Pressure-assisted filling of low-melting glasses into

advertisement

Pressure-assisted filling of low-melting glasses into microcapillaries

(Druckunterstütztes Füllen von Mikrokapillaren mit niedrigschmelzenden Gläsern)

Der Technischen Fakultät

der Friedrich-Alexander-Universität

Erlangen-Nürnberg

zur

Erlangung des Doktorgrades Dr.-Ing

vorgelegt von

Ning Da

aus Jiangsu, China

Als Dissertation genehmigt

von der Technischen Fakultät / vom Fachbereich Werkstoffwissenschaften

der Friedrich-Alexander-Universität Erlangen-Nürnberg

Tag der mündlichen Prüfung: 03th September 2013

Vorsitzende des Promotionsorgans: Prof. Dr.-Ing. habil. Marion Merklein

Gutachter/in: Prof. Dr.-Ing. Lothar Wondraczek

Prof. Dr.-Ing. habil. Aldo R. Boccaccini

Prof. Dr. Wilhelm Schwieger

Acknowledgements

Good time flies by fast. My four-year dissertation field research and study are coming to a

close. I have benefited from great help in so many ways from the following people:

First of all, I would like to express my deepest appreciation to my Ph.D advisor, Prof. Dr.-Ing.

Lothar Wondraczek. Without his unfailing support- both academic and personal, this

dissertation would not have been finished so smoothly. He gave me freedom while at the

same time also providing intellectual support on critical issues. His knowledge, perception,

inspiring ideas and optimistic attitude in research and scholarship always instilled in me great

interest in my project.

In addition, I would like to thank Prof. Dr. rer. nat habil. Markus Schmidt. I was able to get

through most of the difficulties and frustrations only with his assistance and guidance. What I

have learnt from him is not only the knowledge and the research methodology but also a

commitment to high scientific standards, which always inspires and motivates me.

I am also sincerely grateful to the Institute of Glass and Ceramics, especially the members of

my dissertation committee, for providing with me all the necessary facilities and a pleasant

working environment. I want to thank Prof. Dr. Peter Greil, Prof. Dr. Andreas Rossen, Dr.

Xin Jiang, Nicolai Granzow, and Howard Lee of Max-Plank Institute for their valuable

discussions and suggestions. Special thanks go to Dr. Mingying Peng and his wife Qin Li,

Sebastian Krolikowski, and Robert Meszaros, who offered me great help four years ago when

I had just started out on a new life journey in this beautiful country.

I thank my officemates Lorenz Schlier, Ingo Götschel for providing so much entertainment

and humor in what would otherwise have been a somewhat monotonous and stressful

laboratory environment. Lorenz’s taste in wine and Ingo’s interest in gliding drew me closer

to the native culture.

The financial support of the Cluster of Excellence Engineering of Advanced Materials and the

German Research Foundation (Deutsche Forschungsgemeinschaft, DFG) is also gratefully

acknowledged.

Finally I come to the most personal gratitude. I thank my parents, my grandmother, my aunt,

and my cousins for their faith in me, their understanding, support and love.

III

Contents

Acknowledgements .................................................................................................................. III

Contents .................................................................................................................................... IV

List of figures ............................................................................................................................ X

List of tables .......................................................................................................................... XVI

Zusammenfassung ...................................................................................................................... 1

Motivation .................................................................................................................................. 2

1. Introduction ............................................................................................................................ 3

1.1 Glass rheology .............................................................................................................. 5

1.2 Confinement effects ..................................................................................................... 8

1.3 Structure, heterogeneity and anisotropy ..................................................................... 13

2. The μ-Infiltration Technique: Pressure- and surface-assisted infiltration ............................ 14

2.1 Fluid mechanics.......................................................................................................... 16

2.2 Wettability .................................................................................................................. 18

2.3 Analytic solutions for defined time stages ................................................................. 19

2.3.1 Purely inertial time stage ................................................................................. 19

2.3.2 Visco-inertial time stage .................................................................................. 20

2.3.3 Purely viscous time stage ................................................................................ 20

2.3.4 Viscous and gravitational time stage ............................................................... 20

2.4 Shear rate in pipes ...................................................................................................... 21

2.5 Pressure- and Surface-assisted Infiltration ................................................................. 21

2.6 Viscosity of polymers measured by infiltration method ............................................ 23

IV

3. Multi-material Assessment of Viscosity under Confinement ............................................... 25

3.1 Tellurite glasses .......................................................................................................... 25

3.1.1 Introduction of tellurite glass .......................................................................... 25

3.1.2 Experimental procedure .................................................................................. 27

3.1.3 Raman spectra of TeZnNa glass and glass in capillary ................................. 30

3.1.4 Results and discussion .................................................................................... 31

3.1.5 Viscosities and flow behaviour of alkali-free tellurite glass with suction

method ...................................................................................................................... 40

3.2 Interfacial reactions between tellurite melts and silica ............................................. 48

3.3 Sulfophosphate glasses ............................................................................................... 55

3.3.1 Introduction of sulfophosphate glasses ........................................................... 56

3.3.2 Experimental procedure .................................................................................. 56

3.3.3 Structure of sulfophoshate glasses .................................................................. 60

3.3.4 Rheology of phosphate and sulfophosphate glasses ....................................... 62

3.4 Germanate and sodium borate glass with suction method ......................................... 66

3.4.1 Introduction of germanate glasses ................................................................... 66

3.4.2 Introduction of borate glasses ......................................................................... 67

3.4.3 Experiments and discussion ............................................................................ 68

3.5 Conclusions ................................................................................................................ 72

4. Viscosity of chalcogenide glasses ........................................................................................ 74

4.1 Introduction of chalcogenide glasses ......................................................................... 74

4.2 Experiments and discussion ....................................................................................... 74

4.3 Non-Newtonian Flow ................................................................................................. 78

V

4.4 Conclusions ................................................................................................................ 83

5. Outlook: Fabrication of hybrid-all-solid PCF and their optical application ........................ 85

6. Conclusions and outlook ...................................................................................................... 86

6.1 Thesis conclusion ....................................................................................................... 86

6.2 Prospect ...................................................................................................................... 86

References ................................................................................................................................ 87

List of publications/Veröffentlichungen ................................................................................. 101

VI

Inhaltsverzeichnis

Danksagung .............................................................................................................................. III

Inhalt......................................................................................................................................... IV

Abbildungsverzeichnis .............................................................................................................. X

Tabellenverzeichnis ............................................................................................................... XVI

Zusammenfassung ..................................................................................................................... .1

Motivation .................................................................................................................................. 2

1. Einleitung ............................................................................................................................... 3

1.1 Glass Rheologie............................................................................................................ 5

1.2 Confinement Effekte .................................................................................................... 8

1.3 Structur, Heterogenität und anisotrope ....................................................................... 12

2. μ-Infiltration Technik: Druck-und Oberflächen-gestützte infiltration ................................. 14

2.1 Strömungsmechanik ................................................................................................... 16

2.2 Benetzbarkeit .............................................................................................................. 18

2.3 Analytische Lösungen für definierte Zeitstufen ......................................................... 19

2.3.1 Rein Inertial Zeitstufe...................................................................................... 19

2.3.2 Visco-Inertial Zeitstufe .................................................................................... 20

2.3.3 Rein viskosen Zeitstufe ................................................................................... 20

2.3.4 Viskose und Gravitations Zeitstufe ................................................................. 20

VII

2.4 Newtonsche und nicht-Newtonschen Strömung in Rohren ....................................... 21

2.5 Druck und Oberflächen-gestützte infiltration ............................................................ 20

2.6 Machbarkeit der Viskosität von Polymeren durch Infiltration Methode gemessen ... 22

3. Multi-Material Beurteilung der Viskosität unter Einschluss ................................................ 25

3.1 Telluritgläser ............................................................................................................... 25

