Product configuration analysis with design structure matrix

advertisement

The current issue and full text archive of this journal is available at

www.emeraldinsight.com/0263-5577.htm

Product configuration analysis

with design structure matrix

Product

configuration

analysis

P.T. Helo

Logistics Systems Research Group, University of Vaasa, Vaasa, Finland

997

Abstract

Purpose – Product configurator is a sales and production-planning tool that helps to transform

customer requirements into bills-of-materials, lists of features and cost estimations. The purpose of

this paper is to introduce a method of how to analyse sales configuration models by using a design

structure matrix (DSM) tool. By applying the DSM techniques, the sales configuration managers may

sequence the product configuration questions and organize the connection to production.

Design/methodology/approach – First, the paper explains a sales configuration system structure

from published academic and non-academic works. These sources employ both theoretical and

practical views on the topic of computer-based sales expert systems. Second, the paper demonstrates

an application of using DSM for configuration modelling.

Findings – The current sales configuration approaches include constraint-based, rules-based, and

object-oriented approaches. Product description methods vary, but the general problem remains the

same: the configuration process should be designed in such a way that customer selections do not

affect the previous selections. From the user point of view, answering the questions should be smooth

and fast. In turn this will lead to the growing importance of building more effective product

configuration models. DSM offers a systematic way to organise customer interface in sales

configuration systems.

Research limitations/implications – This paper analyses how DSM could help in planning

product configuration modelling. Comparison of different sequences is presented. The examples used

are hypothetical, but illustrate the suitability of DSM analysis. Companies are trying to establish easily

configured product models, which are fast, flexible and cost-effective for adjustments and

modifications. Use of DSM may help in the roll-out of sales configuration projects. DSM may also be

used as a quick view to represent the complexity of product configurability. The future needs for

configuration tools will be focused towards product model management from the technical limitations

of different data storage approaches.

Practical implications – Configurator software creates product variants, which are logical

descriptions of physical products. Variants have parameters which describe the customer-made

selections. The parameter selections may have interconnections between the choices. Some

selections may affect further selections and some combinations may not be allowed for

incompatibility, cost or safety reasons. There are several commercial software packages available

for creating product configurations. Product description methods vary, but the general problem

remains the same: the configuration process should be designed in such a way that customer

selections do not affect the previous selections. Answering the questions should be smooth and

fast. Configuration of complex products, for instance, airplanes, may include several sub-systems

and have various loops within the quotation process. The use of DSM may help in the roll-out of

sales configuration projects. DSM may also be used as a quick view to represent the complexity of

product configurability.

Originality/value – The paper helps both researchers and practitioners to obtain a clearer view on

the development of sales configuration systems and the potential of systematic DSM-based product

model analysis.

Keywords Sales information, Configuration management, Software tools, Manufacturing systems,

Integration, Design

Paper type General review

Industrial Management & Data

Systems

Vol. 106 No. 7, 2006

pp. 997-1011

q Emerald Group Publishing Limited

0263-5577

DOI 10.1108/02635570610688896

IMDS

106,7

998

1. Introduction

Configurators are software tools that allow a user to define a product that meets certain

given criteria by combining a number of parts, features or functions. In practice, a

configurator is a software application that is used in industry to enable quotation,

marketing, and rapid manufacturing of customised products. Industries are being

forced to move towards increasingly customised and individual products. In order to

do this cost effectively, the engineering phase needs to be accelerated.

The use of configurators decreases the engineering work required in the sales phase,

but also empowers the product development of platform derivative products (Franke,

1998). Configurators may be used for structural analysis, dimensioning or design

verification purposes. Manufacturing may use configurators for downloading the right

software on customer tailored embedded systems. After sales may check the sold

configuration and verify the compatibility of new installations or spare parts with the

current system.

Product configurators capture a lot of information related to engineering and

product pricing (Soininen et al., 1998). The relationships between parameters may be

very complicated and documenting these takes a lot of time and effort. Implementation

of project requires mapping the elements and their interactions. Creating a good

configuration depends on how good the map is. The map describes the selection route

from the requirements to the outcomes of configuration.

