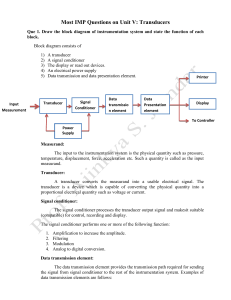

T R A N S D U C E R S

advertisement

T R A N S D U C E R S Dr. Atulkumar H. Patel • A transducer may be defined as any device that T r a converts energy in one form to energy in another form. n s d u c e r s • Most of the transducers either convert electrical energy into mechanical displacement and/or convert some non-electrical physical quantity (such as temperature, light, force, sound etc.) to an electrical signal. • In T r a n s d u c e r s an electronic instrumentation system, the functions of a transducer (being the input device) are two-fold: to detect or sense the presence, magnitude and changes in the physical quantity being measured. to provide a proportional electrical output signal as shown in following figure. C l a s s i f i c a t i o n o f T r a n s d u c e r s • Transducers may be classified according to their applications, method of energy conversion, electrical measuring principle involved, nature of output signal and so on. • Broadly speaking, transducers may be classified into the following groups: Passive transducers - they require an external power supply and their output is a measure of some variation in a physical parameter such as pressure, resistance and capacitance etc.; C l a s s i f i c a t i o n • Self-generating transducers - they do not require an external power source. However, they provide an electrical output when stimulated by some physical form of energy. • A very useful listing of different transducers is given below: o Mechanical - strain gauge type for measuring force, torque and pressure etc. o f o Thermal - thermistors, thermocouples T r a n s d u c e r s o Optical - photoconductive, photoemissive and photovoltaic (solar) cells o Acoustical - microphone o Magnetic - LVDT, permeameters o Chemical - pH and conductivity cells o Nuclear - Geiger-Muller tube, ionization chamber o Biological - electrocardiograph (ECG) and electroencephalograph (EEG) C l a s s i f i c a t i o n o f T r a n s d u c e r s Classification based on Electrical Principle Involved R e s i s t i v e P o s i t i o n T r a n s d u c e r s • It is used to sense the position of an object or the distance it has moved. The physical variable being measured is made to cause a resistance change in the sensing element. • Following figure (a) shows one type of displacement industrial transducer used in measurement and control work. • It consists of a resistance element AB with a sliding contact or wiper W linked with the object being monitored. • As seen, the resistance between W and B i.e., RBD depends on the position of the object. R e s i s t i v e P o s i t i o n T r a n s d u c e r s • It is seen from figure (b) that output voltage V0 depends on the slider position and is, therefore, a function of the shaft position. • The voltage V0 is given by V0 = V R2 R1+R2 • Obviously, V0 is proportional to R2 i.e., position of the wiper, W. • This voltage may be applied to a voltmeter calibrated in millimeter (mm) for visual display. • The above-described potentiometric principle is widely-used despite its limitations. Some of its advantages are as under: R e s i s t i v e its electrical efficiency is high P o s i t i o n the device may be excited by either dc or ac supply T r a n s d u c e r s it provides sufficient output to permit control operations without any further amplification • However, because of mechanical friction between the wiper and the resistance element AB, its life is limited. • Moreover, it becomes noisy as the element wears out. R e s i s t i v e P r e s s u r e T r a n s d u c e r s • It is based on an arrangement in which a change a in pressure results in the change of resistance of a sensing element. • Figure shows two ways of mechanical arrangement for measuring pressure. • Figure (a) shows the bellows type whereas Figure (b) shows the diaphragm type. • In Figure (a) when applied pressure changes, the spring-supported bellows B extends or contracts thereby moving the resistance slider up and down. R e s i s t i v e P r e s s u r e T r a n s d u c e r s • Consequently, changes in the resistance of sensing resistive element become proportional to the changes in pressure. • These changes in resistance can be made part of a bridge circuit and produce an ac or dc signal for pressure determination as shown in the following figure. I n d u c t i v e P r e s s u r e T r a n s d u c e r s • In this case, change in pressure produces a change in the self a inductance of a sensing element. • As shown in figure when pressure being measured increases, the bellows B expands and hence, the movable magnetic core is pushed more inside the coil thereby increasing its self inductance. • Similarly, when applied pressure decreases, the bellows contracts