3.1.1 Einführung von Telluritglas............................................................................. 25

3.1.2 Versuchsdurchführung ..................................................................................... 27

3.1.3 Raman-Spektren von TeZnNa Glas und Glas in der Kapillar ......................... 30

3.1.4 Ergebnisse und Diskussion.............................................................................. 31

3.1.5 Viskositäten und Fließverhalten von Alkali-freie Telluritglas mit saugen-InVerfahren .................................................................................................................. 40

3.2 Grenzflächen-Reaktionen zwischen Schmelzen und Tellurit Silica........................... 48

3.3 Sulfophosphat glas ..................................................................................................... 55

3.3.1 Einführung von Sulfophosphatglas ................................................................. 56

3.3.2 Versuchsdurchführung ..................................................................................... 56

3.3.3 Struktur sulfophoshate Gläser ......................................................................... 60

3.3.4 Rheologie von Phosphat und Sulfophosphatglas ............................................ 61

3.4 Germanate and sodium borate glass with suction method ......................................... 66

3.4.1 Einführung von Germanat Glas....................................................................... 66

VIII

3.4.2 Einführung von Boratgläser ............................................................................ 67

3.4.3 Ergebnisse und Diskussion.............................................................................. 68

3.5 Zusammenfassung ...................................................................................................... 71

4. Die Viskosität der Chalkogenidgläser .................................................................................. 73

4.1 Einführung von Chalkogenidgläser ............................................................................ 73

4.2 Ergebnisse und Diskussion......................................................................................... 74

4.3 Nicht-Newtonsche Durchfluss ................................................................................... 78

4.4 Zusammenfassung ...................................................................................................... 82

5. Ausblick: Herstellung von Hybrid-all-solid photonischen Kristall-Fasern .......................... 85

6. Zusammenfassung und Ausblick .......................................................................................... 86

6.1 Thesis Abschluss ........................................................................................................ 86

6.2 Aussicht ...................................................................................................................... 86

Referenzen ................................................................................................................................ 87

Veröffentlichungen ................................................................................................................. 101

IX

List of figures

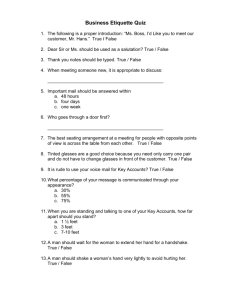

Fig.1.1 Principle types of shear flow. ......................................................................................... 5

Fig.1.2 Three kinds of confinement geometries. (a) Porous confinement, (b) plate confinement,

and (c) capillary confinement ..................................................................................................... 9

Fig.1.3 A liquid droplet on a solid substrate ............................................................................. 11

Fig.2.1 Liquid droplets in equilibrium with a horizontal surface surrounded by a gas. The

wetting angle θ between the horizontal layer and the droplet interface defines the wettability

of the liquid. ............................................................................................................................. 19

Fig.2.2 Schematic representation of pressure cell used to fill silica PCFs and capillaries with

low-melting materials. (a) Pressure, (b) suction methods, and (c) an enlargement picture of

melt flowing into capillary with velocity and contact angle θ. ............................................ 23

Fig. 2.3 Viscosities of commercial honey and silicone oil byconventional rotational

viscometer and the proposed infiltration method. .................................................................... 24

Fig.3.1 Structure of TeO2: (a) α-TeO2, and (b) β-TeO2 ............................................................ 26

Fig.3.2 Structural units of (a) TeO4 trigonal bipyramid (TBP) and (b) TeO3 trigonal pyramid

(TP) in tellurite glass ............................................................................................................... 27

Fig.3.3 Glass transition temperature of TZN01 by calorimetry (A) and dilatometry (B),

respectively. .............................................................................................................................. 28

Fig.3.4 (a) Side-view of a homogeneously TZN01 filled silica capillary; (b) A filled capillary

containing cracks and bubbles; (c) SEM images of TZN01 in capillary with diameter of 15.0

µm ............................................................................................................................................ 30

X

Fig.3.5 Raman measurements of TZN01 filled silica capillaries (diameters 6.25µm).The

spectra have been recorded by illuminating the filling glass strands through the side of the

capillary. ................................................................................................................................... 31

Fig.3.6 (a) Microscopic picture of TZN01, and (b) close-up view ofthe area in red circle in (a),

blue circles are bubbles in glass after cooling. The scale bars are 100 and 20 μm in (a) and (b),

respectively............................................................................................................................... 32

Fig.3.7 Viscosity analysis of the tellurite filling process at different temperatures. The upper

four plots show the square of the filling length as a function of applied pressure and square of

capillary radius. (a)Experimental results at 700°C, (b) simulation at 700°C, (c) experimental

results at 840°C, (d) simulation at 840°C................................................................................. 33

Fig.3.8 Viscosity analysis of the tellurite filling process at different temperatures with VFT

equation. (a) Viscosity of the TZN01 glass as function of temperature. Three different

techniques (beam bending, sinking bar, pressure, suction method) and extrapolated data from

VFT equation have been used to determine the viscosity. (b) Comparison of viscosity data

measured with pressure and suction methods. ......................................................................... 34

Fig.3.9 Viscosities of TZN01 acquired by two data processing methods ................................ 38

Fig.3.10 (a) Parabolic and (b) linear fittings of filling length for TZN01 corresponding to the

filling times .............................................................................................................................. 38

Fig.3.11 Contact angle between silica and TZN01 as a function of temperature for a heating

rate of 3 K/min. Insets: Photographs of the TZN01 specimen on the silica wafer for selected

temperatures. ............................................................................................................................ 39

Fig.3.12 Viscosities of TZN02 at different temperatures. ........................................................ 38

Fig.3.13 Glass transition determined by calorimetry of TZL................................................... 41

XI

Fig.3.14 Side-view of an exemplary filling situation for a capillary with an inner diameter of

70 µm, filled with TZL at 700 °C for 36 s (a), and corresponding Raman spectrum of the

filled section ............................................................................................................................. 42

Fig.3.15 Viscosities of TZL corresponding to capillary diameters at (a) 700, (b) 750 and (c)

800 °C. Contact angles between melts and capillary wall were assumed for calculation. The

viscosity obtained from subtracting surface tension effect from the experiment is presented for

comparison ............................................................................................................................... 44

Fig. 3.16 Simulatively stable flow of Tellurite melt in capillary at various times ................... 46

Fig.3.17 Quadratic filling length as a function of the ratio between observation time and shear

relaxation time (±100Pa-1) for different capillary radii (a). Labels indicate capillary radius. In

(b), the resulting plot of RLW (obtained from the slopes of linear regression lines in (a) over

the real radius R is shown, together with the ratio between R LW and R. Lines in (b) are guides

for the eye, obtained from a fit of RLW/R data to first order exponential decay equation and,

respectively, from a fit of the RLW data to a line with slope 0.96 ............................................. 47

Fig.3.18 (a)Viscosities of TZL under different pressures, and (b) they are constantas a

function of shear rate at required temperatures, respectively. .................................................. 48

Fig.3.19 Viscosity data of TZL from pressure and suction methods, respectively................... 48

Fig.3.20 Schematic diagram of silica-tellurite-silica sandwich. .............................................. 49

Fig.3.21 Raman spectra of as-made bulk TZN and TZN in a silica-TZN-silica sandwich after

annealing for 80 min at 700 °C ................................................................................................ 50