Configuration of complex products may include several sub-systems and have

various loops within the quotation process. In this paper, we analyse how design

structure matrix (DSM) could help planning product configuration modelling. The

remainder of this paper is as follows: firstly, basic types of product architectures are

introduced. Secondly, product-modelling techniques for configurations are reviewed

and feature-based configuration is presented with some examples. Thereafter, the use

of design structure matrices for configuration projects is discussed. Finally, the some

conclusions are drawn from DSM applications.

2. Product architectures

Product architecture is the way that functions are mapped to form a product (Ulrich,

1995). There are two generic types of product architectures, which are excluding each

other: these are integrated architecture and modular architecture. In the case of

modular architecture, each function is connected to a corresponding part, while in the

case of functional architecture; a part may have more than one function. A special case

of integrated architecture is adjustable architecture, which practically means that

there are controllable parameters that can affect the functionality of the product. For

instance, a PC computer is a flexible platform for various applications: the software

part adjusts the functionality of the machine. Products of modular architecture can be

combinations of the following types (Ulrich, 1995):

.

Slot. Components are connected with each other with an interface, which is not

necessarily interchangeable with other components. A car radio is a good

example of this: various radios can be installed in the slot. However, there are no

other components that could be mounted in the same slot.

.

Bus. Bus architecture is based on a standardized interface, which is common to

various parts. For example, the PCI bus in personal computers allows the

addition of modems, network cards, video card, etc. on the same type of rack.

.

Sectional. In sectional architecture, all interfaces are similar and there is no

common part where other parts would connect as in bus architecture. For

instance, SCSI interfaces in computers are connected to each other with a cable.

CD-drives, hard disks and other equipment can be in any sequence.

Modular architectures allow the flexibility for multi-purpose use. The cost efficiency

provided by a widely used platform is enhanced with modular structures (Meyer and

Lehnerd, 1997; Meyer and Utterback, 1993). All modular products are combinations

of these structures. However, there are also other ways to classify modular structures

(Yu et al., 1998). All modular architectures are connected to variant bill-of-materials

(BOM) when considering the modelling part of the process.

From the configuration point of view the product architecture describes how items

in BOM are connected with each other. A list of materials is a typical outcome of a

configuration process. The rules are given in the form of allowing and constraining

connections between items in some product configurators. These connections are very

similar to product architecture decisions.

3. Product modelling for variant products

Most of the product configurators are based on modelling variable BOM. This generic

BOM approach is used in many industries as a practical approach for implementation

of mass customization (Jiao et al., 2000). A product variant is a logical description of a

physical product. All derivative products can be described by product variants.

Variants have parameters, which make them different from other variants. For

instance, parameters for a car could include colour or engine type. There are several

commercial software packages available for creating product configurations. The

technical approaches for describing the rules are:

.

constraint based approach (Van Veen, 1992; Mailharro, 1998);

.

rules based approach; and

.

object-oriented approach (Ghatate et al., 2000).

Product description methods vary, but the general problem remains the same: the

configuration process should be designed in a way that customer selections do not

affect the previous selections. There are various techniques for describing product

variants. In this paper, we will briefly review:

.

BOM table;

.

logical tree; and

.

VAR-variant generator (Van Veen, 1992, p. 82).

3.1 Bill-of-materials table

BOM table is a tool for maintaining modular BOM. End products of the same kind can

be described by individual sequence of parameter values. According to this technique,

the table of BOMs consists of three major parameter types:

(1) Basic parameters. The same for all product variants {Lamp}.

(2) Variant parameter. Selection of several choices {Blue shade, black shade, white

shade}

(3) Option parameters. Choice type – yes/no {Shank}

Product

configuration

analysis

999

IMDS

106,7

1000

Basic parameters describe what basic structure will be used. Variant parameters

describe the selections within the basic structure. Option parameters are add-ons to

any product. The main difference between variant and option is that in order to specify

a product a value must be given for variant parameter, while the option value may be

nil. Variant parameter and option parameters are not depending on each other.

