universiti teknologi malaysia

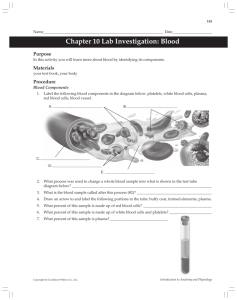

advertisement