fire behavior, fuels and topography

advertisement

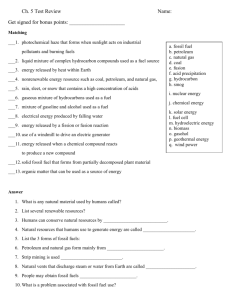

Chapter 6 Fire Behavior, Fuels and Topography FIRE BEHAVIOR, FUELS AND TOPOGRAPHY I. INTRODUCTION Most courses and material concerning fire behavior typically deal with wildfires in the mountainous western United States. This course, however, deals with fire behavior in a different setting: prescribed fire in the 11 ecoregions of Texas. The influence of Texas’s climate, vegetation, topography, coastline and other unique factors known to people familiar with the Lone Star State, can cause both wildfires and prescribed fires to vary radically from fires in the west. Fires are like snowflakes. Collectively they look alike, but when fires are closely examined it is apparent that no two fires burn in the exact same way. The overall objective of this course is to give the trainee a basic understanding of fire behavior in Texas and allow him/her to make some basic predictions on how a prescribed fire will act under the weather, fuel and topographic conditions present on the prescription area. II. FIRE TERMINOLOGY Before we begin discussing fire behavior and the fire environment, let’s review some fire terms and nomenclature, so that we all speak the same language: 1. Head - the forward, wind-driven edge of a fire usually the hottest and fastest-moving area with the highest flames 2. Flanks – the parts of the fire burning perpendicular to the wind 3. Rear – the part of the fire burning into the wind (also known as backing) 4. Islands – unburned patches of fuel inside a burn 5. Fingers – projections of the fire perimeter separate from the head 6. Pockets – areas of unburned fuel outside the fire perimeter that occur between fingers and the head. 7. Spotting – the process by which a fire spreads by lifting or transporting burning or glowing ember and ignition fuels in advance of the main fire. 8. Torching – the process by which a fire races upward from the ground to treetop to treetop. TDA Prescribed Burn School Manual v1.3 5-2002 1 Chapter 6 Fire Behavior, Fuels and Topography 9. Surface Fire – a fire burning above ground level but below the tree canopy 10. Crown Fire – a fire burning from treetop to treetop either in conjunction with or independently of a surface fire 11. Ground Fire – a fire that smolders underground in organic soils 12. Flare-up – a sudden increase in a fire’s rate of spread and intensity 13. Ground Fuels – material located in the duff and soil (organic material) 14. Surface Fuels – grasses, shrubs, and small trees 15. Ladder Fuels – trees and vines located between the surface and the crown 16. Aerial Fuels – the crowns or canopy of the overstory III. PHASES OF COMBUSTION The process of combustion is divided into four distinct phases. Understanding these phases is important to comprehending the overall effect a fire will have towards accomplishing the objectives of the burn. These phases are: 1. Pre-ignition – the products are water and organic gases. This phase is important to preparing the fuel just prior to the next phase so that actual combustion can take place. Some of the fuels, particularly those in the crown may reach this phase, but due to the fire’s velocity, not actually ignite, as a result they will “brown” but not actually burn. 2. Flaming – the major products are water, carbon dioxide, and visible smoke. The importance of this phase is obvious, the visible flame that consumes some of the available fuel. The amount of fuel consumed depends on the speed of the fire. 3. Smoldering – the product is visible smoke. This phase is important due to the continued consumption of available fuels and heat transferred to both the soil and the surrounding vegetation. 4. Glowing – the products are carbon monoxide and carbon dioxide. This phase continues to transfer heat to the area as well as consuming available fuel. The last three phases are the most critical to the prescribed burn manager. The total amount of fuel consumed and the total amount of heat generated determine the overall effect of the fire applied to the area. It is important to be able to determine, and regulate the total effect of the fire in all four areas with particular emphasis on the last three. TDA Prescribed Burn School Manual v1.3 5-2002 2 Chapter 6 Fire Behavior, Fuels and Topography IV. FIRE ENVIRONMENT There are three factors that make up the fire environment. They are: 1. Fuels 2. Weather 3. Topography V. PRINCIPLES OF COMBUSTION