This type of configuration approach is limited. BOM table is able to support only

one-level BOM. In other words, there are no configurable sub-sets available. The lower

levels include a standardised structure, which cannot be effected by the higher-level

parameters. The use of this description method is suitable for the purpose where the

product is quite simple in terms of structure and the number of parameters is low. The

main benefit of this approach is that it is able to handle dependencies between

parameters and structural entities. The approach is also rather simple to learn.

3.2 Logical tree

Logical BOM-tree is another configuration approach. Logical diagram is a tree-based

description of BOM. This approach is beneficial when existing structures can be used

in creating new variations. In this method, logical nodes originating from Boolean

algebra are added into the structure. These nodes can be the following ones:

.

Product nodes (parts, components).

.

AND-nodes.

.

XOR-nodes.

.

Empty node (nil).

Product nodes are normal components, parts and items used in all traditional BOMs.

AND-nodes show which lower level trees are required for higher levels. In traditional

MRP-II software, pseudo-structures describe the same structure. XOR-nodes describe

the structures, where one must select one of the choices. An empty node does not have

any lower structures. It is used in cases where a XOR-node requires a lower level

structure. Figure 1 shows an example of using logical trees describing a table lamp.

Logical BOM-trees allow only item selection related choices. Use of descriptive

features that may affect several items are not allowed. By using this approach it is not

possible to use compatibility parameters such as “colour-red” that would change the

colour of all the parts that can be painted.

3.3 VAR-variant generator

A more advanced configuration approach is the VAR-variant generator. According to

this technique, all products can be described when the following conditions are met:

.

all parameters are independent of each other; and

.

product variants can be unambiguous if the parameter selection is made

accordingly.

BOM is described in a way that the main product X has specific lower level structures.

The lower level structure is not a standard item, but a set of parts, which have one or

more values. These sets are called clusters. Product X can be described by selecting one

expression of each cluster. The expression is selected according to a rule, which defines

the lower level parts (e.g. four doors in a car defines many lower level sub-structures).

Product

configuration

analysis

1001

Figure 1.

Table lamp as a logical

tree

VAR-variant generator is able to handle not only single level BOM, but multi-level

BOMs as well (Van Veen, 1992, p. 88).

VAR-variant generator is based on relational database and can be implemented

with about 15 database tables. The approach is flexible for complex product models,

but on the other hand maintaining models takes a longer time to learn. The drawback

of VAR-variant generator is that it is not able to handle complicated connections such

as equations or function based rules (e.g. wire needed ¼ 3*pi*r pwrð2ÞÞ:

4. Feature based configuration

Many product configurators are based on a relation database model which restricts the

flexibility of use. New object-oriented techniques allow complex relationships which

are not limited to analysis of BOM (Simons et al., 2002). Feature-based configuration is

an approach where a distinction between product features (speed, type, size, etc.) and

items (part1, part2, part3) is made. The product architecture is a different issue

compared to the list of features. By using feature-based configurator the user may give

inputs such as:

.

the product should cost less than $30,000; and

.

the speed should be at least 150 km/h.

These parameters affect many choices and narrow the number of selections. By

fine-tuning some more detailed features the BOM can be created.

4.1 Concepts

The product variants are defined in feature-based configuration as product families. Each

family is an independent data item; it does not share any information with other families.

The family is a top-level data item; it includes all information valid for that family.

IMDS

106,7

1002

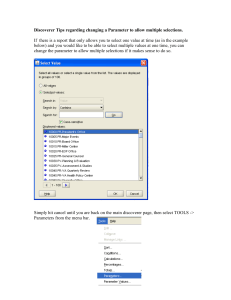

The configurable data is arranged for a family in tabs, for example, feature groups. The

tabs include the same type of information that the user would like to see as at the same

screen. If the product is very simple there is need for just one tab. In most of the cases it is

reasonable to group the selections in tabs that include 4-6 choices. The following picture

gives an example of a product family that is defined to configure a motorbike. The

configurator engine shows the structure of the family and the user can change the order of

tabs or parameters and organize the data so that it is most usable (Figure 2):

.

Product family. A group of similar occurrences is called a product family.

A product family is always on the highest level of BOM and thus cannot be a

component for another product.

.

Parameter. Parameter is in relation with only product family, not to an

individual end-product. A parameter may have values: colour, type.

.