and thus the magnetic core is pulled out of the coil and as a result, coil inductance is decreased. I n d u c t i v e P r e s s u r e T r a n s d u c e r s • The changes in self-inductance can be made a part of an ac a inductance bridge and converted into an electrical signal for pressure measurement. • As compared to the previous resistive arrangement the advantages of this inductive type are as under: no moving parts are used thereby avoiding wear and tear, no extra friction load is imposed on the measuring system. C a p a c i t i v e P r e s s u r e T r a n s d u c e r s • In this arrangement, changes in pressure are detected by the a variations in the capacitance of a parallel-plate capacitor whose one plate is free to move with change in pressure. • The capacitance of the capacitor shown in figure is given by • C = ∈𝑜∈𝑟𝐴 𝑑 where A = plate area, d = plate separation • As seen, C ∝ 1/d i.e., capacitance varies inversely with plate separation. • As shown in figure, the capacitor consists of a static plate N and movable plate M (diaphragm) separated by a dielectric (usually, air). C a p a c i t i v e • P r e s s u r e • T r a n s d u c e r s a • When pressure increases, M bends inwards, thereby decreasing d and, hence, increasing C. However, when pressure decreases, the diaphragm is pulled outwards, d is increased and, consequently, C is decreased. The changes in capacitance can be made part of an ac capacitive bridge to furnish an electrical signal for pressure determination. • A capacitive transducer is inexpensive and easy to construct, particularly effective for high-frequency variations, capable of measuring both static and dynamic phenomena. • Amongst its disadvantages are sensitivity to temperature variations, possibility of erratic or distorted signals due to long leads. S e l f G e n e r a t i n g I n d u c t i v e T r a n s d u c e r s • These utilize the basic generator principle that when there is a relative motion between a conductor and a magnetic field or flux an emf is induced in the conductor. • This relative motion between the conductor and the flux is provided by the physical quantity under measurement. o Tachometer • It is an inductive transducer that directly converts speed into an electrical signal as shown in figure. S e l f G e n e r a t i n g I n d u c t i v e T r a n s d u c e r s • The object whose angular velocity is to be measured is directly a coupled to the rotor which is made of permanent magnet having N - and S poles. • As the rotor rotates, its alternating flux cuts the stationary coils thereby inducing an alternating voltage 'e' in them. • The magnitude of 'e' depends directly on the angular velocity of the rotor. • This emf can be rectified and further amplified for being fed to a dc voltmeter, which is directly calibrated in revolutions per minute (rpm) instead of in volts. S e l f G e n e r a t i n g I n d u c t i v e T r a n s d u c e r s o Electromagnetic Flow meter a • It is also a self-generating inductive transducer and is particularly useful where the pipes cannot be opened to atmosphere i.e., for flow measurement of liquids which contain suspended solids such as sewage or feed to paper mills etc. • However, it should be remembered that it can measure the flow of only those materials which are electrically conductive. • As shown in figure, the meter is a small section of a pipe that is internally lined with an insulating material and has two diametrically opposite metallic electrodes with their ends in flush with the insulation. S e l f G e n e r a t i n g I n d u c t i v e T r a n s d u c e r s • As the conducting fluid passes through the magnetic field of a the two permanent magnets, it cuts the flux and hence an emf 'e' is induced in it whose magnitude is given by e=Blv • Its direction can be found by using Fleming's Right-hand rule. • Here, l is the length of the conductor i.e., diameter MN of the pipe, B is the magnetic flux density and v is the velocity of the fluid. • Since B and l are constant, e ∝ v. Obviously, faster the rate of liquid flow, greater the induced emf 'e'. • This voltage can be fed to a voltmeter which is calibrated in velocity. S e l f G e n e r a t i n g I n d u c t i v e T r a n s d u c e r s • The electromagnetic flow meter has the advantage that its a readings are unaffected by variations in viscosity, density, temperature, pressure and conductivity etc., of the fluid. • Moreover, it causes no drop in the fluid pressure. However, it requires certain minimum flow velocity for correct readings. • Also, the electrodes must be always kept clean which can sometime present a serious problem as in the case of sewage flow. L i n e a r V a r D i f f T r a n s f o r m e r ( ) L V D T • a • It is a passive inductive transducer (or