Three main elements of the fire triangle must be present in order for a fire to burn. These elements are: 1. Heat 2. Fuel 3. Oxygen Without one of these elements, fire cannot exist. In the planning phases of prescribed burning, all three elements should be considered. Once the burner TDA Prescribed Burn School Manual v1.3 5-2002 3 Chapter 6 Fire Behavior, Fuels and Topography understands the role of each side of the triangle and their relationship to time, they will have come a long way towards consistently achieving the objectives of their burns. Heat can be regulated by choosing favorable weather conditions and appropriate firing techniques. Fuel can be regulated by maintaining a particular fire regime and fire breaks. Oxygen can be regulated by choosing weather conditions that will contribute or restrict air movement. VI. HEAT A fire spreads by transferring heat from one piece of fuel to another. There are three ways this occurs. 1. Convection 2. Radiation 3. Conduction The three methods above are listed in the order of their importance. Convection – is the movement of heat through a liquid or a gas (like air). An example is heat rising in a column above a fire. Convection pre-heats fuel quickly, raising them to their ignition temperature. Convection heat usually rises, but may be pushed laterally by wind or slope. Radiation – is emitted from a burning fuel. The simplest example is the heat we feel from the sun. Radiation spreads in all direction, preheating fuels in the immediate vicinity of a fire. Conduction – is movement of heat through solids. An example would be the transfer of heat through a copper pipe. In woodland fires, conduction usually takes place in larger fuels such as fallen logs. However, wood is a poor conductor of heat, which makes the method of heat transfer the least important to the fires spread but very important to the fires effect on stems, root systems and soil. TDA Prescribed Burn School Manual v1.3 5-2002 4 Chapter 6 Fire Behavior, Fuels and Topography At this time, the only measurements that we have of the amount of heat released during a fire is the heat within the flaming front, regardless of location, head, flank, or back. The three measurers of heat are: 1. Reaction Intensity – which is the heat released per minute within a square foot of the flaming front. 2. Fireline Intensity – which is the heat released per second per linear foot of flaming front. 3. Heat per Unit Area – the total heat released within the flaming front in a square foot dependent of time. The important point to remember is that the total heat released and the fuel consumed is not measured by any three of the above. The smoldering and glowing phases of combustion are not taken into consideration by any of the three, however, the Heat per Unit Area does allow for the most complete picture during the flaming phase of combustion. TDA Prescribed Burn School Manual v1.3 5-2002 5 Chapter 6 Fire Behavior, Fuels and Topography EXERCISE 1: Heat Transfer Methods. Fill in the figure below with the appropriate methods of heat transfer. Remember the preheating of fuels may be occurring by all of these methods at the same time, depending on the arrangement or loading of the fuels. All three heat transfer methods are important factors in determining the spread of a wildland fire. VII. OXYGEN Oxygen is necessary for any type of combustion and the surrounding environment contains sufficient oxygen to sustain the fire. However, the environment is able to “feed” the fire to a greater or lesser degree depending on wind velocity. If there is no wind the fire stands straight up and the heat from the fire also goes straight up. If the wind bends the fire over in the direction towards which it is blowing, the flame tip is closer to the ground, and more of TDA Prescribed Burn School Manual v1.3 5-2002 6 Chapter 6 Fire Behavior, Fuels and Topography the heat is dissipated laterally, than vertically. This can be very important during the spring and summer if crown scorch has to be kept to a minimum. The bending or leaning of the flame is where the two terms flame height and flame length come into play. Flame height is the distance from the tip of the flame straight down to the mid-point of the fuel bed, with no wind this could equal flame length because the flame is standing straight up. Flame length, is the distance from the tip to the mid-point of the fuel bed along the flame, so with any kind of wind, flame length will