Display Panel Industry

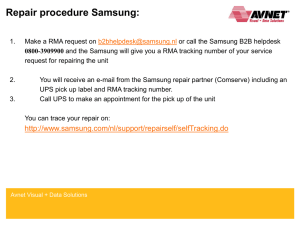

advertisement

The Case of Electronics and Pharmaceuticals Si un Yi(suyi@kiep.go.kr) April 29th, 2015 Santiago de Chile Introduction Display Panel Industry Pharmaceutical Industry Case study of Samsung Display Co., Case study of Boryung Pharmaceutical Company Final Considerations Motivation and drivers of MNCs to include SMEs in their supply base Analysis on governance structure within a value chain Incentives and challenges for SMEs to participate in GVC Government policy to evaluate where assistance is required Research area: two export clusters-Electronics and Pharmaceuticals Electronics: Korea is traditionally strong Pharmaceuticals: small but gradually growing Methodology: interviews, company reports, literature review General description of the Industry Knowledge and capital intensive Strong vertical operation structure: from electronic components to finished products Exists cycle of the final products Stagnant period Strong growth New paradigm Flexible, transparent OLED LED 2000 3D 2010 Tablet PC 2020 Polarizer Glass (or plastic) Colour filter Organic materials Liquid crystal Glass Polarizer Back Light Unit LCD OLED Materials Components Array glass substrate Colour register TAC Film, PVA Film Colour filter Compensation film Protective/release film Reflecting plate, Light guide plate, Diffusion plate, Prism Polarizer Driver IC BLU (CCFL, etc.) Panel maker Set maker LCD Panel maker Laptop PC (Samsung Display, LG Display) LCD PC monitor LCD TV Small LCD monitor World’s leading producers Two dominant global players: SDC, LGD 45% share in the world’s display panel market Strategically important sector in Korean economy 3.4% of total GDP in 2013 Employed 127,000 people US$ 34 billion in exports 16.4 2.85 14.24 2.34 10.91 0.79 12.31 0.47 9.74 0.52 64.85 70.45 78.53 76.8 78.04 13.35 9.76 7.59 8.19 8.81 2009 2010 2011 2012 2013 Latin America Asia North America Eastern Europe Paju Cluster: 26 thousand employees, LG subsidiaries including LG Display and related firms, 450million m2, Tangjeong Cluster: 197 companies related to display panel industry are clustered and producing more than 54% of domestic the production. Employees: 31,000 Annual Sales: 21,191.6 USD (mil) Business Description: Develop and manufacture liquid crystal display boards and display panel components for use in the consumer, mobile and IT sectors Subsidiary of Samsung Electronics, with which creating a strong industrial cluster Manufacturing plants in Korea, China, Slovakia, and soon in Vietnam Back Light Unit(BLU): light source of LCDs (belongs to a module assembly) Accounts for 25% of LCD panel production cost. Simple process and low value added content. SDC is purchasing BLUs from about 20 companies. Supplier Capital (USD, Mil)b Number of employeesb Major products Notes E-Litecom 5.5 187 BLUs for mobile phones, medium-sized liquid crystal modules (LCM) Delivers to Samsung, LG and Apple Samjin LND 8.6 175 Display Tech Kumho Electric 8.4 31.4 224 246 Inzi Display Company Limited 15.4 276 BLUs for TVs, LED lamps, mould frame LCD modules for mobile phones Fluorescent lamps, LED lamps, LED parts (CCFLs, BLUs) Top chassis for panel modules, BTM chassis for BLUs Reygen 7.5 201 BLUs for TVs and monitors, light guide panels (LGPs) Fine DNC 8.0 298 Korea Computer INC. 7.2 273 Top chassis, bottom chassis for LCD/LED TVs Modules for LCD TVs and mobile phones, LED surface-mount technology (SMT) for laptops A-Tech Solution 4.5 480 Mould frames, LED lamps, LGPs for TVs Contractor of Samsung Display. Deliver product for SESL (Samsung Electronics Suzhou LCD), SAMAX (Samsung Mexicana) LG and Samsung partner; also exports to Japan and Taiwan Province of China. LED-SMT for laptop is exported to China first and then indirectly delivered to Samsung Display. For Samsung Display Reducing production cost Flexible management and reduce the risks against volatile cycles of final products and technology change For BLU suppliers Securing steady demand Ensuring timely payments Improving its image and credibility Overcome the issue of limited capital(R&D, human capital) For Samsung Display Leaking knowledge non disclosure agreement, short duration of contract For BLU suppliers Competitive market: few purchasers, large number of suppliers High dependency and limit of sales growth Low value added component, and weak bargaining power for the price Material and Component Technology Plan, 2012(Ministry of Trade, Industry and Energy, MOTIE) Display Shared Growth and Cooperation Committee, 2014(MOTIE) R&D capacity building for SMEs Semiconductor Research Corporation model: universities and research institutes conduct research, MNCs and government invest, remove hurdles for SMEs Technical Support Centre for Touch Panel Industry in Daegu, 