w a t e r r e s e a r c h 8 0 ( 2 0 1 5 ) 2 9 4 e3 0 5

Available online at www.sciencedirect.com

ScienceDirect

journal homepage: www.elsevier.com/locate/watres

Evaluation of poly (aspartic acid sodium salt) as a

draw solute for forward osmosis

Gimun Gwak a,1, Bokyung Jung b,1, Sungsoo Han b, Seungkwan Hong a,*

a

School of Civil, Environmental & Architectural Engineering, Korea University, 1-5 Ga, Anam-Dong, Sungbuk-Gu,

Seoul 136-713, Republic of Korea

b

Energy Laboratory, SAIT, Samsung Electronics, 130 Samsung-ro, Suwon-si, Gyeonggi-do 443-803, Republic of

Korea

article info

abstract

Article history:

Poly (aspartic acid sodium salt) (PAspNa) was evaluated for its potential as a novel draw

Received 8 January 2015

solute in forward osmosis (FO). The inherent advantages of PAspNa, such as good water

Received in revised form

solubility, high osmotic pressure, and nontoxicity, were first examined through a series of

28 April 2015

physicochemical analyses and atomic-scale molecular dynamics simulations. Then, lab-

Accepted 29 April 2015

scale FO tests were performed to evaluate its suitability in practical processes. Compared

Available online 14 May 2015

to other conventional inorganic solutes, PAspNa showed comparable water flux but

significantly lower reverse solute flux, demonstrating its suitability as a draw solute.

Keywords:

Moreover, fouling experiments using synthetic wastewater as a feed solution demon-

Forward osmosis (FO)

strated that PAspNa reversely flowed to the feed side reduced inorganic scaling on the

Draw solution

membrane active layer. The recyclability of PAspNa was studied using both nanofiltration

Antiscaling

(NF) and membrane distillation (MD) processes, and the results exhibited its ease of re-

Wastewater reclamation

covery. This research reported the feasibility and applicability of FO-NF or FO-MD pro-

Desalination

cesses using PAspNa for wastewater reclamation and brackish water desalination.

© 2015 Elsevier Ltd. All rights reserved.

1.

Introduction

Forward osmosis (FO) has gained recognition over the last

decade as an emerging technology for water treatment and

desalination (Cath et al., 2006; Boo et al., 2013; Shannon et al.,

2008; Valladares Linares et al., 2013). In contrast to pressuredriven membrane processes, such as reverse osmosis (RO),

this process utilizes an osmotic gradient between two streams

separated by a semi-permeable membrane as the driving

force for moving water into the higher osmotic potential draw

solution. Consequently, the performance of FO mainly

* Corresponding author. Tel.: þ82 2 3290 3322; fax: þ82 2 928 7656.

E-mail address: skhong21@korea.ac.kr (S. Hong).

1

These authors contributed equally to this work.

http://dx.doi.org/10.1016/j.watres.2015.04.041

0043-1354/© 2015 Elsevier Ltd. All rights reserved.

depends on the osmotic pressure exerted by the draw solution

among many other factors.

Many researchers have demonstrated the feasibility of FO

technology based on its special characteristics, i.e., low energy

consumption, high rejection of a wide range of contaminants

and easy fouling control (Holloway et al., 2007; Kim et al.,

2012). However, FO is still a relatively immature technology

and some remaining limitations, such as low membrane

performance, hinder its industrial application. One of the key

challenges to the further development of FO is identifying a

suitable draw solute. The development of an optimized draw

w a t e r r e s e a r c h 8 0 ( 2 0 1 5 ) 2 9 4 e3 0 5

solute would be a powerful breakthrough for the improvement of FO performance.

The ideal draw solute should be able to provide significantly improved FO performance, and separated easily and

completely by means of a low cost recovery method. In this

sense, three major criteria can be applied to evaluate the

suitability of a draw solute: (1) high water flux; (2) low reverse

draw solute flux; and (3) easy and low-cost recovery from the

diluted draw solution. Additional points, such as water solubility, nontoxicity, and the potential for commercialization,

should be also considered.

Various materials, including conventional inorganic salts,

organic solutes, and newly developed materials, have been

studied and evaluated in the search for an optimized draw

solute. In previous work, traditional draw solutes based on

inorganic salts, such as NaCl and MgCl2, have been extensively studied in various FO fields (Holloway et al., 2007; Achilli

et al., 2010). The draw solutions made from inorganic solutes

produce reasonably high water flux and can be readily separated by RO. However, both energy requirement of RO recovery and corresponding solute leakage in FO have been found

to be high, leading to concerns about operational costs.

To overcome these disadvantages, many novel draw solutes have been proposed and evaluated. Especially, some

types of single molecular organic salts and polyelectrolytes,

such as EDTA sodium salts, sodium polyacrylate (PAANa), and

sodium lignin sulfonate (NaLS) have been investigated as potential draw solutes, taking advantage of their large molecular

size (Hau et al., 2014; Duan et al., 2014; Ge et al., 2012; Yen

et al., 2010; Stone et al., 2013). These types of solutes not

only generated good water flux but also reduced reverse solute

flux significantly. The regenerations of these salts, especially

EDTA sodium salts and PAANa, were also successfully achieved by low-pressure nanofiltration (NF) (Hau et al., 2014) or

ultrafiltration (UF) (Ge et al., 2012), respectively. Despite good

performance in the FO process and recovery system, these

solutes were ultimately found to be impractical due to drawbacks such as commercial availability.

Water-soluble magnetic nanoparticles (MNPs) have also

been investigated as a novel draw solute based on their

superparamagnetic properties. Various hydrophilic single

molecule- or oligomer-coated MNPs such as 2-pyrrolidoneMNP, triethylene glycol-MNP, poly(acrylic acid)-MNP, and

poly(ethylene glycol)diacid-MNP were synthesized to incorporate both large molecular size and magnetic properties and

evaluated for their potential as draw solutes (Ling et al., 2010;

Ge et al., 2011; Na et al., 2014). The large molecular size of these

MNPs is led to better prevention of reverse solute flux but the

coating materials on the MNPs adversely affected the magnetic properties. Therefore, this resulted in a low separation

rate and the separated MNPs showed irreversible aggregation.

The combination of these factors caused difficulty in the recovery and sustainability for these materials. Moreover, the

risk assessment for human health and the environmental

hazards of synthesized nanomaterials are an ongoing concern

in various research fields.