Fig.3.22 Analyses of silica-tellurite interfaces after static contact experiments (sandwich

experiments) at 700 °C. (a) and (b) depict SEM micrographs after 20 and 80 min annealing

time, respectively. (c) is the result of EDS chemical analyses of the interface region shown in

(b). Lines serve as visual guides. (d) The diffusions of the three ions into the silica plate were

XII

fitted with Ficker’s Law (e): XRD diagram as taken of the tellurite-silica interface ex situ

after opening a sandwich which was annealed for 40 min. Labels mark peak positions and

assignment for β-quartz ............................................................................................................ 52

Fig.3.23 Raman spectra of TZN01 filled silica capillaries (strand diameters about 6 µm) and

bulk TZN01.Gaussian deconvolution of Raman peaks were conducted to show the bond

change of TZN01 by confinement............................................................................................ 54

Fig.3.24 Raman spectra of TZL filled silica capillaries (strand diameters about 8µm) and bulk

TZL. Gaussian deconvolution of Raman peaks were conducted. No obvious bond change of

TZL by confinement as that of TZN01 appears. ...................................................................... 55

Fig.3.25 Tg of SP glasses determined by (a) dilatometer and (b) DSC ................................... 58

Fig.3.26 Density and molar volume of (Na, Zn) sulfophosphate glasses as a function of SO42content [143]. © 2011 Published by Elsevier B.V ................................................................... 58

Fig.3.27 Raman spectra of (Na, Zn) sulfophosphate glasses for increasing SO42- content

(replacing P2O5 by SO3). Spectra of crystalline samples are shown for comparison............... 60

Fig.3.28 Deconvoluted Raman spectrum of a (Na, Zn) polyphosphate glass. ......................... 60

Fig.3.29 Cross sections of sulfophosphate glasses in capillaries (SEM pictures) (a) SP05,

(b)SP09, (c)SP14, and (d)SP22 ................................................................................................ 63

Fig.3.30 Viscosity analysis of the phosphate and sulfophosphate glasses measured with (a)

several viscometers at different temperatures (via beam bending, sinking bar, suction method)

and (b) enlargement diagram of melt viscosities (via suction method). .................................. 64

Fig.3.31 Illustration of kinetic fragility, using the Angell plot. Lines are guides for the eye. . 64

Fig. 3.32 The influence of shear stress on the apparent viscosity of sulfophosphate melts. .... 66

Fig. 3.33 Tetrahedra structure unit of GeO4 ............................................................................. 67

XIII

Fig.3.34 Boroxol group (a), layer structure of vitreous B2O3 (b), and chain structure of B2O3

(c) at high temperature ............................................................................................................. 68

Fig.3.35 (a) Viscosity of Ge.01 at respective temperature. Inset figure: microscope figures of

one end of capillary dipping in crucible, which shows the evidence for deviation from the real

viscosity of Ge.01. (top: 22 μm capillary at 1050℃, bottom: 35 μm capillary at 1100℃ after

filling) (b) Comparison of viscosities of Bo.01 proposed by different researchers. ................ 69

Fig.3.36 SEM of germanate glasses in different capillaries with radius (a)4 , (b)10, (c)20,

(d)35, and (e)75 μm. ................................................................................................................. 70

Fig.3.37 EDX results of composition concentration of Ge.01 in capillaries and diffusion or

corrosion of SiO2 in the glass ................................................................................................... 70

Fig.3.38 Raman spectrum of Ge.01 in capillaries and bulk Ge.01 .......................................... 71

Fig.3.39 Viscosities of Bo.01 measured by Leedecke and Sasek, respectively. ...................... 71

Fig.3.40 Phase diagram of Na2O-B2O3-SiO2 ternary system, The red arrow represents the

composition x(25Na2O-75B2O3)-(100-x)SiO2.......................................................................... 72

Fig.4.1 Viscosities of Ch.01(a), Ch.02(b), and Ch.03 (c) corresponding to external applied

pressure..................................................................................................................................... 76

Fig.4.2 Fitting curves

of Ch.03 with VFT, MYEGA, and AM models. Fitting with

macroscopic and microscopic viscosity(a) and with only macroscopic viscosity (b).

Microscopic viscosity in (b) shows the discrepancy with the fitting curves. ........................... 78

Fig.4.3 The square of the filling length as a function of the square of capillary radius

corresponding to different applied pressure for Ge3As52S45 at 250 °C(a) and 300 °C(b). The

slopes of the lines are proportional to 1/η of the glass, indicating the pressure dependence of

viscosity. ................................................................................................................................... 79

XIV

Fig.4.4 The square of the filling length as a function of the square of capillary radius for

different applied pressure for As40S60 at 600 °C(a) and 650 °C(b). The slopes of the lines are

proportional to 1/η of the glass, indicating the pressure dependence of viscosity. .................. 80

Fig.4.5 Viscosities of As40S60 corresponding to the shear rate of melts in capillaries at

respective temperatures ............................................................................................................ 81

Fig.4.6 Fitting curves of viscosity to shear rate by Yue-Brückner equation for As40S60 .......... 83

Fig. 4.7 Structure of As2S3 (a) and stretching under shear stress ............................................. 83

Fig. 5.1 SEM images of endlessly single mode silica fibres which have been filled with lowmelting glasses (hole diameters: 1.6 µm, center distances of neighboring holes: 3.7 µm). (a)

filling glass: tellurite. (b) Filling glass: chalcogenide. ............................................................. 85

XV

List of tables

Table 1.1 Critical cooling rate (K/s) by the impact of contact angle on heterogeneous

nucleation for glass formation. ................................................................................................. 11

Table 1.2 Influence of scale amplitude r of glass structure ...................................................... 11

Table 3.1 Capillaries (d = 4.0, 6.25, 10.2, and 15.0 μm) filled under temperatures and applied

pressures, and filling time. ....................................................................................................... 29

Table 3.2 Filling parameters and surface tensions for TZN01 glass at required temperatures 29

Table 3.3 Filling parameters and surface tension for TZN02 glass at required temperatures .. 30

Table 3.4 Viscosities of 75TeO2-10ZnO-15Na2O for different temperature regimes, obtained

by beam bending and sinking bar viscometry (macroscopic) and from infiltration technique

according to Eq. (2.2.6) (microscopic). .................................................................................... 36

Table 3.5 Tellurite alkali and alkali free glasses with their thermal properties ........................ 40

Table 3.6 Error controlling for using Eq. (2.2.8) to calculate viscosities of the TZL .............. 42

Table 3.7 Raman peak assignment of tellurite zinc sodium glasses ......................................... 53

Table 3.8 Composition and glass forming ability of examined materials (mol.%). ................. 59

Table 3.09 Assignment of experimentally observed Raman-active vibrations in sulfophosphate

glasses....................................................................................................................................... 61

Table 3.10 Theoretical fraction of Qi tetrahedron of sulfophosphate glasses .......................... 62

Table 3.11 Surface tension of sulfophoshpate glasses.............................................................. 63

Table 3.12 Surface tension of germanate and borate glasses. .................................................. 68

Table 4.1 Glass compositions selected for viscosity determination ......................................... 75

XVI

Table 4.2 Extrapolating log η∞ and fragility m of Ch.03 from the three viscosity-temperature

models ...................................................................................................................................... 77

Table 4.1 Viscosities and Re number of Ch.02 and Ch.03 under various externally applied

pressures for two temperatures, respectively. ........................................................................... 82

XVII

Zusammenfassung

In der vorliegenden Arbeit wurde die Infiltrationstechnik zur Untersuchung der Rheologie von

verschiedener

Glasschmelzen

in

Mikrokapillaren

angewandt.

