Utilizing ABAQUS to Analyze the Active Vibration Suppression of

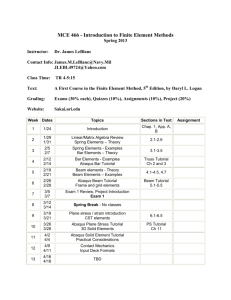

advertisement

Utilizing ABAQUS to Analyze the Active Vibration Suppression of Structural Systems Brian P. Baillargeon1, Senthil S. Vel2 and Jeffery S. Koplik3 1 ABAQUS East, LLC, Warwick, Rhode Island 02886 baillargeon@abaquseast.com 2 University of Maine, Orono, Maine 04469 senthil.vel@maine.edu 3 ABAQUS East, LLC, Warwick, Rhode Island 02886 koplik@abaquseast.com Abstract: ABAQUS can be utilized in the numerical simulation of active feedback control for the purpose of vibration suppression of structural systems. Using the example of active control of a cantilever beam, the Positive Position Feedback (PPF) control algorithm is coupled into an ABAQUS dynamical structural model with the assistance of user-defined subroutines. The transient response of the beam with and without the active control is examined. For a cantilever beam configuration consisting of aluminum facings and a core composed of foam and piezoelectric shear actuators, the ABAQUS solution is found to be in good agreement with experimental values from previous work. Keywords: Active Vibration Suppression, Composites, Dynamics, Piezoelectric Shear Actuator, Positive Position Feedback (PPF). 1. Introduction For more than a decade, there has been intense research in the area of smart/adaptive structures that has demonstrated the viability and potential of this technology. Smart structures, consisting of piezoelectric materials integrated with structural systems, have found widespread use in numerous engineering applications, which includes vibration suppression (Bailey and Hubbard, 1985; Garcia et al., 1992; Fuller et al., 1997). Usually, thin rectangular piezoelectric wafers that are laterally poled are bonded on or within the structure. Application of the electric field in the thickness direction causes the actuators lateral dimensions to change, thus causing the structure to deform. These actuators are referred to as extension actuators. 2004 ABAQUS Users’ Conference 81 Sun and Zhang (1995) proposed the use of a distinctly different mode of deformation by poling the rectangular piezoelectric actuator in the longitudinal direction. Application of the electric field E3 in the thickness direction of a piezoelectric actuator that is poled in the x1 direction causes a shear strain γ 13 = d 35 E3 to be developed, as depicted in Figure 1(a). The coefficient d35 is the piezoelectric shear coefficient. This type of actuator is referred to as a shear actuator. The piezoelectric shear actuators, when sandwich between two elastic face sheets, will cause transverse deformation of the structure as shown in Figure 1(b). A piezoelectric shear actuator is utilized in this study, but the methodology used for the active feedback control can be utilized for any smart structure. Recently, experimental investigation has shown that piezoelectric shear actuators are a viable option for vibration suppression applications (Baillargeon, 2003; Baillargeon and Vel, 2003). A numerical model that accurately predicts experimental behavior is essential for the design of high performance vibration suppression control systems. In the previous studies, finite element models were created in ABAQUS that accurately predict the transient response of the active vibration suppression of a cantilever beam. The feedback control system in these works was limited due to fact that the algorithm to couple the response between the control system and the structure was inherently explicit and relied on file reading and writing operations; therefore, the analysis needed a small time step to produce an accurate response of the control system. In this work, a more robust feedback control algorithm is implemented using two user-defined