/COMPUTERS ¾ Parts, 90 days , no labor ¾ Stainless steel frypots, 1 year, 90 days labor ¾ Computers 1 year, no labor G-19 INTRODUCING THE MCDONALD LOV (LOW OIL VOLUME) FRYER This fryer was released to production on December 21, 2007 for McDonalds. This new fryer, BIELA14 is based on the BIRE14 and the heating components and contactor boxes resemble those used in the earlier fryer. The fryer is different than its predecessor. Oil is automatically topped off from a reservoir in the fryer cabinet. Filtration is automatic and hands off. The frypot is shallower, 30 rather than 50 pounds. The computer is new, an M3000. It resembles the M2000 but the programming is different. Warranty below: All parts (except frypots) including elements and computers: Two (2) years parts and labor Two (2) hours travel and 100 miles Frypot Warranty: Ten (10) year, frypot and labor Frypot are warranted against manufacturing defect or seam leak. Filing warranty claim for Start up and Training should include service invoice, LOV Start-Up Form and LOV Training Sign Off Form. START UP AND LOV TRAINING LOV Start-Up Form 819-6355 LOV Fryer Training Outline Form 819-6357 LOV Training Sign Off Form 819-6356 All are posted on the Frymaster Website under Forms Two hours are allowed (at normal labor rate) for Start-Up on one system, fry or protein station. Travel and mileage will be paid. Tech should have copy of training outline form with them when start up is done. Two hours are allowed for LOV training (at normal labor rate). LOV training sign-off form must be signed by McDonald’s personnel when start-up and training are completed. Start-up and training must be done on the same trip. Travel and mileage will only be paid for one trip. TRAINING DECLINED – WARRANTY VOIDED IF DEFECTIVE LOV PARTS ARE REQUESTED TO BE RETURNED TO FRYMASER PLEASE RETURN WITH LOV PARTS TAGS PROVIDED BY FRYMATER – PART NUMBER 819-6389. G-20 LOV™ Fryer Start-up Form 8700 LINE AVENUE SHREVEPORT, LA 71106 (800) 551-8633 Date_____________________ Store Name Store # (if applicable) Address City/State Store Phone ( ) Technician Service Agency Address City/State Country FRYER/FILTER MODEL NUMBER Verify exhaust blank-off plates are installed with Electric Fryers Verify Universal hoods have 2” (50mm) of clearance behind fryer Verify Seal Angle, Stand-off Channel & Gravity Blade are properly installed Vat #1 AMP DRAW Electric Vat #1 L1 L2 L3 YES NO YES NO YES NO N/A (GAS) N/A (Universal Hood) Remove Warranty Label date tabs Ensure fryer is mounted on casters provided by the factory, properly restrained in accordance with the operator’s manual, & level. Perform SETUP on all computers. Refer to manual. Record Software Computer_______MIB_______AIF_______ATO_______ Program computers for products to be cooked as per managers request - FR FRIES, HASH BRN, NUGGETS, MCCHICK, etc. Refer to manual. Attach product stickers to buttons. Is the fry system being installed connected to a BULK OIL SUPPLY / DISPOSAL SYSTEM (RTI) YES NO Place full JIB in fryer for ATO system, or fill provided JIB from Bulk Oil system (as applicable). Refer to manual. Thoroughly clean and dry all vats. Fill all vats with oil to ½” below cold oil line. Allow fryers to heat to set point (see gas and electric checks below) and verify temperatures are at set point +/- 5°F / 2°C. Verify that oil level is below ATO level sensor (upper oil level line) but above AIF sensor (lower oil level) (add/remove oil if necessary) and that each vat tops off from JIB. While the units are heating up, perform gas pressure checks and / or current draw checks outlined below and record readings in the area provided. GAS fryers, check incoming gas pressure (Natural Gas: 6-14" W.C.; LP Gas: 11-14" W.C.) Check for proper combustion; fryers should have a bright orange flame after approximately 1 minute of operation. Adjust blower air inlet to achieve 2.5 – 3.5 uA (micro amps) on each igniter flame sense circuit. ELECTRIC fryers ensure applied voltage matches the rating plate. Ensure all phases are balanced and there is no current draw when controller heat light is off. Gas Left uA Right uA SERIAL NUMBER (10 DIGIT) Vat #2 Vat #3 Vat #4 Vat #5 Vat # 6 Vat # 7 Vat # 8 Vat # 9 Vat # 10 Vat #2 Vat #3 Vat #4 Vat #5 Vat # 6 Vat # 7 Vat # 8 Vat # 9 Vat # 10 Verify that all filter parts (filter pan, filter screen, filter pad or paper, hold-down ring, crumb tray, and O-rings) are present. Visually inspect the oil drain and return system to ensure all connections are tight. Verify filter pan