OCS Study BOEM 2014-611

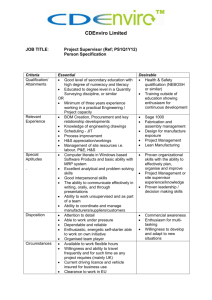

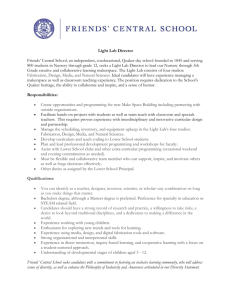

advertisement