be longer than flame height. The reason we us the mid-point of the fuel bed, rather than the ground is because the flame may not begin on the ground, particularly where crown fires are concerned. Another term applied to wind with respect to flame is “Mid Flame Wind Speed” which is the speed of the flame at the mid-flame of the total height. Most often the speed taken at eye level in the field is accepted as mid flame wind speed. Flame moving up slope will be closer to the ground and therefore closer to the fuels. This allows for faster preheating and preparing of the fuels for when the fire arrives to ignite them. Of course this is why fire tends to move much faster up hill than down or on flat ground. TDA Prescribed Burn School Manual v1.3 5-2002 7 Chapter 6 Fire Behavior, Fuels and Topography FUELS I. INTRODUCTION Fuel is any organic material that is living or dead, that can ignite and burn. Fuels are found in almost infinite combinations of kind, amount, size, shape, position and arrangement. The fuel on a given acre may vary from a few hundred pounds of sparse grass to 100 or more tons of logging slash. It may consist of dense conifer crown, deep litter and duff, moss layers and underground peat, or a mixture of any of these forming a fuel complex. We can estimate potential fire behavior by analyzing the physical properties and characteristics of fuels. Topographic and weather factors must also be considered before rate of spread and general fire behavior of fires can be determined. A. Fuel Levels and Components A systematic approach to looking at the fuel complex is to divide it into three broad groups or levels—ground, surface and aerial fuels. Aerial Fuels: All green and dead materials located in the upper forest canopy including tree branches and crowns, snags, moss, and high shrub. When aerial fuels are present we are concerned with crown or canopy closure. Timber stands with open canopies usually have a faster spreading surface fire than closed canopy stands, and torching of individual trees with possible spotting. Unless very strong winds are present, crowning is unlikely without a closed canopy. Closed canopy stands that are greater than six feet in height, whether timber or tall shrubs, offer the best opportunity for a running crown fire. It is important to note that few fires become running crown fires. Surface Fuels: All materials lying on or immediately above the ground including needles or leaves, duff, grass, small dead wood, downed logs, stumps, large limbs, low shrubs, and reproduction. Surface fuels are less compact than ground fuels and have other characteristics more favorable for faster rates of spread. Surface fuels include litter, grass and shrubs to about six feet in height. If no aerial fuels are present, surface fuels have an open environment subject to stronger winds and more heating and TDA Prescribed Burn School Manual v1.3 5-2002 8 Chapter 6 Fire Behavior, Fuels and Topography drying by solar radiation. Thus, fires run through this fuel level with low to high rates of spread. Surface fuels are what generally carry a prescribed fire and are therefore considered the most important the most important fuel type and will receive the most emphasis in this section. Ground fuels: All combustible materials lying beneath the surface including deep duff, roots, rotten buried logs and other woody fuels. Ground fuels are important in relation to line construction and mop-up operation, but contribute very little to the actual fire intensity and rate of spread of the fire front. Do to the compactness of ground fuels they produce very slow burning or smoldering fires. II. FUEL CHARACTERISTICS A. Fuel Characteristics which affect Fire Behavior 1. Loading 2. Size and shape 3. Compactness TDA Prescribed Burn School Manual v1.3 5-2002 9 Chapter 6 Fire Behavior, Fuels and Topography 4. 5. 6. 