Engineering Economics

advertisement

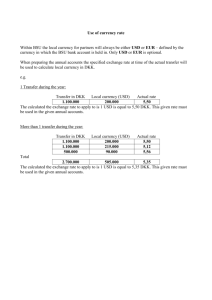

Case studies Engineering Economics Aage U. Michelsen ISBN 978-87-89359-30-4 Aage U. Michelsen : Virksomhedsøkonomi for Ingeniørstudierne 26. udgave 2015 Udgiver : Bodano Publishing & Communication ApS Copyright © Bodano 2015 Bodano Publishing & Communication ApS Postboks 63 3060 Espergærde Telefon : 38 74 78 76 E-mail : case@bodano.dk 2 Foreword This collection of case studies is designed to be used as educational material in the teaching of business economics to engineering students. Many engineering students are primarily interested in the technical disciplines and perceive “economics” as uninteresting and more or less irrelevant to the solution of technical problems. A main objective of this collection of case studies is to illustrate that in business, the economic dimension is highly relevant in the resolution of the vast majority of technical problems. By presenting the economic problems in a technical context, it is hoped that a greater number of engineering students will become interested in economic studies and see the relevance of this. An emphasis has been placed on making the cases realistic, in that they reflect concrete problems faced by the companies. At the same time, it has been necessary to simplify some of the problems to make them suitable for educational use. In ­addition, some of the numerical values have been changed for reasons of confidentiality. Most numerical values, however, have the proper order of magnitude. Proposed solutions have been prepared for the numerical problems in the cases, designed to complement textbook theories and models. Some cases also contain discussion portions, which include keywords or keyword-like phrases. In addition, because the case studies are based on concrete business situations, they can provide the basis for broader discussions - for example, regarding the given assumptions and the consequences of alternative assumptions. The author extends a sincere thanks to the employees of the companies that have contributed to the preparation of the case studies. Without their involvement, many of the realistic aspects would have been missing. 3 With respect to the next edition, we welcome comments about the level of difficulty of the problems and selection of topics. These comments should be directed to the book’s author : Master of Science in Engineering Aage U. Michelsen Aage.U.Michelsen@gmail.com 4 Table of Contents CaseSolution Danfoss Manufacturing Capacity Constraints 842 Disa Reduction of energy costs 1145 Energinet Social benefits of investment in a Great Belt power link 1648 H. Lundbeck A/S Insourcing – Made Possible by the Reduction of Production Costs 2051 MT Højgaard A/S Inclusion of Project Earnings in the Company’s Consolidated Financial Statement 25 54 A/S Storebælt Annuities with Different Payment-Interval Lengths 3157 Velux A/S Calculations with the Introduction of New Technology for Windows 5 3661 6 Cases 7 CASE: Danfoss Manufacturing Capacity Constraints Danfoss is a global corporation with 58 sales companies in 46 counties and ap­proximately 400 resellers and distributors worldwide. Danfoss’ corporate head­ quarters is located in Denmark. With approximately 24,000 employees, an annual revenue of 34.4 billion DKK, and an export market share of 98 %, Danfoss is one of the leading and largest industrial companies in its field. Danfoss produces cooling automation, industrial automation, frequency c­ onverters, comfort automation (e.g. radiator thermostats), automatic controls for remote heat­ ing plants, components for oil burners, thermostats for refrigerators and freezers, compressors for air conditioners, and hydraulics for agricultural and construction machinery. Danfoss has 59 modern factories in 18 countries, at which are produced approxi­ mately 250,000 components per day. In this case study, one of Danfoss’ production departments has been simplified, so as to consist of two main areas of capability : a turning department and a milling department. In the production department, two main product types are produced : A and B. Production data for the two product types are shown in table 1. Working Time (hours/unit) Product Selling Price (DKK/unit) Turning Dept. Milling Dept. Material Usage (DKK/unit) A 530 0.5 0.5 205 B 640 0.8 0.4 248 Table 1 : Production data for the product types A and B. 8 As Postgraduate you help Canada win on efficiently cooled ice Danfoss is looking for candidates to the Danfoss Postgraduate Program. We offer positions within Research & Development, Supply Chain, Sales & Marketing and Finance. Join us to build a better tomorrow. We are Danfoss. We are Engineering Tomorrow. facebook.com/DanfossCareers youtube.com/user/DanfossGroup twitter.com/danfosscareers 4 business critical project assignments form the Postgraduate Program. linkedin.com/company/danfoss CASE: Danfoss The variable costs for salaries, etc. are 150 DKK/hour and 180 DKK/hour in the turning and milling departments respectively. It is assumed that the capacities in the next month are 1,000 and 800 hours in the turning and milling departments respectively. PS .: In reality, the numerical values of the capacities are of course much larger, but the use of the small numerical values in this example aims to illustrate an overview and does not change the fundamental problem. Question 1 What is the maximum contribution margin earned in this production department in the next month ? Due to production problems at a subcontractor, it has been determined that there will only be enough materials to produce 800 units of product type A in the next month, while there will be sufficient materials for product type B. Question 2 What is the maximum contribution margin that can now be earned in the next month ? It now appears that a foreign supplier can deliver additional materials for the ­production of product type A. The price for these materials, however, will be h ­ igher than the 205 DKK per unit listed in table 1. Question 3 What should the maximum price for these additional materials be, if it is to be ­profitable to import them ? Please find the solution on page 42. 10 CASE: Disa Reduction of energy costs DISA in Hoeje Taastrup produces molding equipment, mainly DISAMATIC® ­machines, which are automatic molding machines for the production and handling of sand molds in foundries. The DISAMATIC® concept is based on a patent from the 1960s, acquired by Professor Vagn Aage Jeppesen, DTU. The idea of the patent was to change the traditional casting of metal in h ­ orizontal box molds to casting in vertical box-less sand molds. This idea - followed by intense product development and the use of modern production techniques - has made DISAMATIC® a world market leader in the field of mass-produced castings. In addition to Denmark, DISA has production facilities in the Czech Republic, India and China. In addition, DISA has built up an extensive network of agents in more than 50 countries. DISA has a long tradition of innovation, reliability and commitment in order to increase the competitiveness of its customers. As a result, DISA today experiences the trust and loyalty of leading foundries worldwide. DISA is part of the Norican Group, which also includes Wheelabrator. Like so many other companies, DISA has been considering moving production to a low-wage country, but DISA found that for reasons of product development, it was desirable to maintain a share of their production in Denmark. In close ­collaboration with production, product development is gaining valuable experience and knowledge, which is of great importance for further product development. For ­production to be continued in Denmark, it was necessary for production costs to be ­significantly reduced. DISA therefore launched a major project to have a contractor build a new head­ quarters for DISA’s future production and administration on a site in Hoeje Taastrup. DISA had previously been housed in buildings in Herlev, but these buildings were more than 50 years old, so they had become obsolete. By building a new 11 CASE: Disa factory, it was possible to design buildings exactly adapted to DISA’s work p ­ rocesses in a reduced total area (half of the original size). In the business case, objectives were established to reduce the costs of energy consumption, operation and m ­ aintenance and rent by about 7.5 million DKK/year. Subsequently, it has been found that DISA was successful in reducing these costs by more than 10 million DKK/year, due in large part to extraordinarily large savings in energy costs. The subsequent assignment deals with two of the many projects that were implemented in order to reduce energy costs : • Reduction of the cost of lighting in production facilities. • Reduction of heating costs. In the production facilities in Herlev, halogen lamps were used for lighting, but these were replaced by LED lamps in the new factory. Table 1 shows data for the two types of lamps. Halogen LED 450 200 Energy consumption (Watts) 160 160 Burning time (hours/year) Number of lamps (no.) 6,240 6,240 Price (DKK per Lamp) 1,220 3,360 Lifetime (hours) 2,000 15,000 Table 1 : Data for halogen lamps and LED lamps It is assumed that the prices quoted for both lamp types include installation. The price of 1 kWh is assumed to be 1.00 DKK. Question 1 How much was the annual cost of energy consumption reduced when halogen lamps were replaced with LED lamps ? When assessing the cost of lighting by the two lamp types, it is also relevant to consider the cost of the lamps. Question 2 How much was the annual cost of lamps reduced when halogen lamps were replaced with LED lamps ? 