Work Study & Method Study: Operations Management

advertisement

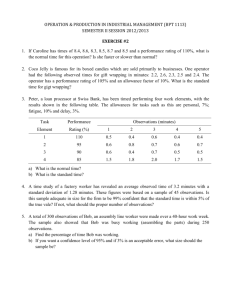

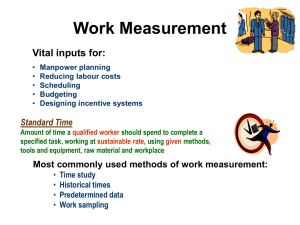

Production Operations management Chapter 14 Work Study/ Method study Work Study- Method study Importance Managing people within operations involves actual design decisions about jobs, methods, relationships between jobs and machines and systems of control and communication. Work design involves complex "people" relationships between operative staff, supervisors and specialists e.g. engineering managers and staff who commission new machines and maintain them. Other specialists may coordinate health and safety systems or monitor performance and plan maintenance People are not mere extensions to machines or horsepower to be switched on and off. A worker's performance may be better than a machine's capability - yet a machine may outstrip the human being for many tasks. Work Study Definition People can be hurt/injured physically by operating environments or trapped socially and psychologically in them/by them. How operational systems are designed and the jobs and performance relationships within them are of great operational, economic and social importance. In this context then work study is : A collection of techniques used to examine work what is done and how it is done - so that there is systematic analysis of all the elements, factors, resources and relationships affecting the efficiency and effectiveness of the work being studied. Work Study-Objectives Considerable diplomacy and sensitivity is needed by the industrial engineer or operations manager who becomes involved in work study (or business process improvement) investigations. Method study and work measurement are two principal activities of work study which originated in the work of F. W. Taylor . FW's "scientific management" imperatives are: winvestigate the work situation and identify weaknesses where and why is poor performance happening? The "scientific" title for this approach to management means placing emphasis on wdata gathering and rational analysis Work Study- Objectives wcertain narrow assumptions about the objectivity of efficiency criteria wthe existence of direct, deterministic relationships between worker performance and incentive payments and wconsideration of the worker to some extent as a machine. Thus we can evaluate and introduce improvements in operating methods. This includes type of equipment, its use, layout of operations, supply and use of materials, materials handling, work organization, effectiveness of planning procedures and so on. Work Study- Benefits Using data on measured work, unmeasured work and idle time we can attempt to derive effectiveness indices. Constable and New exemplify efficiency and effectiveness indices a.efficiency while performing measured work (ratio of standard/measured hours of work produced and the actual time taken) b.effectiveness which includes waccounting for work done for which no measured time exists. Such work is typically paid for by an agreed hourly/day rate i.e. there is no direct, measured relationship between pay and how much work is actually completed in that hour. Work Study- Benefits wOf course a supervisor may pass a judgment or state that the amount of work and its quality are inadequate. wrecognition of possible idle time caused e.g. by management not allocating any work, supplier/materials delays, machine breakdowns etc. wImproved work flow wBasis of sound incentive scheme w Provides better job satisfaction. wFare wages to employees wReduced manufacturing cost Time & Motion study A time and motion study would be used to reduce the number of motions in performing a task in order to increase productivity. The best known experiment involved bricklaying. Through carefully scrutinising a bricklayer's job, Frank Gilbreth reduced the number of motions in laying a brick from 18 to about 5. Hence the bricklayer both increased productivity and decreased fatigue. The Gilbreths developed what they called therbligs ("therblig" being "Gilbreth" spelled backwards, with a slight variation), a classification scheme comprising 17 basic hand motions. Relationship of Time & Motion study to work study Both time & motion study which resulted from the integration of concepts and practices developed by F,W Taylor. However time study is quantitative analysis leading to establishing time standards ,Whereas motion study is Qualitative analysis leading to establishment of time standards. Work study as a discipline is concerned with : Better ways of performing tasks Exercising control over the output in respect of those jobs by setting standards for performance Relationship of Time & Motion study to work study Motion Study is designed to determine to best way to complete a repetitive job Time Study measures how long it takes an average worker to complete a task at a normal pace Motion and time study helps management determine how much is produced by workers in a specific period of time, therefore making it easier to predict work schedules and output. Motion and Time Study is a scientific method designed by two different people for the same purpose, to increase productivity and reduce unit cost. The two methods evaluate work and try to find ways to improve processes. Relationship of Time & Motion study to work study Motion Study Improve methods It measures distance, or how much you move to do a job, and how much you get done in a period of time Time study Establish standards Looked at the average time it took an average worker Users of Time Study have to establish standards, this works in the service industry, Relationship of Time & Motion study to work study Work Study Method Study Motion Study Work Measurement Time Study Work Study- Method study Methods study - is an analysis of ways of doing work. The memonic SREDIM (a common-sense heuristic or general problem-solving