7. Horizontal arrangement Vertical arrangement Chemical content Moisture content Fuel Characteristic Fire Behavior Fuel Characteristic 1. Fuel Loading: Fuel loading is the oven-dry weight of fuels in a given area usually expressed in tons/acre or pounds/acre. Fuel loadings vary greatly by fuel groups. For example grass fuel types can vary from <1 to 5 tons/acre, shrub fuel types from 2-80 tons/acre. Logging slash from 10 to 200 tons/acre and timber litter from 4 to 12 tons/acre. When interpreting and predicting fire behavior, we are more concerned with the surface fuel loading; in particular those dead fuels that are less than 3 inches in diameter and live fuels of less than 1.4 inch diameter. The total fuel loading on a site can be much more than what we have shown here. Much of the vegetation on a site may not be available to carry fire due to its height above the ground or high moisture levels. Fuel loadings are generally separated by different sizes of live and dead fuel particles. Dead fuels are broken into four size classes according to their diameter. They are: TDA Prescribed Burn School Manual v1.3 5-2002 10 Chapter 6 Fire Behavior, Fuels and Topography 1. Grasses, litter and duff; < ¼ inch in diameter (1 hour fuels). 2. Twigs and small stems; ¼ to 1 inch in diameter (10 hour fuels). 3. Branches; 1 to 3 inches in diameter (100 hour fuels). 4. Large stems and branches; > 3 inches in diameter (1000 hour fuels). Fuel loading is usually measured in tons/acre (T/A) or pounds/acre (lb/A) for lighter fuels such as grass. 2. Size and Shape: Surface-area-to volume ratio is the ratio of the surface area of a fuel to its volume using the same unit of measurement. The higher the ratio (1:3,000) the finer the fuel (grass). The lower the ratio (1:6) the larger the fuel (logs). We know from our experience in starting campfires, wood stoves, or fireplaces that small fuels ignite and sustain combustion easier than large pieces of fuel. Less heat is required to remove fuel moisture and raise a small fuel particle to ignition temperature. TDA Prescribed Burn School Manual v1.3 5-2002 11 Chapter 6 Fire Behavior, Fuels and Topography The size and shape of firebrands affect the amount and distance of spotting. Small embers ordinarily produce short-range spotting only, because they cannot sustain combustion for the period of time required for long-distant transport. Live cedar often produces short-range are spotting due to the smallness of the firebrands. Oak leaves larger and more aerodynamic (especially Live Oak) than live cedar. Therefore, firebrands from oak trees can often cause spotting over 300 ft. Cones, cedar fronds, bark plates and pine needles are examples of some firebrands which have been lifted into convection columns and then deposited 10 miles or more down wind from the fire. In these cases, their flatness and greater surface-area-to-volume ratios have increased the aerodynamic qualities of the particles, thus making it easier for convection columns to lift them to greater altitudes. The shape of fuels is also important to spotting down slope by rolling firebrands. Pine cones, round logs and round yucca plants are particularly troublesome in their respective area. TDA Prescribed Burn School Manual v1.3 5-2002 12 Chapter 6 Fire Behavior, Fuels and Topography 3. Compactness Compactness can be simply defined as the spacing between fuel particles. The closeness and physical arrangement of fuel particles affects both ignition and combustion. Rates of spread in closely compacted fuels (forest litter) are usually slower than rates of spread in loosely compacted fuels (grasses). Fuel bed depth is the average height of surface fuel that is contained in the combustion zone of a spreading fire front. Orientation of the fuel refers to the horizontal or vertical orientation o the fuel arrangement that carries the fire. Vertically oriented fuels are found in the grass and shrub groups, which rapidly increase in depth with an increase in fuel load. Horizontally oriented fuels are found in the timber litter and logging slash fuel groups and slowly increase in depth as the load is increased. Observation of the location and orientation of fuels in the field help one decide which fuel groups are represented. For more information and assistance on determining fuel categories and groups refer to Aids to Determining Fuel Models for Estimating Fire Behavior in this notebook. TDA Prescribed Burn School Manual v1.3 5-2002 13 Chapter 6 Fire Behavior, Fuels and Topography 4. Horizontal Continuity Horizontal continuity is the horizontal distribution of fuels at various levels or planes. Horizontal continuity applies to all levels of the fuel complex but the continuity of fine fuels is especially important to the spread of surface fires, since prescribed fires burn most often in this fuel level. This characteristic influences where a fire will spread, how fast it will spread and whether the fire travels through surface fuels, aerial fuels or both. Discontinuous or patchy fuels are difficult for a fire to travel through and usually require