12 CASE: Disa The economic assessment of the two lamp types in the following question 3 should now also take into account that the amount of investment in the two lamp types is different. It can be assumed that the average working capital is calculated as half of the lamps’ price and that DISA uses a discount rate basis of 15 % per annum. Question 3 What is the main reason why lighting costs were reduced by the transition from halogen to LED : • The lamps’ energy consumption • The lamps’ lifetime and price • The return on the capital invested in the lamps ? When calculating a result based on given assumptions, it is often useful to conduct a sensitivity analysis : how sensitive is the result to changes in the assumptions. An example of this is investigated in question 4 : the influence that burning time has on the result. In the above, it is assumed that the lights are turned on for 6,240 hours/year. This means that work takes place in a 3-shift operation (i.e., for 24 hours a day) for 260 days a year. In a company that only works in two shifts, the lamps are only turned on for 2/3 of the time, i.e. in 2/3 ∙ 6,240 = 4,160 hours per year. Question 4 How will the three types of costs calculated in question 3 change if the lamps are only turned on for 4,160 hours a year ? The following question 5 deals with the cost of heating. It was the reduction of these costs that was the largest contributor to the reduction in energy costs f­ ollowing the relocation from Herlev to Taastrup. This reduction was mainly because the b ­ uildings in Taastrup are much more energy efficient and designed for DISA’s needs. Costs were also reduced because the former factory in Herlev was heated by an older oil heater, while the new factory in Taastrup is heated by district heating. Data for the heating of the two factories is shown in table 2. 13 CASE: Disa Herlev Oil consumption (L/year) Taastrup 680,000 Oil price (DKK/L) 7.70 District heating (MWh/year) 805 District heating price (DKK/kWh) 1.00 Area (m ) 2 26,000 13,000 Table 2 : Data on heating and space in Herlev and Taastrup. Question 5 The buildings in Taastrup are more energy efficient and they are heated by district heating. By what percentage have these two conditions - in your opinion - reduced the costs for heating in Taastrup ? Please find the solution on page 45. 14 CASE: Disa DISA is leading for sustainability Join DISA in Shaping the Industry DISA is a world-leading supplier of complete foundry solutions and services. Our World-Class Technology Center in Taastrup is founded on innovation and sustainability. We continuously strive to shape the industry through leading solutions, global teamwork and speed. We help our customer profile themselves as environmentally responsible foundries to sharpening their competitive edge. Join our World-Class Technology Center and help the foundry industry become more sustainable. If you want to be a part of our global team, please contact our HR department DISA Industries A/S, Højager 8, DK-2630 Taastrup T: +45 44 50 50 50 E: disa.industries@disagroup.com www.disagroup.com 15 Norican Group is the parent company of DISA and Wheelabrator. CASE: Energinet Social benefits of investment in a Great Belt power link Energinet.dk manages the interests of society when Denmark is to be supplied with electricity and natural gas. They own the energy motorways and are responsible for ensuring fair competition in the market for electricity and natural gas for the benefit of consumers. Energinet.dk : • Ensures that there is always power in electrical outlets and gas in gas taps • Ensures the supply of gas as North Sea production subsides, and further develops the future gas system with more renewable energy • Develops future energy systems that can handle significantly more renewable energy, especially from wind turbines, including the integration of electricity and gas in synergy • Ensures well-functioning markets for electricity and gas - competitive and transparent prices • Provides funding for environmentally friendly electricity and cogeneration Energinet.dk is an independent public enterprise owned by the Danish Ministry of Climate, Energy and Building with 850 dedicated and highly skilled employees. Based on the values of business orientation, development, responsibility and commitment, they constantly emphasize organizational and personal development. The company is headquartered in Erritsoe near Fredericia and has locations in Ballerup, Stenlille, Egtved, Lille Torup, Tjele and Vester Hassing. The company has a turnover of approximately 10 billion DKK annually. The company works with many different interest organizations both within and outside of Denmark. The following assignment is based on the initial consideration of whether – as part of the further development of the electricity market – there should be built a Great Belt power link of 600 MW, so that East and West could be electrically connected. Such a decision required considerable consideration, and as a means to facilitate the decision-making process, business cases were used to illustrate the benefits and 16 CASE: Energinet costs of the project. Parts of such business cases illustrate the social benefits and costs of a particular project. The project became a reality and the link was completed in 2010. In the following assignment, imagine that you were employed as a planner in ­Energinet.dk and that you had been asked to calculate the economic ­consequences of the Great Belt power link of 600 MW as described above. The project was ­scheduled to start in early 2007, and the link should be ready for operation in early 2010. Costs for procurement, construction and commissioning of the technical ­components : cable purchase, laying of cable, expansion of substations etc. were estimated to amount to 820 million DKK in 2007, 400 million DKK in 2008 and 150 million DKK in 2009. The life of the link was estimated to be 20 years, starting in 2010 and ending in 2029. For simplicity reasons, it is assumed that there are the following four different types of benefits of the Great Belt power link : 1. Operational benefit Operational benefit is an expression of the value of increased trade and thus allows for more optimal dispatching of electricity among generating units with lower total cost of production as a result. Operational benefit was estimated to be 33 million DKK annually. 2. The benefit of sharing reserves A Great Belt power link allows for the sharing of electricity reserves between East and West Denmark. This allows the total Danish demand for reserves to be reduced, providing an estimated cost reduction of 90 million DKK annually. 3. The benefit of potential synergies in regulating This is the benefit of potential synergies in regulating power by equalizing ­imbalances between the two regions. The cost reduction resulting from synergies was estimated to be 10 million DKK annually. 4. The benefit of better market functioning This is the benefit of better market functioning by reducing the possibility of abuse of market dominance. This reduces the so-called deadweight losses, since ­competition will increase. The gain from such improvements was estimated to be 31 million DKK annually. 17 CASE: Energinet Operating cost is a maintenance cost that should be expected each year. It was ­estimated that it would cost 12 million DKK annually to maintain the power link. Once the link was put into operation, there would be electrical losses on the network, which was estimated to be 12 million DKK annually. All annual amounts of the costs, savings, gains and benefits were assigned to the end of the year and an interest rate of 6 % per year was used. Question 1 What was - established at the beginning of the year 2010 - the total social surplus or deficit from the Great Belt power link ? Energinet.dk estimated that there was a risk that the project could be delayed a year, so the link would first become operational in early 2011. In this case, it was expected that in the year 2010, additional construction costs would amount to 50 million DKK. The link’s life was still projected to be 20 years from the start of ­operations. Question 2 If the project was delayed in this way, what would then - calculated at the beginning of the year 2010 – be the total social surplus or deficit from the Great Belt power link ? It is often discussed what demands should be placed on the return of public investments. Question 3 What is the answer to question 2, if an interest rate of 5 % per year instead of 6 % per year is used ? The values of the four benefit values used in the solution of question 1 are all subject to uncertainty, especially the value of the reduction in market dominance. The Board of Energinet.dk therefore considered the following question : Question 4 If the assumptions underlying question 1 are taken to be valid, how much should the value of the reduction of market dominance be changed, such that the social benefit of the project will be equal to 0 DKK ? Please find the solution on page 48. 