Whirlpool Europe

advertisement

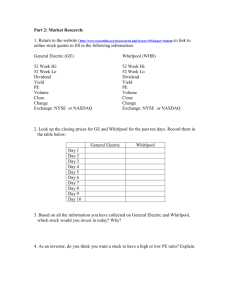

PSPL Whirlpool Europe Supply chain introduction Whirlpool Europe introduction • Whirlpool Corporation & Whirlpool Europe – Who we are • Whirlpool Europe Supply chain – Supply Chain organization – Supply chain network – Supply chain processes – Supply chain KPI – Supply chain planning system architecture – Demand management • Operational demand management & S&OP – Product introduction process ( Perfect launch ) LEAD to WIN • Whirlpool Europe Supply Chain strategy • Whirlpool Europe Employees Engagement -2- 1 PSPL World Leader in Domestic Appliances WHIRLPOOL CORPORATION Operates in 170 countries 40% bigger than nearest competitor 95 years specialist in home appliances “At home” in over 200’000’000 households world-wide -3- Whirlpool Corporation Today World Leader in Domestic Appliances The world’s leading manufacturer and marketer of major home appliances. Products: Full line of major home appliances 2006 revenues: $18.1 billion 2006 net earnings: $ 486 million 2006 units shipped: 55,000,000 Manufacturing: 13 countries in 4 continents Marketing: 170+ countries Employees: approximately 80,000 worldwide Brands: Compelling portfolio of consumer preferred brands -4- 2 PSPL Brand Portfolio We Touch All Key Consumer Segments Cooking passionates Creative & modern mentality Look for professional-like results Premium segment Quality minded Very brand conscious Home enthusiast Up market Style and design minded Time pressure Fashion oriented Technology / design driven Mass market Young families Value sensitive Passionate about simplicity Looking for reassurance -5- Whirlpool values The Essence of Whirlpool’s Five Values in 2007 Respect Respect others and believe in individual ability Integrity Always do the right thing Diversity and Inclusion Make the most of diversity to obtain better results Teamwork Achieve more working together Spirit of Winning Win in business by winning The hearts and minds of our customers -6- 3 PSPL Whirlpool in Europe Whirlpool in Europe Whirlpool in Europe g #4 position as manufacturer; #1 as Whirlpool brand g Sales US $3,4 billion g Brands: Whirlpool, Bauknecht Ignis, KItchenAid across the region; Maytag in some markets, Laden in France, Polar in Poland g Serves Europe, Middle East and Africa g 31 sales offices, export in other 38 countries g Shared Services Center, Dublin, Ireland g 14,000 employees approx Factories European Operations Centre . S.Africa. 27 -7- Supply Chain the key elements • Business processes • Business models • Distribution Models • The 3 Axises • Markets • Products • Product sourcing -8- 4 PSPL Supply Chain Process S&OP Order Intake Order mgmt Supply Planning Production Planning Demand mgmt Built To Order Make To Stock Deliver From Stock Footprint design Distribution mgmt Logistics providers selection & negotiation Carriers mgmt Warehouse mgmt Service level mgmt Factories Customer Order To Delivery Suppliers Trade -9- Supply Chain Business Models Suppliers Factory FDC/CDC RDC TP’s Customer PUSH - Forecast driven PULL - Order driven MTS Make To Stock Forecast Order VMI Vendor management inventory Forecast Stock re-fill USS Upstream Stock Forecast Order BTO Forecast Built To Order Order Decoupling point = point synchronisation between TP order and supply WE business models well supported by organisation, processes and systems -10- 5 PSPL Planning Processes & time horizons Week 1 Month (M) Week 2 Week 3 M+1 to current year end M+1 M+2 M+3 M+4 M+5 Week 4 M+12 Next Year Weekly buckets rolling Forecast Forecast at SKU / location level / category, including OSP generation Visibility only Mid to Long term Demand Plan Daily buckets rolling Supply Plan by SKU / Location Distribution planning Supply Plan Mid to Long term Demand & Supply Matching Daily buckets rolling Production Schedule Frozen Liquid Visibility, planning in SNP Pre-seq Daily run Component requirements Weekly / Monthly MRP run Daily buckets rolling Deployment Deployment plng. SKU/location Deployment Execution Profit plan per SKU / Market Oct/Nov For coming year Profit Plan / Budget -11- Whirlpool Europe’s delivery models Factory DCs’ M TS BBP’s BTO / DD Regional DCs’ Trade Consumer -12- 6 PSPL The 3 axises • Markets • Distribution profile • Trade partners • Brand value & positioning • Products • Brand portfolio • product portfolio • SKU