magnetic displacement transducer). It is commonly employed to measure force (or weight, pressure and acceleration etc., which depend on force) in terms of the amount and direction of displacement of an object. o Construction • As shown in figure, it consists of one primary winding and two secondary windings which are placed on either side of the primary mounted on the same magnetic core. L i n e a r V a r D i f f T r a n s f o r m e r ( ) L V D T • a • The magnetic core is free to move axially inside the coil assembly and the motion being measured is mechanically coupled to it. The two secondary S-1 and S-2 have equal number of turns but are connected in series-opposition so that emf 's induced in them are 180o out of phase with each other and, hence, cancel each other out. • The primary is energised from a suitable ac source. • The induced voltages E1 and E2 in the two secondaries are equal but anti phase as shown separately in the following figure. • Hence, net secondary voltage across terminals A and B is zero. L i n e a r V a r o Working • When the core is in the centre, E1 and E2 are equal and opposite. • Hence, they cancel out and the output voltage V0 is zero. • When the external applied force moves the core towards coil S-2, E2 is a D i f f T r a n s f o r m e r increased but E1 is decreased in magnitude though they are still anti phase with each other. • (E2- E1) and which is in phase with E2• • Similarly, when the magnetic core moves towards coil S-1, E1 > E2 and V0 = E1- E2 and is in phase with E1. • ( ) L V D T Hence, there is some net output voltage available whose magnitude is • It is seen from above the magnitude of V0 is a function of the distance moved by the core and its polarity or phase indicates as to in which direction it has moved. If core is attached to a moving object, the magnitude of V0 gives the position of that object. L i n e a r V a r D i f f T r a n s f o r m e r o Advantages it gives higher output voltages for small changes in core position. It a means that its sensitivity (v/m) is high. Sensitivity ranges from 50 mV/mm to 300 mV/mm it can operate over a temperature range from-265°C to 600°C it is available in radiation-resistant design for operation in nuclear reactors o Applications in accelerometers, jet engine controls in close proximity to exhaust gases, ( L V D T measurement of roll position, ) measurement of material thickness in hot strip or slab steel mills. • a P i e z o e l e c t r i c T r a n s d u c e r Production of electric potential by means of mechanical pressure is called piezoelectric phenomenon. It is exhibited by crystals of quartz, tourmaline, Rochelle salt and ceramics such as barium titanate. • Crystal and ceramic microphones and phonograph pick-up cartridges are common examples of devices using piezoelectric effect. • Obviously they are of self-generating type. • In following figure a crystal placed between a solid base and the force-summing member F (i.e. The mechanical elements that are used to convert the applied force into a displacement are called forcesumming devices.). • a P i e z o e l e c t r i c T r a n s d u c e r • When pressure is increased on the top surface of the crystals, a potential difference is developed across its opposite faces. The voltage V0 is found to be directly proportional to the magnitude of the pressure. However, if applied pressure is decreased, even then potential difference is developed though with opposite polarity. • Conversely, if an ac voltage of suitable frequency is applied across the two opposite faces of such a crystal, it expands and contracts and starts vibrating with its natural frequency which is very stable. • Because of this property, piezoelectric crystals are used in highfrequency accelerometers. • The principal disadvantage of this transducer is that it cannot measure static condition i.e., it produces voltage only when the applied pressure is changing. • a S t • I change. In other words, it utilizes resistance variations of a wire to sense the strain produced by the force acting on the wire. r a It is a passive transducer which converts a given strain to a resistance • It is extensively utilized for measuring weight, pressure, mechanical force or displacement etc. n G o Construction a • u g e Following figure (a) shows the construction of a bonded strain gauge. • a S • a I n G flexible plate which is bonded or cemented to the member undergoing stress [Figure(b)]. t r It consists of a few loops of fine constantan wire mounted on a The hairpin looping of the wire increases its length in the direction of the applied stress and, hence, increases the sensitivity of the gauge. o Working Principle • When a tensile stress is applied to the member (top of a jar, for a example), it will elongate