Parameter value. Value is an occurrence of property in parameters; for instance,

values for parameter “colour”: black, blue, white. The value of parameters

describes the parameter-value combinations that are allowed: colour-black,

colour-white, type-standard, type-customised.

.

Attributes. Attribute is a property connected to family level, parameter, value,

item. An attribute tool can be used for describing compatibility between

selections (110 V or 2), consumption of resource (e.g. these options will take

1,000 W of power, the power supply can feed 1,200 W).

.

Rules. Rules define allowed or denied combination of two or more attributes,

parameter values, BOM items or variables.

A feature-based product configurator can translate the product model into configurator

user interface. Figure 3 shows an example of feature-based configuration. Product model

details are input by the product model administrator. The user interface can be

generated automatically from features or tailored for custom web design. Finally, sales

engineers and the purchaser of the product may see the result in their configurator tools.

4.2 The rules for the family

The rules define how the values for each parameter are displayed. In a simple case the

configurator is just used to manage the family structure and there is no need to make

complicated rules. In that case both of the rules, for features and options, are allowed as

default. The basic rule types are:

Figure 2.

Examples of configuration

structure

Product

configuration

analysis

1003

Figure 3.

Example of sales

configurator user interface

generated from product

model

.

.

.

deny a combination;

allow a combination; and

set value-based on a selection.

The setup of the rules depends on the number of restrictions the family might have.

In case most of the features are compatible, allowing combinations is the most

appropriate selection. If there is a situation where there are a lot of rules between the

parameters the denied model could be the case. Thus, if there are 200,000 variants and

just a few rules, one should use a deny type of model. And if there are hundreds of

possible variants and huge number of non-compatible constraints between the

parameters, then one should use the allowing type of model.

There may be two types of parameters: features and options. This enables you to

group the parameter to a group where there are a lot of correlations between the rules

and to a group where almost any option is valid. By making this analysis the product

modeller may decrease the number of required rules significantly.

The features are used when there are rules that define that, e.g. there should be

specific values for A and B to enable C to have certain values. In that case, C does not

IMDS

106,7

1004

Figure 4.

Example of configuration

selection paths

have any values before the engine administrator allows the values for C to be displayed

for the specific combination of the rules of A and B. Typically in this case the features

use the denied model and only the values that are especially enabled are displayed. If

there is a case where parameter C has hundreds of values and only a few of them are

possible on a specific combination of A and B, then it is easier to disable all the choices

and enable only the few that are available. The options are typically parameters that

can be used for every parameter combination. In case of the options you deny a specific

combination of parameter values.

Figure 4 shows the usage of features and options. All the possible values for the first

feature A are available. But only after selecting a1, a2, or a3 b1, b3 and b4 are available.

Then a combination of {(a1, b1), (a2, b2), . . . ,(a3, b3)} enables the values c1, c2, c3, c4, c5

and c6. In the engine we call the blue enables sources and green results targets. So there

is no value for parameter H if no predecessor has allowed values for the parameter.

In case of options the engine allows the denial of specific combinations. After

selecting value 3c in parameter 3 the user cannot select values 8d or 8j for parameter 8.

There can be relations between features and options as well. The above example denies

after selecting g2 the selection of 7a or 7c.

The product modeller should keep the rules as simple as possible and be sure to

check out the rule type for the selected parameters. There is no sense to allow

combination 6a ! 9b, because parameter 9 is type option and all the values are

allowed as default so the rule is useless. Feature-based configuration is a flexible

platform for building product models. Building a map of interactions between different

parameters and items takes the majority of time in any product configuration project.

5. Design structure matrix

DSM is an approach used for system analysis of decomposition and integration. DSM

is a square matrix showing interactions flow between elements. The elements may

present components of a product, phases of product development, people in

organisations or design parameters of a product (Browning, 2001; Smith and Eppinger,

1997). This method introduced by Steward (1981) has been used in many industrial

applications. The examples mentioned in the literature include design of automobiles,

design of jet engines and design of a microprocessor (Ulrich and Eppinger, 1994).