Draw solutes based on thermosensitive materials with

temperature dependent phase separation behavior have

received increasing attention (Ling et al., 2011; Noh et al., 2012;

Zhao et al., 2014; Cai et al., 2013). Solutes such as N-acylated

295

polyethyleneimine (PEI) derivatives and poly (sodium styrene4-sulfonate-co-n-isopropylacrylamide) (PSSS-PNIPAM) are

soluble in water under their lower critical solution temperature (LCST), but agglomeration of polymer chains occurs

above the LCST (Noh et al., 2012; Zhao et al., 2014). Based on

this thermoresponsivity, the diluted draw solutes can be

easily concentrated by thermal recovery methods such as

membrane distillation (MD). In spite of all these pioneering

work, a practical solution to the low performance of FO due to

their low osmotic pressure has remained elusive. Despite the

enormous research efforts undertaken in terms of these

various solutes, each has had serious drawbacks, and therefore, the search for a practical and optimized draw solute

must continue if the successful application of FO is to be

achieved.

Considering the aforementioned requirements for a draw

solute, poly (aspartic acid sodium salt) (PAspNa) is a more

suitable candidate than the previously studied solutes.

PAspNa, a kind of polyelectrolyte commonly used as an

antiscalant, has many properties which suggest it may have

potential as an alternative draw solute of FO. It has significantly large molecular size and good water solubility.

Furthermore, it is non-toxic and commercially available with

reasonable unit price. As these various merits of PAspNa had

been verified through our autonomous evaluation procedure

for screening draw solutes, in order to show the potential of

PAspNa as a new draw solute systematically, this paper is

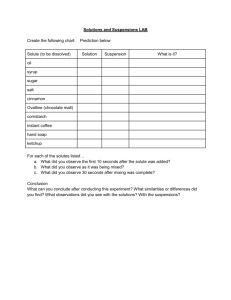

organized with detailed scrutiny for physicochemical analyses and practical performance measurements. The evaluation flow for selecting new draw solute was composed of

four stages and all the criteria of each level were categorized

in Fig. 1.

To assess the suitability of PAspNa, we first analyzed the

physicochemical properties of PAspNa as a draw solute, specifically its molecular characteristics, water solubility, osmotic pressure, viscosity, and toxicity. The basic performance

aspects of PAspNa as a draw solute in FO, such as its water flux

and reverse solute flux, were examined using deionized (DI)

water as the feed solution. The effect of reverse PAspNa flux

on inorganic fouling was also assessed through a scaling

experiment using inorganic synthetic wastewater as the feed

solution. Finally, recyclability studies were explored using

nanofiltration (NF) and membrane distillation (MD) processes.

2.

Materials and methods

2.1.

Preparation of PAspNa

Commercially available PAspNa (CAS-No. 181828-06-8) in

powder form was obtained from Lanxess AG (Cologne, Germany). For the characterization analyses, including molecular

structure and toxicity, purified PAspNa was used, and the

molecular structural data obtained was used to inform the

molecular dynamics study of its solvation behavior in water.

Unwanted NaOH was removed from the PAspNa through

rigorous washing with MeOH/distilled water (1:9 vol%) followed by drying in vacuo at 80 C. For all the FO and recovery

tests, unrefined PAspNa was used as supplied, in order to

directly evaluate its real-world applicability.

296

w a t e r r e s e a r c h 8 0 ( 2 0 1 5 ) 2 9 4 e3 0 5

monomer units. The syndiotactic configuration was found to

have the lowest energy, and was verified by ab initio calculations using a short polymer strand. The molecular weight

used for the commercially available PAspNa was informed by

the GPC results, which corresponded to approximately 10

monomer units. For simplification of chemical structure,

PAspNa was consisted of only a-form of L-aspartic acid units

(See Fig. S1). For more details of the simulation methodology is

described in the supplementary information.

2.4.

Cell culture and cellular toxicity test

A colorimetric assay using 3-(4, 5-Dimethylthiazol-2-yl)-2, 5diphenyltetrazolium bromide (MTT) was performed to

examine the cellular toxicity of PAspNa. Normal human fibroblasts from neonatal foreskin, obtained from the dermatology unit of Ajou University Hospital in the Republic of

Korea, were used as target cells. The cells were grown as

adherent culture and maintained in Dulbecco's modified eagle's medium (DMEM) supplemented with 10% fetal bovine

serum, 100 U/mL penicillin (Gibco BRL), and 100 mg/mL streptomycin (Gibco BRL) at 37 C in a humidified atmosphere with

5% CO2. For testing, cells at a concentration of 2 104 cells per

well were seeded in a 24-well plate. After 24 h, PAspNa dissolved in serum-free DMEM at different concentrations was

introduced to the cells, which were then incubated at 37 C in

a humidified atmosphere with 5% CO2 for 72 h. The control

cells were treated with the same amount of serum-free

DMEM. Then, MTT solution (1 mg/mL, PBS) with one tenth of

the total volume of the cell media was added. The cells were

then incubated under the same conditions for a further 4 h.

After removing the media, 500 mL of DMSO was added to

dissolve the precipitated formazan crystals formed in the

well. The absorbance of the sample proportional to cellular

viability was measured spectrophotometrically at 540 nm

with a background absorbance at 650 nm by a microplate

reader (PowerWave X, Bio-Tek Inc., VT, USA).

Fig. 1 e Evaluation flow for selecting new draw solute.

2.2.

Physicochemical properties

The molecular weight of PAspNa was measured by aqueous

gel permeation chromatography (GPC) (Breeze System, Waters, USA) using 0.02 N NaNO3 as the eluent at a flow rate of

0.8 mL/min. The amount of sodium in PAspNa was quantified

with an inductively coupled plasma-atomic emission spectrometer (ICP-AES) (ICPS-8100, Shimadzu, Japan). The viscosity and osmolality of PAspNa were measured using an SV-10

Vibro Viscometer (A&D Company LTd., Japan) and Osmomat

030 (Gonotec GmbH, Germany), respectively.

2.3.

Atomistic model of draw solute for solvation

behavior study

In the simulations, the chemical structure of the PAspNa was

represented by a single chain polymer strand in the syndiotactic configuration, with a degree of polymerization (n) of 10

2.5.

FO process

All of the FO experiments were conducted with a lab-scale FO

unit as described elsewhere (Boo et al., 2013; Kim et al., 2012;

Boo et al., 2012). A custom-built cross-flow FO cell with symmetric rectangular channels (7.7 cm in length, 2.6 cm in width

and 0.3 cm in height) on both feed and draw sides was used for

the co-current flows of the feed and draw solutions. The crossflow velocity of both solutions was fixed at 8.5 cm/s and the

temperature was maintained at 25 ± 0.5 C. Two types of flat

sheet membranes made with different materials were used,

namely, asymmetric cellulose triacetate (CTA) and thin film

composite (TFC) membranes (Hydration Technology Inc.,

Albany, OR, USA). The membrane coupons were inserted in

the membrane cell in two different orientations; active layer

facing the feed solution (AL-FS) mode, and active layer facing

the draw solution (AL-DS) mode. PAspNa draw solutions of

different concentrations in DI water were prepared at an

initial volume of 1 L. Two different types of solution, i.e., DI

water and inorganic synthetic wastewater, were used as the

feed solution. DI water was used to evaluate basic FO performance such as water flux and reverse solute flux, and

w a t e r r e s e a r c h 8 0 ( 2 0 1 5 ) 2 9 4 e3 0 5

inorganic synthetic wastewater was employed for the fouling

experiments. The chemical composition of the synthetic

wastewater shown in Table 1 is based on the secondary

effluent quality from selected wastewater treatment plants in

California, USA (Boo et al., 2013; Huertas et al., 2008). All feed

solutions were prepared at the same initial volume of the

draw solution, i.e., 1 L. The water flux, Jw, given in units of liters per square meter per hour (LMH), was calculated by

recording the mass change in the draw solution reservoir

versus time, thus:

Jw ¼

DV

ADt

(1)

where DV (L) is the volume change over the time interval Dt

(h), and A (m2) is the effective membrane surface area.

