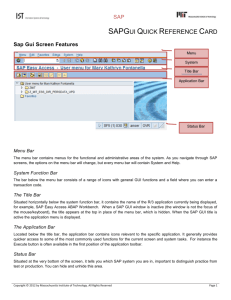

click on . Here

advertisement