elements. The validity of his approach is compared with the previous experimental works. Feedback control systems involving piezoelectric materials have been successfully implemented into ABAQUS in the past by Ashour (2001) and Ray et al. (2000). Ray et al. implemented a state feedback control algorithm, whereas Ashour utilized a nonlinear control for plate vibrations. A distinctly different feedback control algorithm, namely Positive Position Feedback (PPF), is implemented in this study (Goh and Caughey, 1985; Fanson and Caughey, 1990; Dosch et al., 1992; Meyer et al., 1998). Also, a detailed description of how the control algorithm is incorporated into the finite element model using the subroutine UEL is given. 2. Adaptive Sandwich Beam 2.1 Constitutive equations We begin by constructing a rectangular Cartesian coordinate system, shown in Figure 1, to describe the infinitesimal deformations of an adaptive sandwich beam. The equation of motion and charge equation of electrostatics, in the absence of body forces and free charges, are: σ ij , j = ρu&&i , D j , j = 0 , (i, j = 1, 2, 3) (1) where σ ij is the Cauchy stress tensor, ρ is the density, ui are the mechanical displacements and Dj is the electric displacement vector. A comma followed by the index j indicates partial differentiation with respect to the xj-coordinate. A superimposed dot indicates differentiation with respect to time t, and a repeated index represents a summation over the range of that index. 2004 ABAQUS Users’ Conference 82 The constitutive equations for a piezoelectric material poled in the x1-direction are as follows: ⎧ ε 11 ⎫ ⎡ S11 ⎪ ε ⎪ ⎢S ⎪ 22 ⎪ ⎢ 12 ⎪⎪ ε 33 ⎪⎪ ⎢ S13 ⎨ ⎬=⎢ ⎪2ε 23 ⎪ ⎢ 0 ⎪ 2ε 13 ⎪ ⎢ 0 ⎪ ⎪ ⎢ ⎪⎩2ε 12 ⎪⎭ ⎣⎢ 0 ⎧ D1 ⎫ ⎡d11 ⎪ ⎪ ⎢ ⎨ D2 ⎬ = ⎢ 0 ⎪D ⎪ ⎢ 0 ⎩ 3⎭ ⎣ S12 S13 0 0 S 22 S 23 S 23 S 33 0 0 0 0 0 0 S 44 0 0 0 0 0 0 0 S 55 0 d12 d13 0 0 0 0 0 0 0 0 0 d 35 0 ⎤ ⎧σ 11 ⎫ ⎡ d11 0 ⎥⎥ ⎪⎪σ 22 ⎪⎪ ⎢⎢d12 0 ⎥ ⎪⎪σ 33 ⎪⎪ ⎢ d13 ⎥⎨ ⎬ + ⎢ 0 ⎥ ⎪σ 23 ⎪ ⎢ 0 0 ⎥ ⎪σ 13 ⎪ ⎢ 0 ⎥⎪ ⎪ ⎢ S 66 ⎦⎥ ⎪⎩σ 12 ⎪⎭ ⎣⎢ 0 0 0 0 0 0 d 26 0 ⎤ 0 ⎥⎥ ⎧ E1 ⎫ 0 ⎥⎪ ⎪ ⎥ ⎨E2 ⎬ , 0 ⎥⎪ ⎪ E3 d 35 ⎥ ⎩ ⎭ ⎥ 0 ⎦⎥ (2) ⎧σ 11 ⎫ ⎪σ ⎪ 0 ⎤ ⎪ 22 ⎪ ⎡∈11 0 0 ⎤ ⎧ E1 ⎫ ⎪⎪σ ⎪⎪ ⎪ ⎪ d 26 ⎥⎥ ⎨ 33 ⎬ + ⎢⎢ 0 ∈22 0 ⎥⎥ ⎨ E 2 ⎬ , σ 0 ⎥⎦ ⎪ 23 ⎪ ⎢⎣ 0 0 ∈33 ⎥⎦ ⎪⎩ E3 ⎪⎭ ⎪σ 13 ⎪ ⎪ ⎪ ⎪⎩σ 12 ⎪⎭ where σ ij is the Cauchy stress tensor, ε ij is the infinitesimal strain tensor, Sij are the elastic compliances, dij are the piezoelectric strain coefficients, Ej are the components of the electric field vector and ∈ij are the components of the electric permittivity tensor. The following equations relate the infinitesimal strains and electric field vector to the mechanical displacements and electric potential: ε ij = 2.2 1 (u i , j + u j ,i ) , E j = −φ, j . 2 (3) Adaptive sandwich beam setup An adaptive sandwich cantilever beam is constructed consisting of aluminum facings and a foam core consisting of two piezoceramic shear actuators and foam. The beam configuration used in this study can be found in Figure 2. This is the same configuration studied in both Baillargeon (2003) and Baillargeon and Vel (2003). The aluminum facings are composed of 6061-T6 aluminum. The core is composed of two axially-poled PZT-5A shear actuators (Morgan Electro Ceramics) and a lightweight foam core (Baltek Corporation R82.80). The pieces of the beam are firmly bonded together using an adhesive film that was placed in an autoclave to cure. The dimensions of the beam are 0.305 m in length and 0.0142 m in total thickness. The material properties of the aluminum facings are E = 69 GPa, ν = 0.33 and ρ = 2730 kg/m3 for Young’s modulus, Poisson’s ratio and density, respectively. The Baltek Airex R82.80 foam core has material properties of E = 62 MPa, G = 23 MPa and ρ = 80 kg/m3 for Young’s modulus, Poisson’s ratio and density, respectively (Baltek Corporation, n.d.). The piezoelectric