Circuit Lab Manual - University of Wisconsin

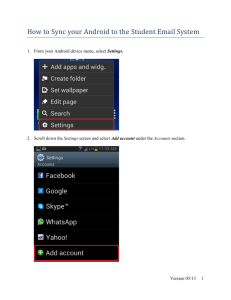

advertisement