strong winds with spotting for good fire coverage. Continuous fuels, however provide available fuels at one or more levels giving allowing the fire to spread uniformly for great distances. TDA Prescribed Burn School Manual v1.3 5-2002 14 Chapter 6 Fire Behavior, Fuels and Topography Horizontal continuity in aerial fuels or the effects of a closed versus open timber canopy plays a major role in fire behavior. A forest canopy not only shades surface fuels and prolongs moisture retention but also greatly reduces wind speeds from levels above the canopy to levels near the surface. Generally, the greater the crown closure, the greater the wind speed reduction. This certainly does have an effect on surface fires burning in these closed environments. If torching out of individual trees occurs then we have an entirely new fire environment with which to be concerned. 5. Vertical Arrangement Vertical arrangement is the relative height of fuels above the ground as well as their vertical continuity, both of which influence fire reaching various fuel strata. When fuels are mostly vertically continuous, we call this a fuel ladder, or ladder to transport fire into the forest canopy. The intensity of the surface fire and the live fuel moisture usually determine whether a fire will travel up through the green ladder fuels. A dangerous condition exists when a fire has only burned through the surface fuel level, drying the aerial fuels. A slight change in the environment and the fire can cause a reburn of the canopy—a very dangerous situation. 6. Chemical Content All fuels, living and dead, contain fiber that is known as cellulose. Fuels also contain chemicals and minerals than can enhance or retard combustion. Chemical contents include the presence of volatile substances such as oils, resigns, wax and pitch. There are certain fuels having rather high amounts of these volatile substances that can contribute to rapid rate of spreads and high fire intensities. On the other hand, certain fuels may be high mineral content, which can reduce fire spread and intensity. A burn manager is primarily concerned with volatile substances that make the job more difficult. A few fuels such as duff and “cow pies” are excellent receptors of fire brands that hold over fire primarily due to their high mineral contents that enhance smoldering at much lower TDA Prescribed Burn School Manual v1.3 5-2002 15 Chapter 6 Fire Behavior, Fuels and Topography ignition temperatures. Other moderate to highly volatile fuels in Texas include Juniper, Oak, and Pine. 7. Fuel Moisture Fuel moisture content is the amount of water in a fuel expressed as a percent of the oven-dry weight of that fuel. Fuel moisture can exceed 100% and ranges from 0-30% for dead fuels and 30-300% for live fuels depending on species and their growth stage (Table 1). The formula for obtaining fuel moisture is: [(Wet Weight – Dry weight)/Dry Weight] x 100 = % Fuel Moisture Table 1. General estimates for live fuel (foliage) moisture content. Stage of vegetative development Fresh foliage, annuals developing, early in growing cycle. Maturing foliage, still developing with full vigor. Mature foliage, new growth complete and comparable to older perennial foliage. Entering dormancy coloration starting, some leaves may have dropped from stem. Completely cured. TDA Prescribed Burn School Manual v1.3 5-2002 Moisture content (Percent) 300 200 100 50 Less than 30, treat as dead fuel 16 Chapter 6 Fire Behavior, Fuels and Topography A technique used for obtaining live fuel moisture in Juniper and other species is described in the appendices. Fine dead fuels less than ¼ inch, such as grass and needle/leaf litter, are most responsible for the spread of fire. In fact, the fine fuels are considered the primary carrier of a surface fire. The live-to-dead ratio becomes critically important when evaluating the potential for a fuel to burn. The greater the amount of dead fuel compared to live fuel, the more flammable the fuel. The dead component of the fuel is extremely important since it is the dead material that carries the fire and heats the live component t ignition. With insufficient dead fuels present, a live stand may not burn even under good burning conditions. Normally, at least one-third of the fine fuel complex must be dead or cured in order to have an adequate ratio of live-to-dead to carry a fire. In Review: Fuel Characteristics Influencing Fire Behavior: Of the seven fuel characteristics