Dabei

wurden

der

„Confinement-Effekt“ der Kapillare und der „Grenzflächeneffekt“ zwischen Schmelzen und

Kapillare berücksichtigt. Die Viskosität von handelsüblichem Honigs und des Silikonöls

wurde mittels der oben genannten Infiltrationsmethode analysiert und mit der Viskosität aus

rotationsrheometrischen Untersuchungen verglichen. In einem weiten Bereich der

Schergeschwindigkeit

war die durch die

Infiltrationstechnik

ermittelte scheinbare

Mikroviskosität konsistent mit der Makroviskosität. Dadurch ließ sich die Durchführbarkeit

dieser Infiltrationsmethode zur Bestimmung der Viskosität der Glasschmelzen, die nicht mit

der Kapillare in Wechselwirkung treten, nachweisen. Auf dieser Grundlage wurde die

Viskosität verschiedener Schmelzen untersucht und mit VFT-, MYEGA- und AM-Modellen

diskutiert.

Es wurden Tellurit- und Sulfophosphatglasschmelze, welche eine Grenzflächenreaktion mit

der Silicakapillare aufwiesen, wurden untersucht. Es zeigte sich, dass sowohl in der Phosphatals auch in der Sulfophosphatglasschmelze nicht newtonsches Flieβverhalten auftrat. Der

pseudoplastische Effekt ließ sich durch die Kettenverhakung erklären. Telluritschmelze mit

dreidimensionalen

Einheiten

und

Pyrophsophatschmelze

zeigten

im

untersuchten

Schergeschwindigkeitsbereich ein newtonsches Fließverhalten. Während die Germananteund

die

Boratschmelze

sehr

stark

die

Silicakapillare

korrodierten,

war

die

Chalkogenidschmelze, die keine Benetzung und keine Korrosion mit Silika zeigte, ein guter

Kandidat für die Untersuchung des Fließverhaltens. Bei der Chalkogenidschmelze wurde

jedoch nicht-newtonsches Fließverhalten in bestimmten Schergeschwindigkeits- oder

Viskositätsbereichen beobachtet. Dies ließ sich durch Entschlaufung oder Ausrichtung der

kettenförmigen Einheiten unter Scherung in der Chalkogenidschmelze erklären.

1

Motivation

Until now, comparatively little has been known about the rheology of glass melts, although

the material has been used for many centuries. There are several methods for determining

viscosity, but various disadvantages limit their applicability to glass melts. This work provides

a new technique which may be applied in the study of viscosity of glass melts. It is based on

infiltration of glass melts into a highly-confined micro geometry. The design of this new

technique may offer a facile way to investigate chalcogenide and other low-melting inorganic

liquids which are usually difficult-to-handle and easily oxidized. Intergrating the visicosity of

glass melts and undercooled liquids, a complete viscosity to temperature diagram can be

acquired, which facilitate to investigate the forming and cooling of glasses. In addition, the

diagram helps better understanding and optimizing viscosity models and theories. To

investigate the infiltration technique, several low melting-glasses were chosen as research

objects. The glasses were selected in consideration of two aspects: the interacting ability with

silica and the flow behaviour. Viscosities of these melts were then studied under external

forces and in confined conditions. The rheological properties of the confined melts are closely

linked with their structure but also with the surface and wetting behaviour at confinement

interfaces. Besides, question that whether and how the micro confinement influence on the

glass melts needs to be interpreted. First, the nano confinement on glass transition

temperature was reviewed, which demonstrated the depression of glass transition temperature

is proportional to the reciprocal of confinement. Then, the ignored micro confinement in the

research was expatiated both theoretically and experimentally.

On the other hand, infiltration of glass melts in micro-confinement geometries also offers

extensive applications. For instance, all-solid photonic crystal fibres (PCFs) can be fabricated

by infiltrating glass melts into a silica PCF template. This kind of all-solid PCF broadens and

optimizes the merits of silica PCF, ranging from super-continuum generation to optical filters

and polarizers. Another application is to fabricate dental ceramics by infiltrating glass into

ceramics. This process may effectively eliminate the pores during sintering, which can

improve visual appearance, strength and fracture toughness of the ceramics. Furthermore,

specific studies of relaxation, solidification, and, more generally, the frozen structure of

glasses after cooling in the confinement geometry can be performed.

2

1. Introduction

Glass has been applied extensively in art and is widely employed as ordinary commodity and

construction material. In the common understanding, glass does not bend or flow due to its

hardness and brittleness. However, artists and glass workers, and even scientists would argue

the state of the glass [1, 2]. For example, Philip Gibbs asked ‘Is glass liquid or solid?’ [1]. A

liquid has no determinate shape and depends on the form of container under certain pressure

and temperature, while a solid is rigid. To exploit this question, viscosity, a measure of the

resistance of the liquids to flow, is an important characteristic. Viscosity of glasses and

(supercooled) liquids spans dozens of orders of magnitude [2, 3]. Supercooled liquids are

materials below their melting point without existing solids [4]. The sharp increase in viscosity

may cause an undetectable flow, even of "solid" glasses. From the point of view of

thermodynamics, no obvious first-order phase transition can be observed when a supercooled

liquid turns to glass [5, 6]. This phenomenon confuses people, make it hard to judge whether

glass is liquid or solid. On the other hand, the surprisingly high viscosity of glass resulting

from little structural variation at the transition temperature (Tg) becomes one of the most

attractive research fields for scientists.

In this work, a new method has been developed and applied to infiltrate micro-capillaries with

glass melts, and to measure their viscosity, liquid flow behaviour and other properties inside

micro-confinement. In the past, various viscometers were developed and able to access a

viscosity range above 1 Pa·s [7]. However, attention has rarely been paid to its application on

high-viscosity liquids such as glass melts. The infiltration technique requires detailed

knowledge of the flow, relaxation and solidification behaviour of the glass that is to be

pumped into the capillary. More specifically, little is known about the properties of glass

melts in highly constrained micro-scale geometries and under mechanical load, and further

about the frozen structure after cooling inside confined geometry [8]. Phenomena like

viscosity and structure related to external pressure, crystallization and solubility of gases need

to be studied in the infiltration technique [8 - 19]. Compared to organic fluids (and

particularly polymer melts), these areas are typically difficult to assess for glass melts because

of experimental limitations [8, 20], such as complex equipment and low operating

temperatures. However, the knowledge influences not only PCF fabrication but also various

other applications such as micromechanical forming processes or the design of anisotropic

3

glasses [8, 20, 21]. With the new technique, we can overcome these previous boundaries but

several objects need to be studied and solved:

(1) How to treat the microscopic viscosity? Can it be regarded as bulk viscosity?

(2) What are the influences of the interfacial effects between confined glass melts and a

capillary?

(3) Does the micro confinement change the flow behaviour of melts, such as, from Newtonian

to non-Newtonian flow?

(4) Does this flow behaviour alter the structural rearrangement of melts after cooling down?

To solve these questions, the following experiments were designed. Firstly, viscosities of

polymers, which do not interact with silica capillary, were studied with the present technique

and compared to data obtained by conventional rotational viscometers. The results show that

the viscosities obtained from micro capillaries agree well with the bulk data. Based on this

observation, in the second step, several kinds of glasses were chosen to perform the viscosity

measurement according to two aspects: the interaction with silica and the flow behaviour.

Besides "inert" chalcogenide melts, tellurite and phosphate glasses were investigated in detail.

Some chalcogenide glasses were chosen and surveyed because of their perfectly non-wetting

property with silica, which excludes the influence of interfacial reactions. The technique is

shown to provide a convenient route to learn about the flow behaviour of chalcogenide melts.

However, close studies are still needed to answer questions (3) and (4).

