X Process Costing

T o

4 p i i c

X

Process

Costing

LEARNING OUTCOMES

By the end of this topic, you should be able to:

1.

Discuss the differences between process costing and job order costing;

2.

Define the concept of equivalent unit in process costing;

3.

Prepare a Production Report using the Weighted Average method and the First In First Out (FIFO) method;

4.

Explain the effects of non-uniform manufacturing input increase and the existence of various production departments; and

5.

Prepare journal entries to account for the manufacturing costs.

X

INTRODUCTION

This topic discusses the process costing system. The process costing system is a costing system that is commonly used in industry that processes homogeneous products in sequence. Important concepts like physical unit and equivalent unit will be discussed first before discussing the Weighted Average method and First

In First Out (FIFO) method in detail. The final part of this topic discusses transferin cost.

4.1 FOREWORD

In Topic 3, we have discussed job order costing in depth. Besides job order costing, there is another system that is used to determine the cost of a product.

This system is called process costing system. It is more suitable for a production process that is sequential and for products that are homogeneous. Usually, when

TOPIC 4 PROCESS COSTING W 87 a product has to go through several processes in sequence, the process costing is used to account for the costs and calculate the cost per unit.

4.2 PROCESS COSTING ENVIRONMENT

The previous discussion touched on the suitability of process costing system. It also has to be stated that: x

Process costing is suitable for a product that uses constant resources, that is, the same resources used for each product unit. If the use of resources is not the same, then the job order costing is more suitable. x

Besides that, the products in process costing are produced in bulk such as in the chemical industry, food industry, petroleum industry, medical industry and others. For service firms, process costing is applied for large firms or firms that have large service chains such as banks, post offices, electricity, water supply and others.

A production process can be divided into two types. These two types of processing

Figure 4.1: Two types of production process

Sequential processing means that a product has to be completed in one process before it is transferred to the next production process, until it finally becomes a finished product.

88 X TOPIC 4 PROCESS COSTING

Example 4.1

A sequential processing example has the following scenario:

We take the example of a fried chicken where before the chicken is fried, it has to be cleaned properly, salt has to be applied, and then fried. These processes are called sequential processing because they must follow the sequence. It is not proper to fry the chicken before cleaning and applying salt to it.

Parallel processing means that more than one process is carried out simultaneously and they are united to become one final process in the end to produce the finished product.

Parallel costing can also be seen as sequential costing if we see it from another angle.

Example 4.2

As an example, processes 1, 2 and 3 are in the same channel (channel 1), whereas processes 4, 5 and 6 are in another channel (channel B). Channels

A and B can operate simultaneously.

However, as an example, process 2 cannot be started as long as process 1 is not completed. Thus, we can see that there is also a sequential process in a parallel production process. Regardless of the type of production process, the more important condition required for a costing system to be used is that there is a use of constant resources and that the products produced are the same.

A simple example of parallel processing is the preparation of food for a wedding feast. In this scenario, we take two processes going on simultaneously, that is preparing the ingredients and frying the chicken.

These two processes go on simultaneously (in parallel), but finally they are joined together into one last process, that is, cooking in the pot.

TOPIC 4 PROCESS COSTING W 89

4.3 DIFFERENCES BETWEEN PROCESS COSTING

AND JOB ORDER COSTING

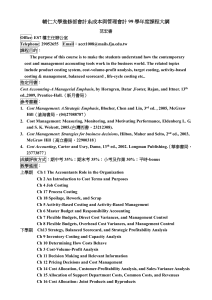

This section gives the differences between process costing and job order costing in a more organised form. Table 4.1 shows four main features of process costing and their differences from job order costing.

Table 4.1: The Four Main Features of Process Costing and

Their Differences from Job order Costing

Process Costing Job Order Costing

Products are of the same type and are uniform.

The products are of various types and forms.

Process costing involves production on a large scale and in large quantities.

Job order costing involves small quantity products and is based on customer orders.

The goods produced have to go through various levels of processing before various levels of processing and the cost becoming finished goods and the cost of

The product does not have to go through of the product is calculated when the the finished goods is based on the cost at the final processing. product is completed.

The report of the costs involved is made using the Production Report.

