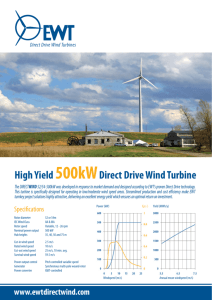

High Yield500kWDirect Drive Wind Turbine

advertisement

Direct Drive Wind Turbines High Yield 500kW Direct Drive Wind Turbine www.ewtdirectwind.com The DIRECTWIND 52/54-500kW was developed in response to market demand and designed according to EWT’s proven Direct Drive technology. This turbine is specifically designed for operating in low/moderate wind speed areas. Streamlined production and cost efficiency make EWT turnkey project solutions highly attractive, delivering an excellent energy yield which ensures an optimal return on investment. Power (kW) Specifications Rotor diameter IEC Wind Class Rotor speed Nominal power output Hub heights 52 or 54m IIA & IIIA Variable, 12 - 26 rpm 500 kW 35, 40, 50 and 75 m Cut-in wind speed Rated wind speed Cut-out wind speed Survival wind speed 2.5 m/s 10 m/s 25 m/s, 10 min. avg. 59.5 m/s Power output control Generator Power converter Pitch controlled variable speed Synchronous multi-pole wound-rotor IGBT-controlled Windspeed (m/s) www.ewtdirectwind.com Cp (-) Yield (MWh/y) Annual mean windspeed (m/s) Direct Drive Wind Turbines Direct Drive Wind Technology In EWT turbines the rotor directly drives the synchronous generator, without the use of a gearbox. This is important because various studies have concluded that the dominant cause of downtime is malfunctioning of gearboxes. The generated energy is fed into the grid via a modern back-to-back full-power converter which controls the output, so grid requirements can be met. This makes the DIRECTWIND turbine suitable to operate in weak grids. Advantages of EWT’s Direct Drive Technology: • Superior availability levels • Low maintenance costs • No need to replace gearboxes • Reduced noise levels • High yields / return on investment • Low cost of ownership Power quality & Site conditions The DIRECTWIND turbine feeds generator power into the grid by means of a modern ‘back-to-back’ type full-converter system. This converter contains a number of programmable functions like a capability to control the reactive power output. Built-in grid-fault-ride-through technology is available on demand. All the advanced grid-connection features combined make the DIRECTWIND the perfect choice for solitary applications, weak grids and demanding locations with constrains in site access. The combination of advanced control features and proven wind technology makes the DIRECTWIND also a first-class choice with regard to energy yield. Fewer components, high reliability, reduced maintenance and excellent energy yield ensure an optimal return on investment. We are looking forward to showing you what our DIRECTWIND systems can offer. DSP - DIRECTWIND Service Program EWT stands for high-quality direct drive turbines characterized by reliability and cost efficiency. To ensure optimal performance and trouble-free operation of our DIRECTWIND turbines, we have a extensive service and maintenance program in place. The DIRECTWIND Service Program offers: • Preventive maintenance • Corrective maintenance • Availability guarantee • Power curve guarantee EWT B.V. • Business Interruption compensation Lindeboomseweg 51 3825 AL Amersfoort The Netherlands T +31 (0)33 454 05 20 F +31 (0)33 456 30 92 sales@ewtdirectwind.com www.ewtdirecwind.com • Extended product warranty The company EWT is a designer and manufacturer of direct drive wind turbines active in Europe, North America and Asia. EWT was established in 2004 and is based in the Netherlands. The company has an extensive product line, an engineering department covering all relevant disciplines and a dedicated service and maintenance organisation. Disclaimer: The information included herein is provided to you for general information purposes only. Although every effort has been made to ensure the accuracy of such information, EWT makes no representation or warranty of any kind, express or implied, as to the correctness, accuracy, reliability or completeness of the information. www.ewtdirectwind.com Copyright EWT 2013 © Direct Drive Wind Turbines Proven robust 900kW Direct Drive Wind Turbine The DIRECTWIND 52/54 – 900kW is a pitch controlled variable speed wind turbine that combines continuous market driven innovation with highly advanced direct drive technology. The DIRECTWIND 52/54 – 900kW turbine boasts a track record