actuators are transversely isotropic with principal material directions in the longitudinal direction of the 2004 ABAQUS Users’ Conference 83 beam (Figure 1). The electric field is applied through the thickness of the actuators via electrodes at the interface between the piezoelectric material and aluminum facings. Since there is no published data for PZT-5A poled in the x1-direction, the relevant material properties are inferred by tensor transformations of the fourth order elastic tensor, third order piezoelectric tensor and second order dielectric permittivity tensor of PZT-5A poled in the x3-direction (Berlincourt and Krueger, n.d.). The transformed material properties can be found in Table 1. The beam is excited by a proof-mass actuator, consisting of a low voltage piezostack (mass 0.015 g) and a steel block (0.126 g) that is attached to the end of the beam. This excitation source is used to produce a repeatable harmonic disturbance to the beam for the experimental work of the same situation. The application of a harmonic voltage to the piezostack, causes a harmonic strain to be developed in the thickness direction of the stack. This results in a harmonic force to be developed at the tip of the beam due to the inertia of the steel block. This is akin to an unbalanced motor at the end of the beam. The two embedded piezoelectric shear actuators P1 and P2 (refer to Figure 2) are used to suppress the vibrations caused by the proof-mass actuator. 3. Control design Active feedback control is implemented to control the vibrations of the beam through use of the Positive Position Feedback (PPF) algorithm. PPF was first introduced by Goh and Caughey (1985). This controller is advantageous for feedback control because it is not sensitive to spillover and it is not destabilized by finite actuator dynamics. Recently, Friswell and Inman (1999) have shown that PPF control may be formulated as an output feedback controller. The PPF controller is modeled as a second order system that is fed by the positive position coordinate of the structure. The response of the compensator, magnified by a gain, is then fed back to the structure to achieve feedback control. The equations that describe the structure-compensator interaction are as follows: ξ&& + 2ζ nω nξ& + ω n 2ξ = G pω c 2η , (4) η&& + 2ζ cω cη& + ω c 2η = ω c 2ξ , where ξ is the modal coordinate that describes the deformation of the structure, ω n is the natural frequency of the structure, ζ n is the damping ratio of the structure, η is the compensator coordinate, ω c is the compensator frequency, ζ c is the damping parameter of the compensator and Gp is the feedback gain coefficient. 4. Finite element model of the adaptive beam The numerical model used in this study utilized the commercial finite element package ABAQUS (ABAQUS Inc., 2003) to examine the behavior of the active feedback control of a cantilever beam. A two-dimensional plane stress analysis of the sandwich beam is performed using CPS8R and CPS8RE 8-node biquadratic plane stress elements for the elastic and piezoelectric materials, 2004 ABAQUS Users’ Conference 84 respectively. An implicit dynamic analysis is performed to examine the efficacy of ABAQUS to accurately predict the response of the active vibration suppression of the beam. The feedback control is numerically couples the compensator and the structure using two user-defined elements via the UEL subroutine within ABAQUS/Standard. A mesh convergence study is performed to ensure that the finite element model has converged to an acceptable limit. The fourth natural frequency of the beam without the proof-mass actuator is utilized as the convergence criterion. As a result of the convergence study, a mesh consisting of 3936 elements and 12516 nodes is used to model the adaptive beam. Damping