Each process will be carried out by a particular department resulting in cost to be accounted for according to the department, and based on the process carried out.

Relatively, process costing requires less resources in order to be carried out as compared to job order costing because we do not need to record the costs involved for each product such as that done in job order costing. It is sufficient to just record the cost according to the production department.

Job order costing reports its cost using the Job Cost Sheet.

SELF-CHECK 4.1

You have studied both process costing and job order costing. Now think of the main features that are different between these two costing systems.

90 X TOPIC 4 PROCESS COSTING

4.4 PRODUCTION COST FLOW OF PROCESS

COSTING

Figure 4.2 shows the production cost flow of process costing

Figure 4.2: Production cost flow of process costing

Based on Figure 4.2, the production inputs which consist of direct material, direct labour and manufacturing overhead will be used in each sequential production process. However, for each process, the input can be put in at different stages. As an example, perhaps in Process B, raw materials are only put in at the final stage before it is transferred to Process C. If this occurs, as long as the product is not completed in Process B, the raw materials will not be put in. Finally, this will have a particular effect on the calculation of the cost per unit. This matter will be discussed in detail in this topic.

4.5 WORK IN PROCESS ACCOUNT FOR EACH

PROCESS

In the earlier section of this topic, it was mentioned that process costing has to go through several processes. To explain the matter more clearly, especially in the context of accumulating and calculating cost, we shall use this illustration:

Figure 4.3: Cost flow of the product

TOPIC 4 PROCESS COSTING W 91

The Figure 4.3 shows the cost flow of the product and how it has to go through three processing levels, namely, Process A, Process B and Process C.

(a) The product has to pass through Process A, where the total cost incurred in

Process A consists of direct raw materials cost, direct labour cost and manufacturing overhead cost. These costs will be put into an account known as the Work in Process A account. At the end of the process, the accumulated costs will be transferred to the Work in Process B account;

(b) In Process B, the total costs from process A will be added to the total direct materials cost, direct labour cost and manufacturing overhead cost incurred in Process B. At the end of Process B, the same thing will be done, that is, the total costs incurred in Processes A and B will be transferred to process

C; and

(c) Finally, once all the costs are transferred to Process C, they are added to the costs incurred at Process C to become the whole total cost of the final product.

4.6 JOURNAL ENTRIES TO RECORD COST

FLOW IN PROCESS COSTING

Table 4.2 shows the journal entries that are involved for transactions or activities connected with process costing.

Table 4.2: Journal entries

Recording for purchase of Direct Material

Materials Inventory

Debit (RM) Credit (RM) xxx

xxx

Recording of Productions Costs Incurred in Process A Debit (RM) Credit (RM)

Work in Process A Inventory

Direct Raw Materials xxx xxx

Salaries Payable

Manufacturing Overhead

Recording of Transfer of Cost from Process A to

Process B

Work in Process B Inventory

Work in Process A Inventory xxx

Debit (RM) xxx xxx

Credit (RM)

xxx

92 X TOPIC 4 PROCESS COSTING

Recording of Productions Costs Incurred in Process B Debit (RM) Credit (RM)

Work in Process B Inventory xxx

Direct Raw Materials xxx

Salaries Payable

Manufacturing Overhead xxx

xxx

Recording of Transfer of Cost from Process B to

Process C

Work in Process C Inventory

Work in Process B Inventory

Debit (RM) Credit (RM) xxx

xxx

Recording of Productions Costs Incurred in Process C Debit (RM) Credit (RM)

Work in Process C Inventory xxx

Salaries Payable

Manufacturing Overhead

Recording of Transfer of Cost from Process C to

Finished Goods

Finished Goods Inventory

Debit (RM) xxx xxx xxx

Credit (RM)

Work in Process C Inventory

Recording of Sales Revenue and Cost of Goods Sold

Cash/Accounts Receivable

xxx

Debit (RM) xxx

Credit (RM)

Cost of Goods Sold

Finished Goods Inventory xxx xxx

4.7 CONCEPT OF EQUIVALENT UNIT

Now that we have understood the process costing environment, the next section will discuss process costing in more detail. Let us begin with the concept of equivalent unit.