The reverse solute flux, Js, given in units of grams per

square meter per hour (gMH), was determined by converting

conductivity and total organic carbon of the feed DI water

using Equation (2).

Js ¼

DðCt Vt Þ

ADt

NF process

A lab-scale NF system similar to that reported in our earlier

publications (Ju and Hong, 2014) was used for the recyclability

experiments. TFC flat sheet membranes (model NF270-4040D)

with a 200e300 Da molecular weight cut-off (MWCO) from

Dow Chemical Company were used. For stable operation, a

porous stainless steel spacer 1.75 mm thick was placed in the

feed channel. The membrane cell specifications and flow

conditions were the same as those of the FO experiments. The

feed solutions were PAspNa solutions ranging from 0.01 to

0.03 g/mL. Hydraulic pressure was applied to keep a constant

pressure of 20 bar, and the temperature of the feed PAspNa

solution was maintained at 20 ± 0.5 C. The water flux was

calculated with Equation (1), but the mass change in the

Table 1 e Chemical composition of the synthetic

wastewater solution used in the inorganic fouling

experiments (Boo et al., 2013).

Compound

Sodium citrate

Ammonium chloride

Potassium

phosphate

Calcium chloride

Sodium bicarbonate

Sodium chloride

Magnesium sulfate

permeated water was measured instead of the draw solution.

The salt rejection was computed with Equation (3).

R¼

Cp

1

100

CF

(3)

where R (%) is the salt rejection, Cp (g/L) is the solute concentration of the permeate water, and CF (g/L) is the solute concentration of the feed solution.

2.7.

MD process

MD experiments were carried out using the same lab-scale

set-up as for the FO tests during 3 h. The effective membrane area, flow rate, and direction were identical to those of

the FO experiments. Polytetrafluoroethylene (PTFE) flat sheet

membrane (EMD Millipore, Germany) of 0.2 mm pore size was

used. The PAspNa feed solution was prepared and maintained

at 60 ± 0.5 C, while the permeate solutions were cold DI water

maintained at 20 ± 0.5 C. The water flux was calculated with

Equation (1).

(2)

where Ct (g/L) and Vt (L) are the reverse solute concentration

and the volume of feed solution, respectively, at an arbitrary

time t. The conductivity was measured using a conductivity

meter (Hach-Lange, UK), and the amount of total organic

carbon was analyzed with a TIV-V CPH (Shimadzu, Japan).

2.6.

297

Molecular

weight

(g/mol)

Concentration

(mM)

294.09

53.49

136.09

1.16

0.94

0.45

147.01

84.01

58.44

246.47

0.5

0.5

2.0

0.6

3.

Results and discussion

3.1.

Physicochemical properties of PAspNa

In order to investigate the suitability of the new draw solute,

the physicochemical characteristics of PAspNa were explored

on the basis of our evaluation procedure. The basic molecular

characteristics of PAspNa were first analyzed to identify its

molecular size and composition. Its water solubility, osmotic

pressure, and toxicity were also assessed.

3.1.1.

Molecular characterizations

Commercially available PAspNa is supplied in oligomeric

form. To define the composition of PAspNa as a polyelectrolyte, we first analyzed its molecular weight and total

sodium content by aqueous GPC and ICP-AES, respectively.

The average molecular weight of PAspNa, represented by Mn,

was found to be 1313 g/mol, and the polydispersity index (PDI)

was found to be 1.14. The number of sodium ions per carboxylic group was shown to be almost unity, with the result

for Na content being 93.7 mol% (Table S1). These characteristics of the PAspNa was used the molecular dynamics simulation study of the next section. In addition, 1H NMR

spectroscopy was used to explore the structural properties of

PAspNa related to biodegradability. As shown in the 1H NMR

spectra (Fig. S2), both unpurified and purified PAspNa clearly

show characteristic peaks of well-defined aspartic acid units

with broad peaks for a/b-amide methine protons at d ¼ 4.4 and

4.6 ppm, and also another broad peak from methylene protons

at 2.7 ppm. Moreover, regardless of purification method, both

1

H NMR spectra of PAspNa showed almost no peaks in the

8e10 ppm region, where branched and/or opened amide

groups would resonate. Thus, it is indicated that the content

of irregular forms in the PAspNa is very small. In general, the

irregular structural forms display a much slower biodegradation rate than the linear form (Tomida and Nakato, 1997;

Rowenton et al., 1997). As the PAspNa sample consists

almost entirely of linear type molecules with a negligible

298

w a t e r r e s e a r c h 8 0 ( 2 0 1 5 ) 2 9 4 e3 0 5

(a)

2.0

1.5

1.0

0.5

0.0

0.0

Water solubility

To verify the high water solubility of PAspNa through its solvation behavior at the atomic-scale, we examined how water

molecules exist around the draw solute molecules by investigating the pair correlation function, g(r), between the two

oxygen atoms of the PAspNa carboxylate ion (COO) and

water molecules as a function of distance, r. In order to

demonstrate the suitability of PAspNa as draw solute through

comparison study with the criteria of material selection, we

also investigated PAANa with a similar molecular weight

(nominal molecular weight ~ 1200 g/mol), which is a previously reported polyelectrolyte draw solute. To simplify our

approach, we assumed that PAspNa and PAANa are (1) a

syndiotactic linear molecule with short side chains, and (2)

composed of 10 repeat units. Since the number of solvating

water molecules would simply increase proportionally to the

number of repeating units in the model molecule, we assumed

that PAANa has the same number of repeating units as

PAspNa. In addition, the oxygen and hydrogen atoms of the

water molecules surrounding the carboxylic groups were

taken into account as solvating molecules.