is introduced into the model via the Rayleigh damping material model intrinsic to ABAQUS in order to obtain a realistic transient response of the cantilever beam. The Rayleigh damping model assumes that the damping ratio depends upon the frequency through only two constants that are usually chosen based upon matching the system damping to the experimental values at two of the system’s natural frequencies. The relationship between the damping ratio and the structural frequency is as follows: ζi = α 2ω i + β ωi (5) 2 where ζ i and ω i are the damping ratio and frequency of the ith mode, respectively, α is the mass proportional damping constant and β is the stiffness proportional damping constant. We are primarily interested in the fundamental mode of vibration; therefore, a stiffness proportional damping ( α = 0 ) model is assumed. The stiffness damping parameter β is calculated from an experimental damping ratio determined in Baillargeon (2003) and Baillargeon and Vel (2003). Using the logarithmic decrement, the damping ratio of the fundamental mode of the cantilever sandwich beam is ζ 1 = 0.00584 . The compensator is modeled as a spring-mass-damper system. The elements SPRING1, DASHPOT1 and MASS are utilized to model the stiffness, damping and mass of the compensator. Using these features, the quantities that define the compensator, such as the compensator frequency ω c and compensator damping ratio ζ c are developed. The piezoelectric stack actuator is modeled as a monolithic piezoelectric material. This is done due to the lack of reliable property data for the stack from the manufacturer. An equivalent piezoelectric strain coefficient is determined by comparing experimental and numerical results. This results in a piezoelectric strain coefficient d 22 = 7.995 × 10 −8 m/V (Baillargeon, 2003; Baillargeon and Vel, 2003) for the stack. 4.1 Structure-compensator user-defined element First, we examine the coupling of the structure to the compensator. Since the compensator is a second order system, we assume that the compensator is composed of a spring-mass-damper system. It is clear from Equation 2 that the structural coordinate applies a force that is proportional to the deformation of the structure. This coupling can be achieved by applying a 2004 ABAQUS Users’ Conference 85 force on the compensator degree of freedom uc that is proportional to the structural coordinate us. Mathematically, the user-defined element’s force vector appears as follows: ⎧ 0 ⎫ ⎨ 2 ⎬, ⎩ω c u s ⎭ (6) In this study, the deformation of the structure is fed onto the compensator via the strain at 0.0254 m from the root of the beam. The infinitesimal longitudinal strain is approximated using the following relationship: ε= u1 − u 2 . l (7) where ε is the longitudinal strain, u1 and u2 are the displacement in the longitudinal direction of two nodes at the surface of the cantilever beam 0.0254 m away from the root and l is the initial longitudinal length between the two nodes. The structural degree of freedom us is determined from a coupling equation of the following form: us = 4.2 u1 − u2 . l (8) Compensator-structure user-defined element Next, we examine the coupling from the compensator to the structure. Examination of Equation 4 reveals the coupling between the displacement degree of freedom of the compensator and potential degrees of freedom of the actuators of the adaptive beam. A Lagrange multiplier method is used to apply the constraint between the compensator and the structure in the following form: ( ) λT G p ω c 2 u c − φ s = 0 , (8) where λ is the Lagrange multiplier, uc is the compensator displacement degree of freedom and φ s is the potential degree of freedom of the structure. This constraint is also implemented using a user-defined element via the UEL subroutine within ABAQUS/Standard. This results in a three degree of freedom element of the following form, where the matrix on the left is the Jacobian, the vector in the middle is the degrees of freedom and the vector on the right is the residual force vector: ⎡ 0 ⎢ ⎢ 0 ⎢G ω 2 ⎣ p c 2 G p ωc ⎤ ⎥ 0 −1 ⎥ , e ⎥⎦ −1 0 2 ⎧u c ⎫ ⎧ − G p ω c λ ⎪ ⎪ ⎪ λ ⎨φ s ⎬ , ⎨ ⎪ λ ⎪ ⎪− G ω 2 u − φ p c c s ⎩ ⎭ ⎩ ( ⎫ ⎪ ⎬, ⎪ ⎭ ) (9) where the factor e is a small number to make the Jacobian positive definite. 