discussed above compactness, loading, chemical content, size and shape and moisture content are the characteristics that influence fire ignition. While Compactness, loading, horizontal continuity, chemical content, size and shape and moisture content influence rate of spread and fire intensity. It is important to note that not all fuels burn during a prescribed fire, depending on factors of fuel availability. Consumption tends to vary by fuel category with nearly 100% consumption n grass fuels and as little as 5-25% in timber litter fuel types. Specialists that work with fire and try to develop methods of predicting fire behavior have broken down all ecosystems into physical models that represent how a fire will burn. Many different inputs and fuel characteristics are involved with these models, but the basic one is fuel loading as it relates to fuel size. How much dead fuel, how much live fuel and how much dead fuel in the size classes of 0 – 0.25 inches (1 hour fuels), 0.26 – 1 inch (10 hour fuels). 1 to 3 inches (100 hour fuels) and 3 to 7 inches (1000 hour fuels). TDA Prescribed Burn School Manual v1.3 5-2002 17 Chapter 6 Fire Behavior, Fuels and Topography All of the above has contributed to the development of 13 basic fuel models for predicting fire behavior. These 13 fuel models have been classified into 4 categories. Models 1-3 are the grass models, models 4-7 are the brush or shrub models, models 8-10 are the timber models and models 11-13 are the slash models (Table 2). For a detailed explanation of these models and their characteristics refer to the publication Aids to Determining Fuel Models for Estimating Fire Behavior provided in this notebook. TDA Prescribed Burn School Manual v1.3 5-2002 18 Chapter 6 Fire Behavior, Fuels and Topography Table 2. Description of the 13 fuel models in fire behavior as documented by Albini (1976). Moisture of extinction Fuel loading Fuel Typical fuel complex Model Fuel Bed Dead Fuels Depth Percent --------------------Tons/acre------------------- Feet 1 hour 10 hours 100 hours Live 1 2 3 Grass and grassShort grass (1 foot) Timber (grass and Tall grass (2.4 feet) 0.74 2 3.01 0 1 0 0 0.5 0 0 0.5 0 1 1 2.5 12 15 25 4 5 6 7 Chaparral and shrub Chaparral (6 feet) Brush (2 feet) Dormant brush, Southern rough 5.01 1 1.5 1.13 4.01 0.5 2.5 1.87 2 0 2 1.5 5.01 2 0 0.37 6 2 2.5 2.5 20 20 25 40 8 9 10 Timber litter Closed timber litter Hardwood litter Timber (litter and 1.5 2.92 3.01 1 0.41 2 2.5 0.15 5.01 0 0 2 0.2 0.2 1 30 25 25 11 12 13 Slash Light logging slash Medium logging slash Heavy logging slash 1.5 4.01 7.01 4.51 14.03 23.04 5.51 16.53 28.05 0 0 0 1 2.3 3 15 20 25 Fuel Model 1 TDA Prescribed Burn School Manual v1.3 5-2002 Fuel Model 3 19 Chapter 6 Fire Behavior, Fuels and Topography III. FUEL MOISTURE Fuel moisture is one of the most important characteristics of fuels in Texas. Burn managers are primarily concerned with two kinds of fuel moisture. There is live fuel moisture and dead fuel moisture, which should be self explanatory. Live fuel moisture is affected by live plant’s metabolism and growing season. Dead fuel moisture is affected by the humidity and soil moisture to a large degree. As mentioned earlier in the unit fuel moisture is measured by obtaining a fuel sample, weighing the sample immediately after clipping and then drying the sample to a constant weight and then using the following formula: [(Wet Weight – Dry weight)/Dry Weight] x 100 = % Fuel Moisture Fuels are constantly exchanging moisture with the surrounding air. Factors that contribute to a change in dead fuel moisture include precipitation duration, precipitation amount, temperature, relative humidity and wind. Wind can both dry and wet fuels depending on the relative humidity. During periods of high humidity and precipitation there is a net gain in fuel moisture. However, when the air is dry, with low humidity, fuels are giving up more moisture to the air than they receive. The fuel itself can regulate the amount of moisture it can absorb or lose, for example waxy coatings can prevent moisture from getting in, while rotten material tends to prevent loss of moisture because it holds it like a sponge. Several factors influence the rate of moisture exchange between fuels and the air. These include water vapor pressure difference, presence or absence of wind, size of fuels, compactness of fuels and proximity of fuels to damp soil. A. Equilibrium Moisture Content Equilibrium Moisture Content is