Constructing Suburbia: The Hidden Role of

advertisement

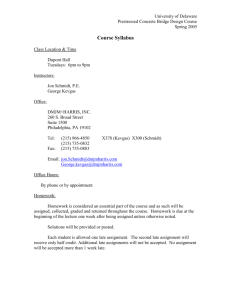

CONSTRUCTING SUBURBIA THE HIDDEN ROLE OF PRESTRESSED CONCRETE Robert M. Frame III and Richard E. Mitchell M oving into their new ranch-style houses in post-World War II suburbia, young families needed more than residences. A new suburban infrastructure accompanied the better-known housing boom of the era. Educational, social, and religious needs required schools, community centers, and places of worship. For commerce, developers conceived shopping centers and the supermarket. Spacious industrial parks accommodated the expansive, low-rise office buildings and industrial plants where many would 158 M I N N E S OTA H I S TO RY work. Automobiles, the common denominator of suburban transportation, would ride on new roads, as the federal government funded a massive national interstate highway system. To meet demand while keeping costs down, architects, engineers, and contractors stressed speed, economy, and efficient construction over complex, unique architectural styles. Speed meant mass production of standardized building components for quick on-site assembly. Similar criteria governed highway construction. The new limited-access freeways crossed over and under many existing roads instead of intersecting them. Multiple crossings meant that many new, identical bridges had to be built quickly and economically. Ornate design was out and economy was in. Contractors quickly adapted a new technology for concrete, prestressing it to create the simple modular panels, planks, and beams needed for long-span floors, roofs, and bridges. Under controlled factory conditions, plants mass-produced these modular components to standardized specifications. Seemingly overnight, buildings and structures of all kinds—including motels, shopping centers, sports stadiums, and high schools—began incorporating prestressed-concrete products. And Minnesota firms began producing structures ranging from a small prestressed-concrete picnic shelter to major parking ramps and the elevated roadways at Minneapolis—St. Paul International Airport. Often visible yet unrecognized, prestressed concrete became a key structural material in buildings of all types. C oncrete components generally come in three forms: plain, reinforced, and prestressed. Although widely used since the late 1890s, reinforced concrete’s special properties limit its application. Like stone, concrete is very strong in compression— facing: Installing prestressed decking on an elevated roadway at the new Minneapolis— St. Paul International Airport, about 1960 (Northwest Architect, Jan.–Feb. 1961, facing page 74). The challenge—successfully met, as the 1990s photo (above) shows—was to support maximum “live loads” with minimum construction depth. when a force or load pushes directly on it, as on a vertical column. Placed horizontally, as a beam, it tends to crack with tension along the bottom edge unless it is reinforced with metal. The longer the distance a beam spans, the larger or deeper it must be to reduce cracking or breaking. As the distance increases, a reinforced- concrete beam can require such size and depth that it becomes impractical to use. A properly engineered beam, prestressed with highly tensioned steel strands or cables, can span the same distance and be thinner, lighter in weight, and use less concrete without cracking or breaking.1 While Americans constructed countless reinforced-concrete structures, they were less curious than a few pioneering Europeans who championed the theory and use of prestressed concrete. As early as 1904, Eugene Freyssinet, a French bridge engineer, pondered the concept of prestressing to increase concrete’s BOB FRAME is a senior historian in the Minneapolis office of Mead & Hunt Inc., a national engineering firm, where he works with the survey, evaluation, and rehabilitation of historic bridges. He has a PhD in American studies from the University of Minnesota and an MPA from Harvard’s Kennedy School. RICK MITCHELL AICP is a historic preservation planner in Mead & Hunt’s office in Austin, Texas. He has spent more than 20 years documenting historic buildings and bridges and a lifetime experiencing prestressed concrete’s contributions to American suburbia. W I N T E R 20 1 4 –1 5 159 resistance to tension. When fully developed years later, the tensioned strands of high-strength steel, combined with high-strength concrete, allowed prestressed concrete to withstand much greater tension without cracking or permanently bending. Freyssinet was a passionate visionary and accomplished bridge designer but was less adept at