As plotted in Fig. 2(a), the g(r) curves between COO of both

PAANa and PAspNa, and the oxygen of water (OW) showed

similar values of unity for r < 2 nm. The sharp peaks below

r ¼ 0.35 nm, representing possible hydrogen bond formation

between the fully ionized carboxylate groups and the water

molecules, suggest that approximately equal numbers of

water molecules are present for every COO in both PAANa

and PAspNa. There are 2.41 and 2.21 water molecules present,

respectively. The function g(r) between the COO and two

hydrogens of water (HW) is also shown in Fig. 2(b). The trends

of both curves are very similar to Fig. 2(a) and every COO

group of PAANa and PAspNa had 2.45 and 2.26 water molecules, respectively. As the number of water molecules existing

around the draw solute could be interpreted to the water

solubility directly, these two pair correlation functions assure

that PAspNa has comparable water solubility to PAANa.

For the simulation of PAspNa and PAANa configurations in

water, we illustrated the first shell of solvation with the end

carboxylate group of each draw solute molecule using spatial

distribution functions (SDF) which gives the probability of

finding an atom in the three-dimensional space around the

central molecule. The SDF is shown for water molecules at a

distance of less than 0.35 nm, where the first solvation shell is

found, from the COO of PAspNa and PAANa. As depicted in

Fig. 3, the water molecules are almost spherically distributed

around the carboxylate groups.

PAANa_10mer

PAspNa_10mer

2.5

0.5

1.0

1.5

2.0

r (nm)

3.0

2.5

g(r) [C(COO-), HW]

3.1.2.

3.0

g(r) [C(COO-), OW]

amount of branching, its structure is more prone to biodegradation. Considering an increasing environmental concern

and discharge limitations, the biodegradability of PAspNa

could make it more suitable as draw solute due to its ecofriendliness. According to previous studies, however, biodegradable polymer, which was used as an antiscalant, could

accelerate biofouling on a membrane surface (Vrouwenvelder

et al., 2000). This gives a deducible fact that an inevitable

leakage of PAspNa to feed solution may cause an aggravated

membrane fouling in FO. In order to confirm the impact of

biodegradable draw solute on the FO performance, further

research should be needed.

(b)

PAANa_10mer

PAspNa_10mer

2.0

1.5

1.0

0.5

0.0

0.0

0.5

1.0

1.5

2.0

r (nm)

Fig. 2 e Pair correlation function between the two

carboxylate oxygens (COO¡) of the draw solutes and (a) the

oxygen of water (OW) and (b) both the hydrogens of water

(HW). The solid and dashed curves indicate PAspNa and

PAANa, respectively.

Our previous study also compared the hydrogen bonding

dynamics between charged carboxylic group and water molecules of both PAANa and PAspNa (Ramachandran et al.,

2013). Quantitatively, the average number of H-bonds for

PAANa and PAspNa is 48 and 56, respectively. This result indicates that the PAspNa has a more favorable interaction with

water, which results in relatively open conformations of the

solute. Indeed, the radius of gyration (Rg) of PAANa was

calculated to have a much smaller size of 0.7 nm with a narrow distribution, while PAspNa showed a very broad distribution of Rg. These demonstrated facts, i.e., the large

configuration and molecular size of solvated PAspNa, through

the analytical scrutiny lead us to expect much less reverse

solute flux, which makes it the more suitable draw solute,

than PAANa.

3.1.3.

Osmotic pressure and viscosity

To examine the driving force potential for FO, the osmotic

pressure of PAspNa was measured in terms of osmolality. As

shown in Fig. 4(a), the osmolality of PAspNa solution has an

299

w a t e r r e s e a r c h 8 0 ( 2 0 1 5 ) 2 9 4 e3 0 5

2.5

O smo lality (O s mo l/kg )

(a)

2.0

1.5

1.0

0.5

0.0

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.30

0.35

Concentration (g/mL)

5.0

4.5

(b)

Viscosity(cP)

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.00

0.05

0.10

0.15

0.20

0.25

Concentration (g/mL)

Fig. 4 e (a) Osmolality of the PAspNa solution as a function

of concentration. (b) Viscosity of the PAspNa solution at

different concentrations.

Fig. 3 e Image of spatial density isosurface of water

molecules within 0.35 nm of the carboxylate oxygens

(COO¡) of the first residue of (a) PAANa and (b) PAspNa.

almost linear correlation with concentration from 0.05 to

0.3 g/mL. The osmolality values ranges from 0.21 to 2.15

Osmol/kg corresponding to osmotic pressure from 5.08 to

51.5 atm. According to previous studies, simulated seawater

(0.6 M NaCl) and 0.72 g/mL PAANa (1200) produced an osmotic

pressure of approximately 27.6 and 44.5 atm, respectively

(Achilli et al., 2010; Ge et al., 2012). In comparison with these

osmotic pressure values, 0.3 g/mL PAspNa generated a much

higher osmotic pressure, indicating its great potential as an

alternative draw solute. Especially, in the case of polyelectrolytes, it has been reported that the osmotic pressure

can be implied from the water activity, which is influenced by

freely mobile counterions in proximity to charged polyions

(Vlachy, 2008; Manning, 1972). Lower ion pairing between

counterions and polyions leads to more freely mobile counterions, resulting in reduced water activity around them. This

can be correlated to the results of earlier publication, in which

PAspNa has lower ion paring between its charged carboxylic

groups and Na counterions than in PAANa (Ramachandran

et al., 2013), resulting in a higher osmotic pressure. The

possible ion pairing was represented by the value for average

number of ion pairs <Nip>, which was calculated to be 0.9 and

1.8 for PAspNa and PAANa, respectively.

Viscosity may affect the efficiency of FO performance by

causing a serious concentration polarization (CP) effect.

Therefore, the viscosity was measured and used as another

criterion for draw solute evaluation. As illustrated in Fig. 4(b),

the viscosity of the solution increased exponentially as the

PAspNa concentration increased from 0.05 to 0.3 g/mL. At all

concentrations, the viscosity was lower than 4.4. This phenomenon is explained by the fact that high concentration not

only causes high friction between the neighboring PAspNa

molecules, but also reduces the water activity. When converting the unit to relative viscosity, a maximum value of 5.0

300

w a t e r r e s e a r c h 8 0 ( 2 0 1 5 ) 2 9 4 e3 0 5

was recorded at 0.3 g/mL PAspNa. This viscosity is significantly higher than that of simulated seawater, i.e., 1.08, but

much lower than the measured value of 0.3 g/mL PAANa

corresponded to 13.0.

3.1.4.

Cellular toxicity

To assess the toxicity of PAspNa, we performed an in vitro

toxicology test by means of an MTT assay with primary

cultured human fibroblast cells. Control cells were treated

with the same medium as in the PAspNa-treated experimental cell groups, but without PAspNa, in order to exclude

the effect of the medium on the cells. We examined the

cellular toxicity of PAspNa at 3000 ppm total dissolved solids

(TDS), which is ten times the concentration of the maximum

accepted TDS value for drinking water, i.e., 300 ppm (WHO,

1996). As shown in Fig. 5, the PAspNa-treated cells showed

almost the same or better cellular viability than the control,

which was treated with empty media. This indicates that even

under the tested maximum concentration of 3000 ppm for

72 h, PAspNa does not show any significant toxicity to human

skin cells. Although this in vitro toxicology test is admittedly

quite different from the test for determining the standard TDS

value for drinking water, this is meaningful in that it shows

exposure to PAspNa does not harm human skin cells.