18 På de fleste arbejdspladser venter medarbejderne på mulighederne Hos os er det stik modsat Vi søger stærkstrømsingeniører, der vil være med til at forbinde energi og mennesker Energinet.dk varetager samfundets interesser, når Danmark skal forsynes med el og naturgas. Vi ejer energiens motorveje og har ansvaret for at skabe fair konkurrence på markedet for el og gas til gavn for forbrugerne. Vi er en selvstændig offentlig virksomhed med 850 engagerede og fagligt højt uddannede medarbejdere. CASE: H. Lundbeck A/S Insourcing – Made Possible by the Reduction of Production Costs Lundbeck is a Danish research-based pharmaceutical company that develops and manufactures products for the treatment of central nervous system disorders. Lundbeck is one of the world’s leading companies within this field. In 2014, the company had a total revenue of 13.5 billion DKK. Lundbeck currently employs approximately 5,700 employees in 57 countries, of which 2,000 are based in Denmark. Lundbeck’s ambition is to be a growth company, both financially and p ­ rofessionally. Financial growth is considered to be a basic prerequisite for the continued development of the company and its employees. To bring Lundbeck into a new growth period, it is necessary that future expenditures are carefully considered. The company must utilize its resources optimally in the coming years to maintain and develop its professional standard, so Lundbeck continues to be the ideal workplace for highly skilled employees. The idea behind outsourcing is that companies should concentrate on tasks for which their core competencies are utilized, while secondary tasks should be given to subcontractors, who are specialists in performing such tasks. Particularly since the 1990s, many Danish companies have increasingly outsourced their p ­ roduction activities. This was also the case for Lundbeck, which in 2004 had outsourced nearly 70 % of its finished goods production. In 2006, however, Lundbeck d ­ ecided to focus on developing the best supply chain in the pharmaceutical industry. L ­ undbeck therefore launched a series of lean projects, which showed that it was possible to achieve such significant productivity improvements that it became profitable to insource production tasks that were previously outsourced. This case study deals with two of the implemented lean projects. 20 CASE: H. Lundbeck A/S The following questions 1 and 2 relate to some considerations made prior to the start of a project that aimed to investigate whether it would be profitable to convert a packaging line. The packaging line in question was constructed 5 years ago, and the investment in the line was then at 20 million DKK. The packaging line is now expected to have a remaining life of 5 years. With the current production, 4 million finished product packages containing ampoules are packed per year. Ampoules are small glass bottles approximately 3 cm. in length containing liquid. The ampoules can be broken at the top, so the liquid can be drawn into a syringe, which is then given by injection to patients. Finished goods production consists of loading the ampoules into cardboard boxes with inserts. This production occupies the packaging line in the two shifts that are working on it. The project aimed partly to increase the productivity of the finished product pack with ampoules and to convert the packaging line, so it would be possible to utilize the freed-up capacity for packaging drop containers. Drop containers are also small glass bottles containing liquid, but the drops are taken orally by the patient. A pipette is incorporated into the container’s lid for measuring the dosage. The finished goods production consists of affixing a label to the drop container, after which it is packed into a cardboard box with an instruction manual. A few years ago, the packaging of drop containers was outsourced to a subcontractor that packages 3 million drop containers per year. With the current production, the OEE1 on the packaging line is 40 %, but it is expected that the OEE can be increased to 60 % by implementing the lean p ­ roject. This increase must be achieved through improvement suggestions from ­employees. On the packaging line, the packaging time for a finished product pack containing ampoules is 50 % greater than the packaging time for a drop container. Question 1 If the packaging line’s OEE is increased from 40 % to 60 %, what proportion of the outsourced packaging of the drop containers would it be possible to insource, using the freed-up capacity ? It is estimated that the investment in the above modification of the packaging line will be 7 million DKK. Furthermore, it is estimated that the increase in production resulting from the increased OEE would subsequently increase costs for operation and maintenance of the packaging line by 1 million DKK per year. OEE (Overall Equipment Effectiveness) indicates the percentage of the current production output out of the possible output at 100 % efficiency. 1 21 CASE: H. Lundbeck A/S The payment to the subcontractor to which the packaging of the drop containers is outsourced is 1.50 DKK per pack. Transportation costs to and from the subcontractor is 250,000 DKK per year. In addition, there will be a reduction of 350,000 DKK per year for transportation of finished goods if the packaging of the drop containers is insourced. A discount rate of 10 % per year is used. Question 2 Would you recommend that Lundbeck implements the conversion of the p ­ ackaging line, or that Lundbeck continues to produce only the finished product packs of ampoules on the packaging line ? The following questions 3, 4, and 5 deal with another of Lundbeck’s packaging lines. On this line, it was possible to package about 40 million blister cards in 2005. Production here is quantified in the number of blister cards – and not the number of completed product packs – as a completed product pack may contain from 1 to 10 blister cards. The costs are estimated to be : • Fixed costs on the packaging line = 3.0 million DKK/year • Salary costs = 1.5 million DKK/year • Variable costs = 750 DKK per 10,000 blister cards It was considered to outsource the packaging process to a subcontractor, who would perform the packaging for 1,500 DKK per 10,000 blister cards. Additional costs for transportation and administration would be 500,000 DKK per year. Question 3 Would it be profitable to outsource the packaging to the subcontractor in q ­ uestion ? Before the decision on outsourcing was made, Lundbeck implemented a project to determine whether productivity of its packaging line could be increased so much that it would be profitable for Lundbeck to continue to do the packaging. Twenty different products were packaged on the packaging line, and the project was ­specifically focused on reducing changeover times, using the thinking and approach of SMED2. SMED (Single Minute Exchange of Dies), developed by the Japanese Shiego Shingo, aims to ensure that all changeovers must be able to be performed in under 10 minutes. 2 22 CASE: H. Lundbeck A/S It is assumed that the fixed costs of the packaging line will not change as a result of the increased production. Labor costs are also expected to remain the same, as working hours will not change. Question 4 How many blister cards per year must it be possible to package on the line, if it is to be profitable for Lundbeck to perform the packaging ? In light of the above, Lundbeck decided to continue to do the packaging them­selves, and carried out a number of lean projects in order to increase the capacity of the packaging line. These projects led to very significant productivity improvements, as illustrated in table 1, which shows the completed production in the period 2005-2011. Year 2005 2006 2007 2008 2009 2010 2011 Production 40.0 45.9 49.7 60.5 70.0 84.0 92.2 Table 1 : Annual production (in millions of packaged blister cards) in the period 2005-2011. Question 5 What is the future value at the end of 2011 because Lundbeck did the packaging themselves rather than outsourcing it to the subcontractor ? Is this value an expression of the gain Lundbeck realized during the project ? Please find the solution on page 51. 