A Biologically Inspired Robotic Ribbon Fin

advertisement

A Biologically Inspired Robotic Ribbon Fin

J. Edward Colgate

Dept. of Mechanical

Engineering

Northwestern University

Evanston, IL 60208 USA

Michael Epstein

Dept. of Mechanical

Engineering

Northwestern University

Evanston, IL 60208 USA

Index Terms—Biomimetic robotics,

swimming, black ghost knifefish.

gymnotiform

Malcolm A. MacIver

Depts. of Mechanical and

Biomedical Engineering

Northwestern University

Evanston, IL 60208 USA

fish

Abstract—The robotic ribbon fin is a propulsive mechanism

inspired by the long fin of the agile, South American black ghost

knifefish. The natural ribbon fin can produce rapid accelerations

in any of multiple directions, enabling the fish to quickly reach

points within the range of its weakly electric sensing system. We

discuss the design and control of the robotic ribbon fin and

introduce a computational model of the thrust which will be

useful for closed-loop control and gait optimization algorithms.

The robotic ribbon fin has potential application in future

underwater vehicles that require a high degree of

maneuverability, rapid accelerations and effective stationkeeping.

I. INTRODUCTION

In this paper, we introduce a new robotic fish fin inspired

by the long, ribbon-like fin of the South American black

ghost, a remarkable fish with integrated electric sensing and

locomotor systems. We then develop a computational model

of the ribbon fin which enables us to estimate the thrust forces

on the fin. This model exploits simplifying assumptions about

the fluid interactions and fin deformations to provide a

straightforward relation between the system dynamics and

resultant forces, without resorting to more complex

computational solutions (see [1-4]). We use the model to

simulate forward swimming of the black ghost and compare

the results with those in the literature, and then simulate a

comparable robot gait.

This effort builds upon the prior work of MacIver, Fontaine

and Burdick [5]; Sfakiotakis and Tsakiris [6]; McIsaac and

Ostrowsky [7, 8] and Ekeberg [9].

II. THE BLACK GHOST KNIFEFISH

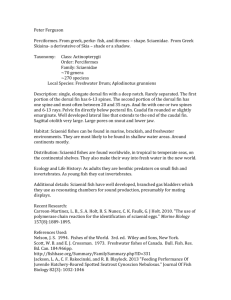

The South American black ghost knifefish (Apteronotus

albifrons) can be found in rapidly flowing, sandy-bottomed

rivers and creeks from Venezuela to Paraguay. Adults grow to

lengths of about 15 – 50 cm and they are nocturnal hunters of

tiny insect larvae and crustaceans [5, 10].

Figure 1: The black ghost knifefish (from Dr. Axelrod's Atlas of Freshwater

Aquarium Fishes)

The black ghost generates a weak electric field, about

1 mV/cm, to sense its environment and locate prey. The fish

will typically swim past its target while processing the

sensory information, then rapidly reverse course and capture

the prey. The black ghost’s ability to accelerate in any of a

number of directions enables effective coverage of all points

within its sensing range [5, 11].

The ribbon fin is the black ghost’s primary propulsive

element and runs about two thirds of the length of its

underbelly. The fin is supported and actuated by bony rays

spaced approximately 1 mm apart and 1 cm in length, though

as the fin tapers at either end, the rays become progressively

shorter. The fish has two smaller pectoral fins, located on

either side of the body towards the front, which it uses for

steering and stability.

The black ghost swims forward by oscillating the fin rays

slightly out of phase with each other, thereby producing a

traveling wave along the fin, from front to back, while

keeping its thin, flat body mostly rigid; it can move backward

with similar agility by reversing the wave’s phase velocity

[12, 13]. The fish can execute rapid, sharp turns by rolling its

body about the head-to-tail axis and then actuating the ribbon

fin to produce thrust normal to the axis [5, 11]. This is

unusual behavior for fish, whose deep body plans are

interpreted as providing stability to counter roll [14], but it is

an effective mechanical solution for movement in unactuated

directions.