alignment. The pan should slide smoothly into position with an “A” displayed on the MIB. Ensure pick-up tube is fully engaged in the pan suction tube. “P” should be displayed on the MIB when the pan is pulled forward. Perform an Auto Filter on a vat to ensure the filter pump is operational and check the drain and return system for leaks. Two (2) hours are allowed for the above to Start-Up one system; fry or protein station 819-6355 G-21 APR 08 LOV™ Fryer Training Outline Form Two (2) hours are allowed for the following training / demo for each fry and protein station. Ensure all trainees refer to the Operation Manual for the following. Hands on demonstration and performance are essential for all trainees. CREW / FILTRATION PERSON(S) / MANAGERS OVERVIEW Provide an overview of what a LOV is Vs traditional fryer Explain the benefits when used properly COMPUTER – Refer to Operations Manual Chapter 4 Identify M2007 Computer buttons and functions / LED’s for LOV ON / OFF Buttons – Full and Split Functions Product Buttons - Multi product cooking buttons and entering codes for programming Cook Cycle Buttons – Start a cook cycle / cancel alarms and change from Dedicated to Multi Product Filter Buttons – Off - Cooks Remaining / On = Press and hold to access Filter Menu / Menu navigation Temp Button – Off – Versions of software / On = 1(X) actual temp 2(X) set-point Info Button – 1(X) Recovery check of fryer / Press and hold 3 seconds = Filter Stats, Usage, Last Load Filter Light LED JIB LED / JIB Reset Master Power Switch (per vat) (US ONLY) MIB Display Window – “A” for Auto or “P” filter pan installation issue. Check for proper installation of pan. Demonstrate how to use the operating controls – Cooking Functions Turning the computer ON / OFF for heating the vats One button cooking – Dedicated Mode Two button cooking – Multi Product. Show REMOVE / DISCARD message if start timer not pushed. Changing from breakfast to lunch and back Cancel a cook cycle or alarms Demonstrate JIB System (JIB and Bulk Oil Systems) Demonstrate setup of the JIB Filling vats with oil (Bulk or JIB) AUTO TOP-OFF (ATO) Instruct on function of Yellow “JIB Empty” LED (Use remaining oil in box) Demonstrate when JIB is changed JIB reset must be pressed to reset light Demonstrate Auto Top-Off on a vat by moving oil out of vat AUTOMATIC INTERMITTENT FILTRATION (AIF) Demonstrate assemble of the filter pan (Emphasize need for daily pad change / more often as needed) Demonstrate AIF cycle on “TEST” menu item. Air bubbles should only be observed in unit being filtered. Show Blue LED, SAY “YES” TO THE BLUE LIGHT Show “FILTER NOW” displayed on vat to be filtered Demonstrate new skimming procedure Show FILTER ERROR routine flowchart (monitor oil returned to vat levels – should be where it started) Show FILTER BUSY message by sending filter system into Filter Error. FILTER BUSY on all other vats. 2 consecutive FILTER ERROR and unit goes to SERVICE REQUIRED an authorized technician is needed. Show location of thermal reset on Filter Motor G-22 FILTRATION PERSON(S) / MANAGERS FILTER MENU NON BULK OIL SYSTEM Demonstrate how to access FILTER MENU Show AUTO FILTER & explain what it does Show MAINT FLTR Show DISPOSE & explain what it does (Use of SDU) Show DRAIN TO PAN & explain what it does Show FILL POT FROM PAN & explain what it does BULK OIL SYSTEM Demonstrate how to access FILTER MENU Show AUTO FILTER & explain what it does Show MAINT FLTR Show DISPOSE & explain what it does Show DRAIN TO PAN & explain what it does Show FILL POT FROM PAN & explain what it does Show FILL POT FROM BULK & explain what it does STORE MANAGERS ONLY (OR DESIGNATED PERSONS) Demonstrate how to access LEVEL 1 PROGRAMMING – Code 1234 Demonstrate Product Selection and setting up an item Demonstrate how to add a new Menu Item – setup a test menu item (short cook cycle) Demonstrate the AIF Clock Function (Should not be necessary to use – we want to filter each time) Deep Clean High Limit Check Setup Mode Demonstrate how to access LEVEL 2 PROGRAMMING – Code 1234 Product Compensation – Sensitivity E-Log – Error Log ( Last 10 error codes ) Passwords – Set passwords for setup, Usage, Level 1, Level 2, and Filter Error Alert Tone – Alarm Volume Filter After – Global setting for the vat on how many cook cycles per vat before filtering Filter Time – How often to filter on a time Vs cook cycle basis Demonstrate how to access INFO MODE Show FILTER STATS menu Show REVIEW USAGE menu Show LAST LOAD menu Demonstrate Deep Clean Procedures – as much