In collaboration with colleagues Dr. Markus Schmidt and Nicolai Granzow in the Max Planck

Institute for the Science of Light, we have used the technique to fabricate as-yet impossible

all-solid PCFs in a new way, and this will open the path to various new applications, such as

optical filters and fibre polarizers. The approach was found to enable a novel route towards

optical fibre devices that combine the properties of glasses which are, usually, considered

incompatible because of significant differences in their thermomechanical and rheologic

properties. Exemplarily, photonic band-gap guidance has been demonstrated in the soprepared silica-tellurite PCF [22]. Various potential applications, ranging from supercontinuum generation to optical filters and polarizers have been discussed for silicachalcogenide as well as silica-tellurite waveguides [22 - 24].

This thesis consists of five chapters. Chapter 1 gives an introduction of the background of this

project. In addition, a literature review concerning glass rheology, confinement effects,

structure, heterogeneity and anisotropy of glasses is presented. Chapter 2 describes the

4

infiltration technique and theoretical background. Chapter 3 gives experimental procedures

and discusses viscosities of various glasses and the interfacial reaction between glass melts

and capillary. Chapter 4 describes the viscosity and flow of chalcogenide melts in capillaries

under different shear rates. Chapter 5 presents the outlook for optical application by the

infiltration technique.

1.1 Glass rheology

Viscosity is a property of a liquid which describes its resistance to shear flow. It is b ( )n ,

the proportionality between shear stress (σ) and shear rate ( )n. Viscosity is defined as η =

/ [6]. Then, Ostwald-de Waele's relationship turns to b ( )n1 [25]. The value of the

exponent n defines the type of flow in the respective liquid. It is n = 1 for ideal Newtonian

flow. If n < 1, viscosity decreases with increasing shear rate, which is called "shear thinning".

Shear thickening occurs when n > 1. The principal types of flow are illustrated in Figure 1.1.

Shearing stress,

Bingham plastic

Shear thinning

n<1

Newtonian

n=1

Shear thickening

n>1

Shear strain rate

Fig.1.1 Principle types of shear flow.

Most fluids exhibit non-Newtonian characteristics and this is often related to the influence of

the externally applied stress on the structure of a flowing medium [26]. Therefore, the

examination of non-Newtonian behaviour has often been used to explore the structural state

of a liquid. Several theories have been developed for investigating the relation between flow

behaviour and structure. For instance, the Grasseley theory proposes that entanglement of

structural units is responsible for the shear thinning effect in polymeric liquids [27]. Another

5

example is the non-Newtonian flow theory proposed by Bottinga, who finds a dependence of

the viscosity on applied shear stress [28].

In typical supercooled liquids, viscosity may vary with temperature over a large range. It

increases continuously and steeply when the supercooled liquid freezes into a glass. In

industrial glass fabrication, this behaviour being made use of as each forming process

(pressing, blowing, drawing, rolling, ...) can be performed only in a certain range of viscosity§

[29, 30]. Besides, the quality of glasses, such as homogeneity, striae, inclusions, and bubbles,

depends on the viscosity of glass melts during processing, as well. Viscosity has a direct

influence on whether bubbles or solid inclusions can be removed from the melt [31].

Viscosity theory and data on supercooled liquids have received much attention in recent years

[32 - 37]. Classical techniques, such as beam bending method (measuring range: 109 to 1013

Pa·s) [38, 39], sinking bar method (measuring range: 101 to 104 Pa·s) [40], and rotational

method (measuring range: 100 to 107 Pa·s) [29], were developed. Several empirical or semiempirical models have been established to describe the temperature dependence of viscosity.

——————————————————

§

Viscosity ranges for glass making operations, taken from [29, 30]

Glass melting

0.5 to 1.5

Sealing glasses to other glasses or to metals

2.5 to 2.8

Producing gobs for container forming

2.6 to 3.2

Glass pressing

3.0 to 5.3

Surface of a bottle during blowing

4.7 to 9.0

Sinter glass powder to a solid body

5.0

Sinter glass powder to form a porous body

7.0 to 7.8

Dilatometric softening point

10.3 to 0.7

Annealing range

11.0 to 3.0

Stress release occurs in a few seconds

11.8

Temperature for matching expansion curves for seals

13.0 to 3.5

Stress release too slow to be useful

Above13.6

Note: values are given as log (viscosity in Pa·s)

6

The most popular empirical model is Vogel-Fulcher-Tammann equation (VFT equation) [41 43],

log10 (T ) log10

B

T T0

(1.1)

where the empirical fit parameter T0 is often understood as the temperature at which the

majority of sub-Tg structural relaxations cease to exist. η∞, B, T0 are fitting constants specific

to a given glass. This model has been extensively employed for viscosity-temperature fitting

and industrial production, but it converges to infinity at T = T0. The alternative AvramovMilchev (AM) model [44] is derived from an atomic hopping consideration, where the

activation energy of viscosity changes with temperature. To account for this, a stretched

exponential is introduced,

(T ) 0 exp( )

(1.2)

T

where η0, α, τ are fitting parameters. VFT and AM models can only describe the temperature

and viscosity relationship at intermediate temperatures. The VFT equation overestimates the

viscosity below the glass transition temperature. Semi-empirical first principles approaches to

viscosity usually follow Adam and Gibbs [45]. They assumed that a liquid is a combination of

a number of cooperatively rearranging regions. The size of these regions grows as the liquid is

cooled down, being similar to the growth of a crystal. Therefore, the configurational entropy

of the system decreases until the cooperatively rearranging regions become one

configurational state [46 - 49]. This process induces sharply decreasing entropy of the liquid,

which leads to infinitely high viscosity.

log log

B

TS

(1.3)

where log η∞ is the logarithmic viscosity at infinite temperature, S is the entropy of the

material, B is a constant, and T is the temperature. Viscosity is inversely proportional to the

entropy of the materials determined by their configurational distribution. At a high (or low)

temperature, the Arrhenius equation is usually suitable to describe the viscosity with low

(high) activation energy Ea.

A·

exp E / RT

(1.4)

a

7

where A is a constant, and R is the ideal gas constant. Only a few supercooled liquids, such as

SiO2, GeO2, exhibit more or less Arrhenian behaviour. Most other supercooled liquids display

super-Arrhenius behaviour, that is, a hyperbolic curve of viscosity with regard to temperature.

The curvature extent that the viscosity η deflects from Arrhenius behaviour defines the liquids

as either strong or fragile [46]. Therefore, SiO2, and GeO2 are defined as strong glasses. There

are systematic or physical problems existing in the above models, even though they are

successful in fitting and predicting a viscosity to temperature relationship. Recently [47], the

Mauro-Yue-Ellison-Gupta-Allan (MYEGA) model was proposed to account for these

problems, in particular, for ‘the dramatic rise in viscosity as the supercooled liquid cools

towards the glass transition with very little change in structural features’. The model starts

from the Adam-Gibbs equation and is compared to the VFT and AM models. In short, it

circumvents convergence of the VFT equation as well as divergence of the configurational

entropy when approaching low or high temperature as in the AM model [47].