3.2.

FO performance

In the previous section, we demonstrated that the PAspNa is a

good candidate for a new draw solute for FO in terms of material characteristics, including its large molecular size, high

osmotic pressure, and non-toxicity. To evaluate the practical

suitability of PAspNa in real membrane processes, basic FO

performance tests were carried out using both CTA and TFC

membranes. A simple economic feasibility was also assessed

based on the results of the FO performances.

3.2.1.

Basic performance: CTA membrane

As most of draw solute researches have been conducted with

CTA membranes, this study also used CTA membrane to

measure the water flux and reverse solute flux of PAspNa in

FO. Fig. 6 shows that, in both AL-FS and AL-DS modes, as the

concentration of PAspNa increased from 0.1 to 0.3 g/mL, the

water flux also increased. Its increment was not proportional

to that of the concentration, reflecting the correlation between

osmotic pressure and CP of the PAspNa solution. More specifically, higher concentrations of PAspNa not only generate

greater osmotic driving force, which lead to higher water flux,

but also simultaneously reduce its diffusivity. The enhanced

hindrance of diffusion at high concentration of PAspNa exacerbates the CP effect, which results in a non-linear relationship between the concentration and water flux.

Furthermore, the water flux in AL-DS mode always surpassed

that observed in AL-FS mode. This means that the internal CP,

which occurs in AL-FS mode, has a greater effect on the flux

decline than the external CP in AL-DS mode (Yen et al., 2010).

The reverse solute flux in both operational modes increases

following the same trend as that seen for water flux. The

maximum value of reverse solute flux was recorded as 2.4

gMH at the concentration of 0.3 g/mL under AL-DS mode.

The specific reverse solute flux, which refers to the ratio of

reverse solute flux to water flux, i.e., Js/Jw, is usually used as an

indicator of draw solute loss per volume of water permeation

in the FO operation. So, we first calculated the Js/Jw of 0.2 g/mL

PAspNa, of which an osmotic pressure of 26.6 atm, based on

the results of the FO experiments. As NaCl and MgCl2 are

extensively used as draw solutes, we also referred to their Js/Jw

values as comparative benchmarks for a better evaluation of

PAspNa: 0.035 g/mL of NaCl and 0.034 g/mL MgCl2 with an

osmotic pressure of 27.6 atm were adopted as model concentrations. As shown in Fig. 7(a), PAspNa has the lowest

value of Js/Jw, 0.19 g/L, while those of NaCl and MgCl2 are

recorded as 0.75 g/L and 0.57 g/L, respectively (Achilli et al.,

2010). This result indicates that PAspNa has a lower loss to

the feed solution than the inorganic salts for each liter of

water produced during the FO operation.

For a more specific comparison in an economic perspective, we also calculated the FO operating cost of those solutes.

As an operating cost of draw solution in FO usually regarded

as a cost for replenishing draw solutes, the costs were

computed by multiplying the Js/Jw values and unit solute

120

Water flux (LMH)

Cellular Viability [%]

20

80

60

40

20

0

Control

10

100

1000

3000

Concentration of PAspNa [ppm]

Fig. 5 e Cell viability of human fibroblast cells after a 72 h

incubation with PAspNa at predetermined concentrations.

25

Water flux (AL-FS, LMH)

Water flux (AL-DS, LMH)

Reverse solute flux (AL-FS, gMH)

Reverse solute flux (AL-DS, gMH)

20

15

15

10

10

5

5

0

0.05

0.10

0.15

0.20

0.25

0.30

Reverse solute flux (gMH)

25

100

0

0.35

Concentration(g/mL)

Fig. 6 e Basic FO performance results, including water flux

and reverse solute flux, with the CTA membrane.

301

w a t e r r e s e a r c h 8 0 ( 2 0 1 5 ) 2 9 4 e3 0 5

3.2.2.

0.8

(a)

Js/Jw

0.6

0.4

0.2

0.0

NaCl

MgCl2

PAspNa

20

FO operating cost, 10-3$/L

(b)

15

10

5

0

NaCl

MgCl2

PAspNa

Fig. 7 e (a) Specific reverse solutes flux, Js/Jw, of PAspNa

and (b) FO operating cost compared to two conventional

inorganic draw solutes, namely NaCl and MgCl2.

prices. The specific conditions for this assessment were

summarized in Table 2. As illustrated in Fig. 7(b), the operating

cost of PAspNa is recorded as the lowest value among three

draw solutes. Considering those of NaCl and MgCl2 are 0.011

and 0.016 $/L, respectively, the replenishment cost of PAspNa,

0.002 $/L, is a remarkably low value. Although, much more

weight of PAspNa is needed to express a comparable osmotic

pressure with NaCl or MgCl2, which results in high initial investment cost (specific cost, 5th column in Table 2), in the long

run, a more important cost associated with the draw solution

is the operating cost. Therefore, it is logical to judge that

PAspNa has a potential as an alternative draw solute from the

economic perspective.

Basic FO performance: TFC membrane

PAspNa was also evaluated using a TFC membrane with a pH

tolerance of 2e11 in order to prevent the possibility of membrane damage caused by its basicity, which was pH~10.3 at all

the concentrations tested. As shown in Fig. 8(a), the FO performance with the TFC membrane, including water flux and

reverse solute flux, shared very similar characteristics with

the performance seen with the CTA membrane. More specifically, both water flux and reverse solute flux increased under

both operational modes as the concentration of PAspNa

increased. The water flux under AL-DS mode always clearly

surpassed that observed under AL-FS mode, and the

maximum water flux was recorded as 31.8 LMH under AL-DS

mode at a PAspNa concentration of 0.3 g/mL.

Because intensely high water flux is observed in Fig. 8(a),

PAspNa solutions with concentrations under 0.1 g/mL, which is

the minimum concentration employed in the preceding FO

experiments with the TFC membrane, were additionally used as

the draw solution in AL-DS mode. As shown in Fig. 8(b), the

water flux of the PAspNa solution increased linearly with concentration at low concentrations ranging from 0.01 to 0.1 g/mL.

However, this trend of increasing water flux changes suddenly

at 0.1 g/mL. Beyond 0.1 g/mL, the rate of water flux increase with

concentration is much lower. This result is attributed to the fact

that the increase in water flux is inversely proportional to that of

solution viscosity. In addition, a reasonable water flux of 4.81

LMH was achieved at the lowest concentration, 0.01 g/mL. This

meaningful result gives us a potential that the NF process,

which requires a feed solution of low osmotic pressure, could be

the optimal recovery method for use with PAspNa as a feed

solution. Thus, the hybrid FO-NF process could be practical at

low PAspNa concentrations under 0.1 g/mL, attaining a

competitive FO performance and ease of recovery through low

pressure-driven NF. In addition, to compare the FO performance of PAspNa draw solution, same FO experiments were

conducted differing only in their use of 0.3 g/mL PAANa draw

solution. In these tests, as in the PAspNa draw solution tests,

unpurified PAANa solution was used as draw solution. As

shown in Fig. 9, the water flux from the PAspNa draw solution

test was higher than that from the PAANa draw solution test.