over 400 operating turbines in many different wind climates. Power (kW) Specifications Rotor diameter IEC Wind Class Rotor speed Nominal power output Hub heights 52 or 54m IIA & IIIA Variable, 12 - 28 rpm 900 kW 35, 40, 50 and 75 m Cut-in wind speed Rated wind speed Cut-out wind speed Survival wind speed 2.5 m/s 13.5 m/s 25 m/s, 10 min. avg. 59.5 m/s Power output control Generator Power converter Pitch controlled variable speed Synchronous multi-pole wound-rotor IGBT-controlled Windspeed (m/s) www.ewtdirectwind.com Cp (-) Yield (MWh/y) Annual mean windspeed (m/s) Direct Drive Wind Turbines Direct Drive Wind Technology In EWT turbines the rotor directly drives the synchronous generator, without the use of a gearbox. This is important because various studies have concluded that the dominant cause of downtime is malfunctioning of gearboxes. The generated energy is fed into the grid via a modern back-to-back full-power converter which controls the output, so grid requirements can be met. This makes the DIRECTWIND turbine suitable to operate in weak grids. Advantages of EWT’s Direct Drive Technology: • Superior availability levels • Low maintenance costs • No need to replace gearboxes • Reduced noise levels • High yields / return on investment • Low cost of ownership Power quality & Site conditions The DIRECTWIND turbine feeds generator power into the grid by means of a modern ‘back-to-back’ type full-converter system. This converter contains a number of programmable functions like a capability to control the reactive power output. Built-in grid-fault-ride-through technology is available on demand. All the advanced grid-connection features combined make the DIRECTWIND the perfect choice for solitary applications, weak grids and demanding locations with constrains in site access. The combination of advanced control features and proven wind technology makes the DIRECTWIND also a first-class choice with regard to energy yield. Fewer components, high reliability, reduced maintenance and excellent energy yield ensure an optimal return on investment. We are looking forward to showing you what our DIRECTWIND systems can offer. DSP - DIRECTWIND Service Program EWT stands for high-quality direct drive turbines characterized by reliability and cost efficiency. To ensure optimal performance and trouble-free operation of our DIRECTWIND turbines, we have a extensive service and maintenance program in place. The DIRECTWIND Service Program offers: • Preventive maintenance • Corrective maintenance • Availability guarantee • Power curve guarantee • Extended product warranty • Business Interruption compensation The company EWT is a designer and manufacturer of direct drive wind turbines active in Europe, North America and Asia. EWT was established in 2004 and is based in the Netherlands. The company has an extensive product line, an engineering department covering all relevant disciplines and a dedicated service and maintenance organisation. EWT B.V. Lindeboomseweg 51 3825 AL Amersfoort The Netherlands T +31 (0)33 454 05 20 F +31 (0)33 456 30 92 sales@ewtdirectwind.com www.ewtdirecwind.com Disclaimer: The information included herein is provided to you for general information purposes only. Although every effort has been made to ensure the accuracy of such information, EWT makes no representation or warranty of any kind, express or implied, as to the correctness, accuracy, reliability or completeness of the information. www.ewtdirectwind.com Copyright EWT 2013 © PowerWind 500 The PowerWind 500 is perfectly tailored to the requirements of smaller community wind installations. It combines a superb profitability due to outstanding energy yield with a low sound power level. Moreover its aesthetic design and reduced heights make the PowerWind 500 perfect to integrate in community surroundings. The PowerWind 500 is a variable-speed, pitch-controlled wind turbine, certified in accordance with IEC wind class IIA. It has a rated power output of 500 kW and a rotor diameter of 56 m. The turbine design is based on the wellproven modular drive train concept and combines robust mechanical engineering with state-of-the-art power electronics. Many years of wind energy experience and the success of the 900 kW PowerWind 56 have been drawn on in the creation of this new model. Designed to simplify