as practical TROUBLESHOOTING Common error messages FILTER ERROR – a problem in the filtration system exists FILTER BUSY – A FILTER ERROR exists on another vat and must be cleared Probe Failure – Temperature circuitry has a problem Ignition Failure – Unit is not heating Low Temp – Oil temperature below set point – may occur during cooking cycle Recovery Fault Call Service – Vat did not meet minimum specs for temperature recovery Frymaster’s Hot line and ASA contact person / with phone numbers 819-6357 G-23 APR 08 LOV™ TRAINING SIGN OFF FORM Date of Training _____________________ Store Name Store # (if applicable) Address City/State Store Phone ( ) Technician Service Agency Address City/State Country FRYER/FILTER MODEL NUMBER SERIAL NUMBER (10 DIGIT) Training has been conducted on the following areas: 1) Computer functions 2) Operating the Fryer 3) JIB System 4) Auto Top Off 5) Auto Filter and Filter Menu 6) Level 1 Programming 7) Level 2 Programming 8) Accessing Info Mode 9) Explain Deep Cleaning Process 10) Troubleshooting Training / Demo Signature Sheet – Key Personnel * Store Manager’s Signature * Filtration Person Signature Printed Name Printed Name Signature Printed Name O/O / Staff Personnel Printed Name Technician’s Signature * - Mandatory Attendee Printed Name * Key Shift Person TRAINING DECLINED – WARRANTY VOIDED O/O / Corporate Manager Signature Printed Name 819-6356 G-24 Dec 07 LENGTH OF COVERAGE BURGER KING Frypots are warranted against manufacturing defect and/or weld seam failure HIGH EFFICIENCY-H50/55 ¾ July 1, 2006 Seven year parts and labor on frypot assembly ¾ Installed September 1995-June 2006 ¾ Seven year parts and labor on frypot assembly or lifetime frypot assembly. (Warranty was selected at time of purchase from Frymaster) ¾ Installed before September 1995 Frypot assembly - lifetime NON HIGH EFFICIENCY-STAINLESS STEEL Example: MJCF, MJ45, and MJ35 ¾ First year parts and labor ¾ Second and third years frypot assembly only ¾ After third year, lifetime on bare pot ELECTRIC Example: H17/14/22/, RE/PRO ¾ One year-parts and labor ¾ Lifetime on pot ¾ EPRI fryers installed after April 1, 1997, three years part and labor on elements and triacs or solid state relays COMPUTERS ¾ First year computer, labor ¾ Second and third years, computer only ¾ Spare computers that ship with fryers have a 3 year warranty, same warranty as the computer that ship on the fryer. SHORTENING DISPOSAL UNIT Example: SDU ¾ 90 Days Parts and Labor ¾ One year, pump only, no labor SINGLE BASKET DISPENSER Example: SINBAD ¾ One year parts and labor FENWAL THERMOSTATS ¾ First year thermostat and labor, second year, thermostat only PURCHASED REPLACEMENT PARTS/FRYPOTS/COMPUTERS ¾ Parts, 90 days , no labor ¾ Stainless steel frypots, 1 year, 90 days labor ¾ Computers, 1 year, no labor G-25 LENGTH OF COVERAGE HARDEES/CARL’S JR./CKE FRYPOTS-frypots are warranted against manufacturing defect and/or weld seam failure. HIGH EFFICIENCY Example: FPH350 /MJH50/H55 ¾ February 2004, Ten years, seven years parts and labor on frypot assembly, three years on frypot assembly. ¾ After May 1, 1998-January 2004, seven-year parts and labor on frypot assembly. ¾ Before May 1, 1998, one year parts and labor Lifetime on frypot assembly NON-HIGH EFFICIENCY Example: FM345ESD ¾ First year - complete frypot assembly, and all parts and labor ¾ Second through fifth year - complete frypot assembly ¾ After fifth year - bare pot COLD ROLL FRYPOTS-NON STAINLESS STEEL Example: FM345ST ¾ One year - parts and labor TUBE FRYER Example: F2TCFSD ¾ One year parts and labor ¾ Ten year on bare pot ELECTRIC Example: FPH314/17/22,RE/PRO ¾ One year parts and labor ¾ Pot only – lifetime COMPUTERS ¾ First year labor, computer ¾ Second and third year, computer only SHORTENING DISPOSAL UNIT Example:SDU ¾ First 90 days – all parts and labor, between 90 days and one year, pump only PURCHASED REPLACEMENT PARTS/FRYPOTS/COMPUTERS ¾ Parts, 90 days no labor ¾ Stainless steel frypots, 1 year, 90 days labor ¾ Computers, 1 year, no labor G-26 LENGTH OF COVERAGE YUM - KFC,LJS, PIZZA HUT, A & W BASIC FRYER & FILTER SYSTEM ¾ One year parts and labor ¾ All frypots are warranted against manufacturing defect and/or weld seam failure HIGH EFFICIENCY- H50/55 ¾ One year parts and labor ¾ Frypots Installed before May 1998, lifetime on frypot assembly Installed after May 1998, 7 year parts and labor on frypot assembly NON-HIGH EFFICIENCY (MJCF, MJ45, MJ35) ¾ One year parts and labor ¾ S/S Frypot - First year frypot and labor, second and third