Management • Product sourcing • Factories • Suppliers • Low cost country localization -13- Whirlpool Europe KPI 7 PSPL Whirlpool Europe KPI • Markets • ATR • DTP • DFA • DOS available to request Delivery to promise Demand forecast accuracy Day of sales • Products • SKU counting • Obsolescence • Product sourcing • PSA Production scheduling accuracy • Distribution • CPU Cost per unit -15- Processes & Performances Supplier(s) Factory Frozen Planning Mid/Long Term Call-Off Call-Off Forecast Forecast FDC SCM Market OTD-RDC Market Market OTD-Planning OTD-TP’s Serv Liquid Capacity Capacity Panning Panning GM GM S&OP S&OP TP’s Customers Monthly Monthly ODP/PP ODP/PP DFA-AGG DFA-AGG Call-Off Call-Off Fixed Fixed Daily Daily Plan Plan Daily Daily Planning Planning Weekly Weekly Forecast Forecast DFA-SKU DFA-SKU Short Term DOS DOS Frozen Plan Transit Stock Execution Normal Sales Orders Orders Submission Submission Orders Orders Entry Entry Orders Orders Submission Submission ATP ATP BI-CATR BI-CATR Material Material Delivery Delivery SQR SQR Production Production Execution Execution PSA PSA D/W D/W Blocked Blocked Products Products BTO Orders Orders Entry Entry Production Production Execution Execution PSA PSA D D Process discipline & data accuracy key elements FDC FDC Shipment Shipment DOS DOS Orders Orders Mgmt Mgmt SER SER GIT GIT DTP DTP DTR DTR BI-CDTR BI-CDTR RDC RDC Delivery Delivery Orders Orders Mgmt Mgmt -- BTO BTO BTO BTO FR FR -16- 8 PSPL KPI Description Example Title: Title: Available Available To To Promise Promise (ATR) (ATR) Description: Description: ItIt measures measures our our ability ability to to promise promise on on the the TP’s TP’s request request (product, (product, quantity, quantity, requested requested delivery delivery date) date) at at the the time time of of order order entry. entry. Frequency: Frequency: A A Trade Trade Partner Partner request request (product, (product, quantity, quantity, requested requested delivery delivery date) date) is is considered considered successful successful when when the the product/quantity product/quantity is is promised promised at at the the requested requested delivered date (first commitment). delivered date (first commitment). Formula Formula Description: Description: Element Element of of count: count: successful successful requested requested qty, qty, requested requested qty qty Source Source (Dept., (Dept., System, System, Report Report Name): Name): ATP ATP == total total successful successful requested requested qty qty // total total requested requested qty qty Ownership Ownership (Function, (Function, Dept, Dept, Name): Name): -17- Whirlpool Europe Supply chain planning system architecture 9 PSPL Key business requirements drove the design of the to-be Supply Chain processes in scope What-if-analysis What-if-analysis Exception Exception based based planning planning Supply Supply chain chain integration integration One consensus One consensus plan plan Constrained Constrained Supply Supply Planning Planning •• Material Material Constraints Constraints •• Capacity Constraints Capacity Constraints •• Transportation Transportation Constraints Constraints Production Production Planning Planning & & Scheduling Scheduling Demand Demand Management Management Consensus Consensus based based forecasting forecasting Demand Demand differentiation differentiation // Order Order type type visibility visibility Component demand planning Component demand planning Sales Parts Production Production Planning Planning & & Scheduling Scheduling Improved Improved feasibility feasibility of of production production sch. sch. Order type visibility Order type visibility Critical Critical components components planning planning Full Full BTO BTO // DD DD potential potential Supply Daily Daily planning planningProduction Frozen period Frozen period on on daily daily rolling rolling horizon horizon Closed Closed loop loop planning planning Order Intake Intake // GATP GATP Order Order management management // Order Mid Term Demand Demand Management Management Strategic Material Planning Short Term Planning horizon Long Term Constrained Constrained Supply Supply Planning Planning Full Full BTO BTO // DD DD potential potential Forecast consumption Forecast consumption Improved Improved feasibility feasibility of of master master schedule schedule Flex. Flex. allocation