1

III. ROBOTIC APPARATUS

IV. COMPUTATIONAL MODEL

A. Modular Design

The robotic ribbon fin was designed with commercial

three-dimensional CAD software (SolidWorks, SolidWorks

Corporation, Concord, Mass., USA). All structural parts were

precision cut from lightweight aluminum 6061 alloy sheets on

a high-speed, CNC milling machine.

A. Fluid Interaction

We employ a fluid drag model which has been used

extensively in the literature [6, 7, 9, 12] (see also [15-17]) to

analyze forces on swimming robots. The model assumes a

large Reynolds number flow regime and that all forces acting

on a propulsive element are due to the motion of that element

in the fluid, i.e. the effects of the fluid’s motion are not

considered. The results of initial testing of the robotic ribbon

fin and data reported for the black ghost indicate a Reynolds

number of 103–104 [5, 18].

The movement of the robot’s propulsive elements through

the fluid causes pressure differentials to develop on either side

of the elements, resulting in drag forces which act in

opposition to the motion. The drag force on a single

propulsive element moving through the fluid is given by:

Fn = − 12 ρCS v n

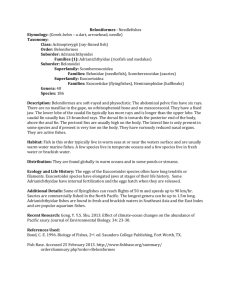

Figure 2: Robotic ribbon fin (left, shown upside down for clarity) and closeup view of a single actuator module (right). Motors are shown in blue.

The modular design of the robotic fin enables us to

experiment with different materials for the rays and flexible

membrane; in the preliminary trials, we used 1.6 mm diameter

brass rods and thin latex sheet approximately 0.1 mm thick.

The current version of the fin is assembled from sixteen

identical actuator modules, each of which has a digital RC

servo motor (Model DS168, Japan Radio Corp.), a 1:1 ratio

miter gear pair, ray and holder, as shown in Figure 2. The

motors operate at voltages ranging from 4.8–6.0 volts DC,

with a higher voltage associated with greater speed and

torque. At 4.8 volts, each motor delivers 0.33 Nm of torque

and rotates at a maximum speed equivalent to 1.2 revolutions

per second.

B. Motor Control

The motors are controlled by a pulse width modulated

(PWM) signal of fixed amplitude and a frequency of 50 Hz.

The motor position is commanded by varying the duration of

the pulse from a minimum of 1.0 ms, to a maximum of 2.0 ms

and the particular motors we use have a total range of 80°.

The PWM control signals are generated by a

microcontroller board (ServoCenter, Yost Engineering, Inc.,

Portsmouth, Ohio, USA) which is capable of addressing

sixteen motors independently. The board is connected by

RS232 serial interface to a Windows PC, and custom

MATLAB software is used to send binary command data to

the microcontroller.

2

uv

(1)

where Fn is the force exerted by the fluid on the n-th

propulsive element; ρ is the density of the fluid; C is a shapedependent drag coefficient; S is the effective area of the

propulsive element that confronts the fluid; vn is the velocity

of the n-th propulsive element and uv is a unit vector in the

direction of the velocity.

We can resolve this force into components which act

parallel and perpendicular to the surface of each propulsive

element. For a smooth, thin and flat body, the parallel drag

coefficient, and hence the parallel force, is negligible [6, 7].

Therefore, we can assume that the force acting normal to the

surface of the propulsive element is nearly equal to the entire

force on the element:

Fn ≅ Fn⊥ = − 12 ρCS [v n • u ⊥ ] 2 u ⊥

(2)

where Fn⊥ is the component of the drag force acting

perpendicular to the surface of the n-th propulsive element; vn

is the n-th element’s velocity relative to the fluid and u⊥ is a

unit vector normal to the surface of the element (and within

90° of the velocity vector).