TOPIC 4 PROCESS COSTING W 93

Example 4.3

Imagine the following scenario:

While doing your studies at OUM, you took several courses for each semester. Say that one day, you were given an assignment that contained 5 questions by one of your lecturers.

You could only complete 3 questions because you were short of time and you were only studying part-time. You had 2 questions more that you could only partially-complete. In this matter, the equivalent unit for the process of completing the assignment is only 4 questions, that is, 3 fully completed questions added with 2 more partially-completed questions. It is hoped that this illustration gives you a simple idea of equivalent unit which is a very important element in discussing the topic of process costing.

The cost determination in process costing is made at the end of the period and in actual production conditions as not all goods processed will be fully completed.

Thus, it is necessary to compute the equivalent unit so that the product cost per unit, whether fully or partially completed, can be calculated accurately. In process costing, the equivalent unit is the finished unit that is produced with the resources allocated. The calculation is simple whereby the percentage of completion is used to get the equivalent unit.

The eequivalent unit is the completed unit that is produced with the available resources allocated.

Example 4.4

As an example, suppose that there are 3,000 units of a product processed by a production department, but only 2,000 units are completed while 1,000 units more are categorised as partially completed with a 25% percentage of completion. Thus, the equivalent unit is 2,250 units [2,000 + (25% x 1,000 units)].

This means that the resources allocated for producing 3,000 units have 2,000 units fully completed and 1,000 partially completed with a 25 percentage of completion. If these resources were focused only on producing finished goods, only 2,250 finished goods would be produced. The physical units in the example are 3,000 units, namely, the units seen physically regardless of whether they are completed or not.

Suppose the resources used by the department is RM27,000. In this case we cannot say that the production cost for one unit of product is RM9.00

(RM27,000/3,000 units). This is because the product consists of two

94 X TOPIC 4 PROCESS COSTING components, that is, one that is fully completely and one that is partially completed. Thus, it is more suitable to divide the RM27,000 with the equivalent unit of 2,250 to get RM12.00 per unit. From here, the cost of the finished product that is transferred to the finished goods inventory account is

RM24,000 (RM12 x 2,000 units). The balance of RM3,000 (RM12 x 250 units) will be accounted for as work in process.

The ending work in process in the current period will become the beginning work in process in the next period if we intend to complete the partiallycompleted product. From here, we can see that the computation of the equivalent unit is very important in process costing.

SELF-CHECK 4.2

What do you understand by the term equivalent unit? Why is the concept considered important in determining the cost in process costing?

4.8 METHODS OF DEALING WITH BEGINNING

WORK IN PROCESS

There are two methods that can be used to calculate the product cost per unit in the beginning Work in Process inventory that is continued in the current period. method. This is illustrated in Figure 4.3.

Figure 4.3: Two methods of dealing with beginning work in process

TOPIC 4 PROCESS COSTING W 95

(a) Weighted Average Method previous period to the costs incurred in the current period to calculate the product cost per unit for units that are transferred out and units that remain as ending inventory in the department at the end of a period. The costs are accumulated again and only one average cost per unit is calculated.

The second method is the first in-first out (FIFO) method.

The ffirst in first out method separates the costs incurred in the previous period from the costs incurred in the current period. This method also separates the units in the beginning inventory from the units processed in the current period. It assumes that the units in the beginning inventory will be processed and transferred out before the units in the current period are started.

In short, the FIFO method calculates in detail the costs involved in the previous period and in the current period. We will discuss these two methods by using examples so that they are clearer and easier to understand.

4.9 WEIGHTED

We will discuss the use of the Weighted Average method using the example below:

Example 4.5

Muizuddin Berhad is a company that produces a product known as Comele that goes through processes in two departments, that is, the Mixing

Department and the Bottling Department. The following is the information taken from the Mixing Department for the month of October 2010.

96 X TOPIC 4 PROCESS COSTING

Production:

Units in process, 1 October 2010, 75% completed

Units started

Units completed and transferred out

Units in process, 21 October 2010, 25% completed

40,000

80,000

100,000

20,000

Cost:

Work in process, 1 October 2010 Direct materials RM5,000

Conversion cost RM2,000

Costs added throughout October 2010 Direct materials RM17,050

Conversion cost RM3,250

It is assumed here that direct labour and overhead (conversion cost) is incurred uniformly throughout the production process. There are times in different situations, as mentioned before, that the direct materials may be put in at the beginning of the process or the end of the process. If this occurs, then the computation of the equivalent unit for the direct materials will differ depending on when they are put into the production process.