year frypot assembly only After third year, lifetime on the bare pot TUBE FRYERS (KSCF218G, TB14G) ¾ One year parts and labor ¾ S/S Frypot- First year frypot and labor, second through tenth year – frypot only ELECTRIC FRYMASTER ¾ One year parts and labor ¾ Frypot- First year, frypot and labor After first year, lifetime on bare frypot After May 2003 – EPRI element, solid state Triacs, first through third year, parts and labor ELECTRIC DEAN ¾ One year parts and labor ¾ Five year mild steel ¾ Ten year stainless steel FLAT BOTTOM FRYERS ¾ One year parts and labor ¾ Frypot- First year frypot and labor, second, third, and fourth year, frypot only COMPUTER ¾ First year, computer and labor ¾ Second and third year computer only SHORTENING DISPOSAL UNIT Example: SDU ¾ One year – parts only PURCHASED REPLACEMENT PARTS/FRYPOTS/COMPUTERS ¾ Parts, 90 days ¾ Stainless steel frypots, 1 year, 90 days labor ¾ Computers, 1 year, no labor G-27 MISCELLANEOUS WARRANTY BUFFALO WILD WING COMPUTER WARRANTY ¾ Two year warranty ¾ First year, computer and labor ¾ Second year, computer only BOSTON MARKET RETHERMALIZER ¾ Change complete pot, part numbers 8068025SP Natural Gas, 8068026SP LP Gas . No Bare Pot -One year parts and labor ¾ Ten year on the pot assembly I-HOP EXTENDED WARRANTY (DEAN)Models: SM20/SM50 ¾ 2-year parts and labor ¾ Additional 3 year warranty on mild steel frypot ¾ Additional 8 year warranty on stainless steel frypot MARSHALL AIR HEAT LAMP ¾ One year heat lamp and labor Complete heat lamp should be replaced. Part number 8068836. There are no individual parts for field repair. When filing a warranty claim for a heat lamp, use the fryer model and serial number. MERCO HEAT LAMP ¾ One year parts and labor NOTE: When filing a claim for a Merco Heat Lamp, use the Frymaster fryer serial number. HATCO HEAT LAMP ¾ Warranty claims for Hatco heat lamps should be filed with Hatco. RUBIO’S ¾ 2 year warranty on computer – 1st year computer and labor, 2nd year computer only DROP-IN FRYERS-FRYMASTER ¾ 90 days all parts; no labor ¾ 2 years fenwal thermostat; no labor ¾ Lifetime on stainless steel frypot (for original owner) (International frypot warranties vary) DROP-IN FRYERS-DEAN ¾ 90 days all parts-no labor ¾ Ten years on stainless steel frypot (for original owner) (International frypot warranties vary) BRINKER ELECTRIC RETHERMALIZER ¾ One year parts and labor on all parts ¾ 2 years on elements, controllers -2nd year part only no labor G-28 RUBY TUESDAY’S ¾ Two years parts and labor on all parts ¾ Frypots - Standard frypot warranty RAISING CANE’S ¾ Two years parts and labor on all parts ¾ Frypot – ten years, no labor after first year G-29 STANDARD LABOR TIME ALLOWANCE Frymaster maintains a standard labor time allowance chart that our servicers comply with. These times are fair and adequate to perform each specific task. This standard applies to both warranty and out-of-warranty service, and is available to our customers. • Note: Time shown includes time to diagnose and perform service listed. Travel time is not included. Under normal circumstances, a reasonably competent technician can complete the task within the time allowed. PLEASE ADHERE TO THESE GUIDELINES. THANK YOU. G-30 H50/52/55 SERIES MAXIMUM HOURS TARGET** HOURS 3.5 6.0 2.5 4.5 6.5 5.5 FRYPOT REPLACEMENT EUROPEAN MODELS W/FILTER (FRYERS WITH 96-98 SERIAL NUMBERS ONLY) COMPUTER OR CONTROLLER REPLACEMENT PROBE, TEMPERATURE REPLACEMENT 8.0 1.0 1.0 7.0 1.0 1.0 HIGH-LIMIT THERMOSTAT INTERFACE BOARD REPLACEMENT IGNITION MODULE REPLACEMENT IGNITOR PLUG REPLACEMENT GAS VALVE REPLACEMENT GAS VALVE REPLACEMENT, EUROPEAN MODELS 1.0 1.0 1.0 1.0 2.0 2.5 0.5 1.0 1.0 1.0 2.0 2.5 BLOWER MOTOR REPLACEMENT BASKET LIFT RELAY REPLACEMENT BASKET LIFT RODS REPLACEMENT BASKET LIFT MICROSWITCH REPLACEMENT BASKET LIFT MOTOR REPLACEMENT 1.0 0.5 2.0 1.0 1.5 0.5 0.5 2.0 1.0 1.5 FILTER MOTOR REPLACEMENT FILTER PUMP REPLACEMENT FILTER DRAIN SWITCH REPLACEMENT 2.0 2.0 0.5 1.5 2.0 0.5 FILTER RELAY REPLACEMENT DRAIN VALVE REPLACEMENT (WITH FILTER) DRAIN VALVE (WITHOUT FILTER) REPLACEMENT FILTER OIL RETURN VALVE REPLACEMENT 1.0 1.5 0.5 2.0 1.0 1.5 0.5 2.0 BURNER & INSULATION REPLACEMENT (without filter) BURNER & INSULATION REPLACEMENT, EUROPEAN MODELS (and filter models) 1.5 1.5 2.0 2.0 GAS VALVE RELAY REPLACEMENT SOUND DEVICE REPLACEMENT TRANSFORMER REPLACEMENT SOLENOID VALVE REPLACEMENT FILTER PUMP & FILTER SYSTEM HEATERS 0.5 0.5 1.0 1.0 1.5 0.5 0.5 1.0 1.0 1.5 * * * * FRYPOT REPLACEMENT (NON FILTER) FRYPOT REPLACEMENT WITH FILTER SYSTEM