Centrifugal Pump Experiment Pump History

advertisement

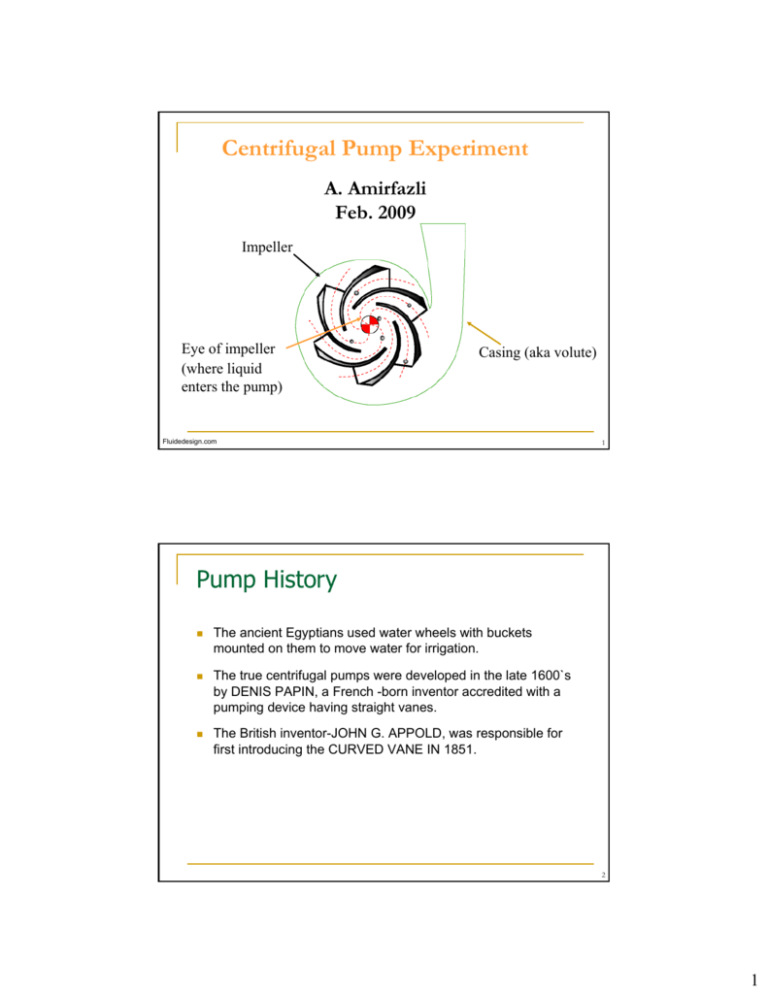

Centrifugal Pump Experiment A. Amirfazli Feb. 2009 Impeller Eye of impeller (where liquid enters the pump) Casing (aka volute) Fluidedesign.com 1 Pump History The ancient Egyptians used water wheels with buckets mounted on them to move water for irrigation. The true centrifugal pumps were developed in the late 1600`s by DENIS PAPIN, a French -born inventor accredited with a pumping device having straight vanes. The British inventor-JOHN G. APPOLD, was responsible for first introducing the CURVED VANE IN 1851. 2 1 Centrifugal Pumps Centrifugal Pumps belong to wider group of fluid machines called turbo machines. Pumps add energy to a fluid stream. As such they have a wide application: Water distribution systems Industrial processes Buildings; municipality; irrigation (farming). Oil pipelines; power plants; refineries Machineries Lubrication; fuel 3 OBJECTIVES 1. To measure the performance of a centrifugal pump and compare the results with theoretical predictions. 2. To compare them with the manufacturer’s specification. 3. To investigate affinity laws for pumps (MecE 330). 4. To study the performance characteristics of pumps in parallel and series system configurations. 4 2 Centrifugal Pump Impeller Eye of impeller (where liquid enters the pump) Casing (aka volute) Fluidedesign.com 5 6 3 motor outlet inlet pump 7 Experimental Setup Return line Pressure transducer tank Measurement tank (flow rate) pumps 8 4 Piping arrangement for conducting series or parallel pump experiments 9 Experimental Measurements The head produced by pumps is measured (pressure transducer) The flow rate of the pumps is measured (gravitometry method… similar to Boiler Exp.) 10 5 Torque is measured by determining the force required to hold the motor casing steady The RPM (rotational speed) of pump is selected/set The geometrical information for pump impeller (vane angles, radius, etc.) is known/given 11 Head-Discharge Curve 10 1500 RPM Head, H (m) 9 1100 RPM 8 7 750 RPM Shut-off head 6 5 4 3 2 1 0 0 20 40 60 -4 3 80 Flow rate, Q (x10 m /s) 100 12 6 Velocity Triangle and Adding Energy to the Fluid Top view Side view V2 U = Ω.r2 V2θ V2r V1 V2rel r1 β2 b V2 r2 V2 13 RED: high pressure impeller eye www.fortunecity.com BLUE: low pressure impeller tip 14 7 Euler Equation . Angular momentum (T): T = mr2V2θ From velocity triangle we have: V2θ = U –V2rcotβ2 . therefore: T = m.r2 [U –V2rcotβ2] . From energy eqn.: TΩ = mgH Then: H= U2 g and ⎡ V2 r ⎤ ⎢1 − U cot β 2 ⎥ ⎣ ⎦ U = r2 Ω Euler Eqn. 15 Non-dimensional Euler Eqn. Ψ = 1 − Φ cot β 2 Where Ψ Head Coefficient (= Hg/U2) and Φ Flow Coefficient (= V2r /U) ideal 16 8 Experimental calculation for Φ and Ψ Ψ (= Hg/U2) is easy to calculate since we directly measure H and we know RPM and radius of the impeller which gives us U (=Ω.r2) To calculate Φ (= V2r /U) again as above we have U, but need V2r (= Q / A exit ) Q is directly measured, but Aexit needs to be calculated! 