As an example, if the direct materials are added at the beginning of the period, then the computation of the equivalent unit for the direct materials in the ending Work in Process inventory is 100% even though the product is not completed. This is because, in terms of the direct materials, it is 100% completed and only the overhead cost has not been incurred fully. On the other hand, if the direct materials are put in only at the end of the process, then the equivalent unit of the direct materials in the ending Work in Process inventory will be zero because as long as the product is not completed, the direct materials will not be put in.

Based on this example, the cost of the beginning work in process consists of two components. The first is RM7,000 (direct materials RM5,000 and conversion cost RM2,000) that was incurred in September 2010 and carried onto October 2008 by the ending inventory of September 2010. The second component is a cost amounting to RM20,300 (direct materials RM17,050 and conversion cost RM3,250) incurred in the current period (October 2010).

According the weighted average method, the two cost components will be added together to get RM27,300. Then it is divided by the equivalent unit to obtain the equivalent unit cost per unit.

Before this can be done, the equivalent unit has to be calculated. The calculation of the equivalent unit for example 4.5 is as shown below:

TOPIC 4 PROCESS COSTING W 97

Beginning inventory

Units started and completed

Ending inventory, 25% completed

40,000

60,000 (100,000 40,000)

5,000

Total 105,000 units

Thus the equivalent unit cost per unit is RM0.26 (RM27,300/105,000 units).

Of the cost of RM27,300, RM26,000 (RM0.26 u

100,000 units) will be allocated to the units completed and transferred out, and the remainder amounting to

RM1,300 (RM0.26 u

5,000 units) will be allocated to the ending inventory.

Based on Example 4.5, we can prepare a Production Report for the month of

October 2010.

Muizuddin Berhad

Production Report Weighted Average Method

Mixing Department for the Month of October 2010

QUANTITY SCHEDULE

Units to be Accounted for

Units in Beginning Work in Process

Units started

Units to be Accounted for

Physical unit

40,000

80,000

120,000

Units Accounted for

Units Completed

Units in Ending Work in Process

Units Accounted for

COST SCHEDULE

Cost to be Accounted for

Cost of Beginning Work in Process

Current Cost Incurred

Total Cost to be Accounted for

Equivalent Unit Cost Per Unit

100,000

20,000

120,000

Total Cost

(RM)

7,000

20,300

27,300

RM0.26

Equivalent unit

Direct

Material

Cost (RM)

Conversion

Cost (RM)

100,000

5,000

100,000

5,000

105,000 105,000

Direct

Material

Cost (RM)

Conversion

Cost (RM)

5,000

17,050

22,050

RM0.21

2,000

3,250

5,250

RM0.05

98 X TOPIC 4 PROCESS COSTING

Cost Accounted for

Units Completed and Transferred

(100,000 x RM0.26)

Ending Work in Process:

Raw Materials (5,000 x RM0.21)

Conversion Cost

(5,000 x RM0.50)

Total Accounted for

Transfer

Out Cost

(RM)

Cost of

Ending

Work in

Process

(RM)

26,000

Total (RM)

26,000

26,000

1,050

250

1,300

1,050

27,300

250

4.10

FIRST IN FIRST OUT (FIFO) METHOD

Basing on the same example, that is, Muizuddin Berhad, this time we will use the

FIFO method to calculate the equivalent unit. The calculation is as follows:

Example 4.6

Beginning inventory

Units started and completed

Ending inventory, 25% completed

10,000

60,000 (100,000 40,000)

5,000

Total 75,000 units

The most distinct difference in calculating the equivalent unit using the FIFO method is in the calculation of the equivalent unit for the beginning inventory.

According to the FIFO method, the equivalent unit for the beginning inventory is calculated based on the effort needed in October to make the beginning inventory carried forward from September complete.