24 CASE: MT Højgaard A/S Inclusion of Project Earnings in the Company’s Consolidated Financial Statement MT Højgaard aims to be the most productive company in the building and construction industry. In 2014, the company realized a turnover of 7 billion Danish Kroner and employed an average of about 4,000 employees. MT Højgaard is organized into a number of business units and subsidiaries within facilities & concrete, commercial and residential construction, high rises, ­renovation, as well as offshore & steel bridges. A small part of the company’s ­activities take place outside of Denmark. In support of its production, the company has created a number of corporate staff functions called Production Support, ­Purchasing, Customers & Markets, Work Environment & Quality, BIM / VDC, and Design & Engineering. All units are independent profit or cost centers with their own budget and accounting. MT Højgaard’s corporate result is composed of the sum of the profits generated in the business units and subsidiaries, minus the costs of the corporate staff f­ unctions. MT Højgaard submits quarterly consolidated financial statements to the stock exchange, and the consolidated financial statements provide the basis for external stakeholders’ to assess the company’s ability to manage an economically profitable business. Until a few years ago, MT Højgaard used the accounting principle called the completed contract method. In this method, the results from a project in a business unit or subsidiary were included in the consolidated financial statement when the developer had received the finished project. 25 CASE: MT Højgaard A/S • The advantage of the completed contract method was that at the time of a ­project’s inclusion, there was no uncertainty about the project’s results. All necessary information appeared in the accounting. • The disadvantage was, conversely, that the completed contract method does not necessarily give a true picture of MT Højgaard’s ability to operate a p ­ rofitable business. The reason was that major projects that extended over several years were only first included in the accounting in the financial year in which they were completed. This meant that in a year with few completed projects, the company could show a loss, while in a year with many completed projects, the company could end up with an excessive profit. As with other major construction companies, MT Højgaard therefore changed to use the long-term contract method, in which the results of all projects are accounted for on an ongoing and pro rata basis, based on the projects’ degree of completion. The following data is included in the calculation of the pro rata result : A : The expected revenue from the developer B : The expected project result C : The posted project costs D : The project’s degree of completion E : The realized project result The expected project result, B, is calculated as the difference between the expected revenue, A, and the expected project costs. It is therefore true that : A – B = the expected project costs The project’s degree of completion is calculated based on the posted project costs at any given time : D = C/(A – B) The realized project result, E, is calculated as the degree of completion’s proportion of the total expected project result : E=D∙B An example with numerical values to illustrate the method shown : A : 100 million DKK B : 20 million DKK C : 40 million DKK 26 CASE: MT Højgaard A/S D : 40 / (100 – 20) = 0.50 E : 0.50 ∙ 20 = 10 million DKK In this example, half of the expected project costs are incurred and posted (D = 0.50), so half of the expected project result (E = 10 million DKK) can be included in the financial statement. The advantage of using the long-term contract method is that it gives a more ­accurate picture of MT Højgaard’s current ability to generate profits. The disadvantage is, conversely, that there is now a requirement that a project manager must always know his project’s expected financial results quite precisely. If he does not, the method is misleading. An example project is shown in table 1. The amounts are in thousands of Danish Kroner. Expectations per year Year 1 Year 2 Year 3 100,000 100,000 100,000 1) Total revenue 2) Total project result 20,000 20,000 20,000 Interim financial statement for Year 1 Year 2 Year 3 3) Posted costs 20,000 20,000 40,000 4) Degree of complation 5) Project result Year 1 Year 2 Year 3 Accumulated financial statement 6) Posted costs 7) Project result Table 1 : Example 1 of a project process. Explanation of table 1 : 1) and 2) indicate the expectations of, respectively, the total revenue and the overall project result the project manager in this case has had at the end of each of the three years. 3) indicates the costs which are posted in each of the three years. Question 1 What numerical values must be in rows 4), 5), 6), and 7) ? 27 CASE: MT Højgaard A/S Has the project manager in this case had control of the project economy ? The construction industry traditionally operates with quite a modest profit margin, which is why it is of paramount importance that the project manager has control over costs. Question 2 By what percentage would the realized project result in year 3 have been greater if the project manager was able to reduce the costs in year 3 by 5 % ? Another example project is shown in table 2. The amounts are in thousands of Danish Kroner. Expectations per year Year 1 Year 2 Year 3 100,000 100,000 100,000 1) Total revenue 2) Total project result 20,000 10,000 -5,000 Interim financial statement for Year 1 Year 2 Year 3 3) Posted costs 20,000 25,000 60,000 4) Degree of complation 5) Project result Year 1 Year 2 Year 3 Accumulated financial statement 6) Posted costs 7) Project result Table 2 : Example 2 of a project process. Question 3 Question 3.1 What has the project manager’s estimate of the total costs in table 2 been at the end of each of the three years ? Question 3.2 What could be the reasons that the assessment of the cost has evolved in this way through the project ? Question 3.2 What project result would have been realized in this project process in each of the three years ? 28 My tasks vary throughout the entire construction process. In collaboration with the architect, I currently work on ensuring the durability of the supporting structures at the New Psychiatric Department in Vejle. Merdzan Ismaili, Design Engineer Read more at mth.com Follow us on Facebook, LinkedIn and Twitter CASE: MT Højgaard A/S Question 3.3 If the project manager already at the beginning of year 1 had foreseen how the project costs would evolve, could the project’s results have been recognized in a more accurate way ? Could there be other benefits of early detection of a bad project economy ? Please find the solution on page 54. 30 CASE: A/S Storebælt Annuities with Different Payment-Interval Lengths The Great Belt Fixed Link is an essential part of many Danes’ journeys when they travel between the eastern and western parts of the country. A total of 11,361,421 vehicles drove over the bridge in 2014, and the average daily traffic was 31,128 vehicles. By comparison, in 1997, the last full year of ferry o ­ perations, ­approximately 8,300 vehicles were transported across the Great Belt daily. Rail traffic has also benefited greatly from the fixed link. An average of 145 trains ­crossed the Great Belt each day in 2014, versus 40-45 before the bridge opened. The link’s societal importance requires that both road and railway across the Great Belt is open around the clock - all year round. A/S Storebælt is responsible for o ­ rganizing the operation, so that travelers experience a fast, flexible, and safe ­transportation option between the eastern and western parts of the country. The Great Belt Fixed Link is designed for a service life of 100 years, but with timely implementation of necessary maintenance, the basic concrete and steel construction can ensure a lifetime of well over 100 years. For A/S Storebælts’ ­operations organi­ zation, it is therefore essential to have good access to all concrete and steel surfaces, so regular inspections can be carried out and necessary repairs u ­ ndertaken in a timely manner, without inconveniencing travelers. The operations organization’s needs were only accommodated to a limited extent when the link was constructed, and A/S Storebælt has therefore had to subsequently develop and acquire several different platform solutions. The following exercise deals with considerations on the choice of a platform for the inspection and maintenance of the west bridge’s two concrete box girders. The west bridge has a total of 128 bridge spans, supported by 126 bridge pilings and two abutments. The bridge spans’ concrete is given a routine inspection every two years. 