Chemical Safety Number: RMP 034 Approving

advertisement

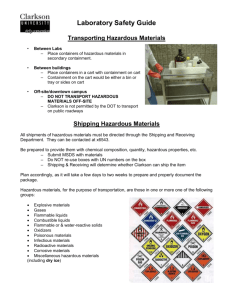

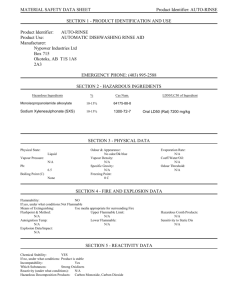

TRENT UNIVERSITY RISK MANAGEMENT POLICIES AND PROCEDURES MANUAL Subject: Chemical Safety Approving Authority: VP Administration Contact: EHS Officer Number: RMP 034 Effective Date: December 14, 2007 Applicable Legislation: Control of Exposure to Biological or Chemical Agents, R.R.O. 1990, Regulation 883 Designated Substances Regulations (R.R.O. 1990, Regulation 835, 836, 837, 838, 839, 840, 841, 842, 843, 844, 845, and 846) Environmental Protection Act, R.S.O., c.E.19 Fire Protection and Prevention Act, 1997, Regulation 388/97, Fire Code Industrial Establishments, R.R.O. 1990, Regulation 851 Occupational Health and Safety Act, R.S.O. 1990, c.O.1 Transportation of Dangerous Goods Act, 1992, c.34 Workplace Hazardous Materials Information System, R.R.O. 1990, Regulation 860 Intent (a) To encourage and promote the safe use of potentially hazardous chemicals. (b) To comply with the Occupational Health and Safety Act, the Regulations for Industrial Establishments and related statutes. Definitions: hazardous Any material with one or more of the following properties: material Compressed gas; Flammable or combustible; Oxidizing; Poisonous; Corrosive; Dangerously reactive, Except for: wood or products made of wood; tobacco or products made of tobacco, or; manufactured articles; Cosmetics, devices, drugs or food within the meaning of the Food and Drug Act, unless used in University operations, including teaching and research. spills An unintentional release of a hazardous material likely to result in one or more of the following: impairment to the quality of the natural environment - air, water, or land; injury or damage to property or animal life; SOP adverse health effects; safety risk; making property, plant, or animal life unfit for use; loss of enjoyment of normal use of property; or interference with the normal conduct of business. Standard Operating Procedure: Documentation outlining the essential safety instructions and procedures to be followed when conducting laboratory work that presents extraordinary risks. Requirements of the Control of Exposure to Biological or Chemical Agents Regulation: 3 (1) Every employer shall take all measures reasonably necessary in the circumstances to protect workers from exposure to a hazardous biological or chemical agent because of the storage, handling, processing or use of such agent in the workplace. R.R.O. 1990, Reg. 833, s. 3 (1). Requirements of the Designated Substances Regulation (eg. benzene): 6. (1) Every employer to whom this Regulation applies shall cause an assessment to be made in writing of the exposure or likelihood of exposure in a workplace of a worker to the inhalation, absorption or contact with benzene. (2) In causing the assessment to be made, the employer shall consider and take into account such matters as, (a) the methods and procedures used or to be used in the production, processing, use, handling or storage of benzene; (b) the extent and potential extent of the exposure of a worker to the inhalation, absorption or contact with benzene; and (c) the measures and procedures necessary to control such exposure by means of engineering controls, work practices and hygiene practices and facilities. (3) In causing the assessment to be made, the employer shall consult thereon with the joint health and safety committee and the committee may make recommendations with respect to the assessment. (4) A copy of the assessment made by an employer shall be given by the employer to each member of the joint health and safety committee. Requirements of the Environmental Protection Act: 14. (1) Subject to subsection (2) but despite any other provision of this Act or the regulations, a person shall not discharge a contaminant or cause or permit the discharge of a contaminant into the natural environment, if the discharge causes or may cause an adverse effect. Requirements of the Ontario Fire Code: 4.12.3.1. (1) Except as provided in Article 4.2.6.4., containers used for the storage of flammable liquids or combustible liquids in a laboratory shall be of not more than 5 L capacity and shall conform to Subsection 4.2.3. (2) Except as permitted in Sentence (3), not more than 300 L of flammable liquids and combustible liquids, of which not more than 50 L shall be flammable liquids, shall be permitted in the open area of a laboratory. (3) Quantities in excess of those permitted in Sentence (2) shall be stored in cabinets conforming to Subsection 4.2.10. or in a room conforming to Subsection 4.2.9. (4) Containers of flammable liquids or combustible liquids shall be kept closed when not in use. 4.12.4.1. (1) Except as provided in Sentences (2) to (4), a laboratory shall conform with the requirements of Section 2.8. (2) Fire drills required in Subsection 2.8.3. shall be held at intervals not greater than six months in laboratories. (3) Personnel working in laboratories shall be trained in the safe handling of flammable liquids and combustible liquids. (4) Measures shall be taken to prevent access to laboratories by unauthorized persons. 