the wire thereby increasing its length but u decreasing its cross-sectional area. g e • Both these factors increase wire resistance because 𝑅= 𝜌 • 𝑙 A The increase in wire resistance is proportional to the force causing the elongation. • a S Hence, resistance of a strain gauge is indicative of the pressure or force applied to the surface to which the gauge is bonded. t o Gauge Factor r • a The two physical quantities of interest are the fractional (i) change in resistance and (ii) change in length. The ratio of the two gives the I n gauge factor, K G ∴ a u • g 𝐾= ∆𝑅 𝑅 ∆𝑙 𝑙 = ∆𝑅 𝑅 𝑠𝑡𝑟𝑎𝑖𝑛 ,σ The value of K for metallic gauges varies from -12 (for nickel) to +6 (for alloys) whereas its value for semiconductor gauges varies from 50 e to 200. • Use of silicon strain gauge is spreading because it can measure even ‘micro strain' due to its high gauge factor. • a S t • r n G a strain, greater resistance change means higher value of K. From the above strain a I Higher the gauge factor of a gauge, greater its sensitivity. For a given • = ∆𝑅 𝑅 𝐾 For a given wire and gauge of known value strain ∝ ∆𝑅 • The changes in resistance can be measured with the help of the u bridge shown in the figure. The null indicator is calibrated in g newton/m2 to give the value of stress directly. e • As seen from figure, a dummy gauge has been used alongwith the active one in order to compensate for temperature variations. o Advantages it is rugged, easy to install and use a S t in ac applications, it is capable of measuring variations up to 100kHz r it has excellent linearity and hysteresis characteristics a I it is comparatively less sensitive to shock and undesired vibrations n it is available in multi element or rosette gauge form for simultaneous G a u g e measurement of strain in more than one direction o Temperature transducers may be divided into the following four main a T e m p e r a t u r e T r a n s d u c e r categories: Temperature Transducer Thermistors Thermocouples These are semiconductors having negative temperature coefficient These consist of a pair of dissimilar metal wires whose one end forms the temperature sensing end • a R e s i s t a n c e RTDs are made of a suitable length of platinum, nickel or tungssten wire whose resistance increases with increase in temperature i.e., which has positive temperature coefficient. • The relationship between temperature and resistance of the metallic wires is given by Rt = R0 (1 + αt) T e m p . D e t e c t o r s Rt = conductor resistance at toc R0 = conductor resistance at 0oc α = temperature coefficient of resistance • The α represents the percentage change in resistance per oc change in temperature. • For example, α = 0.00385 for platinum. It means that a platinum wire with R0 = 100 Ω when kept in an environment at 100°C will have its resistance increased to 100 (1+100 x 0.00385) = 138.5 Ω. • a R e s i s t a n c e Above equation may be written as Rt - Ro = α Ro Δt or ΔR = α Ro Δt • For given values of α and Ro , ΔR α Δt . • Hence, by measuring ΔR with the help of Wheatstone bridge circuit shown in the figure change in temperature can be found out. T e m p . D e t e c t o r s • Alternatively, the null temperatures directly. detector can be calibrated to read • a R e s i s t a n c e • RTDs are commonly used for temperature measurement in the range180°C to 650°C. They are generally of the probe type for immersion in the medium whose temperature is to be measured (Figure). T e m p . D e t e c t o r s • For industrial purposes, the sensing element i.e., resistance wire is mounted inside a protecting tube for guarding against any mechanical damage and contamination. • a T • It is a temperature-sensitive semiconductor with a high negative temperature coefficient of resistance. In other words, resistance of a thermistor decreases considerably h when its temperature increases. Likewise, its resistance increases e when its temperature decreases. r m • This high sensitivity to temperature changes makes the thermistor i extremely well-suited for precise temperature measurement, control s and compensation. t o • lower temperature range of – 100 0C to + 350°C. r s Hence, they are widely used for such purposes particularly in the o Construction • Thermistors are made by sintering mixtures of metallic oxides such as manganese, nickel, cobalt and copper etc. • a • • e i s t o r s Beads are as small as 0.15 mm in diameter and are either glass-coated or sealed in the tips of solid glass probes. r m Thermistors are formed into rods, discs, washers and beads for special applications. T h Their resistance varies from 0.5 Ω to 100 M Ω. • These probes are used for measuring the temperatures of the liquids. o Response Time a • resistance. T h • e change in temperature. m • s Suppose, a