2004 ABAQUS Users’ Conference 86 5. Results and discussion The active feedback control of the cantilever beam is the subject of this study. The excitation source of this system is the proof-mass actuator, consisting of a low-voltage piezoelectric stack actuator and steel block, attached to the tip of the beam. The two piezoelectric actuators P1 and P2 are utilized for the active vibration suppression. The cantilever beam has a natural frequency of ω1 = 74.443 Hz with the added inertial from the proof-mass actuator (Baillargeon, 2003; Baillargeon and Vel, 2003). The beam is excited at the fundamental natural frequency for 0.1 s, and it is allowed to decay naturally or with the aid of active vibration suppression. The parameters utilized for the compensator of the PPF control are a compensator natural frequency ω c = 1.3ω1 , a compensator damping ratio ζ c = 0.3 and scalar gain 2 Gc = 17 × 10 −5 V-s . A plot for the beam’s tip acceleration for the transient numerical simulation can be found in Figure 3, whereas the transient experimental results can be found in Figure 4. As can be seen from an examination of both Figures 3 and 4, the numerical model is in good agreement with the experimental behavior of the adaptive cantilever beam. The settling time, defined as the time at which the tip acceleration settles to 2% of its maximum value, reduces from approximately 1.0 s to 0.254 s in the numerical simulations when the PPF controller is used. This represents a reduction in settling time of approximately 76.9%. In comparison, settling times of the beam with and without PPF control are approximately 0.90 s to 0.272 s, which is a 69.8 % reduction in the time it takes the acceleration to settle to 2% of its maximum value. 6. Concluding remarks We have implemented active feedback control into an ABAQUS finite element model of a cantilever beam with two embedded piezoelectric shear actuators using two user-defined elements. Each of the elements couples either the compensator to the structure or vice-versa for the PPF control algorithm. The results of the numerical analysis are compared to that of experimental results from a previous study to validate that the user-elements are working correctly. An implicit transient analysis is performed on the cantilever beam consisting of aluminum facings and a core composed of piezoelectric shear actuators and foam. The beam is excited using a proof-mass actuator composed of a piezoelectric stack actuator and steel block. This excitation is akin to an unbalanced motor at the end of the beam. The duration of the excitation is 0.1 s, and then the beam is allowed to decay due to passive structural damping or with the aid of active vibration suppression. Comparing the results from the numerical and experimental simulations shows that ABAQUS can accurately predict the response of an actively controlled structure using the PPF control algorithm implemented with the two user-defined elements developed in this study. 2004 ABAQUS Users’ Conference 87 7. References 1. ABAQUS Inc, “Analysis User’s Manual version 6.4,” 2003. 2. Ashour, O. N., “Nonlinear Control of Plate Vibrations,” Ph. D. Thesis, Virginia Polytechnic and State University, 2001. 