31 CASE: A/S Storebælt A general inspection is carried out every six years, and this replaces the routine inspection that year. Every year, an inspection of the two bridge bearings found on each bridge piling is also conducted. The final choice was between two platforms that are conceptually very different : Type A : I n principle, a traditional scaffold which is mounted on vehicles on the top of the bridge. Type B : I n principle, a reversed tower crane, which is suspended from a trolley ­placed on rails which are mounted on the underside of the bridge. Data for the two types are shown in table 1. The last row in table 1 includes the cost of moving type A from one side of the bridge to the other. Question 1 What is the cost for each of the two types of platforms for implementing a general inspection, a routine inspection of the concrete, and an inspection of the bridge bearings ? An annuity is a series of payments with equal time intervals between the individual payments. If the payments are equal, it is known as a constant annuity. Question 2 How can the costs of inspection of concrete and bridge bearings for each type of platform be described by three different constant annuities ? 32 CASE: A/S Storebælt Type A Type B Investment (millions of DKK) : Supporting construction 18 20 7 10 Supporting construction 50 50 Equipment (electrical, hydraulics, etc.) 25 25 Supporting construction *) 1,5 % 1 % Equipment (electrical, hydraulics, etc.)*) 2,5 % 2,5 % 2 2 3 2 Inspection time for general inspection (hours/span) 1,75 2,50 Inspection time for routine inspection (hours/span) 0,7 1,0 1 1 1,5 1,5 Operator 300 300 Inspector 600 600 2 0 250.000 0 Equipment (electrical, hydraulics, etc.) Lifetime (years) : Maintenance costs (DKK/year) : Number of operators for operation of platform Concrete inspection : Number of inspectors Bridge bearings inspection : Number of inspectors Inspection time (hours/bridge piling) Payroll costs (DKK/hour) Time spent crossing the bridge pilings (hours/bridge piling) Cost for moving between road and rail girders (DKK) Table 1 : Data for the two platforms *) The costs are indicated as a percentage of the investment amount The time between two consecutive annuity payments is called the “payment ­interval.” The net present value, NPV, of a constant annuity – as we know – can be calculated as : NPV = a ∙ [1 – (1 + i)-n]/i, where : i = the interest rate per payment interval. n = the number of payment intervals. A/S Storebælt uses a discount rate of 7 % per year. 33 CASE: A/S Storebælt Question 3 If the annuity payment interval is 2 years or 6 years, what is then A/S Storebælt’s discount rate per payment interval in these two cases ? Question 4 Which of the two types of platforms would you recommend that A/S Storebælt acquires ? Please find the solution on page 57. 34 We bring Denmark together Why not join our team? One moment I’m out inspecting the Storebælt Bridge. The next, I’m sitting at my desk. My work challenges me both professionally and physically. I like this variety in my working day. Martin Duus Hansen Operations Manager, Construction Structural Engineer, Steel Sund & Bælt will be recruiting engineers for construction, operation and maintenance work over the next few years – one of them could be you. At Sund & Bælt, you will enjoy a career of professional challenges and freedom with responsibility. Great colleagues and ongoing training are also part of the package. Read more about your future career here: www.sundogbaelt.dk Sund & Bælt’s most important objective is to make travelling easier. Customers use our traffic facilities every day, i.e. the Storebælt link, the Øresund motorway and the Øresund rail line with associated stations as well as the ports at Odden, Ebeltoft, Spodsbjerg and Tårs. We are also undertaking the planning work for a fixed link across the Fehmarn­ belt with associated Danish landworks. Moreover, we own BroBizz A/S, which offers comprehensive electronic payment for driving on toll roads in Scandinavia and Austria. CASE: Velux A/S Calculations with the Introduction of New Technology for Windows For more than 70 years, the VELUX Group has created better housing for people worldwide by bringing daylight and fresh air through the roof. Our product portfolio consists of both skylights and skylight modules, as well as a wide range of decoration and sun-screening products, roller shutters, installation products, and intelligent remote controls. These are products that contribute to a healthy indoor environment and sustainable solutions - for playing and learning, working, and pleasure. With sales offices and factories in more than 40 countries, we operate globally and have approximately 10,000 employees worldwide. The VELUX Group is owned by VKR Holding A/S, a foundation and family owned limited liability company. You can read more at www.velux.com. Engineers in the VELUX Group typically work with product development, manufacturing, logistics, testing, and quality, or in administrative support functions. Many development projects are undertaken in collaboration with colleagues in the VELUX Group’s global organization and with Danish and foreign partners. Introduction of new technology Over the years, many different window pane variants have been developed, to be able to offer customers a variety of features such as better insulation properties, sun protection, and laminated glass. A new technology now makes it possible to put a coating on the window pane which resists the adhesion of dirt and debris, giving the window a self-cleaning effect in the rain. 36 CASE: Velux A/S The VELUX Group sales subsidiaries around the world see great value in being able to offer this coating to their customers, and studies have shown that customers are willing to pay extra for this feature. Technologically, it is possible to apply this coating to the window panes, if in cooperation with the glass supplier 10 million DKK is invested in new equipment. This investment is to be borne by the VELUX Group. In addition, the raw materials for the finished window will be 15 DKK more expensive. When the window with the new coating is mounted in the frame, it must be handled more carefully and requires additional quality control before and after this process. This means that labor costs will increase by 12 DKK per window. Calculation for a normal window without the new coating Materials 800 DKK 57.1 % Salary 200 DKK 14.3 % Additional costs 100 DKK 7.1 % 40 DKK 2.9 % Cost price 1,140 DKK 81.4 % Sales costs 100 DKK 7.1 % Marketing 90 DKK 6.4 % Profit 70 DKK 5.0 % 1,400 DKK 100.0 % Depreciation and interest Selling price The sales of windows are assumed to be 200,000 units per year, and a discount rate of 7 % per annum is used. Question 1 If the investment in the new equipment is to be financed and depreciated over two years, how much would this increase the line item “depreciation and interest” in the above calculation ? Question 2 If the VELUX Group wishes to continue to have a profit margin of 5 %, by how much should the selling price of a window be increased as a result of the new coating ? Based on market research, the sales subsidiaries raise the selling price of the windows with the new coating by 45 DKK. Based on the answer to question 2, it is shown that this will result in a reduction in the profit margin per window for the VELUX Group. 37 CASE: Velux A/S Question 3 Can a reduction in the profit margin per window be perceived as an indication that the investment in the new technology is not profitable ? Question 4 Calculate the profitability of the investment in the new technology if the investment shall accrue interest and be paid off over a five year period. Question 5 What is the minimum amount by which the selling price can be increased, in order for the investment to be profitable over a five year period ? Please find the solution on page 61. 38 I’m proud of working for a company that was sustainable even before the term was invented Bringing light to life... That’s what the VELUX Group is all about. In more than one sense. Our products create healthy indoor environments. And our workplace gives people the chance to grow. velux.com/careers CASE: Velux A/S 40 CASE: Velux A/S solutions 41 Solution: Danfoss Manufacturing Capacity Constraints Solution question 1 With next month’s production volumes of product types A and B designated as x and y respectively, the capacity constraints can be expressed as : 0.5 ∙ x + 0.8 ∙ y ≤ 1,000 (turning department) 0.5 ∙ x + 0.4 ∙ y ≤ 800 (milling department) By rewriting these two equations for the capacity constraints, we obtain : y = -0.625 ∙ x + 1,250 (turning department) y = -1.25 ∙ x + 2,000 (milling department) These two limiting lines are plotted in figure 1. y 2.000 Milling Dept. 1.250 Turning Dept. 0 x 0 1.600 2.000 Figure 1 : Limiting lines for the capacity of the two production departments. The shaded area in figure 1 indicates the available production possibilities, that is, the technical possibilities. The task is now to find the optimal option from among these possibilities. The criterion is “maximizing the contribution margin”. The contribution margins (CM = sales - cost of materials – salary costs) for the two product types are : 42 Solution: Danfoss CMA = 530 – 205 – (0.5 ∙ 150 + 0.5 ∙ 180) = 160 DKK/unit. CMB = 640 – 248 – (0.8 ∙ 150 + 0.4 ∙ 180) = 200 DKK/unit. The total CM can be expressed as : CM = CMA ∙ x + CMB ∙ y A total contribution margin of K DKK/month can be