In this example, as the beginning inventory is only 75% completed, therefore

25% is yet to be completed. So, to calculate the equivalent unit, the beginning inventory units of 40,000 units is multiplied by 25%, making the equivalent unit to be 10,000 units. The rationale behind this calculation is because according to the FIFO method, the cost of production for the current period has to be separated from the cost incurred in the previous period. Thus, the beginning inventory needs to be separated from the units in the current period. The part of the beginning inventory that is not completed (in our

TOPIC 4 PROCESS COSTING W 99 example, it is 75%) can be considered as the units of the current period because it is completed in the current period, and incurs cost in the current period.

Based on this example, the Production Report will be as follows:

Muizuddin Berhad

Production Report FIFO Method

Mixing Department for the Month of October 2010

QUANTITY SCHEDULE

Physical unit

Units to be Accounted for

Units in Beginning Work in Process

Units started

40,000

80,000

Units to be accounted for

Units accounted for

COST SCHEDULE

120,000

Equivalent unit

Units Accounted for

Direct

Material Cost

Conversion

Cost (RM)

Units started and completed 60,000

Units completed from Beginning

60,000

40,000 10,000 10,000

Work in Process

(RM)

60,000

Units in Ending Work in Process 20,000 5,000 5,000

120,000 75,000 75,000

Cost to be Accounted For

Cost of Beginning Work in Process

Current cost incurred

Total cost to be accounted for

Total Cost

(RM)

7,000

20,300

27,300

Direct

Material Cost

(RM)

5,000

17,050

22,050

Conversion

Cost

(RM)

2,000

3,250

5,250

Equivalent Unit Cost Per Unit

Cost Accounted for

Units in Beginning Work in Process:

From previous period

From current period

(10,000 u

RM0.27)

Units started and completed

(60,000 u

RM0.27)

RM0.27

Transfer

Out Cost

(RM)

7,000

2,700

RM0.23

Cost of Ending

Work in

Process (RM)

16,200

RM0.04

Total

(RM)

7,000

2,700

16,200

100 X TOPIC 4 PROCESS COSTING

Ending work in process:

(5,000 u

RM0.27)

Total Cost to be Accounted For 25,900

1,350

1,350

1,350

27,250

Please note that when calculating the cost of the equivalent units according to the FIFO method, only the cost of the current period is taken into account. For example, to calculate the cost per equivalent unit of raw materials, only

RM17,050 is taken to be divided by 75,000 units. This gives the cost per equivalent unit as RM0.23. The practice is logical as the calculation of the equivalent unit also disregards the beginning inventory unit. Only additional work done to complete the beginning inventory is calculated (0.25 u

40,000 =

10,000 units). Thus, it is logical that the cost that is taken into account is only up to that of in the current period.

The second distinct difference is in the cost allocation to the completed units and the incomplete units. In this case, the units that are transferred out will consist of two components, which are, units from the beginning inventory that are completed in the current period and units that are started and completed in the current period.

In this example, 100,000 units that are transferred out consist of 40,000 units from the beginning inventory units and the remaining 60,000 units are from the units started and completed in the current period. From the 40,000 beginning inventory units, there are also two cost components involved. The first component is the cost that is carried forward from September amounting to RM7,000. The second cost component is the cost that is added from October to make the beginning inventory fully complete. This amount is RM2,700.

Finally, we can see that the total cost accounted for here is only RM27,250, while the cost to be accounted for is RM27,300. The difference of RM50 is caused by rounding error and it can be overcome simply by adjusting the figures and made as the transferred-out cost.

Thus, it can be said here that there are two distinct differences between the weighted average method and the FIFO method.

(a) The first difference is in the calculation of the equivalent unit for the beginning inventory, followed by the calculation of the equivalent unit cost per unit.

(b) The second difference is in the allocation of cost for the units transferred out and for the units remaining at the end of a period.

TOPIC 4 PROCESS COSTING W 101

According to FIFO, a clear separation must be made to identify the source from where the completed units are transferred out. This means that from the total units transferred out, it is necessary to identify how many units are from the beginning inventory and how many units are from the units started and completed in the current period. This identification is important because the cost per unit for each category is not the same. The difference, if looked at from a macro view, is logical because the production input in the current period always has a higher cost than the input in the previous period, partly as a result of inflation.

4.11 TRANSFER-IN COST

Our discussion thus far has only focused on one production department only.