logistics, the PowerWind 500 is particularly benefical for locations which are difficult to access or have weak infrastructure. PowerWind 500 The PowerWind 500 has a superb profitability due the highest energy yield in its class. ·· Higher energy yield than all other comparable wind turbines in the same class due to large rotor diameter ·· Variable speed and pitch control allow maximum energy production at reduced drive train loads ·· Mulitple tower sizes from 44-50 m Low sound power level due to reduced rotor speed. ·· Sophisticated turbine design concept allows lower rotational speed and therefore a very low sound power level The PowerWind 500 is modelled after the proven modular drive train concept — sharing the same mechanical robustness as the established PowerWind 56. ·· The newly developed PowerWind 500 is designed with a maximum rated power of 500 kW ·· High reliability due to sophisticated components from reputable European manufacturers ·· Robust engineering By using a full-scale converter in the megawatt class, the PowerWind 500 benefits from the experience gained with multi-megawatt turbines. ·· Minimal disturbances (harmonics and flicker) due to use of a full-scale converter ·· Large reactive power control range for potential of grid support ·· Fault ride through in accordance with international grid requirement (optional) By consciously reducing the system dimensions, difficult logistics requirements are met. ·· Transport in containers possible ·· Transport of the three rotor blades on a single truck ·· Lesser crane requirement than multi-megawatt turbines, therefore significantly higher crane availability ·· No special permit for road transport required in many countries PowerWind 500 With its full range of features, the PowerWind 500 perfectly matches the requirements of smaller community wind installations. ·· Highest energy yield due to large rotor diameter ·· Low sound power level due to reduced rotor speed ·· Compact design facilitates logistics and installation even in difficult locations ·· Full-scale converter makes the system suitable even for weak grids All key components are sourced from reputable European manufacturers and meet high durability standards. ·· Close cooperation with leading companies in the wind industry ·· Core suppliers certified to ISO 9001: 2008 PI PW500 DataSheet en 03 The modern control concept offers web-based system monitoring and control. ·· Simple web-based remote monitoring (SCADA) independent of a specific site Performance Rated power output Cut-in wind speed Rated wind speed Cut-out wind speed Rotor diameter Rotor swept area Rotor speed Speed control Aerodynamic breaking Operating temperature range Power factor Wind class Gearbox Gear ratio Mechanical brake Yaw drive Yaw brake 500 kW 3 m/s 10 m/s 25 m/s 56 m 2,463 m² 6-24,9 rpm Individual electrical pitch Individual full span pitch -20 °C to +45 °C 0.9 ind. to 0.9 cap. IEC 61400 IIA One planetary and two spur gears 1:54.2 Disc brake on high-speed shaft (hydraulic) 3 AC motor drives with planetary gear Friction brake The high importance given to environmental protection is clearly reflected in our design. ·· Where possible, no hydraulic units are used ·· Enclosed oil and grease collecting trays ·· Use of a readily biodegradable, non-water hazardous transformer fluid (Midel) Compliance with all applicable safety standards is guaranteed. ·· Lightning and surge protection corresponds to the lightning protection zone concept of IEC 61400-24 ·· Design of the tower fixtures is in accordance with DIN EN 25817-B and EN 50308 The PowerWind 500 was developed to provide easy service and maintenance. ·· Accessibility to all main components with the possibility of easy replacement ·· Customized service packages available Generator Asynchronous, air-cooled Nominal rotation 1,350 rpm Enclosure class IP 55 Converter Full-scale converter (water-cooled) Tower Conical steel tower Hub height 44, 46, 49, 50 m Nacelle Glass fibre reinforced plastic Blades Glass fibre reinforced plastic Blade length 27.1 m Number of blades 3 Control system PowerWind SCADA PowerWind SCADA System Grid connection 50 Hz/690 V Available from: PowerWind GmbH Kehrwieder 8 20457 Hamburg Germany info@powerwind.de For further information: www.powerwind.de Subject to technical modifications. © 2011 PowerWind