FRYPOT REPLACEMENT EUROPEAN MODELS W/O FILTER (FRYERS WITH 96-98 SERIAL NUMBERS ONLY) COMPLETE FRYPOT INSULATION KIT REPLACEMENT REPLACEMENT UPPER COMBUSTION CHAMBER (upper rails) * Use time for replacement of appropriate frypot (filter/non-filter) plus 1.00 hour. ** Under normal circumstances, a reasonably competent technician can complete the task within this time. NOTE: Time allowance shown includes time to diagnose and perform service listed. Travel time is not included. These times are to be used as a guide for replacing single parts. If multiple parts are replaced, these times will be significantly reduced. G-31 FRYMASTER MJ45, MJ47, MJCF, MJCFE, FMP/FPP45/KJ3FC DEAN 60, 65 & 80, 1824G & 2424G, 218G SERIES MAXIMUM HOURS TARGET** HOURS FRYPOT REPLACEMENT (NON FILTER) FRYPOT REPLACEMENT WITH FILTER SYSTEM DRAIN VALVE REPLACEMENT (NON-FILTER) DRAIN VALVE REPLACEMENT WITH FILTER SYSTEM 3.5 4.5 0.5 1.5 3.5 4.5 0.5 1.5 OPERATING THERMOSTAT REPLACEMENT (includes calibration) HIGH-LIMIT THERMOSTAT REPLACEMENT TEMPERATURE PROBE REPLACEMENT GAS VALVE REPLACEMENT 1.5 1.0 1.0 1.5 1.5 0.5 1.0 1.5 REGULATOR REPLACEMENT THERMOPILE/THERMOCOUPLE REPLACEMENT 0.5 2.0 0.5 1.5 MELT CYCLE TIMER REPLACEMENT PRESSURE SWITCH REPLACEMENT INTERLOCK RELAY REPLACEMENT TRANSFORMER REPLACEMENT 0.5 1.0 0.5 1.0 0.5 1.0 0.5 1.0 COMPUTER REPLACEMENT INTERFACE/THERMATRON BOARD REPLACEMENT BASKET LIFT RELAY REPLACEMENT BASKET LIFT RODS REPLACEMENT 1.0 1.0 0.5 2.0 1.0 1.0 0.5 2.0 BASKET LIFT TIMER REPLACEMENT BASKET LIFT MICROSWITCH REPLACEMENT BASKET LIFT MOTOR REPLACEMENT 0.5 1.0 1.5 0.5 1.0 1.5 FILTER MOTOR REPLACEMENT FILTER PUMP REPLACEMENT FILTER DRAIN SWITCH REPLACEMENT FILTER READY LIGHT/RESISTOR 2.0 2.0 0.5 0.5 1.5 2.0 0.5 0.5 FILTER RELAY REPLACEMENT FILTER OIL RETURN VALVE REPLACEMENT 1.0 2.0 1.0 1.5 FILTER PAN HEATER FILTER PAN CONTACT BLOCK 1.5 1.0 1.5 1.0 SOUND DEVICE REPLACEMENT BURNER TARGET REPLACEMENT PIEZO ELECTRIC SPARK 0.5 1.5 1.0 0.5 1.5 1.0 ** Under normal circumstances, a reasonably competent technician can complete the task within this time. NOTE: Time allowance shown includes time to diagnose and perform service listed. Travel time is not included. These times are to be used as a guide for replacing single parts. If multiple parts are replaced, these times will be significantly reduced. G-32 FRYMASTER DEAN ELECTRIC FRYERS MAXIMUM HOURS TARGET** HOURS FRYPOT REPLACEMENT (NON FILTER) FRYPOT REPLACEMENT WITH FILTER SYSTEM HEATING ELEMENT REPLACEMENT CONTACTOR REPLACEMENT TEMPERATURE PROBE REPLACEMENT 3.0 4.0 2.0 1.5 1.0 3.0 4.0 2.0 1.0 1.0 OPERATING THERMOSTAT REPLACEMENT HIGH-LIMIT THERMOSTAT REPLACEMENT COMPUTER REPLACEMENT BASKET LIFT RELAY REPLACEMENT BASKET LIFT RODS REPLACEMENT 1.0 1.0 1.0 0.5 2.0 1.0 1.0 1.0 0.5 2.0 BASKET LIFT MICROSWITCH REPLACEMENT BASKET LIFT MOTOR REPLACEMENT FILTER MOTOR REPLACEMENT FILTER PUMP REPLACEMENT 1.0 1.5 2.0 2.0 1.0 1.5 1.5 2.0 FILTER DRAIN SWITCH REPLACEMENT FILTER RELAY REPLACEMENT DRAIN VALVE REPLACEMENT (WITH FILTER) DRAIN VALVE (NON-FILTER) REPLACEMENT 0.5 1.0 1.5 0.5 0.5 1.0 1.5 0.5 FILTER OIL RETURN VALVE REPLACEMENT TILT SPRING REPLACEMENT INTERFACE BOARD REPLACEMENT HEAT RELAY REPLACEMENT 2.0 1.0 1.0 0.5 1.5 1.0 1.0 0.5 LATCH RELAY REPLACEMENT TRANSFORMER REPLACEMENT SOUND DEVICE REPLACEMENT FILTER TRANSFORMER REPLACEMENT FILTER PUMP & FILTER SYSTEM HEATER REPLACEMENT 0.5 1.0 0.5 1.0 0.5 1.0 0.5 1.0 1.5 1.5 SOLID STATE RELAY REPLACEMENT ELECTRONIC THERMOSTAT CONTROLLER 1.5 1.0 1.0 1.0 ** Under normal circumstances, a reasonably competent technician can complete the task within this time. NOTE: Time allowance shown includes time to diagnose and perform service listed. Travel time is not included. These times are to be used as a guide for replacing single parts. If multiple parts are replaced, these times will be significantly reduced. G-33 FRYMASTER MJ35, FMP35, J2X, J2XLR, J1C, J1X, GF14 & GF40, SERIES; DEAN GAS 20, 25, 35, 38, 42, 50, 52, 62,YSCF214,TB114 SERIES MAXIMUM HOURS TARGET** HOURS 2.5 4.5 1.0 2.5 4.5 1.0 1.5 1.5 0.5 1.0 1.5 0.5 PILOT MAGNET REPLACEMENT BURNER TARGET REPLACEMENT THERMOPILE/THERMOCOUPLE/CE REPLACEMENT PILOT BURNER REPLACEMENT DRAIN VALVE REPLACEMENT (NON-FILTER) DRAIN VALVE REPLACEMENT WITH FILTER ELECTRONIC THERMOSTAT CONTROLLER REPLACEMENT INTERFACE BOARD REPLACEMENT COMPUTER REPLACEMENT 0.5 1.5 0.5 1.0 0.5 1.5 0.5 1.5 0.5 1.0 0.5 1.5 1.0 1.0 1.0 1.0 1.0 1.0 FILTER MOTOR REPLACEMENT FILTER PUMP REPLACEMENT BASKET LIFT RELAY REPLACEMENT BASKET LIFT RODS REPLACEMENT BASKET LIFT TIMER