Fume Hoods

advertisement

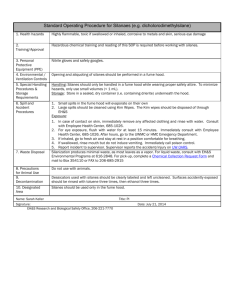

LOCAL JOINT HEALTH AND SAFETY COMMITTEE DEPARTMENT OF BIOMEDICAL SCIENCES STANDARD OPERATING PROCEDURE 1. SAFE USE OF FUME HOODS Effective Date: October 2002 Author: R. Braham, Department of Biomedical Sciences Purpose: To promote the correct and safe use of fume hoods Approvals Required: Faculty Supervisor, Local JHSC, EHS 2. DEFINITIONS: Fume Hood: a special ventilation device which exhausts air that contains hazardous substances or gases from the workplace through duct work to the outside environment. (Not to be confused with a Biological Safety Cabinet equipped with HEPA filters designed to protect workers and the environment from contamination by microorganisms.) Sash: The front opening of the fume hood which can be raised or lowered. Air Flow Alarm: an audible safety device for performance verification and operator health protection which alerts the user or a dispatcher at a remote location to insufficient air flow through the fume hood. Velometer: An instrument used to measure the face velocity in linear metres per second or feet per minute in a fume hood. 3. REQUIREMENTS: Applicable Legislation: Ontario Environmental Protection Act, R.R.O. 1990, General - Air Pollution Regulation 346 Occupational Health and Safety Act: Ontario Regulation 833, R.R.O. 1990, Control of Exposure to Biological or Chemical Agents and Ontario Regulation 851, R. R. O. 1990, Industrial Establishments, Section 128(3): The discharge of air from the exhaust system shall be in such a manner so as to prevent the return of contaminants to any workplace. Relevant Standards: CSA Standard Z316.5 - 94, Fume Hoods and Associated Exhaust Systems NFPA 45, Fire Protection for Laboratories Using Chemicals Internal Requirements: University of Guelph Safety Policy 851.07.05 Scheduled Maintenance/Inspection Training/Competency 4. DESCRIPTION OF THE TASK: General Guidelines to Observe: When using a fume hood, wear a labcoat as the basic article of Personal Protective Equipment. Chemical fume hoods are designed to prevent hazardous material contaminants from entering the breathing zone and exposing the user. To function effectively, fume hoods must be kept clean, free of unnecessary apparatus and operated with the smallest practical sash opening. All fume hoods should provide a face velocity of between 0.4 and 0.5 metres per second, i.e. 80 to 100 linear feet per minute with a sash opening of 30 cm, i.e. 12 inches. When the fume hood is not in use, the sash should be closed to 10 cm i.e. 4 inches, and the fan turned off. Never use the hood as an area for the accumulation of equipment or for the storage of corrosive or volatile liquids. Fume Hood Interiors may have adjustable baffles, and are constructed with liners made from stainless steel, or unpainted or painted cement board. Other than perchloric acid fume hoods which are all steel and designed to be flushed down with water after each use, fume hoods need to be maintained in a clean condition which requires the occasional wiping down of all surfaces with soapy water, including the baffles and the baffle adjusting hand control knobs. The build-up of grime and dust, especially in the hard to reach areas around the baffles, has a major influence on flow rate efficiency. Baffle Settings are the most misunderstood aspect of fume hood use. Generally, baffles may be adjusted to three positions depending on the operating application. • For normal operation set the back baffle controls to the middle position so that fumes are exhausted through slots at the bottom, middle and top of the hood. • For exhaustion of lighter-than-air or hot gases set the back baffle controls in the up position so that the top slot is fully open and the bottom slot is restricted. • For exhaustion of heavier-than-air gases or fumes generated at the work surface pull the slide-lock baffle control forward and in the down position so that the top slot is restricted and the bottom slot fully opened. Air is then drawn laterally across the work surface. Sash : the fume hood sash is a sliding safety shield made from laminated safety glass. Keep the sash clean, and during fume hood use move the sash to the lowest position that provides access to the work surface while protecting the head and upper body. Never use a fume hood with the sash wide open or with your head bent over inside the sash opening. Fume Hood Operating Instructions: • Turn on the interior light for proper illumination of the work area. • Turn on the exhaust fan and verify that the fume hood is operating properly. (If the hood is not equipped with an Air Flow Alarm devise, this can be achieved by checking whether a paper tissue held at the opening of the lowered sash is drawn into the fume hood.) • Set the baffle openings in the hood for the type of work being conducted (described above). • Set up equipment and apparatus as far back on the work surface as is practical so that air flow into the hood is not impeded. • Set the sash opening so that the head and upper body are protected. • When work in the hood is complete, remove apparatus and equipment, wipe the work surface clean, turn off the light and exhaust fan and close the sash to 4 inches. Fume Hood Maintenance/Inspection: While fume hoods should be maintained in working order through regular routine cleaning and checking by the users, for safety and efficiency considerations, they also need to be on at least an annual documented inspection. The University of Guelph Maintenance Department documents inspections, cleaning and repairs carried out on fume hood exhaust fan motors and duct work inaccessible to the user, and on Air Flow Alarm calibration and testing. It is, however, user responsibility to verify and record the fume hood face velocity using a velometer. This should be done to coincide with health and safety workplace inspections or as required following repairs and maintenance. • In the Department of a hand-held velometer is kept on the safety shelf in Rm. Bld. • Note that on the left side of the velometer there is a turn knob indicating HI and LO Range settings. In the centre of the knob is an orifice through which air must pass in order to record air flow though the open sash of the fume hood. When the knob is turned clockwise, the larger orifice is exposed which corresponds to a needle reading in the front window of the velometer on the lower scale in a range of 0 to 200 feet per minute. When the knob is turned anti-clockwise, a smaller orifice is exposed which corresponds to a needle reading on the upper scale in a range of 0 to 800 feet per minute. • With the fume hood exhaust fan on and the sash opening at 12 inches, set the velometer knob on LO Range. Hold the velometer sideways at a central point 6 inches below the bottom of the sash so that air is drawn unimpeded through the velometer orifice. Record the reading on the lower scale. Readings may also be taken at points left and right of centre in order to establish a mean face velocity rate across the width of the fume hood. 5. CONTINGENCY PLAN AND REPORTING: The fume hood is a safety device. If the exhaust system fails while in use, discontinue the work, shut off accessory equipment, lower the sash completely and vacate the immediate work area. Report the breakdown to the Maintenance Department. Corrosive or flammable solvent spills in the fume hood should be handled by referring to the appropriate SOPs for handling corrosive, hazardous or flammable materials. Fume hood users should be familiar with the location of fire extinguishers and spill kits. 6. WASTE MANAGEMENT AND ENVIRONMENTAL RESPONSIBILITY: While a fume hood, per se, does not generate waste, be aware that the improper use or malfunctioning of a hood may lead to the contamination of the quality of air in the immediate location requiring reportable action to EHS and/or the Maintenance Department. 7. REFERENCES: Ontario Environmental Protection Act Occupational Health and Safety Act University of Guelph Safety Policy 851.07.05 Operation and Maintenance Manual e.g. For Norlab Fume Hoods 8. DISTRIBUTION OF COPIES: Technicians, Graduate Students, Project Students, other University of Guelph employees working in the lab. Dr. Faculty Supervisor Environmental Health and Safety Local JHSC, Department of Biomedical Sciences Written By: R. Braham, Staff Technician Approved By: Faculty Supervisor Date: October 2002