achieved by the combination possibilities of x and y that satisfy the condition : K = 160 ∙ x + 200 ∙ y This line is known as the iso-CM-line, as “iso” means “same”, and exactly the same CM is obtained at all points along the line. By rewriting the equation, we get : y = -0.8 ∙ x + K1 From among the technical possibilities (the shaded area in figure 1), the option which achieves the greatest CM can be found for a given value of K1 by plotting a line in figure 1 and the parallel displacement of this line as much as the constraints allow. Since the size of the slope coefficient on the CM line lies between the sizes of the slope coefficients of the two limiting lines, the greatest CM is obtained where these two lines intersect. The greatest CM can be found by solving two equations with two unknowns : y = -0.625 ∙ x + 1,250 y = -1.25 ∙ x + 2,000 This gives us : x1 = 1,200 units/month y1 = 500 units/month The greatest CM which can be generated is as follows : CMmax = 160 ∙ 1,200 + 200 ∙ 500 = 292,000 DKK Solution question 2 The material shortage results in a new limiting line : x = 800 units/month. The maximum CM is now obtained where this limiting line intersects the limiting line for turning capacity. The intersection point of these two lines is : (x2, y2) = (800, 750) 43 Solution: Danfoss From which we now get : CMmax = 160 ∙ 800 + 200 ∙ 750 = 278,000 DKK/month. The material limitation leads to a reduction in the CM of : ∆CM = 292,000 – 278,000 = 14,000 DKK/month. Solution question 3 Referring to the solution for question 1, CM can generally be expressed as : CM = 160 ∙ x + 200 ∙ y The acquisition of additional materials for the production of product type A will maximize the CM by constantly moving down the limiting line for the turning capacity. The relationship between x and y can therefore be expressed as : y = -0.625 ∙ x + 1,250 Inserting this context into the CM equation, we get : CM = 35 ∙ x + 250,000 DKK/month. (Check - as a control - if this is in accordance with the solutions to questions 1 and 2!). Increasing x thus gives a growth in the CM of : dCM/dx = 35 DKK/unit. Marginal CM expresses the “added value” (also called “shadow price”) by increasing x by one unit. This means that the additional price for materials for product A shall not exceed = limit CM = 35 DKK/unit of A. Since the limit CM is constant, it can – if the incremental price is <35 DKK /unit of A – be worthwhile to import materials to increase production, until the limit of the milling capacity is reached, i.e. for the production that is calculated in the solution of question 1. If the additional cost of materials is = 35 DKK/unit of A, then the CM is not ­increased by the import of additional materials. This can be illustrated by the fact that the marginal CM for product type A with this additional cost is = 160 – 35 = 125 DKK/unit. The slope of the CM line becomes in this case = -125 / 200 = -0.625. The CM line now has the same slope as the limiting line for the turning capacity. Thus, the CM is not changed now by moving up or down this limitation. 44 Solution: Disa Reduction of energy costs Solution question 1 Annual costs for energy consumption : Halogen : 450/1,000 ∙ 160 ∙ 6,240 ∙ 1.00 = 449,280 DKK/year LED : 200/1,000 ∙ 160 ∙ 6,240 ∙ 1.00 = 199,680 DKK/year The change from halogen to LED therefore resulted in a reduction in the cost of energy used for lighting in the production facility of 449,280 – 199,680 = 249,600 DKK/year. Solution question 2 Halogen : Cost of lamps : 6,240/2,000 ∙ 160 ∙ 1,220 = 609,024 DKK/year. LED : Cost of lamps : 6,240/15,000 ∙ 160 ∙ 3,360 = 223,642 DKK/year. The change from halogen to LED therefore resulted in a reduction in the cost of the lamps of 609,024 – 223,642 = 385,382 DKK/year. Solution question 3 Halogen : Interest = 160 ∙ ½ ∙ 1,220 ∙ 0.15 = 14,640 DKK/year. LED : Interest = 160 ∙ ½ ∙ 3,360 ∙ 0.15 = 40,320 DKK/year. Table 3 shows the total calculated costs for energy consumption, lamps and interest. 45 Solution: Disa Costs Halogen LED Savings Energy consumption (DKK/year) 449,280 199,680 249,600 Lamps (DKK/year) 609,024 223,642 385,382 Interest (DKK/year) 14,640 40,320 -25,680 1,072,944 463,642 609,302 Total (DKK/year) Table 3 : Cost of energy consumption, lamps and interest for halogen and LED. In the public debate, the transition to LED lighting is primarily motivated by the argument that it reduces energy consumption. However, as seen in Table 3, in this situation, it is actually the cost of the lamps which results in the greatest r­ eduction in cost. Although the price of the LEDs is greater, the longer life of the lamps means that the total cost of the lamps is actually lower. It can also be seen in Table 3 that the difference in the interest on capital that is tied to the two lamp types is of secondary importance. Solution question 4 The formulas for calculating the costs of energy consumption (question 1) and lamps (question 2) show that these costs are both directly proportional to the time that the lights are tuned on. A reduction in the burning time from 6,240 to 4,160 hrs./year, i.e. 2/3, would thus reduce both the cost of energy and the cost of the lamps by 2/3, and the reduction in the cost of lamps will thus continue to be greatest. A change in the assumption of burning time will not change the relative relationship between these two costs. The formulas for calculating interest costs (question 3) show that these are independent of the burning time. Solution question 5 The cost of heating in Herlev was : 680,000 L heating oil per year at 7.70 DKK per L => 680,000 ∙ 7.70 = 5,236,000 DKK/ year. The cost of heating in Taastrup is : 805 MWh/year at 1.00 DKK/kWh => 805 ∙ 1.00 ∙ 1,000 = 805,000 DKK/year. The move from Herlev to Taastrup has resulted in a reduction in the cost of heating of 5,236,000 – 805,000 = 4,431 million DKK /year. A significant proportion of this cost reduction is a result of the difference in the sizes of the buildings : the b ­ uildings 46 Solution: Disa in Herlev were 26,000 m2, while the buildings in Taastrup are only 13,000 m2. ­Assuming that the costs for heating are directly proportional to the size of the area, the cost of heating 13,000 m2 in Herlev would have been : ½ ∙ 5,236,000 = 2,618,000 DKK/year. The cost reduction due to the change from oil to district heating as well as the move to more energy efficient buildings can thus be calculated to be : 2,618,000 – 805,000 = 1,813,000 DKK/year. This corresponds to a reduction of 1,813,000 / 2,618,000 ∙ 100 ≈ 69 %. 47 Solution: Energinet Social benefits of investment in a Great Belt power link Solution question 1 The discounted value (DV) of the payments made for the establishment of the link, DVe, calculated at the end of the year 2009 (= the beginning of the year 2010), is : DVe,2009 = 820 ∙ 1.062 + 400 ∙ 1.061 + 150 = 921.352 + 424.0 + 150.0 = about 1,495 ­million DKK. PS .: If an investment starts at the beginning of year 1, the discounted value ­calculated at this time is called DV0. Therefore, the discounted value calculated at the beginning of 2010 is designated DV2009. The annual social benefit value is represented as 33 + 90 + 10 + 31 = 164 million DKK/year throughout the link’s 20-year life. This must exclude operating costs and the value of the net loss, i.e. 12 + 12 = 24 million DKK/year. The net value of the benefits to society are thus 164 – 24 = 140 million DKK/year. The discounted value of this net value, DVn, calculated at the beginning of 2010, is : DVn,2009 = 140 ∙ [1 – 1.06–20] / 0.06 = about 1,606 million DKK. The total social surplus resulting from the establishment of the link, calculated at the beginning of 2010, is as follows : DV2009 = DVn,2009 – DVe,2009 =1,606 – 1,495 = about 111 million DKK. This is the net present value (NPV) of the project and when NPV is positive, the ­project will – based on the underlying assumptions – increase the benefits to ­society if the project is implemented. 