REPLACEMENT BASKET LIFT MICROSWITCH REPLACEMENT BASKET LIFT MOTOR REPLACEMENT 2.0 2.0 0.5 2.0 1.0 1.0 1.5 1.5 2.0 0.5 2.0 0.5 1.0 1.5 FRYPOT REPLACEMENT (NON FILTER) FRYPOT REPLACEMENT WITH FILTER SYSTEM HIGH-LIMIT THERMOSTAT REPLACEMENT OPERATING THERMOSTAT REPLACEMENT (includes calibration) GAS VALVE REPLACEMENT REGULATOR REPLACEMENT ** Under normal circumstances, a reasonably competent technician can complete the task within this time. NOTE: Time allowance shown includes time to diagnose and perform service listed. Travel time is not included. These times are to be used as a guide for replacing single parts. If multiple parts are replaced, these times will be significantly reduced. G-34 GAS & ELECTRIC SERIES PASTA COOKERS / WATERBATHS / RETHERMALIZERS POT REPLACEMENT, GAS (WITH BURNERS, WITHOUT BLOWER) POT REPLACEMENT [POT IS BARE (8SMS ELECTRIC)] PROBE ASSEMBLY REPLACEMENT BURNERS/ORIFICES REPLACEMENT, GAS ELEMENT REPLACEMENT (8SMS ELECTRIC) CONTACTOR REPLACEMENT (8SMS ELECTRIC) PROBES (HIGH WATER – LOW WATER) REPLACEMENT TEMPERATURE PROBE REPLACEMENT TUBING (AUTO FILL) REPLACEMENT TUBING FITTINGS REPLACEMENT TUBING KIT REPLACEMENT (8SMS ELECTRIC) SOLENOID REPLACEMENT PRESSURE REGULATOR REPLACEMENT, GAS IGNITION MODULE REPLACEMENT, GAS BLOWER RELAY REPLACEMENT, GAS BLOWER REPLACEMENT, GAS IGNITOR REPLACEMENT, GAS COMPUTER REPLACEMENT GAS VALVE REPLACEMENT FAUCET ASSEMBLY REPLACEMENT DRAIN VALVE REPLACEMENT BASKET LIFT RELAY REPLACEMENT BASKET LIFT RODS REPLACEMENT BASKET LIFT TIMER REPLACEMENT BASKET LIFT MICROSWITCH REPLACEMENT BASKET LIFT MOTOR REPLACEMENT TRANSFORMER REPLACEMENT RELAY REPLACEMENT (8SMS ELECTRIC) FITTINGS REPLACEMENT (8SMS ELECTRIC) MAXIMUM HOURS TARGET** HOURS 3.5 3.5 1.0 1.5 1.5 1.0 1.0 1.0 1.5 1.0 1.5 1.0 1.0 0.5 0.5 1.0 1.0 1.0 1.0 1.0 1.5 0.5 2.0 1.0 1.5 1.5 1.0 0.5 1.0 3.5 3.5 1.0 1.5 1.5 1.0 1.0 1.0 1.5 1.0 1.5 0.5 1.0 0.5 0.5 0.5 1.0 1.0 1.0 1.0 1.5 0.5 2.0 0.5 1.5 1.5 1.0 0.5 1.0 ** Under normal circumstances, a reasonably competent technician can complete the task within this time. NOTE: Time allowance shown includes time to diagnose and perform service listed. Travel time is not included. These times are to be used as a guide for replacing single parts. If multiple parts are replaced, these times will be significantly reduced. G-35 UNIVERSAL HOLDING CABINET, UHC, UHC-P FUSE REPLACEMENT HEATER PLATE REPLACEMENT SWITCH (GREEN ROCKER) REPLACEMENT EXHAUST BLOWER REPLACEMENT MASTER CONTROL BOARD REPLACEMENT TRANSFORMER REPLACEMENT FRONT SLOT DISPLAY REPLACEMENT REAR SLOT DISPLAY REPLACEMENT DISPLAY DRIVER REPLACEMENT SLOT BEZEL REPLACEMENT ONE UNIT HOURS STACKED LOWER UNIT HOURS 0.5 1.0 0.5 1.0 1.0 0.5 1.0 1.0 1.0 1.0 1.0 1.5 0.5 1.5 1.5 1.0 1.0 1.0 1.0 1.0 NOTE: Time allowance shown includes time to diagnose and perform service listed. Travel time is not included. These times are to be used as a guide for replacing single parts. If multiple parts are replaced, these times will be significantly reduced. HEATED LANDING ZONE (HLZ) / HEATED PASS THROUGH (HPT) ROCKER SWITCH (HPT) CONTROLLER BOARD (HPT) COMPUTER REPLACEMENT (HLZ) RELAY & FUSE REPLACEMENT (HLZ/HPT) TRANSFORMER REPLACEMENT (HLZ/HPT) AIR PROBE REPLACEMENT (HLZ/HPT) AIR THERMOCOUPLE REPLACEMENT (HLZ/HPT) HEATER PLATE (PLATEN) REPLACEMENT (HLZ/HPT) BLOWER MOTOR REPLACEMENT (HLZ/HPT) HIGH-LIMIT REPLACEMENT KIT (HLZ/HPT) MAXIMUM HOURS TARGET** HOURS 1.0 1.0 1.0 0.5 1.0 1.0 1.0 1.5 1.5 1.0 1.0 1.0 1.0 0.5 1.0 1.0 1.0 1.0 1.0 1.0 ** Under normal circumstances, a reasonably competent technician can complete the task within this time. NOTE: Time allowance shown includes time to diagnose and perform service listed. Travel time is not included. These times are to be used as a guide for replacing single parts. If multiple parts are replaced, these times will be significantly reduced. G-36 VERTICAL TOASTER (VT) MAXIMUM HOURS TARGET** HOURS 1.0 0.5 0.5 1.0 1.0 0.5 0.5 1.0 0.5 1.0 1.0 1.0 1.5 1.5 1.5 1.5 0.5 1.0 1.0 1.0 1.0 1.0 1.0 1.0 COMPUTER REPLACEMENT RELAY REPLACEMENT TRANSFORMER REPLACEMENT CHAIN/SPROCKET REPLACEMENT DRIVE BELT REPLACEMENT (BELT-DRIVE TOASTERS ONLY) TRAY HEATER REPLACEMENT TRAY PROBE REPLACEMENT HIGH-LIMIT REPLACEMENT PLATEN REPLACEMENT COOK BELT ROLLER REPLACEMENT MOTOR REPLACEMENT TEMPERATURE PROBE REPLACEMENT ** Under normal circumstances, a reasonably competent technician can complete the task within this time. NOTE: Time allowance shown includes time to diagnose and perform service listed. Travel time is not included. These times are to be used as a guide