This phenomenon could be simply explained by a viscosity

difference between those two solutions. Although same solution concentration was used, the viscosity of 0.3 g/mL PAANa

solution was recorded much higher value than that of PAspNa

solution. It means that diffusion of PAANa solutes in the

membrane support layer is much slower than that of PAspNa

solutes, resulting in much severe ICP effect. In contrast to the

water flux, the reverse solute flux from the PAspNa test was

Table 2 e Osmotic pressure (pDS ), unit cost ($/kg), specific cost ($/L), specific reverse solute flux (g/L) and FO operating cost

($/L) for each draw solution. The specific cost of each draw solution was obtained by calculating the cost of solute needed to

produce 1 L of draw solution.

Draw solutes

NaCl

MgCl2

PAspNa

a

CDS, g/L

pDS , atm

Cost, $/kg

Specific cost, $/L

Js/Jw, g/L

FO operating

cost, $/L

35.2a

33.8a

200

27.6a

27.6a

26.6

15a

28a

8.8

0.53a

0.95a

1.76

0.74a

0.57a

0.19

0.011a

0.016a

0.002

Reported values from previous study (Achilli et al., 2010).

302

w a t e r r e s e a r c h 8 0 ( 2 0 1 5 ) 2 9 4 e3 0 5

W a t e r f lu x ( L M H )

40

50

Water flux (AL-FS, LMH)

Water flux (AL-DS, LMH)

Reverse solute flux (AL-FS, gMH)

Reverse solute flux (AL-DS, gMH)

40

30

30

20

20

10

10

0

0.05

0.10

0.15

0.20

0.25

0.30

Reverse solute flux (gMH)

50

0

0.35

Concentration (g/mL)

(a)

Wa t e r f l u x ( L M H)

40

50

Water flux (LMH)

Reverse solute flux (gMH)

40

30

30

20

20

10

10

0

0.00

0.05

0.10

0.15

0.20

0.25

0.30

Reverse solute flux (gMH)

50

0

0.35

Concentration (g/mL)

(b)

Fig. 8 e Behavior of water and reverse solute fluxes under

different PAspNa concentrations: (a) comparison of

operation modes (AL-FS and AL-DS) and (b) variations at

low PAspNa concentration conditions in AL-DS mode of

TFC FO membrane.

14

12

10

Water flux (LMH)

Reverse solute flux (gMH)

Viscosity (cP)

8

6

4

2

0

PAspNa

PAANa

Fig. 9 e Water flux and reverse solute flux of 0.3 g/mL

PAspNa and 0.3 g/mL PAANa draw solutions with TFC

membrane in AL-FS mode.

lower than that from the PAANa test. This result is in complete

accord with our prediction in the previous section, which was

that PAspNa may show much lower solute leakage to the feed

solution due to the larger configuration in water compared with

PAANa. The overall comparison test results proved that the

PAspNa had a better FO performance than that of PAANa.

3.3.

Antiscaling effect of reverse PAspNa flux in the FO

process

In various membrane processes, from pressure-driven RO to

thermal-driven MD, inorganic scaling is a serious problem

which causes increased energy consumption, cleaning frequency and membrane replacement (Antony et al., 2011; He

et al., 2009). Particularly, calcium phosphate scaling is regarded as a major difficulty for the treatment of wastewater

effluent by NF or RO (Greenberg et al., 2005). A commonly

applied method to control this inorganic fouling is dosing the

feed solution with a very small amount of effective antiscalant

(He et al., 2009; Rahardianto et al., 2006). The antiscalant reduces crystal formation and deposition on the membrane

surface by impeding crystal nucleation and growth.

As briefly mentioned above, PAspNa is usually used as a

component in antiscalants. Therefore, scaling experiments in

FO were carried out to verify that the reversely flowed PAspNa

could act as an antiscalant in an FO feed solution. To simulate

wastewater reclamation, synthetic wastewater containing

only inorganic ionic species was used as the feed solution, and

0.3 g/mL PAspNa was used as the draw solution. The resulting

flux decline curve was compared to experiments differing

only in their use of a 0.3 M NaCl draw solution which generated a similar initial water flux with 0.3 g/mL PAspNa draw

solution. The initial water fluxes from the 0.3 g/mL PAspNa

draw solution test and 0.3 M NaCl draw solution test were 8.22

LMH and 8.37 LMH, respectively. As shown in Fig. 10(a), a

gradual and constant decline in flux was observed with the

PAspNa draw solution. Although the permeate flux with a

NaCl draw solution initially showed a similar gentle decline, it

dropped abruptly in the middle of the fouling run. To investigate this difference between the two flux decline curves, the

membrane was removed from the membrane cell and

analyzed by scanning electron microscopy (SEM) after each

experiment. As shown in Fig. 10(c), a dense deposition of

inorganic precipitates (specifically, calcium phosphate salts,

see Fig. S3) was observed on the membrane surface after the

NaCl draw solution test. On the contrary, a distinct salt

deposition was not detected in the SEM image of FO membrane obtained after the PAspNa draw solution test (Fig. 10(b)).

To confirm this densely deposited layer originated from

synthetic wastewater, the qualitative and quantitative

chemical characterizations of the fouled FO membranes were

performed with SEM-EDS (Fig. S3) and ICP-AES (Table S2) analyses, respectively. The FO membrane when using NaCl draw

solution shows predominantly the characteristic peak of calcium as well as phosphate organic atoms from supporting

layer of TFC membrane. While FO membrane using PAspNa

draw solution as well as virgin FO membrane do not show the

characteristic peaks from inorganic atoms of wastewater, due

to the relatively low detection limit for inorganic metals of

small atomic mass with SEM-EDS, we could not observe other

303

w a t e r r e s e a r c h 8 0 ( 2 0 1 5 ) 2 9 4 e3 0 5

Fig. 10 e Antiscaling effect of PAspNa draw solution: (a) Flux decline curves obtained during the inorganic scaling

experiments. (b) SEM image of an FO membrane after the scaling experiment using a 0.3 g/mL PAspNa as draw solution. (c)

SEM image of an FO membrane after the scaling experiment using a 0.3 M NaCl as draw solution.

