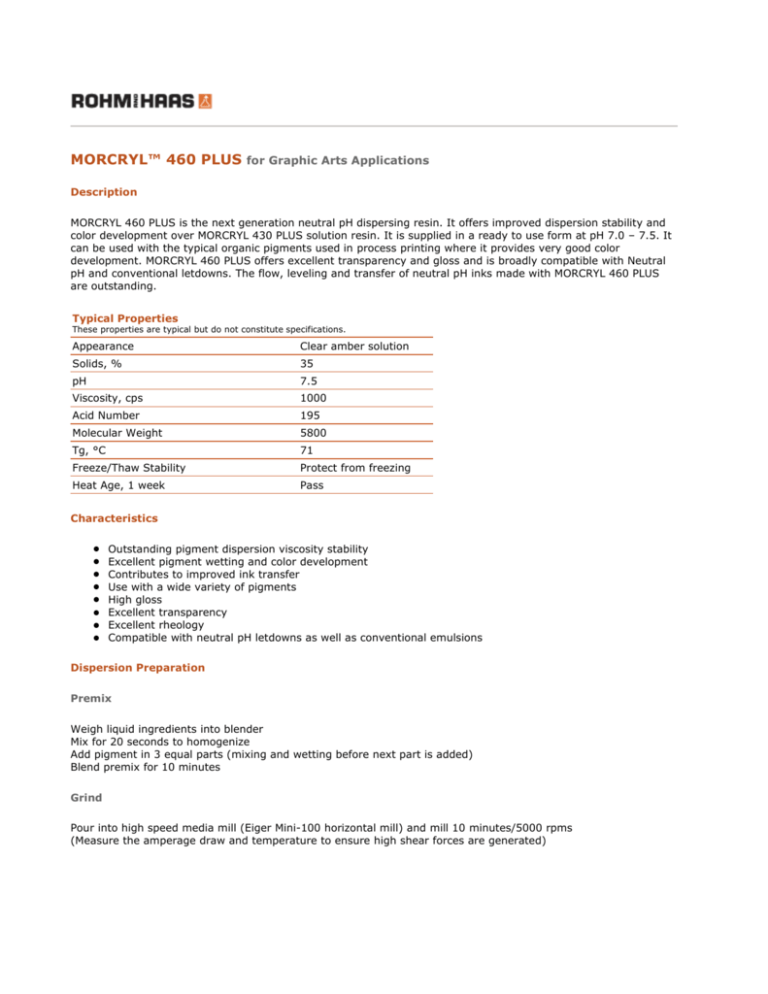

MORCRYL™ 460 PLUS for Graphic Arts Applications

Description

MORCRYL 460 PLUS is the next generation neutral pH dispersing resin. It offers improved dispersion stability and

color development over MORCRYL 430 PLUS solution resin. It is supplied in a ready to use form at pH 7.0 – 7.5. It

can be used with the typical organic pigments used in process printing where it provides very good color

development. MORCRYL 460 PLUS offers excellent transparency and gloss and is broadly compatible with Neutral

pH and conventional letdowns. The flow, leveling and transfer of neutral pH inks made with MORCRYL 460 PLUS

are outstanding.

Typical Properties

These properties are typical but do not constitute specifications.

Appearance

Clear amber solution

Solids, %

35

pH

7.5

Viscosity, cps

1000

Acid Number

195

Molecular Weight

5800

Tg, °C

71

Freeze/Thaw Stability

Protect from freezing

Heat Age, 1 week

Pass

Characteristics

Outstanding pigment dispersion viscosity stability

Excellent pigment wetting and color development

Contributes to improved ink transfer

Use with a wide variety of pigments

High gloss

Excellent transparency

Excellent rheology

Compatible with neutral pH letdowns as well as conventional emulsions

Dispersion Preparation

Premix

Weigh liquid ingredients into blender

Mix for 20 seconds to homogenize

Add pigment in 3 equal parts (mixing and wetting before next part is added)

Blend premix for 10 minutes

Grind

Pour into high speed media mill (Eiger Mini-100 horizontal mill) and mill 10 minutes/5000 rpms

(Measure the amperage draw and temperature to ensure high shear forces are generated)

Dispersion Formulations

Lithol Rubine

Diarylide Yellow

Phthalo Blue

Carbon Black

57DT688

YE-1403

BW-1531

Black Pearls® 450

38

37

38

40

MORCRYL 460 PLUS

26.6

26

26.6

28

Water

34.4

36

34.4

31

1

1

1

1

Pigment

%

BYK

®

022

Total

100

100

100

100

% TS

48.1

46.9

48.1

50.6

3.75/1

3.75/1

3.75/1

3.75/1

Initial Viscosity, cps

800

230

210

300

Aged Viscosity, cps

1000

350

250

500

Red

Yellow

Blue

Black

%

35

35

35

35

MORCRYL 460 PLUS

20

20

20

20

LUCIDENE 4035 PLUS

17

17

17

LUCIDENE 4045 PLUS

16

16

16

7.8

7.8

7.8

Pigment to Binder

Ink Formulations

Ink Dispersion

LUCIDENE 604

33

Water

7.8

Wax

4

4

4

4

Defoamer

.2

.2

.2

.2

Dilute to desired viscosity.

Raw Material Suppliers

57DT688

Lithol Rubine pigment from Flint Group Pigments

YE-1403

Diarylide Yellow pigment from Pacific Coast Enterprises

BW-1531

Phthalocyanine Blue pigment from Pacific Coast Enterprises

Black Pearls 450

Carbon Black pigment from Cabot Corporation

BYK 022

Defoamer from BYK-Chemie

Luciwax™ 37

Wax Emulsion from Hexion Specialty Chemicals

Material Safety Data Sheets

Rohm and Haas Material Safety Data Sheets (MSDS) contain pertinent information that you may need to protect

your employees and customers against any known health or safety hazards associated with our products.

Under the OSHA Hazard Communication Standard, workers must have access to and understand MSDS on all

hazardous substances to which they are exposed. Thus, it is important that you provide appropriate training and

information to your employees and make sure they have available to them MSDS on any hazardous products in

their workplace.

Rohm and Haas Company sends MSDS for all its products, whether or not they are considered OSHA-hazardous, to

both the “bill to” and/or “ship to” locations of all its customers upon initial shipment, including samples. If you do

not have access to one of these MSDS, please contact your local Rohm and Haas representative for an additional

copy.

Updated MSDS are sent upon revision to all customers of record. In addition, MSDS are sent annually to all

customers receiving products deemed hazardous under the Superfund Amendments and Reauthorization Act.

MSDS should be obtained from your suppliers of other materials recommended in this bulletin.

Rohm and Haas Company is a member of the American Chemistry Council and is committed to ACC’s Responsible

Care® Program.

MOREZ, MORCRYL, LUCIDENE and RHOPLEX are registered trademarks of Rohm and Haas Company or of its subsidiaries or affiliates. These

suggestions and data are based on information we believe to be reliable. They are offered in good faith, but without guarantee, as conditions

and methods of use of our products are beyond our control. Rohm and Haas Company makes no warranties, either express or implied, as to

the accuracy of these suggestions and assumes no liability arising out of their use by others. We recommend that the prospective user

determine the suitability of our materials and suggestions before adopting them on a commercial scale. Suggestions for uses of our products

or the inclusion of descriptive material from patents and the citation of specific patents in this publication should not be understood as

recommending the use of our products in violation of any patent or as permission or license to use any patents of the Rohm and Haas

Company.

©Rohm and Haas, 2008

All rights reserved.

August 2007