for replacing single parts. If multiple parts are replaced, these times will be significantly reduced. PRODUCT HOLDING DEVICE (PHD) COMPUTER ASSEMBLY REPLACEMENT TRANSFORMER REPLACEMENT RELAY REPLACEMENT ELEMENT, BOTTOM, REPLACEMENT ELEMENT, TOP, REPLACEMENT SWITCH, POWER, REPLACEMENT MAXIMUM HOURS TARGET** HOURS 1.0 1.0 1.0 1.5 1.5 1.0 1.0 1.0 1.0 1.5 1.5 1.0 ** Under normal circumstances, a reasonably competent technician can complete the task within this time. NOTE: Time allowance shown includes time to diagnose and perform service listed. Travel time is not included. These times are to be used as a guide for replacing single parts. If multiple parts are replaced, these times will be significantly reduced. G-37 SINGLE BASKET DISPENSER (SinBaD) LOAD CELL ASSEMBLY REPLACEMENT DISPENSE MOTOR REPLACEMENT DRUM MOTOR REPLACEMENT DRUM ROTOR ARM REPLACEMENT (BULLET REPLACEMENT) INTERFACE BOARD REPLACEMENT PROXIMITY SENSOR CABLE ASSEMBLY REPLACEMENT COMPUTER ASSEMBLY REPLACEMENT POWER (ON/OFF) SWITCH REPLACEMENT TRANSFORMER REPLACEMENT MAXIMUM HOURS 1.0 1.0 1.0 TARGET** HOURS 1.0 1.0 1.0 0.5 1.0 0.5 1.0 0.5 0.5 0.5 1.0 0.5 1.0 0.5 0.5 ** Under normal circumstances, a reasonably competent technician can complete the task within this time. NOTE: Time allowance shown includes time to diagnose and perform service listed. Travel time is not included. These times are to be used as a guide for replacing single parts. If multiple parts are replaced, these times will be significantly reduced. G-38 WHAT THE WARRANTY DOES NOT COVER Damage due to misuse, abuse, alteration or accident. Improper or unauthorized repair. Failure to follow installation procedures, operation instructions and/or scheduled maintenance procedures as prescribed in the Frymaster Service and Owner’s Manual. Damage in shipment. Removal, alteration, or destruction of the rating plate. Changes in adjustment and calibrations after thirty days from equipment installation date. No adjustments paid on economy fryers (SR series/GF14). Any SR series fryers (SR42, etc.) installed in any type of mobile/concession kitchen will not be covered under warranty. Failure to program computer appliances in accordance with programming procedures prescribed in the Frymaster Service and Owner’s Manual. Equipment exported to foreign countries. Normal maintenance items; i.e., electric bulbs, user assessable fuses, gaskets, O-rings, interior and exterior finishes, cleaning, and abuse to power cord. O-rings not covered under warranty: 8160597, 8160117, 8261392, 8160132 Travel over 100 miles or 2 hours. Note: No travel over 100 miles or two hours will be paid without authorization number. Overtime or holiday charges over the standard rate. Damages (the cost of repairing other property, which is damaged), loss of time, profits, use, or any other incidental damages of any kind. Conversion kits are not covered under warranty unless the unit was shipped out incorrectly, or the Technical Service Department gives authorization. Toll Fees, Truck Fees, Gas Surcharges G-39 TIDBITS OF INFORMATION Before 1991, a bank of fryers shared one serial number. Beginning 1991, each fryer in a bank has its own serial number. Serial number etched on the inside of the frypot started in October 1995. Normal frypot change outs – as soon as serial number of old frypot is verified and claim has been paid , frypot can be thrown away unless it is a “400” material frypot. All “400” material frypots must be returned. Frypots should be tested with a magnet. If the magnet sticks to the frypot, it is “400” material – if in doubt, call the warranty or technical service departmentSerial number tags should not be cut out of a “400” material frypot, the frypot has to be tested for leaks by QA. Frypot cannot be tested with a hole in the pot. Claims for frypots with tags cut out will not be paid. ST is at the end of model number to indicate mild or cold roll steel. SS – means it is a stainless steel frypot. Frypot Part Numbers: 806 or 106 numbers are frypot assemblies (includes baffles and insulation). 