strategy) represents the method study stages 1. select the tasks to study 2. record the facts about it 3. examine these 4. develop a new method 5. install/implement it 6. maintain it Work Measurement Definition Work Measurement is a term which covers several different ways of finding out how long a job or part of a job should take to complete. It can be defined as the systematic determination, through the use of various techniques, of the amount of effective physical and mental work in terms of work units in a specified task. The work units usually are given in standard minutes or standard hours. Why should we need to know how long a job should take? The answer to this question lies in the importance of time in our everyday life. We need to know how long it should take to walk to the train station in the morning, one needs to schedule the day's work and even when to take out the dinner from the oven. Work Measurement Definition In the business world these standard times are needed for: planning the work of a workforce, manning jobs, to decide how many workers it would need to complete certain jobs, scheduling the tasks allocated to people costing the work for estimating contract prices and costing the labor content in general calculating the efficiency or productivity of workers - and from this: providing fair returns on possible incentive bonus payment schemes. Work Measurement Techniques On what are these standard times set? They are set, not on how long a certain individual would take to complete a task but on how long a trained, experienced worker would take to do the task at a defined level of pace or performance. Who sets these standard times? Specially trained and qualified observers set these times, using the most appropriate methods or techniques for the purpose i.e. "horses for courses". How it is done depends on circumstances that obtain. The toolkit available to the comprehensively trained observer is described below. Work Measurement Techniques Selecting the most appropriate methods of work measurement The method chosen for each individual situation to be measured depends on several factors which include: the length on the job to be measured in time units the precision which is appropriate for the type of work in terms of time units (i.e. should it be in minutes, hundredths or thousandths of a minute) the general cycle-time of the work, i.e. does it take seconds, minutes or days to complete Work Measurement Techniques The length of time necessary for the completion of the range of jobs can vary from a few seconds in highly repetitive factory work to several weeks or months for large projects such as major shutdown maintenance work on an oil refinery. It is quite clear that using a stop-watch, for example, on the latter work would take several man-years to time to measure! Thus, more "overall" large-scale methods of timing must be employed. The precision is an important factor, too. This can vary from setting times of the order of "to the nearest thousandth of a minute" (e.g. short cycle factory work) to the other end of the scale of "to the nearest week" Work Measurement Techniques These are the dominant factors that affect the choice of method of measurement. The methods PMTS. At the "precision" end of the scale is a group of methods known as predetermined motion time systems that use measurement units in ten thousandths (0.0001) of a minute or hundred-thousandths of an hour (0.00001 hour). The resulting standard times can be used directly, for very short-cycle work of around one minute total duration such as small assembly work. Work Measurement Techniques However, they often are used to generate regularly used basic tasks such using assembling or disassembling nuts and bolts, using a screwdriver and similar. Tasks of this type are filed as standard or synthetic data-banks. Estimating. At the other end of the scale (long-cycle and project work) we need something which is quick to use. Such a method is estimating. This can exist in three main forms. Analytical estimating relies on the experience and judgment of the estimator. It is just of case of weighing up the work content and, using this experience, stating a probable time for completion, such as "this job will take about eight days to complete". Work Measurement Techniques Category estimating. This is a form of range estimating and requires a knowledge of the work. Estimators may not feel comfortable with overall, analytical estimates upon which may depend the outlay of a great deal of money. They often prefer giving a range estimate such as "this job should take between 12 weeks and 14 weeks to complete", which provides a safety net should things go wrong. Such ranges are not just picked upon at random but are statistically calculated and based on probability theory. Comparative estimating. This is another example of range estimating. Again, estimators rely on experience of the work in order to produce estimates. Work Measurement Techniques This experience can be augmented by the provision of each time-range with a few typical, descriptive, jobs that would guide estimators to the most appropriate range. The estimator would compare the work to be estimated with those in the various ranges until the most appropriate fit is found. Timing. The intermediate method between the two groups above, is timing the work in some way, usually with a stop-watch or computerized electronic study board. This method is retrospective in that the job must be seen in action in order to be timed whereas the other methods are prospective and can be used for timing jobs before they start. Work Measurement Techniques The observer times each element of the work and obtains times that the observed operator takes to do the elements. Each timing is adjusted (rated) by the pace at which the operator was working as assessed by the observer. This produces basic times for the