The main idea of DSM is to map the interactions into a matrix, where elements are

listed on the diagonal. Off-diagonal on the lower side represents information flow that

feeds the following elements; the upper side indicates that the element feeds something

back upstream. Figure 5 shows three basic types of relationship between configuration

elements A and B. The first type is a “parallel” relationship, where elements not

depending on each other may be processed separately. The second type is “sequential”

where element B depends from the input fed from element A. The last stereotype,

“coupled” refers to a set where elements depend on each other. A change in element B

has an effect back to A. This cyclic dependency is called “circuits”. In the configuration

context, the elements may be features describing the products, items that make BOM,

or related to variables which allow advanced calculation of configuration outcomes

(for example, weight and power consumption).

The use of DSM with configurations is two-fold. In one-level configurations, the

main objective is to sequence features in a way that first selection is the most

restrictive question, and the last questions are not having effect on those parameters

already input. There is a greater need for DSM in multi-level configurations where the

challenge is to capture the possible feedback loops and try to formulize

sub-configuration elements. There are several analytical approaches for organising

Product

configuration

analysis

1005

Figure 5.

Stereotypes of system

configurations

IMDS

106,7

1006

matrix. However, in many cases the matrix representation itself helps to re-organise

the feature questions in an applicable sequence. Rules describe the system element

interactions. The possible combinations include interactions between:

.

Features. Parameters and possible values, e.g. colour – green. Feature selections

may affect other features. For instance, all colours may not be available in every

size.

.

BOM. Items that describe the product architectures.

.

Variables. Outcomes of advanced calculations. E.g. weight of product, power

consumption of configured system, sales price or cost structure.

Figure 6 shows an example of DSM showing the elements and their dependencies on

the configuration model. Complex configuration models that include configuration in

several levels are challenged by the questions: how should one organise the

sub-configurations? Which feature selections are common to all configurations, which

features are connected to only one sub-system? Clustering of the DSM creates groups of

features, BOMs and variables that should be handled together. This kind of entity is a

clear sub-configuration. By using tearing and partitioning, the product modeller

smooths the actual configuration process by removing unnecessary feedback loops.

In order to demonstrate how a traditional process flow diagram may be converted to

a DSM matrix, consider the example shown in Figure 7. From the user point of view the

configuration process starts from the top. The sequence is pre-defined and there are

several incompatibilities between different selections, which could be

recommendations or denying. Figure 8 shows the same process described as DSM

presentation. At the upper side of the diagonal, the possible feedback loops in the

configuration process are visible and the feed-forward components are shown at the

lower side. The sequence of process elements could be adjusted manually or by using

advanced automatic clustering systems provided by many DSM software packages.

The result of the analysis can show potential time delays in the order-fulfilment

Figure 6.

Example of configuration

DSM showing interactions

for features, BOM and

variables (Problematics.

DSM software screenshot)

Product

configuration

analysis

1007

Figure 7.

Example of selection

dependencies in computer

server configuration

IMDS

106,7

1008

Figure 8.

DSM example of

configuration system

process from the sales engineering point of view and suggest improvements for the

product architecture as well.

6. Conclusions

The configuration projects are very important for today’s companies achieving

improved response. There is an obvious need to integrate the intra-organisational data

systems such as sales and production (Kumar and Meade, 2002), production planning

and purchasing (Rantala and Hilmola, 2005) as well as inter-organisational systems

such as supplier relationships and logistics (Tarn et al., 2002; Helo and Szekely, 2005).

The examples from high clock speed industries, such as electronics manufacturing,

have shown that the key issue in successful production management is to apply the

new technologies for processes as well (Helo, 2004). Seamless integration between

product engineering and supply chain management may be achieved by using

automated configuration systems. For this reason, systematic approaches are needed

to help managers build configuration processes. This paper has contributed on

suggesting the application of DSM methodology for designing this integration. These

methods may be used when companies are moving towards flexible structures and

agile virtual environments (Ma and Davidrajuh, 2005).

Feature-based configuration and other object-oriented techniques allow great

flexibility in creating product models. Because of these advances in software

engineering, the challenge of building models is no more a technical issue but an issue

of managing the configuration process. The process may incorporate different

companies and logistics operations such as production planning and supply chain

management (Helo and Szekely, 2005; Hsu and Chen, 2004). Configuration is typically

related to sales, but it has important links to engineering, too, such as product

design. The nature of selling technical products is iterative, several reviews are

required before the final configuration is frozen. The key requirements for a modern

configurator are:

.