48 Solution: Energinet Solution question 2 If the project is delayed a year, then the discounted value of the payments for the establishment of link, DVe, calculated at the end of the year 2010 (= the beginning of year 2011), is : DVe,2010 = 820 ∙ 1,063 + 400 ∙ 1.062 + 150 ∙ 1,061 + 50 = 976.633 + 449.44 + 159.0 + 50 = about 1,635 million DKK. The discounted value of the net value of the social benefit, DVn, calculated at the beginning of 2011, is : DVn,2010 = 140 ∙ [1 – 1.06-20] / 0.06 = about 1,606 million DKK. The total social benefit of establishing the link, calculated at the beginning of the year 2011, is thus now : DV2010 = 1,606 – 1,635 = -29 million DKK. Calculated at the beginning of year 2010, the social benefit is : DV2009 = -29 ∙ 1.06-1 = -27.4 million DKK. If the project is delayed, there will thus be a social loss resulting from the implementation of the project. Solution question 3 The discounted value of payments for the establishment of the link, DVe, calculated at the end of the year 2010 (= the beginning of the year 2011) now becomes : DVe,2010 = 820 ∙ 1.053 + 400 ∙ 1.052 + 150 ∙ 1.051 + 50 = 949.253 + 441.0 + 157.5 + 50 = about 1,598 million DKK. The discounted value of the net value of the social benefit, DVn, calculated at the beginning of 2011, is now : DVn,2010 = 140 ∙ [1 – 1.05-20] / 0.05 = about 1,745 million DKK. The total social benefit of establishing the link, calculated at the beginning of the year 2011, is thus now : DV2010 = DVn,2010 - DVe,2010 = 1,745 – 1,598 = 147 million DKK. Calculated at the beginning of year 2010, the social benefit is : DV2009 = 147 ∙ 1.05-1 = 140 million DKK. 49 Solution: Energinet By using an interest rate of 6 % per annum in question 2, the social benefit is calculated as -27.4 million DKK, whereas by using an interest rate of 5 % per annum in this question, it is calculated as 140 million DKK. The social benefit of long-term public investment is therefore very dependent on the requirements for return on such investments. Solution question 4 The gain from reduced market dominance amounts to 31 million DKK year. The ­discounted value of this, DVm, calculated at the beginning of 2010 is : DVm,2009 = 31 ∙ [1 – 1.06-20] / 0.06 = about 356 million DKK. In question 1, it was calculated that the total discounted value of the project at the beginning of the year 2010 is 111 million DKK. If DVm,2009 is reduced by this amount, i.e. if DVm,2009 is only 356 – 111 = 245 million DKK., then the NPV of the project = 0 DKK. If the project is to have a positive discounted value , then the value of the annual reduction in market dominance must therefore be at least : 31 ∙ 245 / 356 = about 21 million DKK. If the value of the annual reduction in market dominance is 10 million DKK lower than the estimated 31 million DKK, then there will not be a social benefit resulting from the implementation of the project. 50 Solution: H. Lundbeck A/S Insourcing – Made Possible by the Reduction of Production Costs Solution question 1 Currently, 4 million finished product packages are packaged per year. An increased OEE from 40 % to 60 %, that is, a 50 % increase, will free up capacity for packaging an additional 2 million finished product packs per year. Since the time for finished product packaging of ampoules is 50 % greater than the time for packaging of drop containers, the increase in OEE will therefore mean that capacity for packaging 3 million drop containers will be freed up. The entire packaging of drop containers can therefore be insourced. Solution question 2 It is stated that the investment in the packaging line 5 years ago was 20 million DKK. This investment has already taken place, so it is “sunk cost” and thereby ­irrelevant to the decision on the conversion of the packaging line. Subsequently, a differential consideration is applied : Invest in redevelopment rather than continuing the current finished product packaging of ampoules. Since the packaging line in both alternatives will be used, the differential consideration can exclude the capital costs of the packaging line. The differential investment for conversion is 7 million DKK, and this investment increases the cost of operation and maintenance by 1 million DKK per year. The costs for the subcontractor are reduced by 1.5 ∙ 3 = 4.5 million DKK / year, and the costs for transport are reduced by 250,000 + 350,000 = 600,000 DKK / year ≈ 0.6 million DKK / year. The costs are thus reduced by -1 + 4.5 + 0.6 = 4.1 million DKK / year. 51 Solution: H. Lundbeck A/S The packaging line’s remaining lifetime is given to be 5 years. If this is assumed to be the lifetime of the investment, the investment’s net present value, NPV, is ­calculated as : NPV = -7 + 4.1 ∙ (1 – 1.10-5)/0.10 = -7 + 15.5 = 8.5 million DKK. The investment in redevelopment is therefore extremely profitable. The investment’s static payback time, PTs, is calculated as : PTs = 7/4.1 = 1.7 years. The investment is thus paid back very quickly. Solution question 3 The costs of insourced production, Ci, are : Ci = (3 + 1.5) + 750/10,000 ∙ 40 = 7.5 million DKK / year. If the packaging is outsourced, the costs, Co, become : Co = 0.5 + 1,500/10,000 ∙ 40 = 6.5 million DKK. The costs should therefore be able to be reduced by 1 million DKK if the packaging is outsourced. Solution question 4 The production size, x, where the costs of insourcing the packaging will be the same as the costs of outsourcing the packaging, can be calculated from : 4.5 + 750/10,000 ∙ x = 0.5 + 1,500/10,000 ∙ x From this, we get x = 53.3 million blister cards per year. The production on the packaging line must therefore increase by (53.3 – 40)/40 ∙ 100 = 33.3 %. Solution question 5 Year 2005 2006 2007 2008 2009 2010 2011 Production 40.0 45.9 49.7 60.5 70.0 84.0 92.2 Cost of outsourcing 6.50 7.39 7.96 9.58 11.50 13.10 14.33 Cost of insourcing 7.50 7.94 8.23 9.04 9.75 10.80 11.42 -1.00 -0.55 -0.27 0.54 1.75 2.30 2.91 Savings with insourcing 52 Solution: H. Lundbeck A/S The future value of the savings, FV2012, calculated at the end of 2011, is : FV2012 = -1.00∙1.106 – 0.55∙1.105 – 0.27∙1.104 + 0.54∙1.103 + 1.75∙1.102 + 2.30∙1.10 + 2.91 FV2012 = -1.77 – 0.89 – 0.40 + 0.72 + 2.12 + 2.53 + 2.91 = 5.22 million DKK. FV2012 is not an expression of the gains Lundbeck has achieved through the implementation of lean projects in this packaging line. Lundbeck has also incurred costs. The majority of these costs resulted from employees having spent time on the project. These costs can be difficult to quantify - not least because employees have acquired new skills and the lean culture of the company has been reinforced, which can form the basis for many improvement projects in the future. 53 Solution: MT Højgaard A/S Inclusion of Project Earnings in the Company’s Consolidated Financial Statement Solution question 1 In year 1, the posted costs are 20,000 thousand DKK, as shown in table 1 in the case text. Because the total project costs are expected to be 100,000 thousand DKK – 20,000 thousand DKK = 80,000 thousand DKK, then the assessed degree of project completion is 20,000 / 80,000 = 0.25. On this basis, the realized project result in year 1 is 0. 25 ∙ 20,000 = 5,000 thousand DKK. In year 2, 20,000 thousand DKK in project costs were also posted. For years 1 and 2, a total of 40,000 thousand DKK were posted. Therefore, it is estimated that the project is half completed (40,000 / 80,000 = 0.50). Expectations per year Year 1 Year 2 Year 3 100,000 100,000 100,000 1) Total revenue 2) Total project result 20,000 20,000 20,000 Interim financial statement for Year 1 Year 2 Year 3 3) Posted costs 20,000 20,000 40,000 4) Degree of complation 0.25 0.50 1.00 5) Project result 5,000 5,000 10,000 Accumulated financial statement Year 1 Year 2 Year 3 6) Posted costs 20,000 40,000 80,000 7) Project result 5,000 10,000 20,000 The project manager here has had control of the economy. The originally expected revenue and the expected project result have been realized, which is why a correct project result has been calculated in each of the three years. 54 Solution: MT Højgaard A/S Solution question 2 The cost in year 3 was 40,000 thousand DKK. A reduction of these costs by 5 % corre­sponds to 2,000 thousand DKK. Whereas in year 3 without cost reduction would result in a project result of 10,000 thousand DKK, a cost reduction of 2,000 ­thousand DKK would result in a project result of 10,000 + 2,000 = 12,000 thousand DKK. A cost reduction of 5 % in year 3 would therefore have resulted in an increase of 20 % in the project result for year 3. Solution question 3 By the end of year 1, the total project cost is estimated to be 80,000 thousand DKK. After 2 years they are estimated to be 90,000 thousand DKK, and after 3 years to be 105,000 thousand DKK. The reasons for this could be, for example : • That the project manager from the beginning has underestimated the costs. • That the project manager throughout the project did not have a sufficiently tight control on the costs. At the end of year 1, the total project costs are estimated to be 100,000 – 20,000 = 80,000 thousand DKK. Since the posted costs after year 1 are 20,000 thousand DKK, the degree of completion is calculated to be 0.25, which results in a project result of 5,000 thousand DKK for year 1. At the end of year 2, the project’s total costs are estimated to be 100,000 – 10,000 = 90,000 thousand DKK. Since the total posted costs for year 1 and 2 are 45,000 thousand DKK, the degree of completion is now calculated to be 0.50, and the ­accumulated project result is now calculated to be 0.50 ∙ 10.000 = 5.000 thousand DKK. The project result for year 2 is therefore 0. At the end of year 3, the accumulated project result was -5,000 thousand DKK. For year 3, the realized project result was -10,000 thousand DKK. 55 Solution: MT Højgaard A/S Expectations per year Year 1 Year 2 Year 3 100,000 100,000 100,000 1) Total revenue 2) Total project result 20,000 10,000 -5,000 Interim financial statement for Year 1 Year 2 Year 3 3) Posted costs 20,000 25,000 60,000 4) Degree of complation 0,25 0.50 1.00 5) Project result 5,000 0 -10,000 Accumulated financial statement Year 1 Year 2 Year 3 6) Posted costs 20,000 45,000 105,000 7) Project result 5,000 5,000 -5,000 An accumulated realized project result of 5,000 thousand DKK in years 1 and 2, followed by a realized project result of -10,000 thousand DKK in year 3 does not give an accurate picture of the situation. If the total project result of -5,000 thousand DKK had been recognized as early as year 1, MT Højgaard would have accommodated this in year 1. The project result for years 2 and 3 would then have been 0. Another advantage of early recognition of bad project economy could have been that there might have been opportunities to allocate resources toward correcting the project. 