B. Idealized Mechanism

Figure 3 shows an idealized mechanism derived from the

robotic ribbon fin. Each of the sixteen rays may be regarded

as a rigid rod of negligible diameter and mass, attached by a

revolute joint at its base to the common axis. The rotation of

each ray is constrained to less than ±40º from the vertical, in

accordance with the observed kinematics of the natural ribbon

fin during forward swimming [5].

2

the ribbon fin can produce thrust, lift and lateral stabilizing

forces simultaneously.

Figure 3: Idealized robotic ribbon fin with the rays as rigid rods and the

flexible fin as rigid, triangular flat plates.

We model the flexible membrane as a series of connected,

rigid, triangular plates of negligible thickness and mass—

hereafter simply “triangles”—whose motion approximates the

twisting and stretching of the membrane. Figure 4 shows that

the shape of the membrane segment between the first two rays

is approximated by triangles ABC and BCD. Since the two

rays rotate about points B and D respectively, triangle BCD

moves in pure rotation around the body axis. Its motion

contributes to the lateral (x) and vertical (y), but not axial (z),

resultant forces acting on the body. Triangle ABC, however,

may rotate about the main axis and about the axis along AB,

depending on the relative linear velocity of the ray tips. The

length of segment AC varies if the ray tips move with a

nonzero relative linear velocity, so both the orientation of

triangle ABC and its area may change with time. Therefore,

the motion of triangle ABC may result in a force with

components in the lateral, vertical and axial directions, and a

magnitude varying with the area of the triangle and the square

of its velocity.

C. Gait Generation

A forward swimming gait can be generated by passing a

traveling wave along the ribbon fin from front to rear. We can

produce such a wave by commanding all rays to oscillate at

the same frequency but with a constant phase lag [6, 19, 20].

The angular position of the n-th ray is then given by (3). The

frequency, amplitude and wavelength may serve as inputs to a

closed-loop control system [6] or a gait optimization

algorithm designed to maximize swimming performance.

(n − 1) L

θ (n,t ) = Θ(n ) sin 2πft − 2π

N λ

where θ(n,t) is the angular position of the n-th ray at time t;

Θ(n) is a function defining the maximum angular deflection in

radians of the n-th ray and therefore the amplitude of the wave

at the n-th ray; f is the angular frequency of the wave; N is the

total number of rays; λ is the wavelength and L is the fin

length.

The phase velocity of the traveling wave generated by (3)

is:

v= λ f

(4)

where v is the wave’s phase velocity.

D. Determining Thrust

To account for the distribution of local forces across the

flexible membrane, we create a mesh of cells on the surface of

the approximating triangles (see Figure 5). The force on a cell

of infinitesimal area is given by the equation below and we

use the experimentally determined drag coefficient for a flat

plate moving normal to the fluid, that is C = 1.28 [21]:

dFi = − 12 ρC dS [v i • u i ⊥ ] 2 u i ⊥

Figure 4: Close-up view of the idealized robotic ribbon fin. (See text for

explanation of annotations.)

In general, for a fin with N rays, the membrane can be

approximated by (2N-2) triangles. Half of these are similar to

ABC in that they may have a varying area and their motion

may contribute to the resultant axial, vertical and lateral

forces acting on the fin. The remaining triangles are similar to

BCD; they move only in pure rotation and contribute to the

resultant forces on the fin in the vertical and lateral, but not

axial, directions. Therefore, by proper actuation of the rays,

(3)

(5)

where dFi is the force on the i-th cell, dS is the area of the

cell, vi is the velocity of the centroid of the quadrilateral cell

region, and ui⊥ is the unit vector normal to the surface of the

cell (and within 90° of the velocity vector).

The instantaneous resultant force acting on the robot is

found by integrating the differential forces over the entire

membrane surface. The time-averaged axial thrust on the

robot during one period of fin undulation is given by:

Fz

=

1T

[ F(t ) • u z ] dt

T ∫0

(6)

where ‹Fz› is the magnitude of the time-averaged thrust over

one period of fin undulation, T is the period, F(t) is the

instantaneous resultant force acting on the fin and uz is a unit

vector in the axial direction.