823 numbers are frypot only. The filter system also has a serial number. October 1995 forward, all frypot serial numbers are ten digits. G-40 WARRANTY POLICY WHAT IS COVERED? The Frymaster and Dean warranty covers all defects in workmanship and material in all commercial cooking appliance and computer/controller equipment manufactured by the Frymaster Dean and sold within the domestic United States and Puerto Rico. WHO IS COVERED? The warranty covers only the original purchaser of Frymaster and Dean commercial cooking appliances and computer/controller equipment. POLICY ADMINISTRATION Frymaster and Dean will strive to establish simple, easily administered warranty policies. The warranty policies will be administered fairly, and in a manner that understands the needs of our customers. WARRANTY STATEMENT Frymaster and Dean will “customize” warranty features for certain customers to better meet their needs. We understand the value of warranty after a sale and will strive to provide the best after-sales service to our customers. FLEXIBILITY Frymaster and Dean will administer its warranty policies with an understanding of how we are viewed by our customers. Our intention is to be fair at all times, drawing out adequate information in order to make sensible decisions pertaining to warranty coverage. G-41 DEAN STANDARD WARRANTY All Dean equipment carries a one-year parts and labor warranty from the date of installation, except for frypots. FRYPOTS *SEE PRORATED STRUCTURE Models: SR38, SR42, SR52, SR62 ¾ One year mild steel ¾ Five years prorated stainless steel* Adjustments will not be paid on the SR series fryers. SR series fryers installed in any type of mobile/concession kitchen will not be covered under warranty. Models: SM 20, SM40¹, SM50, SM60, SM80, SM35¹ ¾ Five year mild steel ¾ Ten year stainless steel ¹SM40 & SM35 installed before January 1, 2000 ¾ One year mild steel ¾ Five year prorated stainless steel* Models: 1824 and 2424 ¾ Four years mild steel ¾ Replacement LJS flat bottom frypot (MS) One year frypot, no labor Models: D20G, D50G, D60G, D80G ¾ Five year mild steel ¾ Ten year stainless steel Models: 118G, 218G (Gas), 18UE (Electric) ¾ Five year mild steel ¾ Ten year stainless steel Models: TC25, TC35 ¾ One year mild steel ¾ Five year stainless prorated* ¾ DROP-IN FRYERS-DEAN ¾ 90 days all parts-no labor ¾ Ten years on stainless steel frypot (for original owner) (International frypot warranties vary) PRORATED FRYPOT STRUCTURE ¾ ¾ ¾ ¾ ¾ 1st Year 100% parts and labor. 2nd year customer pays labor, freight and 20% of current frypot list price. 3rd year customer pays labor, freight and 40% of current frypot list price. 4th year customer pays labor, freight and 60% of current frypot list price. 5th year customer pays labor, freight and 80% of current frypot list price. After fifth year customer pays labor, freight and 100% of frypot G-42 DEAN MODEL NUMBER IDENTIFICATION SM50GMS SM Ï SM – Super Marathon D/HD – Decathlon SR – Super Runner TC – Counter Top PC – Pasta Cooker BG – Bagel Boiler RG – Rethermalizer 50 Ï The number refers to oil capacity: 20, 35, 40, 42, 50, 52, 60, 80 G M Ï Ï G – Gas T – Thermatron E– Controlled Electric M – Millivolt I – Electronic Ignition (24v) HP – High Performance DI – Drop In S Ï “S” at the end indicates stainless steel. No “S” indicates mild steel (see note below) Note: Valid only on units with recent serial numbers ending in “F95” for example. T-Thermatron Controlled I-Electronic Ignition (24V) 1824GTI This number refers to the size of the tank. G = Gas E = Electric G-43 DEAN SERIAL NUMBERS October 1997 – Present Year Ð Sequential number of Model Month Family fryer built Ð Ð Ð 9710FM0054 1994 to 1997 ¾ A series of numbers and a letter; i.e., 45729001D95. The first set of five or six numbers will be the sales order number. The next three numbers are for each individual unit; i.e., 001, 002, etc. The following letter is the month followed by the year. In this method you must have the model number to determine material used in construction. An “S” at the end of the model number signifies stainless steel. If no “S,” the unit is mild steel. 1985 to 1993 ¾ A series of numbers preceded by a “W”; i.e., W048968724SS or MS. The model number is not referenced and must be determined. The first two numbers are the month of production. The next two are the year. The remaining series of numbers are a manufacturing sequence and are not significant. The letters following give the material used in construction: SS = Stainless Steel, MS = Mild Steel. Before 1985 ¾ Model number precedes a series of four or five numbers; i.e., 1414-8479. These must be manually checked in a card file to determine warranty status. G-44 NOTES DEAN LIMITED WARRANTY G-45 THIS PAGE INTENTIONALLY LEFT BLANK Shipping Address: 8700 Line Avenue, Shreveport, Louisiana 71106 TEL 1-318-865-1711 FAX (Parts) 1-318-219-7140 PRINTED IN THE UNITED STATES SERVICE HOTLINE 1-800-551-8633 (Tech Support) 1-318-219-7135 819-5917 MAY 09