elements and hence the whole job, which are independent of the operator and can be used as the time for a trained, experienced worker to carry out the same elements.. Another method of assessing the work is using activity sampling and rated activity sampling. This is a method based on the observer making snap observations at random or systematic sample times, Work Measurement Techniques observing what the operator is (or operators are) doing at the times of those observations Models: A most useful method for standard or synthetic databanks of job or element times is using computer models of the jobs. These are generated as mathematical formulae in which the observed data are inserted to compile a time for completion of the task or project. It is a useful method for recycling time standards for elements of basic work over and over again, only changing the values of the variables to suit each project Steps in Work Measurement Involves assessing the time a job should take to do. Similar steps are involved as to method study 1. Select the tasks 2. Break the job into elements 3. Record the facts,record time taken 4. Analyze them 5. Assess relaxation allowance 6. Calculate basic and standard times for the task 7. Agree the method and its related time Work Measurement Time study Time study is a structured process of directly observing and measuring (using a timing device) human work in order to establish the time required for completion of the work by a qualified worker when working at a defined level of performance. It follows the basic procedure of systematic work measurement of : analysis (of the work into small, easily-measurable components or elements); measurement (of those components); and synthesis (from those measured components to arrive at a time for the complete job). Work Measurement Time study The observer first undertakes preliminary observation of the work (a pilot study) to identify suitable elements which can be clearly recognized on subsequent occasions and are convenient, in terms of their length, for measurement. Subsequent studies are taken during which the observer times each occurrence of each element (using a stopwatch or other timing device) while at the same time making an assessment of the worker's rate of working on an agreed rating scale. (One of the prime reasons for measuring elements of work, rather than the work as a whole is to facilitate the process of rating. Work Measurement Time study The rate at which a worker works will vary over time; if elements are carefully selected, the rate of working should be consistent for the relatively short duration of the element. More information on rating is given within the entry on work measurement.) This assessment of rating is used to convert the observed time for the element into a basic time - a process referred to as "extension". It is essential that a time study observer has been properly trained in the technique and especially in rating. Time study, when properly undertaken, involves the use of specific control mechanisms to ensure that timing errors are within acceptable limits. Work Measurement Time study Increasingly, timing is by electronic devices rather than by mechanical stopwatch; some of these devices also assist in subsequent stages of the study by carrying out the process of "extending" or converting observed times into basic times. The number of cycles that should be observed depends on the variability in the work and the level of accuracy required. Since time study is essentially a sampling technique in which the value of the time required for the job is based on the observed times for a sample of observations, it is possible using statistical techniques to estimate the number of observations required under specific conditions. Work Measurement Time study This total number of observations should be taken over a range of conditions (where these are variable) and, where possible, on a range of workers. Once a basic time for each element has been determined, allowances are added (for example, to allow the worker to recovered from the physical and mental effects of carrying out the work) to derive a standard time. Time study is a very flexible technique, suitable for a wide range of work performed under a wide range of conditions, although it is difficult to time jobs with very short cycle times (of a few seconds). Work Measurement Time study Because it is a direct observation technique, it takes account of specific and special conditions but it does rely on the use of the subjective process of rating. However, if properly carried out it produces consistent results and it is widely used. Additionally, the use of electronic data capture devices and personal computers for analysis makes it much more cost effective than previously. Work Measurement Time study There are various ways in which work may be measured and a variety of techniques have been established. The basic procedure, irrespective of the particular measurement technique being used, consists of three stages ; wan analysis phase in which the job is divided into convenient, discrete components, commonly known as elements; wa measurement phase in which the specific measurement technique is used to establish the time required (by a qualified worker working at a defined level of performance) to complete each element of work; Work Measurement Synthesis A synthesis phase in which the various elemental times are added, together with appropriate allowances (see below), to construct the standard time for the complete job. wThe techniques used to measure work can be classified into those that rely on direct observation of the work, and those that do not. wFor example, some techniques, such as predetermined motion-time systems and the use of synthetic or standard data can provide times from simulation or even visualization of the work. However, the data on which such techniques are based