.

.

flexible modelling features;

smooth configuration process with minimum number of feedbacks; and

easy to learn product modelling.

These requirements have a direct connection to strategic objectives such as profitable

variety management. The companies applying sales configuration tools are trying to

establish easily configured product models, which are fast, flexible and cost effective

for adjustments and modifications. Use of DSM may help in roll out of sales

configuration projects. DSM may also be used as a quick view to represent the

complexity of product configurability.

An analytical approach such as DSM should provide a more quantitative basis for

mass customization and product design strategies. The idea of mass customisation is

that a factory is able to produce one-of-a-kind products with high quality and fast

delivery with a low cost of mass production. The drivers enabling this are new

technological manufacturing applications and advances in designing procedures.

According to Pine (1993):

At its core is a tremendous increase in variety and customisation without a corresponding

increase in costs. At its limit, it is the mass production of individually customized goods and

services.

Use of a product configurator allows maintaining an extensive product variety without

remarkable reductions in productivity. Since, the beginning of the 1990s various mass

customisation applications have been presented (Anderson, 1997; Pine, 1993).

Design-for-manufacturing has become an important research area in product

development as well as the use of product platforms. Despite the innovations,

manufacturers are still balancing between time-to-market, product variety and unit-costs

(Tseng and Jiao, 1998). Tools for assessing the trade-off between these parameters are

required. In practice, the challenges are related to the management of the following issues

(Tseng and Jiao, 1998):

.

measurement and implications of reusability/commonality of parts and products

(Jiao and Tseng, 2000);

.

designing product platforms for cost-effective customisation; and

.

integrated product development for managing the during the product

life-cycle.

Contemporary mass-customisation tools such as product configurators are typically

built based on variable BOM, which are able to deal with technical constraints given in

rule tables. Product modelling techniques have been developed in engineering design

and industrial software design. The aim in engineering design has been to introduce

tools for modular architectures. One of the major challenges has been flexible designs

for manufacturing. Typically, this is derived by assumed market information,

technological constraints and manufacturing related constraints (Tseng and Jiao, 1998;

Yu et al., 1998).

DSM is a powerful approach providing help for product model builders to make a

map of interactions between features, BOM items, and design variables. By using

this kind of configuration sequence analysis, the end-user of the sales configurator

Product

configuration

analysis

1009

IMDS

106,7

should benefit from less complex user interfaces. Taking the production and

logistics into account in product design is a strategic insight. This results in more

powerful automated sales tools for industry and possibility for true mass

customization.

1010

References

Anderson, D.M. (1997), Agile Product Development for Mass Customization: How to Develop and

Deliver Products for Mass Customization, Niche Markets, JIT, Build-to-Order and Flexible

Manufacturing, Irwin Professional Publishing, Chicago, IL.

Browning, T.R. (2001), “Applying the design structure matrix to system decomposition and

integration problems: a review and new directions”, IEEE Transactions on Engineering

Management, Vol. 48 No. 3, pp. 292-306.

Franke, D. (1998), “Configuration research and commercial solutions”, AI EDAM (Artificial

Intelligence for Engineering Design, Analysis and Manufacturing), Special Issue on

Configuration Design, Vol. 12 No. 4, pp. 295-300.

Ghatate, B., Liemandt, J. and Price, A. (2000), “Flash configuration cache”, US Patent US6115547.

Helo, P. (2004), “Managing agility and productivity in the electronics industry”, Industrial

Management & Data Systems, Vol. 104 No. 7, pp. 567-77.

Helo, P. and Szekely, B. (2005), “Logistics information systems: an analysis of software solutions

for supply chain co-ordination”, Industrial Management & Data Systems, Vol. 105 No. 1,

pp. 5-18.

Hsu, L-L. and Chen, M. (2004), “Impacts of ERP systems on the integrated-interaction

performance of manufacturing and marketing”, Industrial Management & Data Systems,

Vol. 104 No. 1, pp. 42-55.

