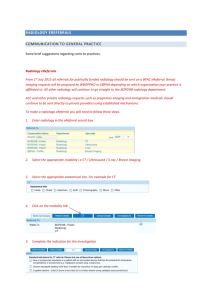

Capacity planning for waiting list management

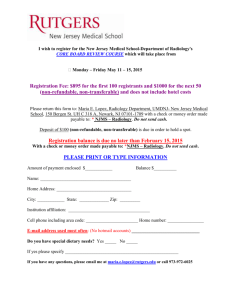

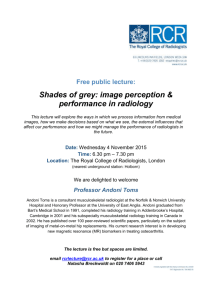

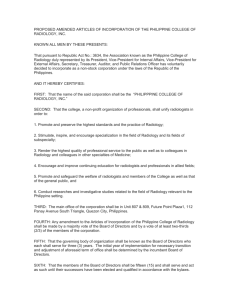

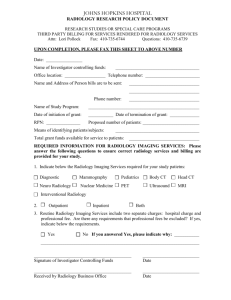

advertisement