Experiment 3A Determination of Atterberg Limits (Liquid Limit test)

advertisement

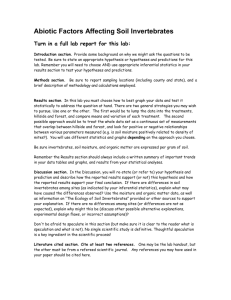

1 Determination of Atterberg Limits (Liquid Limit and Plastic Limit) Experiment 3A Determination of Atterberg Limits (Liquid Limit test) General Water plays an important role in soil mechanics practice when dealing with density, void ratio, settlement and strength characteristics of either disturbed or undisturbed soils. Fine-grained soils in particular can be in one of several states depending on the amount of water in the soil. When water is added to dry soil, the individual particle is covered with adsorbed water forming a thin film around it. If the addition of water is continued, the thickness of the water film will continue to increase, thereby facilitating the sliding effect between adjoining particles. Thus it is a fact that the behaviour of the soil is related to the amount of water in the system (Mandal and Divshikar 1995). Objective To familiarise the general relationship between moisture content and the boundaries of states of soils in terms of limits (i.e. Liquid limit, plastic limit and shrinkage limit). Theory The moisture contents of cohesive soil corresponding to empirically-defined boundaries between states of consistency (liquid, plastic, solid) of the fraction of soil passing a 425 µm sieve. These boundaries, and the soil phases they define, are illustrated in Figure 3A.1. Figure 3A.1 Phases of Soil and the Atterberg Limits (K.H.Head, 1989) Soil and Rock Mechanics Laboratory, Department of Building and Construction, City University of Hong Kong 2 Determination of Atterberg Limits (Liquid Limit and Plastic Limit) Liquid limit (WL) the moisture content at which a soil on losing water passes from the liquid to the plastic solid state. Plastic limit (Wp) the moisture content at which a soil on losing water passes from the plastic state to the semi-brittle solid state, and becomes too dry to be plastic. Plasticity Index (IP) the range of moisture contents within which the soil is in the plastic solid state(ie. the plastic range), in which it can be moulded without cracking. IP=wL-wP Liquidity Index (IL) Relates the moisture content of the fraction of soil which passes a 425µm sieve (wa%) to the liquid and plastic limits. Can give an indication of shear strength. wa − w p IL = Ip 100 wa = × w% where Pa in which w% is the moisture content of the whole soil. Pa is the percentage by dry mass of the portion passing a 425µm sieve. (from Appendix A) At liquid limit (IL = 1), shear strength is about 2kN/m2. (K.H.Head) Liquid Limit (Cone-penetration method) Materials Soil sample with all particles passing 425µm sieve. (see Appendix A) Apparatus 1. A flat glass plate 10 mm thick and about 500mm square. 2. Two palette knives or spatulas and one straightedge. 3. A penetrometer (Figure 3A.2(a)). 4. A cone of stainless steel or duralumin approximately 35mm long with a smooth, polished surface and an angle of 30±10. to ensure that the point remains sufficiently sharp for the purposes of the test, the cone shall be replaced if, after continued use, the point can no longer be felt when brushed lightly with the tip of the finger when the tip of the cone is pushed through a hole 1.5± 0.02mm in diameter, bored through a metal plate 1.75±0.1mm thick. The mass of the cone together with its sliding shaft shall be 80.00 ± 0.1g (Figure 3A.2(b and d). 5. One or more metal cups not less than 55mm in diameter and 40mm deep with the rim parallel to the fat base. 6. A wash bottle or beaker, containing distilled water. 7. Balance readable to 0.01g. 8. Moisture content determination tin. 9. Apparatus for moisture content determination (Experiment 9). Soil and Rock Mechanics Laboratory, Department of Building and Construction, City University of Hong Kong 3 Determination of Atterberg Limits (Liquid Limit and Plastic Limit) Procedure 1. Take a sample of about 300g from the soil paste and place it on the glass plate. 2. Mix the paste for at least 10 min using the two palette knives. (Figure 3A.2c) 3. Push a portion of the mixed soil into the cup with a palette knife taking care not to trap air. Strike off excess soil with the straightedge to give a smooth level surface. 4. Place the cup under the centre of the cone. 5. Hold the stem with one hand. 6. Press the manual release button and let the stem free. 7. Gradually lower the stem until the tip of the cone is exactly in contract with the surface of the sample. (When the cone is in correct position, a slight movement of the cup will just mark the soil surface.) 8. Turn the gear actuator control knok clockwise until the lock shaft touches the top of the stem, take a reading of the pointer on the gauge to 0.1mm. This is the first reading (R1). 9. Adjust the automatic release and locking device to 5 sec. 10. Press the start button. 11. After the 5 sec. countdown finished, take a second reading to 0.1 mm as per step 8 be (R2). 12. Record the difference between the two readings (R2 - R1). This is the first cone penetration. 13. Lift out the cone and clean it carefully to avoid scratching. 14. Add a little more wet soil to the cup, taking care not to trap air, make the surface smooth as in 3 and repeat steps 4 to 12 for second penetration. 15. If the difference between the first and second penetration readings is less than 0.5 mm record the average of the two penetration. If the second penetration is more than 0.5mm and less than 1mm different from the first, carry out a third test. If the overall range is then not more than 1mm, record the average of the three penetrations. If the overall range is more than 1mm remove the soil from the cup, remix and repeat until consistent results are obtained. 16. Take a moisture content sample of about 10g from the area penetrated by the cone and determine the moisture content. 17. Repeat at least three more times using the same sample of soil to which further increments of distilled water (about 4-5 cc) have been added. Proceed from the drier to the wetter condition of the soil. The amount of water added shall be such that a range of penetration values of approximately 15mm to 25mm is covered by the four or more test runs and is evenly distributed. Each time soil is removed from the cup for the addition of water, wash and dry the cup. 18. If at any time during the above procedure the soil has to be left for a while on the glass plate cover the soil with the evaporating dish or a damp cloth to prevent the soil from drying out. Soil and Rock Mechanics Laboratory, Department of Building and Construction, City University of Hong Kong 4 Determination of Atterberg Limits (Liquid Limit and Plastic Limit) (b) (a) (c) (d) Figure 3A.2 Apparatus for Cone Penetrometer Liquid Limit Test: (a) Cone Penetrometer with Automatic Timing Device, (b) Cone and Gauge Plate, (c) Mixing Water into soil for LL Test, and (d) Cross Section of Cone Pentrometer, and cone & gauge plate. Computation and Results: (Form 3A & 3B) Soil and Rock Mechanics Laboratory, Department of Building and Construction, City University of Hong Kong 5 Determination of Atterberg Limits (Liquid Limit and Plastic Limit) 1. Calculate the moisture content of each penetration test made. 2. Plot the relationship between moisture content and cone penetration with the percentage moisture contents as abscissae and the cone penetrations as ordinates, both on linear scales. 3. Draw the best straight line fitting the plotted points. 4. From the linear graph read off the moisture content corresponding to a cone penetration of 20mm to one decimal place. 5. Express the moisture content corresponding to a cone penetration of 20mm to the nearest whole number and report it as the liquid limit (wL) of the soil sample. 6. Express the percentage of material passing the 425µm test sieve.(ρa) Soil and Rock Mechanics Laboratory, Department of Building and Construction, City University of Hong Kong 6 Determination of Atterberg Limits (Liquid Limit and Plastic Limit) passing Forms No. 3A & 3B Soil and Rock Mechanics Laboratory, Department of Building and Construction, City University of Hong Kong