56 Solution: A/S Storebælt Annuities with Different Payment-Interval Lengths Solution question 1 Type A : General inspection of concrete : Inspection time : 1.75 ∙ 128 = 224 hours Crossing of bridge pilings : 2 ∙ 126 = 252 hours Payroll costs : (224 + 252) ∙ (3 ∙ 600 + 2 ∙ 300) = 1.142.400 DKK Moving of platform = 250,000 DKK Total costs = 1,142,400 + 250,000 = 1,392,400 DKK Routine inspection of concrete : Inspection time : 0.7 ∙ 128 = 89,6 hours Crossing of bridge pilings : 2 ∙ 126 = 252 hours Payroll costs : (89.6 + 252) ∙ (3 ∙ 600 + 2 ∙ 300) = 819.840 DKK Moving of platform = 250,000 DKK Total costs = 819,840 + 250,000 = 1,069,840 DKK Inspection of bridge bearings : Inspection time : 1.5 ∙ 126 = 189 hours Crossing of bridge pilings : 2 ∙ 126 = 252 hours Payroll costs : (189 + 252) ∙ (1 ∙ 600 + 2 ∙ 300) = 529,200 DKK/year Moving of platform = 250,000 DKK Total costs = 529,200 + 250,000 = 779,200 DKK Type B : General inspection of concrete : Inspection time : 2.50 ∙ 128 = 320 hours Crossing of bridge pilings : 0 ∙ 126 = 0 hours Payroll costs : 320 ∙ (2 ∙ 600 + 2 ∙ 300) = 576,000 DKK 57 Solution: A/S Storebælt Routine inspection of concrete : Inspection time : 1.0 ∙ 128 = 128 hours Crossing of bridge pilings : 0 ∙ 126 = 0 hours Payroll costs : 128 ∙ (2 ∙ 600 + 2 ∙ 300) = 230,400 DKK Inspection of bridge bearings : Inspection time : 1.5 ∙ 126 = 189 hours Crossing of bridge pilings : 0 ∙ 126 = 0 hours Payroll costs : 189 ∙ (1 ∙ 600 + 2 ∙ 300) = 226,800 DKK/year Solution question 2 Every sixth year, a general inspection is carried out, and this replaces the routine inspection that year. If the costs of a general inspection are composed of the costs of a routine inspection plus an additional amount, then the costs of the concrete inspections can be described by two constant annuities : • An annuity with an amount equal to the cost of a routine inspection every 2nd year. • An annuity with an amount equal to the aforementioned “additional amount” every 6th year. The costs for the inspection of the bridge bearings are an annuity with an annual payment. For the two types, the annuities are thus obtained by : Type A : The costs of 1,392,400 DKK for the general inspection every 6th year are composed of the costs of 1,069,840 DKK for the routine inspection plus an additional payment of 1,392,400 – 1,069,840 = 322,560 DKK. Hereby the costs for the inspection of the concrete can be described by the two annuities : • An annuity with a payment of 1,069,840 DKK every 2nd year • An annuity with a payment of 322,560 DKK every 6th year In addition, there is the annual annuity of 779,200 DKK for the inspection of the bridge bearings. Type B : The costs of 576,000 DKK for the general inspection every 6th year are composed of the costs of 230,400 DKK for the routine inspection plus an additional payment of 576,000 – 230,400 = 345,600 DKK. Hereby the costs for the inspection of the concrete can be described by the two annuities : 58 Solution: A/S Storebælt • An annuity with a payment of 230,400 DKK every 2nd year • An annuity with a payment of 345,600 DKK every 6th year In addition, there is the annual annuity of 226,800 DKK for the inspection of the bridge bearings. Solution question 3 A discount rate, i, of 7 % per year corresponds to a discount rate, i2, over 2 years of : 1 + i2 = (1 + 0.07)2 From this, we get : i2 = 0.1449, that is = 14.49 % over 2 years. Correspondingly, if the payment interval length is 6 years : 1 + i6 = (1 + 0.07)6 i6 = 0.5007, that is = 50.07 % over 6 years. Solution question 4 The supporting construction has a lifetime of 50 years for both types of platforms. Since the lifetime is the same, the choice of the type of platform can be made based on the criterion : Maximum net present value (NPV). Type A : The investment amounts to 18 + 7 = 25 million DKK plus a payment of 7 million DKK after 25 years. The present value of this, PVA,I, is : PVA,I = -25,000,000 – 7,000,000 ∙ 1.07-25 = -26,289,744 DKK Based on the answers to questions 2 and 3, the present value of the payments for the concrete inspections, PVA,C, can be obtained, since the number of payments over the 50 years of the annuity with payments every 2 years is 25, while the number of payments years of the annuity with payments every 6 years is 8 : PVA,C = -1,069,840 ∙ (1 – 1.1449-25)/0.1449 – 322,560 ∙ (1- 1.5007-8)/0.5007 = -7,132,652 – 619,175 = -7,751,827 DKK The present value of the payments for the inspection of bridge bearings, PVA,B is : PVA,B = -779,200 ∙ (1 – 1.07-50)/0.07 = -10,753,542 DKK 59 Solution: A/S Storebælt The costs for maintenance, CA,M, are : CA,M = 18,000,000 ∙ 0.015 + 7,000,000 ∙ 0.025 = 270,000 + 175,000 = 445,000 DKK/ year. The present value of this, PVA,M, is : PVA,M = -445,000 ∙ (1 – 1.07-50)/0.07 = -6,141,332 DKK The net present value of investing in type A, NPVA, is therefore : NPVA = -26,289,744 – 7,751,827 – 10,753,542 – 6,141,332 = -50,936,445 DKK Type B : The investment amounts to 20 + 10 = 30 million DKK plus a payment of 10 million DKK after 25 years. The present value of this, PVB,I, is : PVB,I = -30,000,000 – 10,000,000 ∙ 1.07-25 = -31,842,492 DKK Based on the answers to questions 2 and 3, the present value of the payments for the concrete inspections, PVB,C, can be obtained, since the number of payments over the 50 years of the annuity with payments every 2 years is 25, while the number of payments years of the annuity with payments every 6 years is 8 : PVB,C = -230,400 ∙ (1 – 1.1449-25)/0.1449 – 345,600 ∙ (1- 1.5007-8)/0.5007 = -1,536,083 – 663,402 = -2,199,485 DKK The present value of the payments for the inspection of bridge bearings, PVB,B is : PVB,B = -226,800 ∙ (1 – 1.07-25)/0.07 = -2,643,033 DKK The costs for maintenance, CB,M, are : CB,M = 20,000,000 ∙ 0.010 + 10,000,000 ∙ 0.025 = 200,000 + 250,000 = 450,000 DKK/year. The present value of this, PVB,M, is : PVB,M = -450,000 ∙ (1 – 1.07-50)/0.07 = -6,210,336 DKK The net present value of investing in type B, NPVB, is therefore : NPVB = -31,842,492 – 2,199,485 – 2,643,033 – 6,210,336 = -42,895,346 DKK Since NPVB > NPVA, A/S Storebælt should select type B. 60 Solution: Velux A/S Calculations with the Introduction of New Technology for Windows Solution question 1 Rewriting the investment of 10 million DKK to an annuity, a, over two years, we get : a = 10,000,000 ∙ 0.07/(1 – 1.07-2) = 5,530,918 DKK/yr. With annual sales of 200,000 units, we get an increase in “depreciation and ­interest” of : 5,530,918/200,000 = 27.65 DKK per window Solution question 2 Calculation for a window with the new coating Materials 815 DKK 55.9 % Salary 212 DKK 14.5 % Additional costs 100 DKK 6.9 % 68 DKK 4.6 % Cost price 1,195 DKK 81.9 % Sales costs 100 DKK 6.9 % Marketing 90 DKK 6.2 % Profit 73 DKK 5.0 % 1,458 DKK 100.0 % Depreciation and interest Selling price PS .: The total cost for production, sales, and marketing comes to 1,385 DKK. Since the profit must be 5 % of the selling price, it must be 1,385 / 0.95 = 1,458 DKK per window. The profit is hereby 1,458-1,385 = 73 DKK per window. The selling price of a window must therefore be increased by 1,458-1,400 = 58 DKK 61 Solution: Velux A/S Solution question 3 The profitability of investments resulting in changes in the costs and selling price cannot be judged by how the profit margin in a full-cost calculation changes. Solution question 4 The general criterion for an investment to be profitable is that its net present value must be ≥ 0 DKK. The investment of 10 million DKK in the new technology results in : • An increase in salary costs of 12 DKK per window • An increase in material costs of 15 DKK per window • An increase in the selling price of 45 DKK Overall, this results in a net cash flow of 45 – 12 – 15 = 18 DKK per window, which corresponds to 18 ∙ 200,000 = 3,600,000 DKK/year. The investment’s net present value, NPV, thus becomes : NPV = -10,000,000 + 3,600,000 ∙ (1 – 1.07-5)/0.07 = 4,760,710 DKK Solution question 5 If the investment is to be profitable, then the minimum requirement for the net cash flow, NCF, can be calculated as : NPV = -10,000,000 + NCF ∙ (1 – 1.07-5)/0.07 ≥ 0 DKK From this, we get : NCF ≥ 2,438,907 DKK/yr. or 2,438,907/200,000 = 12.19 DKK per window. Therefore, the selling price of a window must be increased by a minimum of 12.19 + 12 + 15 = approximately 39 DKK, if the investment in the new technology is to be profitable. 62