17 Exit area (Aexit) is equal to area at the impeller outlet minus vane thickness, i.e. Aexit = (2πr2 – 5t).b Impeller thickness at exit r2 There are 5 vanes in the impeller Vane thickness (t) Outer edge β2 β2 β2 on average is ~28° 18 9 Head Coefficient Ψ Dimensionless Head and Flow Coefficients 1.2 1500 RPM 1.0 1100 RPM 750 RPM 0.8 Manufacturer (1750 RPM) Ideal (Euler's) 0.6 0.4 0.2 0.0 0.00 0.02 0.04 0.06 0.08 0.10 0.12 0.14 Flow Coefficient Φ Shut-off head actual (head at zero flow rate) is ~50% of the shut-off head ideal (= U2/g), why? 19 Deviations from Theory Frictional losses in the impeller and casing is not considered in the theory These frictional losses increase with Q Angle at which the fluid leaves the impeller is not β2 (it is always less due to slip) The flow in the impeller is not uniform (1dimensional) as assumed in theory. Some leakage from outlet to inlet of the pump due to clearance between impeller and casing 20 10 Affinity Laws Manufacturers to offer a wide range of pumps use geometrical similarity to enlarge or shrink a particular design. If the Reynolds numbers are large, the head and flow coefficient for geometrically similar pumps will remain constant and therefore: Q1 Ω1 ⎛ D1 ⎜ = Q2 Ω 2 ⎜⎝ D2 ⎞ ⎟⎟ ⎠ H 1 ⎛ D1Ω1 =⎜ H 2 ⎜⎝ D2 Ω 2 3 ⎞ ⎟⎟ ⎠ 2 21 Dimensionless head versus flow coefficient curves for geometrically similar machines 1.0 0.9 Unit 454 Unit 453 0.8 Unit 452 Unit 451 0.7 0.6 Head coefficient 0.5 0.4 0.3 0.2 0.1 0.0 0.00 0.05 0.10 0.15 Flow coefficient 22 11 Cut Impeller Manufacturer to save on development costs, but to offer wide range of pumps with various headflow characteristics often cut impellers and place them in the same casing. Cut impeller pumps are NOT geometrically similar; therefore affinity laws will not apply! 23 Typical Pump Curve www.fortunecity.com 24 12 Dimensionless head versus flow coefficient curves for geometrically dissimilar machines (cut impeller) 0.8 Unit 454 Unit 453 Unit 452 Head coefficient 0.7 0.6 Unit 451 0.5 0.4 0.3 0.2 0.1 0.0 0.00 0.05 0.10 0.15 0.20 Flow coefficient 25 Flow Efficiency Flow efficiency (η) is a measure of how much of the input power (=TΩ) is converted to the fluid power (=pgQH). η= ρgQH TΩ 26 13 Efficiency versus flow coefficient curves 80.0 70.0 Efficiency (%) 60.0 50.0 40.0 1500 RPM 1100 RPM 30.0 750 RPM 20.0 Manufacturer (1750 RPM) 10.0 0.0 0.00 0.02 0.04 0.06 0.08 0.10 0.12 0.14 Flow coefficient 27 Pumps in Series Q = Q1 = Q2 H = H1+ H2 28 14 Pumps in Series 30 Head m 25 2 pumps in series 20 15 A single pump 10 5 0 0 20 40 60 -4 80 100 3 Flow rate (x10 ) m /s 29 Pumps in Parallel H = H1 = H2 Q = Q1+ Q2 30 15 Final Note Check the lab manual for details of what to report and answer any questions posed. 31 16