3

E. Validating the Model

To confirm the validity of the model, we simulate forward

swimming of the black ghost and compare the thrust

determined by the model to that reported in the literature. We

consider a 15 cm long fish, having a 10 cm ribbon fin of 100

rays and use (3) to generate a forward swimming gait. The

control inputs, fin characteristics and resultant thrust are

summarized in the table below:

F. Applying the Model to the Robotic Fin

Next we apply the model to simulate the forward

swimming of the robotic ribbon fin. The results are shown in

the table below:

TABLE II

FORWARD SWIMMING OF THE ROBOTIC RIBBON FIN

Fin Characteristics

TABLE I

FORWARD SWIMMING OF THE BLACK GHOST KNIFEFISH

Fin Characteristics

Number of rays, N

100

Ray length

10 mm

Ray spacing

1 mm

Fin length, L

100 mm

3.0 Hz

Wavelength, λ/L

1.0

Amplitude, Θ(n)

π/6 for all n = {1, 2, …, N}

Thrust

2.0 x 10-4 N

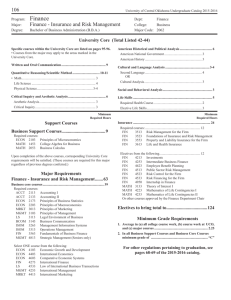

Figure 5 shows the model-generated pressure distribution

across the black ghost’s ribbon fin just after the start of the

simulation. The time averaged thrust calculated by the model

is 2.0 x 10-4 N and the time averaged lateral force is zero, both

of which agree well with prior results reported in the literature

for knifefish [18].

The model also indicates a relatively insignificant

(approximately 4% of the thrust) downward-directed vertical

force on the fish during forward swimming. It remains to be

determined whether such a small force in fact exists, or if it is

an artifact of our discrete model.

16

Ray length

50.8 mm

Ray spacing

11.4 mm

Fin length, L

171 mm

Control Inputs

Control Inputs

Frequency, f

Number of rays, N

Frequency, f

3.0 Hz

Wavelength, λ/L

1.0

Amplitude, Θ(n)

π/6 for all n = {1, 2, …, N}

Thrust

7.9 x 10-2 N

V. DISCUSSION

In this paper, we introduced a new robotic ribbon fin and a

computational model which enables us to estimate the

resultant thrust on the robot. We applied this model to

forward swimming of both the black ghost knifefish and the

robotic fin; results obtained for the knifefish agree well with

those reported in the literature.

We are currently constructing a test bed that will enable

experimental measurement of the propulsive forces generated

by the robotic ribbon fin. Such data will allow us to evaluate

the computational model and the simplifying assumptions

made about the hydrodynamics and fin deformations. Our

future research will be directed toward a better understanding

of the fin and fluid dynamics (for both the robot and the

natural fish) and of the relative impact of the design and

control parameters on the production of thrust.

ON-LINE RESOURCES

Photographs and video of the robotic ribbon fin and a copy

of this document are available at the following URL:

http://www.neuromech.northwestern.edu/publications

ACKNOWLEDGMENT

The authors wish to thank Professors S. Lichter and N.

Patankar of Northwestern University for their suggestions and

insights.

REFERENCES

[1]

[2]

Figure 5: Cell mesh and magnitude of pressure distribution across the black

ghost’s ribbon fin just after the start of the forward swimming simulation.

W. K. Liu, Y. Liu, A. Gerstenberger, D. Farrell, L. Zhang, and X.

Wang, "Immersed Finite Element Method and Applications to

Biological Systems," International Center for Numerical Methods and

Engineering (CIMNE), 2004, pp. 233-248.

R. Cortez, "A vortex/impulse method for immersed boundary motion in

high Reynolds number flows," Journal of Computational Physics, vol.