thermistor is taken from a liquid at 100°C to another at 600°C. The step change in temperature is (600- 100) = 500°C. Its t 63.2 per cent = 500 x 63.2/100 = 316°C. o r It is expressed in terms of time constant which is defined as the time required by the thermistor to reach 63.2 per cent of the total 'step' r i It is the time required by the thermistor to heat up and change its • s The time required by the thermistor to increase its temperature by 316°C is called its time-constant. • In this interval of time the thermistor temperature will increase from 100°C to (100 + 316) = 416°C. Usually, 5 time constants are required by the thermistor to achieve the new temperature. o Advantages it is chemically stable a T it can be used in nuclear environments h it can be connected in series-parallel arrangements for increased e power-handling capacity r m it is used for measuring temperature even at places inaccessible to i s other thermometers. t o Applications o • r Alongwith a Wheatstone bridge circuit, thermistors are used for measuring temperature, thermal conductivity, attitude and wind s velocity etc. • Thermistors are also used in limiting and regulating circuits as time relays, for integration of power pulses, and as memory chips. • a T r m o u p l e s of temperature measurement depends on the thermoelectric or Seebeck effect discovered by German physicist o Construction and Working Principle • If consists of two dissimilar metal wires joined at one end as shown in figure. o c method Thomas Seebeck. h e This • This end A is known as hot or sensing end (or junction). The other end is known as cold or reference end because it is kept at a lower but constant temperature (reference temperature). • When end A is heated, an emf (called thermoelectric emf) in a T h e r m o c mV is produced between it and the cool ends B and C. • The magnitude of this emf depends on (i) the temperature difference between the hot and cold junctions and ( ii) the type of wire materials used. • Since coil ends are kept at constant temperature (generally, o room temperature), the millivolt output is indicative of the u temperature of the hot junction A which is kept in touch with p l e s the object whose temperature is being measured. • In fact, the millivoltmeter is calibrated directly in temperature rather than in mV. • Thermocouples are made from a number of different a T h e r m o c o u p l e s metals covering a wide range of temperature from 270 °C to +2700 °C. • They are available in simple uninsulated wire form, in insulated wire form or contained inside protecting probes or sheaths (of as small diameter as 0.25 mm). • Some of the standard metal combinations commonly used in industry are given below alongwith the value of emf produced per l00°C temperature difference between the hot and cold junctions. chrome! versus constantan -7.5 mV a T h e r m o c o u p l e s iron versus constantan - 5.5 mV chrome! versus alumel - 4 m V nickel versus nickel-iron - 2 m V • Thermocouples when connected in series or parallel as groups are called thermopiles. o Response Time • It is measured in terms of time constant which is defined as the time required by the temperature of the thermocouple to reach 63.2 per cent of the total step change in temperature. Usually, five time constants are needed to reach the final steady value of the temperature being measured. o Applications a T h e in industry, thermocouples are used for measuring temperatures of industrial furnaces, r they are suitable for very low temperature measurements i.e., m in the cryogenic range required in industry, scientific research o c o u p l e s and medical instrumentation, for monitoring the temperature of liquids and gases in storage and while flowing in pipes and ducts, in medical work, extremely small-size thermocouple probes are used for measuring internal body temperature. o Different Types of Photovoltaic Transducers a P h o t o v o l t a i c T r a n s d u c e r s Photoconductive cells or photocells Photovoltaic cell Solar cell Photodiode Photomultiplier tube Photoemissive cell • a A c o u s t i c T r a n s d u c e r s Microphone is an acoustic transducer which converts a sound wave (acoustic energy) into a varying electric current (electrical energy) that can be further amplified and transmitted to distant places by telephone lines or radio. • At the receiving end, the electric currents are converted back into sound waves by loudspeakers or headphones. • Hence, a microphone plays an extremely important role broadcasting, recording and telephony etc. • Microphones may be of the following seven types: 1. carbon microphone 2. ribbon microphone 3. moving-coil microphone 4. crystal microphone 5. ceramic microphone 6. capacitor microphone 7. electret microphone etc. in