1.2 Confinement effects

With decreasing scale of devices, the behaviour of liquids in nano-confinement has received

wide attention [50 - 59]. While it should be noted that the present work reports on the flow of

melts in micro-capillaries, it is still worthwhile to have a brief look at the potential effects

which liquids are exposed to in sub-micrometric or even nanometric confinement. Figure 1.2

presents three confinement geometries. The dark regions in Fig.1.2 (a) indicate confining

walls. Two plates confine a fluid to flow between them in Fig.1.2 (b). The fluid is confined in

cylindrical space in Fig.1.2(c). Jackson and McKenna have found that the glass transition

temperature Tg of a supercooled liquid changes significantly when it is confined in pores with

r around ~1-3 nm [0]. A shift of glass transition temperature, both positive and negative, has

also been observed for supercooled liquids in nano-geometry [53]. Approaching the glass

transition temperature, there occurs a pronounced slowing down of structural unit motion of

supercooled liquid in nano-confinement. This slowing down is generally attributed to an

increasing length scale of cooperativity of units (ζ, 1 to 3 nm). Even given the comparability

between the ζ and r, the reasons for the pronounced change in glass transition temperature can

be either (i) the interfacial reaction between the supercooled liquid and the walls of nano

pores, or (ii) the exact finite size of the pores, or both. F. He et al. studied a molecular glassformer, 2-methyltetrahydrofuran (MTHF), infiltrating it into porous glass with pores of 2.5,

5.0, and 7.5 nm. The same procedure was also performed in a silanized porous glass [53]. The

comparison of these experiments displays the importance of the interfacial reaction between

8

the two contacting media and suggests that severe confinement does not necessarily

contribute to the variation in characteristic properties [53]. Other studies show that a glass

transition temperature depression increases linearly with the inverse of the pore radius [53,

54].

Fig.1.2 Three kinds of confinement geometries. (a) Porous confinement,

(b) plate confinement, and (c) capillary confinement.

The glass transition temperature of a liquid in a confined substance can be described by the

second Ehrenfest relation, which is an equation of irreversible thermodynamics[55],

dTg

dP

VTg

C p

(1.8)

where V, , and C p are the molar volume of the supercooled liquid, the isobaric changes

of the thermal expansion coefficient and heat capacity at Tg, respectively. Davies and Jones

have successfully investigated many pressure-related glass transition cases with the second

Ehrenfest relation[55,56]. Jonas et al. applied the second Ehrenfest relation to

phenomenologically explain the glass transition of a liquid in confined geometries. On the

other hand, the pressure reduction ∆P of liquid inside a cylindrical pore with the radius of r

could be derived by Kelvin equation[57],

P

2

r

(1.9)

where is the interfacial tension of the liquids. Therefore, by combing Eq.(1.8) and

Eq.(1.9), Jonas et al. derived an equation interpreting the depression of the glass transition of

liquid to the geometrical confined pore size r.

9

T VTg

2

C p r

(1.10)

The authors noted that the depression ratio of

T

is less than 5% for the smallest pore [55],

Tg

which is proportional to the reciprocal of confinement. Therefore, the depression ratio of

T

Tg

could be neglected if the glasses were restricted in the smallest micro confinement.

In addition to the influence on glass transition by confinement, crystallization of materials can

be significantly affected. J. C. Dore et al. reported the effects of confinement on the liquid-toplastic crystal transition and the plastic-to-brittle crystal phase transition for cyclohexane

confined in porous silica [58], in which the nucleation point of the plastic crystal phase is

depressed by over 30 oC [59]. Interfacial reaction or confinement effects need to be clarified

as they do on Tg. For bulk glasses, the interface impact on crystallization has been studied,

which is heterogeneous nucleation [60]. Wettability of a liquid droplet on a solid substrate

(Fig.1.3) affects the slowest cooling rate required for avoiding nucleation, as listed in Table

1.1 [60]. It can be deduced that the critical cooling rate of heterogeneous nucleation may be

lower than that of homogeneous nucleation, for example, for Na2O·2SiO2 and

CaO·Al2O3·2SiO2 when the contact angle is larger than 100°[60]. Under confinement, the

high surface-area-to-volume ratio will be a significant factor influencing the behaviour of

crystallization of materials. Therefore, other than the effect of confinement, the interfacial

reaction itself will either inhibit or promote the crystallization of materials depending on the

properties of the materials. Above noted Na2O·2SiO2 and CaO·Al2O3·2SiO2 glass can be

fabricated at a relatively slow cooling rate if confined in a small capillary, which has a contact

angle larger than 100°with the glass melt. With regard to the effect of confinement alone,

fabrication of a single crystal of organic materials along the axis of mico glass capillaries has

been successfully demonstrated [61].

10

Fig.1.3 A liquid droplet on a solid substrate

Table 1.1 Critical cooling rate (K/s) by the impact of contact angle on

heterogeneous nucleation for glass formation, taken from [60].

Materials

Homogeneous

Nucleation

(K/s)

Heterogeneous nucleation (K/s)

θ=100°

θ=80°

θ=60°

θ=40°

SiO2

9×10-6

1×10-5

2×10-4

8×10-3

2×10-1

GeO2

3×10-3

3×10-3

3×10-2

1

20

Na2O·2SiO2

6×10-3

8×10-3

3×10-1

10

3×102

CaO·Al2O3·2SiO2

3×102

3×102

5×103

2×105

2×106

Microfluidic motion in geometries with a characteristic scale length of between 1.0 and 100.0

μm has received much attention [62, 63], for example, because of the trend to miniaturization

in biotechnology, manufacturing all solid hybrid PCFs, and liquid flow in lab-on-a-chip

devices which all require detailed knowledge of liquids flowing in micro-scales.

Table 1.2 Influence of scale amplitude r of glass structure on the properties of glasses, taken from [64].

Structure

Property

Short range

Colour, optical absorption

Ligand field effects: distortion-induced

violation of symmetry selection rules in rareearth and transition-metal ions

Electronic defect-like states, gap states

Electronic excitations

Ultraviolet absorption and transmission

Raman oscillations

Energetic contribution to thermal expansion

= nearest-neighbour interaction

r < 0.5 nm

Medium range

= atom-specific structure elements

and their interconnection

0.5 nm < r < 2.0 nm

Transport properties:

Diffusion, ionic conductivity, viscosity

Non-radiative heat conductivity

Relaxation

Vibrational excitations:

Infrared absorption and transmission

11

Brillouin light scattering

Boson peak

Nucleation

Stability against:

Phase separation/decomposition

Crystallization/devitrification

Low-temperature anomalies:

Specific heat

Heat conductivity

Transformation temperature

Fluctuations of concentration and density

Long range

Chemical durability

Phase separation/decomposition

Crystallization

Opacity, micro-porosity

Rayleigh and Mie light scattering

colour of “striking” glasses

photochromism, photosensitivity

>> ASE dimensions

2.0 nm < r < 100.0 nm

Structure insensitive

Density

Elastic moduli, strength, hardness

Refractive index, dielectric constant

Gas solubility

Radiative heat conductivity

Specific heat

= macroscopic

= averaging orientation and volume

(inhomogeneity)

r < 100.0 nm

In our case, the characteristic length-scale of confinement is just in the range of ~ 1.0 to 100.0

μm. In order to optimize the design and performance of the devices, a detailed understanding

of the flow of melts in such scales is necessary. For example, with our infiltration technology,

the structure of the undercooled liquids may remain after quick freeze. The structure of the

undercooled liquids, which affects the properties of glasses, is also influenced by the shear

rate. Therefore, by controlling the flow of the supercooled liquids, different structural

arrangements may be obtained, further optimizing the properties of glasses. Table 1.2 lists the

influence of scale amplitude r of glass structure on the properties of glasses [64]. It can be

found that optical performance of luminescent activators in glasses will change, if the

structure state is altered in a scale less than 0.5 nm; stability of glasses can be modified if

structure varies in the intermediate range. However, the ignored µm-confinement effect on

glasses has been theoretically demonstrated by Eq. (1.10). Furthermore, the glasses should

present more macroscopic distinctness comparing µm-confinement and nm-confinement if

there was. Analysis of different glasses reveals no properties dependence of glasses under

different µm-confinement conditions, such as undetected structure change of glasses and no

viscosity dependence on the scale of capillaries, which will be discussed in Chapter 3.