This section will discuss the situation whereby we receive materials for processing from a previous department. If this situation occurs, the issue of cost transferred in will be involved. Transfer-in cost is the cost that has been incurred in a previous department and that will be transferred into your department for the purpose of continuing the next process. If this situation occurs, the implication that arises is that we only have to add one more space in the

Production Report known as the ttransfer-in column.

From another angle, the cost in the transfer-in column can also be seen as the raw materials column of the department receiving the final product from the department before it. However, if the receiving department is going to add more raw materials, then another column for direct materials must be set up to account for the raw materials added to the department. Besides this, before calculating the units to be accounted for, the relationship of the units that are transferred in from the previous department has to be given due attention. At the same time when calculating the equivalent unit and the cost per unit for the transfer-in category, any differences that exist must be given attention.

ACTIVITY 4.1

What will happen to the cost calculation if two departments are involved? Think for a moment. How would you account for the cost received from a previous department into your department?

To explain this transfer-in cost, we look at an illustration that involves two departments the Processing Department and the Canning Department. To make it easier to understand, we use the weighted average method (Example 4.7).

102 X TOPIC 4 PROCESS COSTING

Example 4.7

Hafizuddin Berhad produces paint with the brand name Juta. The company uses the process costing system in its calculation of production cost. The production process of Juta has to pass through two departments, the

Processing Department and the Canning Department.

The following is the data on the companyÊs operation in both departments for the month of September 2010.

Canning Department

Units in Beginning

Inventory

2,400 units (100% completed for direct material; 40% completed for conversion cost

3,400 units (100% completed for direct material; 70% completed for conversion cost

Cost of Beginning

Inventory:

Direct Material

Conversion Cost

RM5,050

RM5,520

RM9,000

RM8,980

Cost of Previous

Department

Units Started

RM28,312

Units in Ending

Inventory

15,400

1,400 (100% completed for material; 80% completed for conversion cost

?

600 units (100% completed for material;

50% completed for conversion cost

Current Cost:

Direct Materials RM35,356 RM40,104

Conversion Cost RM87,336 RM69,800

Based on Example 4.7, we will prepare a Production Report using the weighted average method for both departments, namely the Processing

Department and the Canning Departments. The Production Report for the

Processing Department is as a recap of what we have studied earlier on. The transfer-in cost will be shown when we prepare the Production Report for the

Canning Department, that is, the department that receives the finished product from the Processing Department to be made into its raw materials.

TOPIC 4 PROCESS COSTING W 103

The Production Reports for the Processing Department and the Canning

Department for the month of September 2008 will look like the following:

Hafizuddin Berhad

Production Report

Processing Department for the Month of September 2010

QUANTITY SCHEDULE

Physical unit

Units to be Accounted For

Units in Beginning WIP

Units Started

2,400

15,400

Units to be Accounted For 17,800

Units Accounted For

Units Completed

Units in Ending WIP

Units Accounted For

COST SCHEDULE

Cost to be Accounted For

Cost of Beginning WIP

Current Cost Incurred

Total Cost to be Accounted For

Equivalent Unit Cost Per Unit

Cost Accounted For

16,400

1,400

17,800

Total Cost

(RM)

10,570

122,692

133,262

RM7.57

Transfer

Out Cost

(RM)

Equivalent unit

Direct Material

Cost (RM)

Conversion

Cost (RM)

16,400

1,400

16,400

1,120

17,800 17,520

Direct

Material

Cost (RM)

5,050

35,356

40,406

Conversion

Cost (RM)

5,520

87,336

92,856

RM2.27

Cost of

Ending WIP

(RM)

RM5.30

Total

(RM)

Units Completed and

Transferred

(16,400 units u

RM7.57)

Ending WIP:

DRM (1,400 units u

RM2.27)

Conversion Cost

(1,120 units u

RM5.30)

Total Accounted For

124,148 124,148

124,148

3,178

9,114

3,178

5,936 5,936

133,262

104 X TOPIC 4 PROCESS COSTING

Hafizuddin Berhad

Production Report

Canning Department for the Month of September 2010

QUANTITY SCHEDULE

Units to be Accounted For

Units in Beginning WIP

Units Started

Units to be Accounted For

Physical

unit

3,400

16,400

19,800

Units Accounted For

Units Completed 19,200

Units in Ending WIP 600

Units Accounted For 19,800

COST SCHEDULE

Cost to be Accounted For

Cost of Beginning WIP

Current Cost Incurred

Total Cost to be Accounted

For

Equivalent Unit Cost Per Unit

Cost Accounted For

Total Cost

(RM)