promoting his pioneering construction methods as practical applications.2 It remained for others, particularly Gustave Magnel, an engineering professor at Belgium’s University of Ghent, to broaden the appeal of prestressed concrete by demonstrating how it was at once stronger and more economical than reinforced concrete. Magnel studied and tested Freyssinet’s concepts on prestressing linear objects such as bridges. Readily conversant in English, he toured the United States in 1946 lecturing on prestressed concrete, and in 1948 published the influential volume Le Béton Précontraint (Prestressed Concrete).3 The transfer of European technology to the United States and, soon thereafter, to Minnesota was facilitated by Charles Zollman, a student of Magnel who emigrated to the U.S. in 1939 and subsequently translated Magnel’s book into English. Enthusiastic in promoting his mentor’s work, in 1948 Zollman joined Preload Corporation of Boston, then the nation’s leader in designing circular prestressed-concrete tanks, an early adaptation of the technology. After learning of the City of Philadelphia’s proposal to construct the Walnut Lane Bridge high above a road and creek in Fairmount Park, Zollman and Preload officials approached Magnel to prepare plans for a prestressed bridge. The Belgian professor developed a design with three spans: the Explaining the concept of prestressed concrete (Minnesota Highways, Apr. 1960, 6) 160 M I N N E S OTA H I S TO RY main one, at 160 feet, is long even by today’s standards. City engineers gave the approval for the innovative design, provided Magnel undertook extensive full-scale testing of the prestressed girders. These tests, conducted before hundreds of interested engineers and officials, successfully demonstrated that prestressing concrete with steel wires or strands allowed girders to span dramatically greater distances without increasing their bulk. Magnel’s design, cheaper than proposed concrete-arch designs, won approval from Philadelphia’s Art Jury, thanks to its clean and functional appearance.4 Completed in late 1950, Walnut Lane immediately became famous as the first prestressed-concrete beam bridge built in the U.S. Its large beams would prove to be the best model for the many bridges needed as new highway systems expanded dramatically. According to Zollman, “No event was more instrumental in launching the prestressed and precast concrete industry in North America.”5 Prestressed concrete met the needs of the era’s construction market. Not only was this type of beam stronger, longer, and lighter than its reinforced-concrete counterpart, it was a logical candidate for assembly- line manufacturing, resulting in reduced costs and faster production. Based on his European experience, wherein every project was customized, Magnel said in 1954 that mass production of prestressed-concrete bridge components was unlikely or even impossible. U.S. manufacturers proved otherwise. In 1956 the Highway Research Board reported, “Standardization of prestressed units seems to be the trend at the present time. In the near future, it should be possible to purchase prestressed bridge units for various span lengths in beam and slab sections.” Engineers, architects, and contractors, Prestressed concrete met the needs of the era’s construction market. Not only was this type of beam stronger, longer, and lighter than its reinforced-concrete counterpart, it was a logical candidate for assembly- line manufacturing, resulting in reduced costs and faster production. faced with meeting the huge post- World War II demand for buildings, bridges, and other infrastructure, welcomed the new product. Prestressed concrete also gained popularity as an alternative to steel, in short supply in the early 1950s.6 Manufacturing prestressed- concrete beams demands a substantial investment in plant infrastructure, especially to make large bridge beams. Stretching the internal wire strands requires a long bed with massive, strong buttresses at each end to withstand intense stress. The beds, with concrete foundations deep in the ground, can be 300-to-500 feet long so that multiple beams can be made at one time, end to end. Both the design and cost of these casting or tensioning beds is substantial. Since the larger beams for bridges required larger beds than the shorter components for buildings, which typically used panels and planks not found in bridges, plants often focused on manufacturing one or the other. Facilities with either specialization usually also offered precast concrete, which was similar but did not require the new technology. Not every component had to be prestressed, and the precast