Lenzing Fibres

advertisement

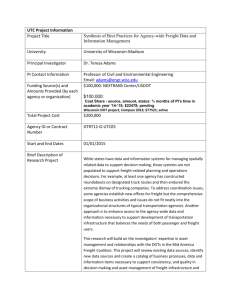

CASE STUDY Fibre manufacturer: Process and cost optimisation in the transport industry THE LENZING GROUP OPTIMISES TRANSPORT LOGISTICS WITH TICONTRACT AND TRANSPOREON It is hardly possible to exploit the benefits of e-sourcing with Ticontract more convincingly than the Austrian Lenzing Group has done in 2013. However, the global supplier for the textile industry went one step further and integrated modules from Transporeon for automatic process control through to invoicing. GLOBAL TRANSPORT ORGANISED MANUALLY Lenzing operates the world's largest integrated pulp and viscose fibre production site and also manufactures a series of chemical liquid materials at its site location in Lenzing. Export freight of the fibre products alone add up to 160,000 tons per year, each week around 150 40-foot containers leave the company site. This generated sales of 1.9 billion euros in 2013. The vast majority of them are destined for the Far East and Asia. The Global Logistics department previously dealt with tender processes for land, air and sea freight transportation manually using Excel spreadsheets. The analysis of the obtained tender information was complex and only partially transparent as a result. Freight rates agreed with forwarders also had to be manually copied into the operational systems. The team sent orders by telephone or email respectively. Invoice control also took a considerable amount of time due to the lack of transparency. OPTIMISE PROCESSES - REDUCE COSTS As a result, Ralf Hammer, Global Transport Planning and Global Logistics Manager at Lenzing, describes the objective of the restructuring project as follows: “Our overall goal was to ensure greater transparency, especially in the processes, and to reduce the costs and time involved.“ The approach Lenzing decided on in 2013 was an integrated solution from Ticontract and Transporeon. In this way, individual modules from transport planning and freight purchase, over rate management, through to accounting and control are interconnected, and they have significantly enhanced the efficiency of Lenzing logistics: “On the one hand, we have achieved significant savings on our freight volumes. On the other hand, we were able to increase productivity enormously and speed CASE STUDY up and improve communication with partners in qualitative terms,” sums up Hammer. FREIGHT COSTS REDUCED BY FIVE PERCENT The figures are actually impressive: savings on freight costs across all divisions are at five percent. The tendered land freight for 2014 had a total volume of 16 million euros and a total of 549 lanes, for which 32 of the invited 97 service providers were commissioned. Transporeon ensures a no-touch order for this purpose: based on the Ticontract rate management, a suitable forwarder is automatically determined and a request is sent. This forwarder may either accept or decline the order in the system. Transporeon best carrier also operates in a similar manner with air freight. Lenzing places the air freight orders in the system. The carrier connected to the system then submits up-to-date offers. Lenzing accepts the appropriate carrier offer and awards the order directly in the system. OPTIMISATION CONTINUES EIN DRITTEL DER OF DIENSTLEISTER ONE THIRD SERVICE GEWINNEN PROVIDERS GAIN BUSINESS 32 SERVICE PROVIDERS The standardised process carried out with Ticontract has led to savings of close to 600,000 euros. The sea freight tender was even more profitable: here, a cost saving of around 529,000 euros was achieved out of a total volume of 5.6 million euros. ADMINISTRATIVE PROCESSES REDUCED BY 80 PERCENT Administrative processes such as auditing, freight rate management, foreign exchange rate, calculation of surcharges for bulkiness or the diesel floater have declined by around 80 percent. Many of these processes are handled automatically by the Ticontract and Transporeon system. 99 percent of the orders are carried out virtually automatically. Rolf Hammer has already identified further areas for optimisation: According to the head office in Lenzing, other locations, such as Heiligenkreuz and Indonesia, will be connected in 2015. And: for carriers and manufacturers alike, long waiting times for delivery and collection at work were previously a hindrance. Lenzing is therefore also planning to implement time window management from Transporeon in 2015. The Lenzing manager is convinced that “with this we will design the physical operational workflows much more efficiently”. CONTACT sales@ticontract.com