46,292

234,052

Units

Equivalent unit

Direct

Transferred in

Material

Cost

(RM)

Conversion

Cost (RM)

19,200

600

19,200

600

19,200

300

19,800 19,800 19,500

Transfer-

In Cost

28,312

124,148

Direct

Material

Cost (RM)

9,000

40,140

Conversion

Cost (RM)

8,980

69,800

280,344 152,460 49,104 78,780

RM14.22

Transfer Out

Cost (RM)

RM7.70

RM2.48

RM4.04

Cost of Ending

WIP (RM)

Total (RM)

Units Completed and

Transferred (19,200 units u

RM14.22)

Ending WIP:

Transfer-In Cost

(600 units u

RM7.70)

DRM (600 units x RM2.48)

Conversion Cost

(300 units u

RM4.04)

Total Accounted For

273,024 273,024

273,024

1,488

7,320

1,488

280,344

TOPIC 4 PROCESS COSTING W 105

4.12 JOURNAL ENTRIES

This section will discuss how journal entries concerning transactions in the

Processing Department and the Canning Department are recorded.

Journal entries for the Processing Department are as follows:

Debit (RM) Credit (RM)

Work in Process Inventory

Processing Department

122,692

Salaries Payable

Manufacturing Overhead

(Record cost when it is entered into the

Processing Department)

Work in Process Inventory

Canning Department

Work in Process Inventory

Processing Department

(Record Transfer-Out Cost from

Processing Department to Canning

Department)

87,336

124,148

124,148

106 X TOPIC 4 PROCESS COSTING

Whereas journal entries for the Canning Department are as follows:

Work in Process Inventory

Processing Department

Materials

Salaries Payable

Manufacturing Overhead

(Record cost when it is entered into the

Canning Department)

Work in Process Inventory

Finished Goods

Work in Process Inventory

Canning Department

(Records Transfer-Out Cost from

Canning Department to Finished

Goods)

Debit (RM)

109,904

273,024

Credit (RM)

40,104

69,800

273,024

TOPIC 4 PROCESS COSTING W 107

To test your understanding, do the following exercise.

EXERCISE 4.1

The following is the data of process A in the manufacturing of product X at the end of March 2010. All materials are put in at the beginning of the process, whereas labour and manufacturing overhead is added uniformly throughout the production process.

Beginning Work in Process

16,000 units incurring cost:

(1 March 2010) Direct Material

Direct Labour

Manufacturing Overhead

Units started in March

Cost of materials added in March

RM 16,000

RM 13,200

RM 9,600

172,000 units

RM 190,800

Cost of labour added in March

Manufacturing overhead cost added in March

RM 205,200

RM 172,400

Units completed and transferred out to Process B

Ending Work In Process, 31 March 2010

180,000 units

8,000 units, completed

You are required to:

Calculate the following:

(a) Equivalent unit for direct labour and conversion cost.

(b) Cost per unit of the direct materials, conversion cost and cost of units completed transferred out to process B.

(c) Transfer-out cost and the cost of ending work in process.

108 X TOPIC 4 PROCESS COSTING x

This topic discusses another system that is used to determine the cost that called process costing system and suitable for production process that is sequential and products that are homogeneous.

x A production process can be dividing into sequential processing and parallel processing.

x The production inputs consist of direct material, direct labour and manufacturing overhead will be used in each sequential production.

x

In process costing, the equivalent unit is the finished unit that is produced with the resources allocated.

x

Two methods used to calculate the product cost per unit are weighted average method and first in-first out method (FIFO).

x

FIFO method calculates in detail costs involved in the previous period and in the current period. Where by, the weighted average method will add the cost incurred in the previous period to the cost incurred in the current period.

Conversion cost

Equivalent unit

First in first out method

Journal enteries

Parallel processing

Production report

Sequential processing

Transfer-in cost

Transfer-out cost

Weighted average method