PAspNa recovery process

To verify the ease and efficiency of PAspNa recovery, a recyclability study was conducted on the two membrane processes, i.e., pressure-driven NF and thermal-driven MD. First,

the NF process was applied to demonstrate the effectiveness

of size exclusion by large molecular size of PAspNa with low

energy consumption. In addition, in order to reduce the viscosity of the PAspNa solution and prove the viability of a

hybrid FO-MD system, the MD process was also adopted as

another recovery method.

3.4.1.

NF process

As PAspNa has a large molecular size and expanded configuration in water, it can be readily separated from water with the

aid of a relatively larger pore size membrane than that of RO.

Therefore, our first set of recyclability studies were designed as

an NF process to verify the recovery convenience of PAspNa.

Diluted PAspNa solutions ranging from 0.01 to 0.03 g/mL were

employed as feed solutions, which guaranteed a higher water

flux than 4.81 LMH under TFC AL-DS mode (Fig. 7(b)). As shown

100

1.2

1.0

95

0.8

90

0.6

0.4

85

0.2

0.0

0.00

Water flux (LMH)

Recovery rate (%)

0.01

0.02

0.03

80

0.04

Concentration (g/mL)

Fig. 11 e Specific water fluxes and recovery rates for

different concentrations of PAspNa solutions in NF

process.

Recovery rate (%)

3.4.

in Fig. 11, specific water flux, defined as the ratio of water flux to

hydraulic pressure, decreased from 1.07 to 0.44 LMH/bar as the

feed PAspNa concentration increased from 0.01 to 0.03 g/mL.

This behavior is attributed to a decrease in the driving force

caused by a reduced difference between the fixed hydraulic

pressure and the feed osmotic pressure at high concentration.

Simultaneously, there was an analogous decrease in rejection

rate, which resulted from increased occurrence of PAspNa

permeating through the membrane. Nevertheless, a high recovery rate of more than 98.9% was achieved at all the concentrations tested in this experiment.

To evaluate the NF recovery performance of PAspNa, EDTA

sodium salt was used as a benchmark, since its recyclability

by NF has already been established. According to Hau et al.

(Hau et al., 2014), 0.07 M EDTA sodium salt, which can

generate a water flux of 4 LMH in FO, was adopted as an NF

Specific water flux (LMH/bar)

inorganic atoms on the surface of the severely fouled FO

membrane when using NaCl draw solution. However, in ICPAES results, the additional inorganic atoms such as sodium,

magnesium and potassium of small atomic mass were also

detected with a higher magnitude of order on FO membrane

when using NaCl draw solution compared to the virgin FO

membrane and FO membrane when using PAspNa draw solution. Not only with the analysis of surface morphology and

chemical composition, we could deduce that severe scaling,

indicated by the rapid flux decline and dense fouling layer,

occurred when using a NaCl draw solution. These results

confirm that reversely flowed PAspNa in the feed solution can

inhibit the physical mechanisms of crystal formation, which

cause inorganic fouling.

304

w a t e r r e s e a r c h 8 0 ( 2 0 1 5 ) 2 9 4 e3 0 5

feed solution, and its specific water flux and rejection rate in

NF ranged between 0.7 and 1.0 LMH/bar, and 80 and 93%,

respectively. Considering an NF performance of 0.01 g/mL

PAspNa had a specific water flux of 1.07 LMH/bar and a

rejection rate of 99.5%, PAspNa recovery under the NF process

was favorably comparable with the benchmark, assuring

satisfactory water production and solute rejection.

3.4.2.

MD process

In the continuous hybrid system combining FO and MD, the

heated FO draw solution is simply a feed solution for MD.

Considering the relationship between viscosity and temperature, a draw solution of high temperature can improve the

efficiency of FO by reducing its viscosity. Therefore, in order to

lower the viscosity of the PAspNa solution and verify the

applicability of the FO-MD hybrid system, MD experiments

were conducted as another recovery method. Fig. 12 shows

water flux as a function of solution concentration. The water

flux decreased from 24.6 to 15.0 LMH as the feed concentration

was increased from 0.1 to 0.3 g/mL. This reduction can be

ascribed to the fact that a higher concentration of PAspNa

solution not only reduces an effective vapor pressure of water

but also causes more severe temperature polarization. They

limit the water vaporization at the membrane surface and

thus, causes a decrease in vapor movement trough the

membrane which results in a decrement of water production

(He et al., 2011). The corresponding recovery rates for water

fluxes were recorded as more than 99.9% at all the concentrations used for this MD tests. Considering both reasonable

water flux and almost perfect regeneration of draw solute, the

successful operation results revealed the suitability of MD as a

recovery method for PAspNa, and the feasibility of the hybrid

FO-MD process for the improvement of FO performance.

4.

Conclusions

The suitability of PAspNa as a novel draw solute in the FO

process was demonstrated by a series of analyses comprising

Water flux (LMH)

30

20

10

0

0.0

0.1

0.2

0.3

Concentration (g/mL)

Fig. 12 e Water flux in the MD recovery process as a

function of concentration.

0.4

an atomistic molecular dynamics simulation and lab-scale

experiments. The inherent advantages of PAspNa, such as

good water solubility, high osmotic pressure, and non-toxicity,

were demonstrated systematically. The results of FO experiments proved the applicability of PAspNa as an alternative

draw solute compared to other previously studied materials,

particularly due to the much lower reverse solute fluxes

accompanying comparable water fluxes. Moreover, the reverse

PAspNa solutes showed a positive effect on the reduction of

inorganic scaling. The recyclability studies conducted by both

NF and MD processes also verified the ease of PAspNa recovery.

Although further studies are needed before PAspNa can be

applied in industry, this study has demonstrated its feasibility

and applicability to wastewater reclamation and/or brackish

water desalination by the FO-NF or FO-MD process.

Acknowledgments

This research was supported by a grant from the Fundamental

R&D Program for Technology of World Premier Materials

funded by the Ministry of Trade, Industry and Energy, Republic of Korea (10037794).

Appendix A. Supplementary data

Supplementary data related to this article can be found at

http://dx.doi.org/10.1016/j.watres.2015.04.041.

references

Achilli, A., Cath, T.Y., Childress, A.E., 2010. Selection of inorganicbased draw solutions for forward osmosis applications. J.

Membr. Sci. 364 (1e2), 233e241.

Antony, A., Low, J.H., Gray, S., Childress, A.E., Le-Clech, P., Leslie, G.,

2011. Scale formation and control in high pressure membrane

water treatment systems: a review. J. Membr. Sci. 383 (1e2), 1e16.

Boo, C., Elimelech, M., Hong, S.K., 2013. Fouling control in a

forward osmosis process integrating seawater desalination

and wastewater reclamation. J. Membr. Sci. 444, 148e156.

Boo, C., Lee, S., Elimelech, M., Meng, Z., Hong, S., 2012. Colloidal

fouling in forward osmosis: role of reverse salt diffusion. J.

Membr. Sci. 390e391, 277e284.