3. Baltek Corporation, “Airex R82,” Baltek Product Data Sheet, < http://www.baltek.com/data/pdfs/products/BEMSPDSairexr82.pdf> (04 November 2003), n.d. 4. Baillargeon, B. P., “Active Vibration Suppression of Smart Structure Using Piezoelectric Shear Actuators,” Master’s Thesis, University of Maine, 2003. 5. Baillargeon, B. P. and S. S. Vel, “Active Vibration Suppression of Sandwich Beams Using Piezoelectric Shear Actuators: Experiments and Numerical Simulations,” Submitted to the Journal of Intelligent Material Systems and Structures. 6. Berlincourt, D., and H. H. A. Krueger, “Properties of Morgan Electroceramic Ceramics,” Revised by C. Near, <http://www.morganelectroceramics.com/pdfs/tp226.pdf> (05 August 2002), n.d. 7. Bailey, T. and J. E. Hubbard Jr., “Distributed Piezoelectric Polymer Active Vibration Control of a Cantilever Beam,” AIAA Journal of Guidance, Control and Dynamics, vol. 8, pp.605611, 1985. 8. Dosch, J. J., D. J. Inman, and E. Garcia, “Self-Sensing Piezoelectric Actuator for Collocated Control,” Journal of Intelligent Material Systems and Structures, vol. 3, pp. 166-185, 1992. 9. Fanson, J. L., and T. K. Caughey, “Positive Position Feedback Control for Large Space Structures,” AIAA Journal, vol. 28, 717-724, 1990. 10. Friswell, M. I., and D. J. Inman, “The Relationship Between Positive Position Feedback and Output Feedback Controllers,” Smart Materials and Structures, vol. 8, pp. 285-291, 1999. 11. Fuller, C. R., S. J. Elliott, and P. A. Nelson, Active Control of Vibrations, San Diego: Academic Press, 1996. 12. Garcia, E., J. Dosch, and D. J. Inman, “The Application of Smart Structures to the Vibration Suppression Problem,” Journal of Intelligent Material Systems and Structures, vol. 3, pp. 659667, 1992. 13. Goh, C. J., and Caughey, T. K., “On the Stability Problem Caused by Finite Actuator Dynamics in the Collocated Control of Large Space Structures,” International Journal of Control, vol. 41, pp. 787-802, 1985. 14. Meyer, J. L., W. B. Harrington, B. N. Agrawal, and G. Song, “Vibration Suppression of a Spacecraft Flexible Appendage Using Smart Materials,” Smart Materials and Structures, vol. 7, pp. 95-104, 1998. 15. Sun, C. T., and X. D. Zhang, “User of Thickness-Shear Mode in Adaptive Structures,” Smart Material and Structures, vol. 4, pp. 202-206, 1995. 2004 ABAQUS Users’ Conference 88 8. Tables and Figures Table 1. Non-vanishing material properties of PZT-5A shear actuators poled in the x1 direction Material Property -1 S11 (Tpa ) -1 S22 (Tpa ) -1 S33 (Tpa ) -1 S12 (Tpa ) -1 S13 (Tpa ) -1 S23 (Tpa ) Value 18.8 16.4 16.4 -7.22 -7.22 -5.74 -1 S44 (Tpa ) 44.3 -1 47.5 -1 47.5 S55 (Tpa ) S66 (Tpa ) 2004 ABAQUS Users’ Conference Material Property -1 d11 (mV ) -1 d12 (mV ) -1 d13 (mV ) -1 d26 (mV ) -1 d35 (mV ) -10 (10 F/m) ∈11 ∈22 ∈33 ρ Value 374 -171 -171 584 584 150.45 -10 F/m) 153.1 -10 F/m) 153.1 (10 (10 3 (kg/m ) 7750 89 Figure 1. (a) Piezoelectric shear actuator and (b) an adaptive sandwich beam containing a piezoelectric shear actuator and foam core. 2004 ABAQUS Users’ Conference 90 Figure 2. Configuration of the adaptive sandwich beam containing two piezoelectric shear actuators. 2004 ABAQUS Users’ Conference 91 Figure 3. Implementation of active vibration suppression of an adaptive sandwich beam using a PPF compensator. 2004 ABAQUS Users’ Conference 92 0.4 Disturbance - off Tip Acceleration (g) 0.3 Without active control 0.2 0.1 0 -0.1 -0.2 PPF control -0.3 Disturbance - on -0.4 0 0.2 0.4 0.6 0.8 1 Tim e (s ) Figure 4. Finite element comparison of the real-time response before and after the PPF controller was initiated. 0.4 Disturbance - off 0.3 Tip Acceleration (g) Without active control 0.2 0.1 0 -0.1 -0.2 PPF control -0.3 Disturbance - on -0.4 0 0.2 0.4 0.6 0.8 1 Time (s) Figure 5. Experimental comparison of the real-time response before and after the PPF controller was initiated. 2004 ABAQUS Users’ Conference 93 2004 ABAQUS Users’ Conference 94