were almost certainly based on earlier observation of actual work. Work Measurement Synthesis Rating Direct observation techniques (such as time study and analytical estimating) include a process for converting observed times to times for the "qualified worker working at a defined level of performance." The commonest of these processes is known as rating. This involves the observer (after appropriate training) making an assessment of the worker's rate of working relative to the observer's concept of the rate corresponding to standard rating. This assessment is based on the factors involved in the work - such as effort, dexterity, speed of movement, and consistency. Work Measurement Synthesis The assessment is made on a rating scale, of which there are three or four in common usage. Thus on the 0-100 scale, the observer makes a judgment of the worker's rate of working as a percentage of the standard rate of working (100). The rating is then used (in a process known as "extension" in time study) to convert the observed time to the basic time using the simple formula: Basic time = observed time x observed rating/standard rating Work Measurement Synthesis Rating is regarded by many as a controversial area of measurement since it is a subjective assessment. Where different observers rate differently, the resulting basic times are not comparable. However, practiced rating practitioners are remarkably consistent. It is important that those undertaking the rating are properly trained, and that this training is regularly updated (to maintain a common perception of standard rating) through rating 'clinics'. Allowances When carrying out work over a complete shift or working day, workers obviously suffer from the fatigue imposed both by the work undertaken Work Measurement Synthesis and the conditions under which they are working. The normal practice is to make an addition to the basic time (commonly referred to as an "allowance") to allow the worker to recover from this fatigue and to attend to personal needs. The amount of the allowance depends on the nature of the work and the working environment, and is often assessed using an agreed set of guidelines and scales. It is usual to allow some of the recovery period inherent in these allowances to be taken away from the workplace (and it is essential in adverse working conditions). Thus, work design should include the design of an effective work-rest regime.. Work Measurement Synthesis The addition of allowances should never be used to compensate for an unsafe or unhealthy working environment. One minority school of thought suggests that relaxation allowances are unnecessary. With work which involves, say, the carrying of heavy weights, this school suggests that the observer automatically adjusts the concept of standard rating to allow for the weight. Thus, if the standard rate of performance for walking on level ground carrying no weight is equivalent to four miles per hour, then an observer rating a worker walking while carrying a weight will not expect the equivalent rate. Work Measurement Synthesis Thus, it is argued that the weight has been allowed for in the adjustment of standard rating and any relaxation allowance is simply a duplication of this adjustment. In many jobs there are small amounts of work that may occur irregularly and inconsistently. It is often not economic to measure such infrequent work and an additional allowance is added to cover such work and similar irregular delays. This allowance is known as a contingency allowance and is assessed either by observation, by analysis of historical records (for such items as tool sharpening or replacement), or by experience. Work Measurement Synthesis The end result is a standard time which includes the time the work "should" take (when carried out by a qualified worker) plus additional allocations in the form of allowances, where appropriate, to cover relaxation time, contingency time and, perhaps, unoccupied time which increases the overall work cycle (such as waiting for a machine to finish a processing cycle). Choosing a measurement technique The choice of a suitable measurement technique depends on a number of factors including: wthe purpose of the measurement; wthe level of detail required; Work Measurement Synthesis the time available for the measurement; wthe existence of available predetermined data; wand the cost of measurement. To some extent there is a trade off between some of these factors. For example, techniques which derive times quickly may provide less detail and be less suitable for some purposes, such as the establishment of individual performance levels on short-cycle work. The advantage of structured and systematic work measurement is that it gives a common currency for the evaluation and comparison of all types of work. Work Measurement Synthesis The results obtained from work measurement are commonly used as the basis of the planning and scheduling of work, manpower planning, work balancing in team working, costing, labor performance measurement, and financial incentives. They are less commonly used as the basis of product design, methods comparison, work sequencing, and workplace design Work Measurement Synthesis The results obtained from work measurement are commonly used as the basis of the planning and scheduling of work, manpower planning, work balancing in team working, costing, labor performance measurement, and financial incentives. They are less commonly used as the basis of product design, methods comparison, work sequencing, and workplace design Work Measurement Analytical Estimating Analytical estimating would normally be used for assessing work over a reasonably lengthy period of time, where it may be difficult and more expensive to collect the information required using other measurement techniques. Also, in some work environments the presence of an individual carrying out work