the point at which the fuel has absorbed 70% of the total amount of water it could hold at that particular temperature and relative humidity. This is the point at which the vapor pressure in the air is equal to the vapor pressure in the fuel and the exchange stops. Equilibrium moisture content can occur in small, fine fuels, but never occurs in larger fuels, as the time required to reach equilibrium in larger fuels is much longer. TDA Prescribed Burn School Manual v1.3 5-2002 20 Chapter 6 Fire Behavior, Fuels and Topography B. lag Time Fuels respond to changes in moisture at different rates. Time lag is a measure of the rate at which a specified size of dead fuel gains or loses moisture. Time lag can also be defined as the time necessary for a fuel particle to gain or lose approximately 2/3 of the difference between its initial moisture content and its equilibrium moisture content. The smaller the fuel the greater the surface-area-to-volume ratio, therefore the quicker it responds to environmental changes such as rain. The dead fuel time lag categories are as follows: 1. 2. 3. 4. 1 hour: fuels that are 0 inch to 1.4 inch diameter. 10 hour: fuels that are ¼ inch to 1 inch diameter. 100 hour: fuels that are 1 inch to 3 inches diameter. 1000 hour: fuels that are 3 inches to 8 inches diameter. The gain and loss of moisture does not occur at a constant rate When conditions change, fuels respond quickly at first. The change in moisture content becomes slower as the fuel moisture gets closer to the equilibrium moisture content. C. Environmental Factors Influencing Fuel Moisture Fuel moisture is directly influenced by temperature, relative humidity, precipitation and shading. Wind alters the exchange of moisture between the fuels and the air. Other site factors of weather and topography influence atmospheric temperature and relative humidity. Since these factors indirectly affect fuel moisture they must be considered when estimating fuel moisture content. These factors are shown below. TDA Prescribed Burn School Manual v1.3 5-2002 21 Chapter 6 Fire Behavior, Fuels and Topography D. Moisture of Extinction Moisture of extinction is defined as the fuel moisture content at which a fire will not spread, or spreads only sporadically and in a nonTDA Prescribed Burn School Manual v1.3 5-2002 22 Chapter 6 Fire Behavior, Fuels and Topography predictable manner. Moisture of extinction varies by fuel situation and is dependent on various fuel characteristics such as fuel loading, fuel size, arrangement and chemical content. Moisture of extinction is lowest (around 12%) for light porous grasses such as buffalograss and tends to be higher (around 30%) for more compacted fuels such as needle litter. Southern rough fuels located in the Southeastern US have a moisture extinction as high as 40 percent. The moisture extinction ranges for different fire behavior fuel models are found in Table 3. Table 3. Moisture of Extinction for each Fuel Model Fuel Model Presence of Fuel Class Moisture of 1-H 10-HR 100-HR LIVE Extinction (%) 1 Short Grass X 2 Timber and Grass X 3 Tall Grass X 4 Chaparral (6ft) X X 5 Brush (2ft) X X 6 Intermediate Brush X X X 7 Southern Rough X X X 8 Closed Timber Litter X X X 30 9 Hardwood Litter X X X 25 10 Timber with Litter X X X 11 Light Logging Slash X X X 15 12 Medium Logging Slash X X X 20 13 Heavy Logging Slash X X X 25 TDA Prescribed Burn School Manual v1.3 5-2002 12 X X X 15 25 X X 20 X 20 25 X X 40 25 23 Chapter 6 Fire Behavior, Fuels and Topography E. Fine Dead Fuel Moisture Tables Now you will be introduced to tables which can give you acceptable estimates of 1-hour timelag fine dead fuel moistures, during daylight hours, under a variety of conditions. We want to discuss briefly how the tables are to be used. First of all, you will determine a reference fuel moisture (RFM) by entering dry bulb temperature and relative humidity into the table below. REFERENCE FUEL MOISTURE (DAYTIME 0800-1959) Relative Humidity (%) Dry 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 Bulb 95 …..100 Temp (F) 4 9 10 - 29 1 2 2 3 4 5 30 - 49 1 2 2 3 4 50 - 69 1 2 2 3 70 - 89 1 1 2 90 - 109 1 1 1 109+ 1 14 19 24 29 34 39 44 49 54 59 64 69 74 79 84 89 94 99 5 6 7 8 8 8 9 9 10 11 12 12 13 13 14 5 5 6 7 7 7 8 9 9 10 10 11 12 13 13 13 4 5 5 6 6 7 7 8 8 9 9 10 11 12 12 12 13 2 3 4 5 5 6 7 7 8 8 8 9 10 10 11 12 12 13 2 2 3 4 4 5 6 7 7 8 8 8 9 10 10 11 12 12 13 2 2 3 4 4 5 6 7 7 8 8 8 9 10 10 11 12 12 12 Exercise 4 Determine