products shared the important advantages of being standardized and mass-produced in controlled factory conditions. With the success of the closely watched Walnut Lane Bridge, the fledgling prestressed industry expanded quickly. Massachusetts Institute of Technology hosted the first national conference on prestressed concrete in August 1951, and within months, prestressed bridges began to be built throughout the country.7 Given bridge designers as the early champions and highway agencies as the clients, testing and development at first focused largely on bridge construction. But architects and builders soon identified other uses for the new technology. Prestressed beams and slabs could increase roof spans, yielding interiors needing fewer support columns, as well as facilitate rapid prefabricated construction of cost- effective, fire-resistant buildings. M innesota soon discovered prestressed concrete. At the second annual concrete conference, held at the University of Minnesota in December 1952, a speaker told attendees that only a year earlier he had predicted that they “were taking part at the virtual beginning of a major W I N T E R 20 1 4 –1 5 161 engineering development. . . . which may well revolutionize construction practices everywhere.” Recalling earlier technological developments, he also mentioned “the notable progress made in this country in prestressed tank and pipe construction.”8 The speaker might well have been referring to a 1939 installation at the St. Paul Regional Water Services’ McCarrons water-treatment plant. Architectural and engineering historian Carl Condit identified this as “the first prestressed concrete structure in the United States.”9 At the time, Engineering News-Record reported that the twin water-clarifier tanks with unsupported, prestressed-concrete domes 150 feet in diameter were “said to be the largest of this type ever built.”10 Still in service today, the domes em- ployed a prestressing system developed by structural engineer William S. Hewett, who earlier used his Hewett System for prestressing concrete to engineer the interior of the landmark 1932 Washburn Park water tower in Minneapolis. Despite these early successes, the Hewett System developed independently of bridge-related beam work, although it may have contributed indirectly to the design of the Walnut Lane Bridge.11 The 1952 conference was the first in Minnesota to offer presentations on prestressing technology to the state’s concrete industry. One speaker was Ross H. Bryan, an engineer from Nashville whose firm, Bryan & Dozier, had in 1950 completed a project that rivaled Walnut Lane for the title of first prestressed-concrete bridge in the U.S. This Tennessee span used concrete blocks that were joined into beams with stressed steel strands. Without mentioning this achievement, Bryan described the block- beam design, making key points that would be repeated regularly by industry proponents: “The two major advantages of plant fabrication are lower costs due to assembly line production and a controlled quality due to experienced supervision.”12 Among the 200 or so conference registrants were at least three of Minnesota’s future prestressed-concrete pioneers: brothers Norbert and Leonard Soukup from Minneapolis and Paul Radichel, from a Mankato family of concrete producers. Radichel would later partner with his brother, Bill, to establish Spancrete Midwest, the company responsible for some of the largest and best-known Twin Cities structures of prestressed concrete.13 But first, the Soukup brothers established a new Minneapolis firm, Northern States Prestressed Concrete Company, and completed Minnesota’s first prestressed bridge. Like Bryan & Dozier’s Tennessee bridge, their Goodhue County span was not on a state highway. And, like the Tennessee engineers, they joined specially designed and cast blocks into a beam stressed with a high-tensile steel cable manufactured by the Roebling firm of Brooklyn Bridge fame. The Soukups cast the blocks and assembled the beams in their plant and trucked them to the site. Multiple beams, arranged side by side, created the bridge, which carried local traffic from Highway 61 to a Boy Scout camp outside of Lake City. Although the bridge was small and the rural location a “narrow back­water strip” of the Mississippi, the final Minneapolis’s landmark Washburn water tower, 1951, its interior an early example of prestressed concrete 162 M I N N E S OTA H I S TO RY WHO’S FIRST? Bryan & Dozier’s small bridge in Madison County, Tennessee, which was started later than Walnut Lane and was finished two months sooner, never achieved the acclaim of the Philadelphia “first.” The Tennessee bridge went up so quickly because it used concrete blocks, tensioned tightly together with wire strands. This much simpler method employed the same prestressing principle as Walnut Lane’s components but instead of casting a single, large beam, it added stressing to smaller blocks aligned end-to-end. There was no need for massive new casting beds; the blocks could be made in existing manufacturing facilities. But this innovation proved to be a sidetrack. The blocks’ maximum length, strength, and capacity could not equal that of the massive Walnut Lane Bridge beams; use was limited to smaller bridges with light traffic. Moreover, the advantage of assembly in 1953 was well attended, according to a report in Construction Bulletin: “On hand to observe . . . and also to acquire information about the new type of construction, were Minnesota county engineers, city engineers, county commissioners, representatives of the Portland Cement Association, and other interested personnel.”14 Again like Bryan & Dozier’s Tennessee bridge, the Goodhue County block-beam construction, though first in the state, did not become a model for the future. No other bridges of similar design and construction have been identified in Minnesota, and Northern States Prestressed Concrete appears to have made no more concrete blocks. Several years later, when the Minnesota Highway Department built the first major prestressed- concrete bridge on a state highway, it used beams, not blocks. That bridge was also fabricated by the Soukups, but through their new company, Prestressed Concrete, Inc. (PCI), in simple construction soon vanished, as larger casting facilities were established. Writing on the development of early prestressed-concrete construction, long-time champion Charles Zollman noted, “It should be recognized that while Bryan’s bridge was the first prestressed bridge completed in the United States, it was a block bridge for secondary roads, while the Walnut Lane Bridge was the first large girder type bridge on a main city parkway. Thus, both bridges could be considered as firsts in their own right.”* *Charles C. Zollman, “Dynamic American Engineers Sustain Magnel’s Momentum,” in Reflections on the Beginnings of Prestressed Concrete in America (Chicago: Prestressed Concrete Institute, 1981), pt. 2, p. 51. Similar block bridges were also built in Michigan, according to Zollman, who does not mention the Minnesota example. corporated in 1952. This firm soon became a significant competitor in the industry.15 S tate highway engineers noticed the early bridges built with prestressed concrete. Iowa’s and North Dakota’s departments both completed their first prestressed- concrete bridge projects in 1953. North Dakota’s example was quickly recognized in Minnesota Highways, published by the state’s highway department. Would Minnesota be next? “Although no pre-stressed bridges have been built as yet by the Department,” the magazine stated in 1953, “it is very probable that this type of construction may be utilized within the immediate future as Minnesota keeps pace with other states in new and progressive construction materials.” The “immediate future,” however, would not arrive for four years.16 Meanwhile, the federal government began transforming the nation with the Interstate Highway System. First authorized in 1944, the system emerged a decade later in the Federal- Aid Highway Act of 1956. The act planned a 41,000-mile network with $25 billion ($218.7 billion today) to be distributed to state highway departments over 13 years. Interstate- highway design standards adopted by the Bureau of Public Roads (predecessor of the Federal Highway Administration) led to the new freeway concept of controlled or limited access, with overpasses and interchanges for unimpeded traffic flow. In 1957 Minnesota Highways touted the efficiency of the new roads, designed to “free the motorist from the delay and accident hazard of hundreds of grade intersections and traffic moving to or from the highway on connecting private driveways.”17 With its quick start, massive influx of dollars, and immediate need for countless bridges, the interstate system created an instant market for large, heavy- duty prestressed bridge beams and W I N T E R 20 1 4 –1 5 163 girders. Initially, few companies had the necessary massive casting and tensioning beds. Minnesota’s portion of the interstate system envisioned $600 million in federal aid and three mainline highways—I-35, I-90, and I-94— connecting the state’s major cities and heavily populated rural areas. Beltline highways would encircle the Twin Cities metro area. The limited-access