12

Therefore, different with nano-confinement, the research does not consider the µmconfinement.

1.3 Structure, heterogeneity and anisotropy

The structure of glasses lacks the periodicity of crystals, nevertheless, a short-range-order

remains. The composition of glasses can be extended to a much broader range than crystalline

materials as no building laws and laws of stoichiometry have to be taken into account - at

least in principle. Zachariasen proposed the random network theory to describe the tendency

of glass formation, which is the most used model for glass structure [6]. Structural units less

than 0.5 nm are the fundamental bricks for building a bulk glass. Together with adjacent

structural units, a short range ordered network is formed. Some parameters, such as bond

length, angle distribution, connectivity and coordination number, define the unit structure.

The structure of a larger dimension, the intermediate range order between 0.5 nm and 2.0 nm,

further contributes to the influence on transport properties, relaxation, nucleation, etc. of

glasses [64]. Some properties of glass are still structure sensitive until the research area

reaches above 100 nm. Various characterization techniques have been developed for revealing

the structure of glass from short order to long order scale. A. C. Wright [65] employed

neutron diffraction to vitrified silica and cristobalite at the short range, which testified the

same structural unit for both cases. The difference between glass and crystal was displayed

only at longer scale. On the other hand, glass is in a thermodynamic non-equilibrium state.

The structure of melts is frozen after supercooling, which results in the non-periodicity and

heterogeneity. The heterogeneity originates from the density fluctuation, which dissipates

within characteristic relaxation times. As Tg is approached, the characteristic relaxation times

become very long, which induces the freezing in of "dynamic" heterogeneity [66]. Techniques,

such as Brillouin scattering and small angle X-ray scattering, have been employed to study

the heterogeneity of glass at both intermediate and long range [67]. Since the glasses are

frozen to the structure of supercooled liquid at a certain temperature, which is denoted as

fictive temperature Tf, thermal history will influence the heterogeneity of glasses. Besides,

additional pressure added on supercooled liquid will change the structure of glasses, which

influence the heterogeneity of glasses as well. Y. Takahashi concluded that the denser regions

in the heterogeneity area are precursors of nuclei in the supercooled phase based on

investigating the Boson peak during crystallization [68]. As mentioned in section 1.3, under

nano confinement, a positive or negative shift of glass transition can be observed. This

confinement scale is in the range of heterogeneity of glasses, which is a possible reason for

13

the shift of glass transition. However, until now there has been no research on the influence of

micro confinement on supercooled liquids. It will in the future be interesting to study its

influence on heterogeneity of glasses, or investigate the crystallization of supercooled liquids.

Structural anisotropy may be induced in usually isotropic glasses as a result of unrelaxed flow

of supercooled liquids, such as in rapid drawing of a fibre. Anisotropy may be reflected in

various structural changes which are, however, still rather unexplored. For example, a fibre

drawn to the dimension of 10 μm may have an anisotropy expressed in birefringence of Δn =

10-5, which can be reduced by thermal treatment [69]. Here, nuclear magnetic resonance

(NMR) spectroscopy was used to show a coordination number shift from 3 to 4 of boron as a

result of fibre drawing [0]. However, such a coordination change may equally well be caused

simply by varying cooling rates [0].

2. The μ-Infiltration Technique: Pressure- and

surface-assisted infiltration

The dynamic flow of liquid inside a capillary had not been studied extensively until the

derivation of the Lucas and Washburn equation [70, 71]. The equation was derived based on

Poiseuille’s law [72] and proven through surveying the dynamic flow of water in given

capillaries under controlled time and external pressure. The coincidence between theoretical

derivation and experiments demonstrates the possibility of measuring the viscosity of liquid

based on this principle. The Lucas-Washburn equation is derived from Newton’s second law

14

without considering the chemical structure of liquids. Therefore, the Lucas-Washburn

equation should be effective in describing the flow of viscous glass melts as well. Researchers

in the polymer domain employed a capillary viscometer with external pressure for

determining viscosity based on the Lucas-Washburn equation [73, 74]. The critical conditions

of the viscometer, however, inhibit its application on viscous mineralic melts. For example,

the flow effects at the entrance to the capillary can only be neglected provided that long dies

have the length to radius ratio of less than 60 [73]. The aperture must be machined precisely,

since the tube radius has a remarkable influence on viscosity. Moreover, the pressure drop for

viscosity determination is difficult to measure directly because of the geometry of the

viscometer [73, 74]. The viscosity temperature range needs to be considered carefully for the

safety of the equipment, since inorganic glasses normally have much higher melting

temperatures than polymers. On the other hand, a conventional rotational viscometer can

measure a viscosity to as low as 1.0 Pa·s or less. It is currently the most popular viscometer

for measuring viscosity of glass melts in this regime [34, 36, 75]. However, a variety of

factors involving glass types, cost, required quantity the employed melt and safety in the case

of toxic or hazardous glasses must be taken into account. In my Ph.D project, I have applied

the infiltration technique, including pressure and suction methods, to measure viscosities of

different glass melts, such as, tellurite, sulfophosphate, chalcogenide, borate and germanate

glass melts. With the infiltration technique, a viscosity range of 0.01 to 10 Pa·s can be

covered. The experimental equipment system is designed according to the Lucas-Washburn

equation. Silica capillaries are chosen as flow matrix for glass melts. For the pressure method,

a pressure system with pressure as high as 200.0 bar is applied as external force to pump

melts into capillaries. For the suction method, a vacuum pump is used to suction the melts. In

the process of the pressure method, a suitable pressure and capillary size are chosen according

to pre-estimation of viscosity, for example, by choosing one capillary and filling it for a

certain time under pressure. After the filling procedure, the length of glass inside the capillary

is measured. Other parameters, (pressure, radius of the capillary, and filling time) are known

and used for calculating viscosity. Finally, we can use this pre-viscosity value to set the

appropriate filling length, pressure, and time to obtain more accurate results according to the

Lucas-Washburn equation. In the process of suction method, two forms of analysis, with and

without vacuum pump are performed: (1) The surface tension dominates the flow of melts

without evacuating. (2) With vacuum pumping, an unbalanced pressure less than one

atmosphere is introduced as external force. Now the surface tension and the unbalanced

pressure dominate the flow of melts. The surface tension effect can be subtracted from the

15

Lucas-Washburn equation. Then, an accurate value of viscosity will be acquired. Application

of the infiltration technique is discussed from both the theoretical and the experimental point

of view. Possible influences of the interfacial interaction between melts and silica capillaries

are considered and surveyed; for example, tellurite glasses, exhibit perfect wetting with silica,

and a stationary layer forms at the TeO2-SiO2 interface by interfacial reaction. This layer

causes a deviation of the effective radius in the Lucas-Washburn equation as it does on actual

viscosity. Nevertheless, this deviation becomes smaller as the radius of the employed capillary

increases. When capillary radii are ≥ 10 µm, the deviation of effective radii will be less than

5%, and the corresponding deviation of viscosity will be at most 10 %. Similar deviation may

be caused by interfacial reaction as with phosphate, borate, and germanate glasses. In order to

avoid interfacial reactions between the filling materials and the silica wall, chalcogenide

glasses are selected. It is well-known that chalcogenide glasses are perfectly non-wetting with

respect to silica; consequently, any viscosity deviation due to interfacial layer formation will

be excluded. Therefore, to find answers to the questions provided above, the following

chapters will be introduced and discussed: (1) Theory and technique of the infiltration method;

(2) Assessment of as-chosen glass melts and their interfacial reaction with silica matrix; (3)

Flow behaviour of chalcogenide melts under micro-confinement condition; (4) Application of

the infiltration method in fabricating all-solid PCFs and their optical applications.