allocation of of capacity capacity to to countries countries Daily planning Daily planning Order Order type type visibility visibility Sales & Operations Planning Inventory Inventory target target setting setting (i.e. Spring forecast, September forecast, etc…) Deployment Deployment planning planning Order Order intake intake // GATP GATP service Differentiated Differentiated TP’s TP’sTrade service level level Distribution Allocation planning Allocation planning Real Real time time order order promising promising -19- Whirlpool process & System tree Financial Target Yearly / Half yearly Profit Planning / Spring & September Forecasting ESS BASE, MS Excel, etc. Profit Plan Monthly/ Weekly Demand Planning Demand Demand Planning Planning Gross Demand Plan Master Planning Monthly /Weekly/ Daily Net requirements / Finished Good Supply Plan Production Planning SNP SNP PP/DS PP/DS Daily Production Plan Production Execution COPICS Transactional FG Stock Deployment SNP SNP Weekly / Daily Deployment Plan Transactional Order Execution R/3 R/3 -20- 10 PSPL Whirlpool Europe Supply chain planning Demand Management Demand Forecast... A demand forecast will never be perfect. However more reliable demand planning has implications: Sales volume increases, because of the higher service level and reduced out of stock Reduction of operational costs, less obsolete inventory risks, less capital cost and lower demand for safety stock APO is the tool to support Whirlpool Demand Driven Planning Process Demand Planning is the APO Module used to update Demand Forecast -22- 11 PSPL Monthly Key Process - Operational Demand Plan (ODP) Participants Objectives ODP ODP OTD Preparation Preparation Consolidation Consolidation Weekly / By weekly Planning, Sales, (MKTG) M+1 / M+2 Promo, Special Actions, BTO plans Start CM Planning, Sales, MKTG M-1 Trends, Results vs plans Finance • Every month, w1/w2 (*) (*) Iberia try to anticipate to last week M-1 Preparatory Meetings M-1 Result Meetings When Who Focus What Sales Timing Submission Submission ACTIVITY Meetings When Who Focus What MKTG Tools ALL: a) Previous ODP b) Profit Plan c) Future Promotions/BTO outlook d) Previous month detailed results e) PIPO outlook f) Current Orderbook g) Run Rates & historical by aggs e) h) S&OP Excessinputs Stock i) S&OP Inputs SPECIFIC: l) BW Monthly GMs h) Sales SKU Forecast (UK) I)SPECIFIC Buying Groups ToT Fcst (France) l)m)Orderbook previous Sales SKU fcst year (same period) n) Buying Groups Total Fcst o) Previous year orderbook (same period) Outcome DP Update ODP Submission ODP Follow up When Who Focus What Weekly Planning CM/M+1 Demand vs plan DP enrichment Monthly Analyses DFA AGG results When Who Focus What Beginning M+2 Planning, MKTG, Sales M+1 Actual demaand vs Fcst Focus Focus on on volumes volumes -------> -------> CM CM // M+1 M+1 // M+2 M+2 onwards onwards -23- Whirlpool Europe Skills & Competencies 12 PSPL Skills & Competencies Project Macro Steps Project Set-up High Level Mapping Macro objectives definition Methodology & tools identification WHO Logistics Staff Org. charts gathering STD functional scheme definition Job titles/activities mapping Reference job titles list Role/Level by job titles Functional Champions identification Snr Logistics Staff Skills mapping by Function/ Functional Area Skills macrogroups identification Progression steps (1 to 5) STD value definition Project Team Project Team DELIVERY Common approach within Operations Key disciplines identification by Function Skills Inventory Go No-Go Logistics Staff Standard Role Roles & skills progression matching Skills Assessment Self Assessment Supervisors’ Assessment Calibration Project Team Project Team Snr Logistics Staff Functional Champions Functional Champions Functional Supervisors Central Organization Design Central Organization Design Central Organization Design Skills needed for business results achievement Requisite set of skills by Function & Functional Area Go No-Go Function’s competency consistency -25- Skills & Competencies Next steps Process Steps in defining Gap Recovery Plan MAINTAIN Day by Day activities support Focus on: BASIC TOOLS & PROFESSIONAL EXPERTISE IMPROVE BREAKTROUGH Supply Chain Strategy Functions mission/goals PMP discussion Focus on: Ad hoc RECOVERY PLAN SUPPLY CHAIN “TOP 5 “ Focus on: TALENT POOL KEY PEOPLE/POSITIONS DEVELOPMENT ACTIONS -26- 13