4.12.5.1. A written spill procedure shall be provided for laboratories in conformance with Article 4.1.6.4. Requirements of the Regulation for Industrial Establishments: 130 A worker who may be exposed to a biological, chemical or physical agent that may endanger the worker’s safety or health shall be trained, (a) to use the precautions and procedures to be followed in the handling, use and storage of the agent; (b) in the proper use and care of required personal protective equipment; and, 131 (c) in the proper use of emergency measures and procedures. No food, drink or tobacco shall be taken into, left or consumed in any room, area or place where any substance that is poisonous by ingestion is exposed. Requirements of the Occupational Health and Safety Act: 36.(1) An employer shall make or cause to be made and shall maintain an inventory of all hazardous materials and all hazardous physical agents that are present in the workplace. 37.(1) (a) An employer shall ensure that all hazardous materials present in the workplace are identified in the prescribed manner. 42.(1) In addition…an employer shall ensure that a worker exposed or likely to be exposed to a hazardous material or to a hazardous physical agent receives, and that the worker participates in, such instruction and training as may be prescribed. Requirements of the Transportation of Dangerous Goods Regulation: 6.1 Training Certificate Requirements (1) A person who handles, offers for transport or transports dangerous goods must (a) be adequately trained and hold a training certificate in accordance with this Part; or (b) perform those activities in the presence and under the direct supervision of a person who is adequately trained and who holds a training certificate in accordance with this Part. (2) An employer must not direct or allow an employee to handle, offer for transport or transport dangerous goods unless the employee (a) is adequately trained and holds a training certificate in accordance with this Part; or (b) performs those activities in the presence and under the direct supervision of a person who is adequately trained and who holds a training certificate in accordance with this Part. handling means loading, unloading, packing or unpacking dangerous goods in a (from the means of containment for the purposes of, in the course of or following Act) transportation and includes storing them in the course of transportation. Requirements of the WHMIS Regulation: 6. (1) An employer shall ensure that a worker who works with or in proximity to a controlled product received from a supplier is informed about all hazard information the employer receives from the supplier concerning the controlled product and all further hazard information of which the employer is or ought to be aware concerning its use, storage and handling. (2) An employer who produces a controlled product in a workplace shall ensure that every worker who works with or in proximity to the controlled product is informed about all hazard information of which the employer is or ought to be aware concerning the controlled product and its use, storage and handling. Policy: 1. Any employee, contractor or sub-contractor working with or near a hazardous material at Trent University shall complete Workplace Hazardous Materials Information System (WHMIS) training before commencing work. Work with hazardous materials shall comply with all WHMIS requirements (see RMP 037, WHMIS). 2. Any employee, contractor or sub-contractor working with a designated substance at Trent University shall comply with all designated substance requirements (see RMP 036, Designated Substances). 3. Any person who prepares hazardous materials for transport, transports hazardous materials, or receives shipments of hazardous materials must complete training in the Transportation of Dangerous Goods (TDG) before commencing work.1 4. Food and drink is prohibited from any room or area containing toxic (poisonous) materials. 5. Hazardous materials with a potential to explode or become easily ignited shall only be used or stored indoors if: a. They are in a hazardous room as defined by sections 121 and 122 of the Industrial Establishments Regulation, O. Reg. 851; or, b. Used in a laboratory and stored in a suitable flammable materials cabinet when not in use. Anyone working with a flammable or potentially explosive material shall have an appropriate level training and fully understand the requirements for the safe handling of those materials. 6. Any person working with hazardous materials will receive instruction in workplace-specific emergency response procedures before beginning work. 7. Chemical spills will be promptly reported to Campus Security (see RMP 031, Reporting and Investigating Incidents, Injuries and Occupational Diseases). 1 TDG training is available through the Risk Management Department. Guidelines: Many of Trent’s employees and students will have a great deal of knowledge and experience and fully understand the hazards of the chemicals they work with. Others, especially those beginning work or studies in a new field, may have a more limited understanding. Failure to appreciate these hazards creates a potential for serious injury and disease and property damage. Accidental release may result in environmental damage. It is vitally important that every person who works with chemicals understands the associated hazards and works in a manner that effectively controls those hazards.