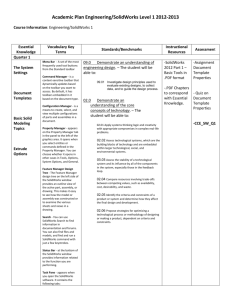

Session 1: Introduction to Solidworks Students will learn the basic

advertisement

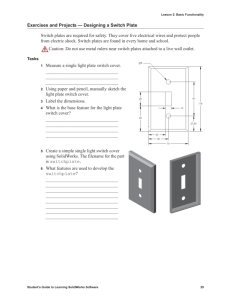

Session 1: Introduction to Solidworks Students will learn the basic functions of extrude, extrude cut, and fillet. 1) Complete Lesson 1 - Parts, from the Solidworks Tutorial. 2) Use the skills learned from the tutorial to draw a solid model of a duplex outlet cover. a) Observe the dimensions of the duplex outlet cover plate. b) Review the cover and determine the CAD functions needed to create the solid model. c) Design the solid model according to the specifications. Save the file as outletplate. 3) Draw a solid model of a light switch cover. a) Observe the dimensions of the duplex outlet cover. b) Create a solid model of the light switch cover. Save your file with the name switchplate. Session 2: Assembly Basics Students will learn shelling, advanced modeling, and the process of combining multiple parts together. 1) Complete Lesson 2 - Assemblies, from the Solidworks Tutorial. 2) Using the light switch cover from Session 1, design and model four identical fasteners to complete an assembly. The fastener design should adhere to the following criteria: a) The fastener must be longer than the thickness of the switchplate. b) The fastener must be 0.25 inch in diameter. c) The head of the fastener must be larger than the hole in the light switch cover. d) Save the model as fastener. 3) Assemble the four fasteners to the light switch cover. Save the file as switchplateassembly. *Note: the format of the file should be .SLDASM Session 3: Drawings Students will learn how to represent 3D models as 2D drawings with dimensions. 1) Complete Lesson 3 - Drawings from the Solidworks Tutorial. *Note: Please do not print the drawing. 2) The following exercise uses the model from the previous session to create a dimensioned drawing. a) Create a new A-size ANSI standard drawing template. b) Upload your Tutor2 model onto the template. c) Create Front and Top views. Add an Isometric view. d) Import the dimensions from the part. Add extra remaining dimensions. e) Create a note on the drawing to label the wall thickness. (Wall Thickness=4 mm) f) Save your file as tutor2drawing. Session 4: Design Tables Students will learn how to implement a table that effectively alters part dimensions. 1) Complete Design Tables from the Solidworks Tutorial. *Note: Please do not delete your table as stated in the tutorial. Session 5: Advanced Drawings Students will learn how to diminsion different drawing views and annotate exploded drawings. 1) Complete Advanced Drawings from the Solidworks Tutorial. *Note: Complete Creating Drawing Views and Assembly Drawing Views ONLY. You do not need to work on the Detailing activity. If you are having problems opening the file (foodprocessor.slddrw), then click here. Go to S:\Solidworks Samples\Samples1\advdrawings to access motorcasing.sldasm 2) The following exercise uses a model created in Session 1: a) Open switchplate and shell the part 0.1 inches. Add a front radius of 5 mm. b) Create a new A-size ANSI standard drawing template. c) Create a drawing for Switchplate. d) Add two Detailed views with dimensions. *This is a sample template. Disregard the dimension values. Session 6: Revolves & Sweeps Students will learn how to use the Revolve and Sweep tools. 1) Complete Revolves and Sweeps from the Solidworks Tutorial (Cstick.sldprt). 2) Create a Candle Stick that fits in the candle holder (save as Candle.sldprt). a) Attempt to make the candle stick with a 30mm diameter. b) Taper the bottom of the candle stick (use the extrude or chamfer tool). c) Make sure you add a wick on the top of the candle (extrude a circle or use the sweep tool). 3) Assemble the candle with the candle holder (save as Cassembly.sldasm). Session 7: Lofts Students should be familiar with lofting, adding extra drawing planes, and shelling. 1) Complete Lofts from the Solidworks Tutorial. 2) Create a bottle with the following dimensions: Session 8: Assembly Mates Students should be familiar with using assembly mates, exploding objects, and implementing movement control. 1) Complete Assembly Mates from the Solidworks Tutorial.