measurement in the work place could be unacceptable. In these cases, analytical estimating may be an appropriate method to use, assuming someone with experience of the work is available to apply their experienced judgment. ( This may be work measurement personnel who have previous experience of this particular work ) Work Measurement Analytical Estimating However, the work content of some jobs cannot be estimated in advance because one is unclear about what is required until an assembly operation has been tested or stripped down. For example, during the progress of repair unforeseen and non standard difficulties can arise. Removing a wooden door from its frame by unscrewing 8 or 12 screws could take five minutes if the screws were recently inserted, or a great deal longer if the screws are rusted and clogged with paint. In summary, the technique is used most commonly in any work environment where a lengthy time (and associated high cost) is needed to collect data. Work Measurement Analytical Estimating This technique of work measurement is used to determine the time values for job having long and non repetitive operations Procedure for Analytical estimating Find out job details Break the job into elements Select time values from standard data for as many elements as possible. Estimate time value remaining elements from past experience Add above time values to get total basic or normal time Add relaxation allowance Work Measurement Analytical Estimating Advantage Perhaps the most significant advantage of using analytical estimating is its speed of application and low cost. Using trained and experienced personnel process and measurement data can be quickly assembled and applied. Helps in planning Reliable Economical Used for estimating labor times for preparing cost estimates Steps to improve labor control Work Measurement Analytical Estimating Disadvantage However, the use of experienced judgment when determining the time necessary to perform a task is the technique's most obvious source of weakness when compared with a more precise technique such as time study. This is why the technique would not normally be used when a more precise and accurate alternative is a feasible and economic alternative, particularly to highly repetitive, standardized operations. Many jobs, such as craft work in the maintenance field, consist of a group of tasks which are periodically repeated but the precise nature of each task varies each time in minor respects Work Measurement Predetermined motion time system (PMTS) Definition: PMT Systems are methods of setting basic times for doing basic human activities necessary for carrying out a job or task. The definition in BS 3138, Glossary of Terms Used in Work Study is: 'Tables of time data at defined rates of working for classified human movements and mental activities. Times for an operation or task are derived using precise conventions. Predetermined motion time data have also been developed for common combinations of basic human movements and mental activities'. Work Measurement Predetermined motion time system (PMTS) The concept of PMTS is to analyze a job into its fundamental human activities, apply basic times for these from tables and synthesize them into a basic time for the complete job. The basic elements include the following: reach for an object or a location, grasp an object , touching it or closing the fingers around it, move an object a specified distance to a specified place, rewraps an object in order to locate it in a particular way, usually prior to: release an object to relinquish control on it, other elements for assembling to, or inserting an object into, its intended location. Work Measurement Predetermined motion time system (PMTS) For each of these actions basic times are tabled. For example, in Work-Factor the time unit is one thousandth of a minute (the Work-Factor Time Unit) whereas in MTM the unit is one hundred-thousandth of an hour (time measurement unit, tmu). The times for basic actions are adjusted for other factors which take into account such variables as: distances moved, in inches or centimeters difficulty in performing the actions, such as avoiding obstacles during moves, closeness of fit during assembling, weight of the object, all of which increase the times to carry out the basic actions. Work Measurement Predetermined motion time system (PMTS) The above basic motions cover most of the actions performed by humans when carrying out work. Other basic activities include: walking to a specified place bending down and stooping kneeling on one knee and kneeling on both knees foot and leg motions sitting down and standing. Mental activities include times for: See, Inspect, Identify, Nerve Conduct, React, Eye focus, Eye travel times, Memorize, Recall, Compute (calculate) and others, mostly from Work-Factor. Work Measurement Predetermined motion time system (PMTS) Levels of detail in systems In order to speed up measurement time the major systems all include different levels of detail, such as: 1.most detailed systems: MTM and Detailed Work-Factor 2.Second level systems: MTM-2 and Ready Work-Factor (abridged versions) achieved usually by the four methods of combining, statistically averaging, substituting and/or eliminating certain basic motions. 