2014(MOTIE) supports manufacturing processes: product design, certification, pilot production and also marketing, and networking General Description of Industry Technology intensive with high value added each time a new drug is patented. High initial capital investment and technology intensity: process from discovery to approval accounts almost 70% of the total cost and takes long time. High regulations of governments for the sake of citizen’s health. Development of new drugs, production of synthetic raw materials within value chain Korea Importing large volumes of drugs, repackaging for final consumption in the local market Discovery Synthesis Of substance Clinical test Approval Manufacturing Sales Big pharmaceutical company University Venture company Public research institute Big pharmaceutical company Big pharmaceutical company University Public research institute CRO (Chemical service) Venture company Venture company CRO (Clinical test) CMO (Manufacturing) Local company World’s 15th largest producer behind Mexico and Brazil Small but growing market participation 270 companies producing final pharmaceutical products, 300 companies for drug substances Technology capability: half way between developing and developed economies(more generic drugs or commercial product than developing new drugs) High dependency on foreign contract research organizations(CROs) Development of 32 new drugs since 1988 Exports Imports (USD, Million) 4,915 5,083 4,418 3,917 1,139 2008 3,881 1,391 2009 1,530 2010 1,753 2011 2,049 2012 Substance Finished product 145 124 95 87 32 21 2004 38 16 2005 43 79 74 64 47 93 38 50 48 54 58 24 2006 2007 2008 2009 2010 2011 2012 2013 Ecuador 1 Argentina 14 Uruguay 3 Uruguay 2 Chile 6 Argentina 1 Chile Ecuador 9 8 Brazil 38 Peru 8 Peru 3 Colombia 13 Brazil 51 Colombia 14% Mexico 22 Substance Mexico 7 Finished Products JW Pharmaceuticals Daewoong Pharmaceuticals LG Life Sciences Dong-A Holdings Green Cross • Export of Imipenem (a type of antibiotic, API) to Brazil from 2005 onwards. • Received the Good Manufacturing Process approval by the Brazilian Health Surveillance Agency (ANVISA) in 2013. • Export of the final antibiotic product to Brazil in collaboration with TARGO. • In 2013, it exported their in-house developed product Nabota (a botulinum toxin formulation) to 15 Latin American countries(Bolivarian Republic of Venezuela, Colombia and Mexico, etc). • It sold their diabetes treatment, Zemiglo, to the Mexican pharmaceutical company Stendhal. • It established a local subsidiary (Dong-A Participações Ltda.) in Brazil in 2013 and sold its products to Latin America through this subsidiary. • It has been exporting GC Flu to Colombia, Guatemala, Nicaragua, Paraguay and Peru. Employees: 1,000 Annual Sales: US$ 312 Million Business description: Manufacture and sell pharmaceutical products Specialized in producing medicines for hypertension and antiviral treatment. Developed its new hypertension drug Kanarb in 2010 and export to LACs from then. R&D: Manufacturing: Develop: Boryung’s central lab(5% of total revenues) Clinical test: Contract Research Organizations developed countries such as Quintiles and Covance(UK), Harland(Switzerland). Drug substance supplied by SMEs, and also developed countries Sales(distribution and marketing): Partnership with local companies such as Stendhal in Mexico and Ache in Brazil Incentives for participating in value chain Creation of trust for other potential buyers Regular and timely payments Challenges for cooperating with MNCs High dependency and low bargaining power Regulatory barrier: needs to attain certification of good management practices and approval from Ministry of Food and Drug Safety Bio Korea International Convention Medistar Initiative, KOTRA(Korea Trade-Investment Promoting Agency) Fairs, to resolve the difficulties in marketing provides market research, interpretation services, training, matchmaking with potential buyers, network services and marketing, global partnering service, and R&D Homologation Agreements with foreign countries reduce institutional barriers Eg. Ecuador Opportunities * Stable demand * Improve credibility * Transfer knowledge/skills * Little negotiating power * Probability of being isolated * Institutional and technological barrier Struggles MNC’s predominant role in global value chain MNC’s intents to reduce dependency on foreign suppliers Open innovation strategy of MNCs that encourages SMEs participation Government’s focused support to strengthen material and part industry which involves large number of SMEs. Display Panel Industry Yet, small participation of MNCs in global value chain Majority SMEs supply ingredients Government’s overall support to increase the export of the product, from reducing trade barriers to financing R&Ds. Pharmaceutical Industry