160, pp. 385-400, 2000.

4

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

R. Mittal, "Computational modeling in biohydrodynamics: Trends,

challenges, and recent advances," IEEE Journal of Oceanic

Engineering, vol. 29, pp. 595-604, 2004.

J. Carling, T. L. Williams, and G. Bowtell, "Self-propelled anguilliform

swimming: Simultaneous solution of the two-dimensional NavierStokes equations and Newton's laws of motion," Journal of

Experimental Biology, vol. 201, pp. 3143-3166, 1998.

M. A. MacIver, E. Fontaine, and J. W. Burdick, "Designing future

underwater vehicles: Principles and mechanisms of the weakly electric

fish," IEEE Journal of Oceanic Engineering, vol. 29, pp. 651-659,

2004.

M. Sfakiotakis and D. P. Tsakiris, "SIMUUN: A Simulation

Environment for Undulatory Locomotion," FORTH-ICS TR-343, 2004.

K. A. McIsaac and J. P. Ostrowski, "A geometric approach to

anguilliform locomotion: modeling of an underwater eel robot,"

presented at IEEE Conference on Robotics and Automation (ICRA),

Detriot, MI, 1999.

K. A. McIsaac and J. P. Ostrowski, "Motion planning for anguilliform

locomotion," IEEE Transactions on Robotics and Automation, vol. 19,

pp. 637-652, 2003.

O. Ekeberg, "A Combined Neuronal and Mechanical Model of Fish

Swimming," Biological Cybernetics, vol. 69, pp. 363-374, 1993.

H. Ortega and R. P. Vari, "Annotated checklist of the freshwater fishes

of Peru," Smithsonian Contributions to Zoology, vol. 437, pp. 1-25,

1986.

M. A. MacIver, N. M. Sharabash, and M. E. Nelson, "Prey-capture

behavior in gymnotid electric fish: motion analysis and effects of water

conductivity," J Exp Biol, vol. 204, pp. 543-57, 2001.

M. Sfakiotakis, D. M. Lane, and J. B. C. Davies, "Review of fish

swimming modes for aquatic locomotion," IEEE Journal of Oceanic

Engineering, vol. 24, pp. 237-252, 1999.

J. E. Colgate and K. M. Lynch, "Mechanics and Control of Swimming:

A Review," IEEE Journal of Oceanic Engineering, vol. 29, pp. 660673, 2004.

D. Weihs, "Stability versus maneuverability in aquatic locomotion,"

Integrative and Comparative Biology, vol. 42, pp. 127-134, 2002.

X. Tu and D. Terzopoulos, "Artificial Fishes: Physics, Locomotion,

Perception, Behavior," presented at ACM SIGGRAPH '94, Orlando,

Florida, 1994.

W. W. Schultz and P. W. Webb, "Power requirements of swimming: Do

new methods resolve old questions?" Integrative and Comparative

Biology, vol. 42, pp. 1018-1025, 2002.

N. Kato, "Pectoral Fin Controllers," in Neurotechnology for Biomimetic

Robots, J. Ayers, J. L. Davis, and A. Rudolph, Eds. Cambridge, MA:

The MIT Press, 2002, pp. 325-347.

R. W. Blake, "Swimming in the Electric Eels and Knifefishes,"

Canadian Journal of Zoology-Revue Canadienne De Zoologie, vol. 61,

pp. 1432-1441, 1983.

D. S. Barrett, M. S. Triantafyllou, D. K. P. Yue, M. A. Grosenbaugh,

and M. J. Wolfgang, "Drag reduction in fish-like locomotion," Journal

of Fluid Mechanics, vol. 392, pp. 183-212, 1999.

M. J. Lighthill, "Large-amplitude elongated body theory of fish

locomotion," presented at Royal Society of London (B), London, 1971.

T. Benson, "Shape Effects on Drag," 2004;

http://wright.nasa.gov/airplane/shaped.html

5