the reference fuel moisture given the following conditions: Temperature 75° and relative humidity 34%:________________RFM Temperature 95° and relative humidity 22%:________________RFM Next you will determine a fuel moisture correction (FMC) value from the tables by considering the month, cloud/canopy cover shading, time of day, site location elevation difference, aspect and slope percent. The correction value is then added to the reference fuel moisture to get the adjusted fine dead fuel moisture (FDFM). TDA Prescribed Burn School Manual v1.3 5-2002 24 Chapter 6 Fire Behavior, Fuels and Topography Fuel Moisture Correction Values Correction Values For Daytime 0800 - 1959 (MAY, JUNE, JULY) Time Apect North East South West North East South West 0800 1000 1200 1400 1600 1800 3 2 3 4 Clear and/or Canopy (Less than 50% shaded) 1 0 0 0 0 0 1 0 0 2 0 0 1 2 1 0 3 4 3 2 5 4 4 5 Cloudy and/or Canopy (More then 50% Shaded) 4 3 3 4 3 4 4 3 3 4 3 3 4 4 4 4 5 5 5 4 Correction Values For Daytime 0800-1959 (FEB.,MARCH, APRIL, AUG., SEPT., OCT.) Time 0800 1000 1200 1400 1600 1800 Apect Clear and/or Canopy (Less than 50% shaded) North 4 2 2 2 2 4 East 3 1 1 1 3 4 South 4 2 1 1 2 4 West 4 3 1 1 1 3 Cloudy and/or Canopy (More then 50% Shaded) North 5 5 4 4 5 5 East 5 4 4 4 5 5 South 5 4 4 4 4 5 West 5 5 4 4 4 5 Correction Values For Daytime 0800 - 1959 (NOVEMBER, DECEMBER, JANUARY) Time 0800 1000 1200 1400 1600 1800 Apect Clear and/or Canopy (Less than 50% shaded) North 5 4 4 4 4 East 5 3 2 3 4 South 5 3 2 1 3 West 5 4 3 2 3 Cloudy and/or Canopy (More then 50% Shaded) North 5 5 5 5 5 East 5 5 5 5 5 South 5 5 5 5 5 West 5 5 5 5 5 TDA Prescribed Burn School Manual v1.3 5-2002 5 5 5 5 5 5 5 5 25 Chapter 6 Fire Behavior, Fuels and Topography Dry Bulb Temperature Relative Humidity Reference Fuel Moisture + Month Shaded or Unshaded Time of Day Aspect Fuel Moisture Correction Value (FMC) = Adjusted Fine Dead Fuel Moisture (FDFM) Exercise 4 Determine the reference fuel moisture (RFM), Fuel moisture correction value (FMC) and the fine dead fuel moisture (FDFM) in the following examples: On June 10 at noon, the temperature was 93° and the relative humidity was 34%: RFM_________ + FMC_________ = __________FDFM On a cloudy March 23 at 2:00 pm (1400), the temperature was 56° and the relative humidity was 45%: RFM_________ + FMC_________ = __________FDFM IV. Combining Influences Affecting Fire Behavior All actions on a prescribed burn should be based on current and expected fire behavior. In this section we will describe the response of fire to important elements of the fire environment. A. Fire Behavior Characteristics As the rate of spread (ROS) of a fire increases, there is a correlated increase in fireline intensity. ROS is often difficult to see and calculate. However, ROS is interrelated to flame length, which is often easier to discern in the field. Therefore, fire suppression limitation can be based on flame length. TDA Prescribed Burn School Manual v1.3 5-2002 26 Chapter 6 Fire Behavior, Fuels and Topography B. Effects of Fuels on Fire Behavior 1. Fuel loading Higher fuel loadings create greater flame lengths (intensities) for a given rate of spread. Increased loading of larger fuels will decrease rate of spread because of the additional time required t for larger fuels to become preheated. 2. Live-to-dead fuel ratio The higher the ratio of dead fuel to live fuel, increases the flammability of fuel complex. The dead fuel is the material that carries the fire and preheats the live component to ignition. 3. Surface-area-to-volume ratio The greater the ratio, the finer the fuel, and the faster a fuel bed will burn. TDA Prescribed Burn School Manual v1.3 5-2002 27 Chapter 6 Fire Behavior, Fuels and Topography 4. Compactness Closely compacted fuels restrict oxygen and inhibit convective/radiant heat transfer and consequently burn slowly (e.g. pine needles). Fuels that are too open and sparse limit heat transfer, allow too much cooling, and will burn poorly. 5. Orientation Vertically oriented fuels (grass and shrub) will burn faster and more efficiently than those lying horizontally (timber litter and logging slash). 6. Examples of Fire Behavior for Fuel Groups In the following example the environmental conditions assumed are a midflame wind of 4 mi/h and a 30% slope. The fuel moisture contents are representative of low and high fuel moisture conditions. Low Fuel Moisture TDA Prescribed Burn School Manual v1.3 5-2002 High Fuel Moisture 28