2.1 Fluid mechanics

Jean Louis Marie Poiseuille experimentally derived, formulated and published the Poiseuille's

law, known nowadays as the Hagen-Poiseuille equation [76],

PR4

8L

(2.1.1)

where Π is the volumetric flow rate, ΔP is the pressure drop, R is the characteristic length of

the capillary (its radius for tabular capillary), η is the dynamic viscosity and L is the length of

the fluid column. To utilize this equation, laminar stationary flow of a uniformly viscous

liquid with zero compressibility is assumed (Newtonian flow). Lucas [70] and Washburn [71]

extended Eq. (2.1.1) by considering the dynamics of capillary rise:

d 2 L dL 2

8 L dL

P PE 2

2

R dt

dt

dt

(2.1.2)

16

This equation describes a typical experimental situation, where a capillary is dipped into a

liquid of density (ρ). As a result of the total effective pressure ΣP, over a certain time t, the

liquid will rise and form a column of height L. ΣP consists of hydrostatic pressure Ph=ρgL (g:

acceleration of gravity), the capillary pressure Pc=2γcosθ/R (with surface tension and

contact angle θ) and other applied body forces PA [8]. The right-hand side of Eq. (2.1.2)

includes the first term for viscous resistance and the second term for inertial effects. The

inertial effect is neglected for laminar flow. If the gravitational effect is neglected, in the

absence of any other forces, Eq. (2.1.2) reduces to

P Pc

2 cos 8 L dL

2

R

R dt

(2.1.3)

which yields, after integration,

L2

R cos

t

2

(2.2.4)

If an additional pressure PA is applied, the left side of Eq. (2.1.3) should be corrected by

ΣP=Pc+PA. Then, integration leads to

R cos R 2 PA

L2

t

4

2

(2.1.5)

Eq. (2.1.5) can be rearranged to yield the dynamic viscosity

(2 R cos R 2 PA )

t

4 L2

for 2 cos

(2.1.6)

RPA , body forces dominate over surface forces. For example, if the employed

capillary radius is larger than 10 μm, and an external pressure of 10 bar is applied, 2 cos

will be much less than RPA, since the surface tension of glass melts is much less than 1.0 N/m.

In the pressure technique, the calculation will be based on this simplification of Eq. (2.1.6) to

R 2 PA

t

4 L2

(2.1.7)

In the case in which an additional pressure PA is less than 1.0 bar, the gravitational and

surface tensional effect need to be considered. In order to obtain an estimate of the impact of

17

gravitational pressure PH, the column equilibrium length LE, which would be necessary to

compensate for capillary and atmospheric forces, can be estimated from the balance.

gLE PA +2 cos / R

(2.1.8)

If the experimentally obtained filling length is less than 3% of LE, the effect of PH can be

neglected. This is generally the case for R < 10.0 µm, which will generate a high equilibrium

length LE. If gravitational effects are not negligible, Eq. (2.1.2) becomes

PA

d 2 L dL 2

2 cos

8 L dL

gL 2

L 2

R

R dt

dt

dt

(2.1.9)

For laminar flow, neglecting inertial effects,

PA

2 cos

8 L dL

gL 2

R

R dt

(2.1.10)

and after integration,

2 cos RPA

gR 2

gRL

tL

ln(1

)

8

gR

2 cos RPA

(2.1.11)

if contact angle θ and surface tension are known, Eq. (2.1.11) can be employed to calculate

the apparent dynamic viscosity from the length of the filled capillary section obtained after a

certain filling time.

2.2 Wettability

Wettability or wetting of liquids within the capillary is a parameter that controls the kinetic

flow of the liquid inside the capillary. A contact angle is formed when a liquid droplet spreads

on the surface of a horizontally solid substrate. This angle is determined by a force balance

between adhesive and cohesive forces [77]. The contact angle θ varies from 0 to 180°, as

illustrated in Fig 2.1. The liquid is regarded as wetting when 0 < θ <90°and non-wetting

when 90° < θ < 180°. θ = 0, 180°correspond to perfect wetting and perfect non-wetting,

respectively [77, 78]. Perfect wetting means that the droplet spreads and forms a film on the

surface of the substrate. Perfect non-wetting means that the drop forms a sphere on the surface

of the substrate.

18

θ

θ

θ

Fig.2.1 Liquid droplets in equilibrium with a horizontal surface surrounded by a gas. The wetting angle θ

between the horizontal layer and the droplet interface defines the wettability of the liquid.

In fact, the interfacial tension of the liquid determines the wetting angle θ, which is a

thermodynamic variable [78]. With l , g denoting the interfacial tension due to the liquid-gas

surface, s ,l denoting the interfacial tension due to the solid-liquid surface and s , g denoting

the interfacial tension of the solid-gas surface, in thermodynamic equilibrium the wetting

angle θ is given by Young's law [79],

s , g s.l l , g cos

(2.2.1)

For two-phase flow in porous media or in capillary, the wetting angle influences the strength

of the capillary pressure Pc in a pore of size R [80],

Pc

2 l , g

R

cos

(2.2.2)

Therefore, the interfacial wettability between glass melts and the capillary should be

considered for obtaining an accurate viscosity value.

2.3 Analytic solutions for defined time stages

The dynamic flow of liquids in a capillary can be separated into several stages depending on

the development of various forces acting on liquids. The flowing states of the liquid will be

classified in the following parts [81, 82], where an external force PA is always considered.

2.3.1 Purely inertial time stage

At the moment of a capillary coming into contact with the liquid, the viscous and the gravity

terms in Eq.(2.1.2) can be neglected so that it becomes [83],

19

d 2 L dL 2

2 cos

PA

L 2

R

dt

dt

(2.3.1)

The length of the liquid column flowing into the capillary can be solved through this

differential equation when the liquid flows at a constant velocity.

2 cos PA R

R

Lt

(2.3.2)

2.3.2 Visco-inertial time stage

Later, the flow transfers into a transition stage. A solution is presented by Bosanquet [81],

which considers the inertial as well as viscous terms,

d 2 L dL 2 8 dL

RPA 2 cos

L 2 2 L

R

dt

dt R

dt

(2.3.3)

Solving this differential equation yields

R(2 cos RPA ) R 2

8

L

t

(1 exp( 2 t ))

8

8

R

2

(2.3.4)

It is noted that in a micro-capillary, if viscosity is too low, flow will become turbulent if one

certain pressure is applied. Thus, the obtained viscosity value is not a real but an apparent

value.

2.3.3 Purely viscous time stage

One period later, an equilibrium stage is reached where the Lucas-Washburn equation

becomes valid (inertia and gravity being neglected),

L2

R(2 cos RPA )

t

4

(2.3.5)

2.3.4 Viscous and gravitational time stage

With the increase in length of the liquid column inside the capillary, the gravity effect can no

longer be neglected. For example, 7.6 cm Hg is equal to 0.1 atmosphere pressure. Fries and

Dreyer [81, 82] show that gravity must be considered for L 0.1LE . An analytic solution

(neglecting inertia) was presented

20

2 cos RPA

gR 2

gRL

tL

ln(1

)

8

gR

2 cos RPA

(2.3.6)

The time from the purely inertial stage to the visco-inertial stage and from the visco-inertial

stage to the purely viscous time stage is proportional to R 2 / . Considering the dimension of

the capillaries (μm) and viscosities of the liquids (less than 10 Pa·s), the transition time is

much less than 1 min, which is shorter than our experimental time scale. Therefore, the

inertial effect can be neglected when deriving the Eq. (2.1.3) and the Lucas-Washburn

equation is applied for viscosities.

2.4 Shear rate in pipes