Cai, Y., Shen, W., Wang, R., Krantz, W.B., Fane, A.G., Hu, X., 2013. CO2

switchable dual responsive polymers as draw solutes for forward

osmosis desalination. Chem. Commun. 49 (75), 8377e8379.

Cath, T., Childress, A., Elimelech, M., 2006. Forward osmosis:

principles, applications, and recent developments. J. Membr.

Sci. 281 (1e2), 70e87.

Duan, J., Litwiller, E., Choi, S.H., Pinnau, I., 2014. Evaluation of

sodium lignin sulfonate as draw solute in forward osmosis for

desert restoration. J. Membr. Sci. 453, 463e470.

Ge, Q., Su, J., Amy, G.L., Chung, T.S., 2012. Exploration of

polyelectrolytes as draw solutes in forward osmosis

processes. Water Res. 46 (4), 1318e1326.

Ge, Q., Su, J., Chung, T.S., Amy, G., 2011. Hydrophilic

superparamagnetic nanoparticles: synthesis,

characterization, and performance in forward osmosis

processes. Industrial Eng. Chem. Res. 50 (1), 382e388.

w a t e r r e s e a r c h 8 0 ( 2 0 1 5 ) 2 9 4 e3 0 5

Greenberg, G., Hasson, D., Semiat, R., 2005. Limits of RO recovery

imposed by calcium phosphate precipitation. Desalination 183

(1e3), 273e288.

Hau, N.T., Chen, S.S., Nguyen, N.C., Huang, K.Z., Ngo, H.H.,

Guo, W., 2014. Exploration of EDTA sodium salt as novel draw

solution in forward osmosis process for dewatering of high

nutrient sludge. J. Membr. Sci. 455, 305e311.

He, F., Sirkar, K.K., Gilron, J., 2009. Effects of antiscalants to

mitigate membrane scaling by direct contact membrane

distillation. J. Membr. Sci. 345 (1e2), 53e58.

He, K., Hwang, H.J., Woo, M.W., Moon, I.S., 2011. Production of

drinking water from saline water by direct contact membrane

distillation (DCMD). J. Industrial Eng. Chem. 17 (1), 41e48.

Holloway, R.W., Childress, A.E., Dennett, K.E., Cath, T.Y., 2007.

Forward osmosis for concentration of anaerobic digester

centrate. Water Res. 41 (17), 4005e4014.

Huertas, E., Herzberg, M., Oron, G., Elimelech, M., 2008. Influence

of biofouling on boron removal by nanofiltration and reverse

osmosis membranes. J. Membr. Sci. 318 (1e2), 264e270.

Ju, Y., Hong, S., 2014. Nano-colloidal fouling mechanisms in

seawater reverse osmosis process evaluated by cake

resistance simulator-modified fouling index nanofiltration.

Desalination 343, 88e96.

Kim, C., Lee, S., Shon, H.K., Elimelech, M., Hong, S., 2012. Boron

transport in forward osmosis: measurements, mechanisms,

and comparison with reverse osmosis. J. Membr. Sci. 419e420,

42e48.

Ling, M.M., Chung, T.S., Lu, X., 2011. Facile synthesis of

thermosensitive magnetic nanoparticles as “smart” draw

solutes in forward osmosis. Chem. Commun. 47, 10788e10790.

Ling, M.M., Wang, K.Y., Chung, T.S., 2010. Highly water-soluble

magnetic nanoparticles as novel draw solutes in forward osmosis

for water reuse. Industrial Eng. Chem. Res. 49 (12), 5869e5876.

Manning, G.S., 1972. Polyelectrolytes. Annu. Rev. Phys. Chem. 23,

117e140.

Na, Y., Yang, S., Lee, S., 2014. Evaluation of citrate-coated

magnetic nanoparticles as draw solute for forward osmosis.

Desalination 347, 34e42.

Noh, M., Mok, Y., Lee, S., Kim, H., Lee, S.H., Jin, G.W., Seo, J.H.,

Koo, H., Park, T.H., Lee, Y., 2012. Novel lower critical solution

temperature phase transition materials effectively control

osmosis by mild temperature changes. Chem. Commun. 48,

3845e3847.

305

Rahardianto, A., Shih, W.-Y., Lee, R.W., Cohen, Y., 2006.

Diagnostic characterization of gypsum scale formation and

control in RO membrane desalination of brackish water. J.

Membr. Sci. 279 (1e2), 655e668.

Ramachandran, S., Katha, A.R., Kolake, S.M., Jung, B., Han, S.,

2013. Dynamics of dilute solutions of poly(aspartic acid) and

its sodium salt elucidated from atomistic molecular dynamics

simulations with explicit water. J. Phys. Chem. B 117 (44),

13906e13913.

Rowenton, S., Huang, S.J., Swift, G., 1997. Poly (aspartic acid):

synthesis, biodegradation, and current applications. J.

Environ. Polym. Degrad. 5 (3), 175e181.

Shannon, M.A., Bohn, P.W., Elimelech, M., Georgiadis, J.G.,

Marinas, B.J., Mayes, A.M., 2008. Science and technology for

water purification in the coming decades. Nature 452,

301e310.

Stone, M.L., Wilson, A.D., Harrup, M.K., Stewart, F.F., 2013. An

initial study of hexavalent phosphazene salts as draw solutes

in forward osmosis. Desalination 312, 130e136.

Tomida, M., Nakato, Takeshi, 1997. Convenient synthesis of high

molecular weight poly (succinimide) by acid-catalysed

polycondensation of L-aspartic acid. Polymer 38, 4733e4736.

Valladares Linares, R., Li, Z., Abu-Ghdaib, M., Wei, C.-H., Amy, G.,

Vrouwenvelder, J.S., 2013. Water harvesting from municipal

wastewater via osmotic gradient: an evaluation of process

performance. J. Membr. Sci. 447, 50e56.

Vlachy, V., 2008. Polyelectrolyte hydration: theory and

experiment. Pure Appl. Chem. 80 (6), 1253e1266.

Vrouwenvelder, J.S., Manolarakis, S.A., Veenendaal, H.R.,

Kooij, D.v.d, 2000. Biofouling potential of chemicals used for

scale control in RO and NF membranes. Desalination 132

(1e3), 1e10.

WHO, 1996. Health Criteria and Other Supporting Information.

Guideline for Drinking Water Quality, second ed., vol. 2. World

Health Organization, Geneva.

Yen, S.K., Mehnas Haja, N.F., Su, M., Wang, K.Y., Chung, T.S.,

2010. Study of draw solutes using 2-methylimidazole-based

compounds in forward osmosis. J. Membr. Sci. 364 (1e2),

242e252.

Zhao, D., Wang, P., Zhao, Q., Chen, N., Lu, X., 2014.

Thermoresponsive copolymer-based draw solution for

seawater desalination in a combined process of forward

osmosis and membrane distillation. Desalination 348, 26e32.