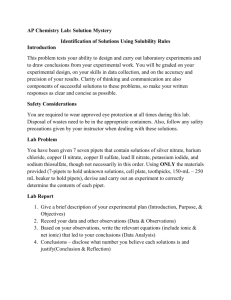

No-waste manual for Educational Institutions

advertisement