3.Third level systems: MTM-3 and Abbreviated WorkFactor (even more abridged) 4."higher level" systems, usually times for complete activities. Work Measurement Predetermined motion time system (PMTS) A predetermined motion time system (PMTS) is frequently used to set labor rates in industry by quantifying the amount of time required to perform specific tasks. The first such system is known as Methods Time Measurement, released in 1948 and today existing in three variations, commonly known as MTM-1, MTM-2, and MTM-3. Another popular PMTS is the Maynard Operation Sequence Technique, which was first released in 1972. That method also has several variations, with the most commonly used being BasicMOST, and others being MiniMOST, MaxiMOST, and AdminMOST. Work Measurement Predetermined motion time system (PMTS) The variations of both systems differ from each other based on their level of focus. MTM-1 and MiniMOST are optimal for short processes with only small hand motions, while MTM-3 and MaxiMOST are more properly used for longer processes that are less repetitive. Unlike time studies, in which an analyst uses a stopwatch and subjectively rates the operator's effort to calculate a standard time, a PMTS requires that the analyst break apart the process into its component actions, assign time values to each action, and sum the times to calculate the total standard time. Work Measurement Predetermined motion time system (PMTS) Most predetermined motion time systems use time measurement units (TMU) instead of seconds for measuring time. One TMU is defined to be 0.00001 hours, or 0.036 seconds. These smaller units allow for more accurate calculations without the use of decimals. In the most in-depth PMT systems, motions observed will be on the level of individual TMUs, like toss (3 TMUs in MiniMOST) and simple pickup (2 TMUs in MTM-1). More general systems simplify things by grouping individual elements, and thus have larger time values – for example, a bend and arise (61 TMUs in MTM-2) and one or two steps (30 TMUs in BasicMOST). Work Measurement Predetermined motion time system (PMTS) Systems with even less detail work with TMU values in the hundreds, like climbing 10 rungs on a ladder (300 TMUs in MaxiMOST) or passing through a door (100 TMUs in MaxiMOST). The choice of which variation of a certain PMTS to use is dependent on the need for accuracy in contrast to the need for quick analysis, as well as the length of the operation, the distances involved in the operation, and the repetitiveness of the operation. Longer operations often take place on a larger spatial scale, and tend to be less repetitive, so these issues are often treated as one. Work Measurement Predetermined motion time system (PMTS) For longer, less repetitive operations, statistical analysis demonstrates that the accuracy of less detailed systems will generally approach the accuracy of more detailed systems. Thus, in order to reduce the time required for analysis, less detailed systems (like MTM-3 and MaxiMOST) are usually used when possible. Conversely, very short, repetitive processes are commonly analyzed with more exact methods like MTM-1 and MiniMOST because of the need for accuracy. Work Measurement Predetermined motion time system (PMTS) Applications of MTM techniques MTM has been used for: Developing effective methods in advance of beginning the production Improving existing method Estimating standard time Estimating labor time Training supervisors Choosing between alternative material Work Measurement Activity Sampling Activity Sampling is a statistical technique that can be used as a means for collecting data. It is defined by BS 3138:41008 as: A technique in which a large number of observations are made over a period of time of one group of machines, processes or workers. Each observation records what is happening at that instant and the percentage of observations recorded for a particular activity or delay is a measure of the percentage of time during which that activity or delay occurs. Work Measurement Activity Sampling It is normally used for collecting information on the percentages of time spent on activities, without the need to devote the time that would otherwise be required for any continuous observation. One of the great advantages of this technique is that it enables lengthy activities or groups of activities to be studied economically and in a way that produces statistically accurate data. Fixed and Random Interval Sampling Activity Sampling can be carried out at random intervals or fixed intervals. Random activity sampling is where the intervals between observations are selected at random e.g. from a table of random numbers. Work Measurement Activity Sampling Fixed interval activity sampling is where the same interval exists between observations. A decision will need to be made on which of these two approaches is to be chosen. A fixed interval is usually chosen where activities are performed by a person or group of people who have a degree of control over what they do and when they do it. Random intervals will normally be used where there are a series of automated tasks or activities as part of a process, that are have to be performed in a pre established regular pattern. If fixed interval sampling were to be used in this situation there is a danger that the sampling point would continue to occur at the same point in the activity cycle. Work Measurement Activity Sampling Confidence Levels Remember, that activity sampling is used for assessing the percentage of time spent on activities. Because activity sampling conforms to the binomial distribution it is possible to use a calculation to determine how many observations will be needed to operate within specified limits of accuracy. The formula for the number of observations is as follows: = 4 x p x (100 - p) L2 Where p is the estimated % time spent on the activity Where L is the limit of error, expressed as a % Work Measurement Activity Sampling Once the above calculation has been completed the observations can begin and activities are recorded at the agreed time intervals. When they have been completed a further calculation can be used to determine the error rate, as follows: Error Rate = ± 2 x √( p x (100 - p) ) Number of observations This is very much an overview to the topic of activity sampling, with a definition of what it is, its advantage over continuous observation and the formulae that can be used to establish the confidence levels that can be obtained. Plant Location End Of Chapter 14