Jiao, J. and Tseng, M.M. (2000), “Understanding product family for mass customization by

developing commonality indices”, Journal of Engineering Design, Vol. 11 No. 3, pp. 225-43.

Jiao, J., Tseng, M.M., Ma, Q. and Zou, Y. (2000), “Generic bill of materials and operations for

high-variety production management”, Concurrent Engineering: Research and

Application, Vol. 8 No. 4, pp. 297-322.

Kumar, S. and Meade, D. (2002), “Has MRP run its course? A review of contemporary

developments in planning systems”, Industrial Management & Data Systems, Vol. 102

No. 8, pp. 453-62.

Ma, H. and Davidrajuh, R. (2005), “An iterative approach for distribution chain design in agile

virtual environment”, Industrial Management & Data Systems, Vol. 105 No. 6, pp. 815-34.

Mailharro, D. (1998), “A classification and constraint-based framework for configuration”,

AI EDAM (Artificial Intelligence for Engineering Design, Analysis and Manufacturing),

Special Issue on Configuration Design, Vol. 12 No. 4, pp. 383-97.

Meyer, M. and Lehnerd, A. (1997), The Power of Product Platforms, Building Value and Cost

Leadership, The Free Press, New York, NY.

Meyer, M. and Utterback, J. (1993), “The product family and the dynamics of core capability”,

Sloan Management Review, Vol. 34, pp. 29-47.

Pine, B.J. (1993), Mass Customization, Harvard Business School Press, Boston, MA.

Rantala, L. and Hilmola, O-P. (2005), “From manual to automated purchasing: case: middle-sized

telecom electronics manufacturing unit”, Industrial Management & Data Systems, Vol. 105

No. 8, pp. 1053-69.

Simons, P., Niemelä, I. and Soininen, T. (2002), “Extending and implementing the stable model

semantics”, Artificial Intelligence, Vol. 138 No. 2002, pp. 181-234.

Smith, R. and Eppinger, S.D. (1997), “Identifying controlling features of engineering design

iteration”, Management Science, Vol. 43 No. 3, pp. 276-93.

Soininen, T., Tiihonen, J., Männistö, T. and Sulonen, R. (1998), “Towards a general ontology of

configuration”, AI EDAM (Artificial Intelligence for Engineering Design, Analysis and

Manufacturing), Special Issue on Configuration Design, Vol. 12 No. 4, pp. 357-72.

Steward, D.V. (1981), “The design structure system: a method for managing the design of

complex systems”, IEEE Transactions on Engineering Management., Vol. 28 No. 3.

Tarn, M.J., Yen, D.C. and Beaumont, M. (2002), “Exploring the rationales for ERP and SCM

integration”, Industrial Management & Data Systems, Vol. 102 No. 1, pp. 26-34.

Tseng, M.M. and Jiao, J. (1998), “Concurrent design for mass customization”, Business Process

Management Journal, Vol. 4 No. 1, pp. 10-24.

Ulrich, K. (1995), “The role of product architecture in the manufacturing firm”, Research Policy,

Vol. 24 No. 1995, pp. 419-40.

Ulrich, K. and Eppinger, S. (1994), Product Design and Development, McGraw-Hill, New York,

NY.

Van Veen, E.A. (1992), Modelling Product Structures by Generic Bill-of-Materials, Elsevier Science

Publishers, Amsterdam.

Yu, J.S., Gonzalez-Zugasti, J.P. and Otto, K.N. (1998), “Product architecture definition based upon

customer demands”, Proceedings of 1998 DETC. 13-16 September, Atlanta.

Further reading

Davis, S.M. (1987), Future Perfect, Addison-Wesley, Reading, MA.

Krishnan, V., Eppinger, S.D. and Whitney, D.E. (1997), “A model-based framework to overlap

product development activities”, Management Science, Vol. 43 No. 4, pp. 437-51.

Corresponding author

P.T. Helo can be contacted at: petri.helo@uwasa.fi

To purchase reprints of this article please e-mail: reprints@emeraldinsight.com

Or visit our web site for further details: www.emeraldinsight.com/reprints

Product

configuration

analysis

1011

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.