design required construction of an estimated 675 bridges in the planned 936 miles of freeways, with “no grade level highway intersections or railroad grade crossings in their entire length.”18 Simultaneously, the Minnesota Highway Department began upgrading the state highway system, thanks to a 1956 state constitutional amendment that revised highway- improvement funding. Major state highways were upgraded to “expressway” standards, with divided traffic lanes, limited access, and overpasses to separate cross-street traffic. The rapid upswing in bridge construction on the interstate and state highways was remarkable. Interstate bridges, usually of similar size and design, created a perfect market for the fledgling prestressed industry’s ability to mass produce quality-controlled, standardized bridge girders. Among the few qualified Minnesota companies were PCI and the Elk River plant of The Cretex Companies, Inc., or simply Cretex, which had been in the concrete business for many years and added prestressing equipment by 1957.19 D espite the growing nationwide interest in prestressed concrete, the decision to build Minnesota’s first prestressed-concrete highway bridge was surprisingly routine. It would carry Ninety-Fourth Street in Bloomington over the future 164 M I N N E S OTA H I S TO RY The decision to build Minnesota’s first prestressed-concrete highway bridge was surprisingly routine. It would carry Ninety-Fourth Street in Bloomington over the future I-35W. I-35W, then called Trunk Highway 65. Following longstanding practice, the designer, Ellerbe and Company, a prominent St. Paul architectural and engineering firm, prepared plans and cost estimates for two alternatives: steel and concrete. In January 1957, Ellerbe’s structural engineer E. L. Gardner concluded: “Calculations revealed the prestressed type design would cost less than steel. Also steel deliveries would not meet contract timing conditions for the project. Therefore, it was agreed the final design would be prestressed concrete.”20 It was that simple. Completed in 1957, Bridge No. 9053—still its only name—is significant as the first prestressed-concrete bridge on Minnesota’s statewide highway system, a landmark remaining in service today. To the general public, however, it is as nondescript and anonymous as the multitude of other bridges over I-35W and its sister interstate highways—and that is the point. Bridge 9053 was followed by many others of similar size and design because its standardized primary components were so easy and cost effective to replicate and maintain. It represented an ideal solution to a bridging problem presented thousands of times on modern American highways and freeways.21 PCI fabricated Bridge 9053’s prestressed-concrete beams at the Soukups’ new facility, built in 1954 in Roseville, a growing suburban com- munity on the northern edge of St. Paul.22 Roseville provided an open, nine-acre site near County Road C and today’s I-35W, with road and rail access—essentially a suburban industrial park. There, the new company installed a substantial prestressing facility, signaling its intention to manufacture large concrete beams, a far bigger operation than its earlier concrete-block beams had required. After installing its large, in-ground casting beds, PCI used them for its first project, making the prestressed beams and panels for the building that enclosed the beds. The Soukups immediately claimed a national record: these “50-foot prestressed channel slabs and the 50-foot prestressed block girders are the longest of their type in the United States,” a Minnesota trade journal reported. They also asserted, “The new installation is the largest prestressing plant in the country.”23 Cretex, which also moved into the prestressed bridge-beam market, had been founded in 1917 as Elk River Concrete Products Company by L. D. Bailey and D. W. Longfellow. Bailey family members, who ran the company for decades, oversaw the creation of The Cretex Companies, Inc., which eventually included other plants in Minnesota as well as in North and South Dakota, Iowa, and Montana. Guided by Albert Bailey, the Elk River plant began producing precast-concrete members and in the MINNESOTA’S FIRST PRESTRESSED-CONCRETE STATE HIGHWAY BRIDGE I-35 Bridge 9053, completed in 1957 and still a work horse today, and (inset) a peek under the span, 2014 Engineers describe Bridge 9053 as a “prestressed concrete beam (PCB) bridge . . . using precast, pretensioned AASHO-PCI Type I beam sections,” a design largely replicated in more than 2,800 prestressed-concrete bridges built in Minnesota since 1957.* The average freeway motorist would find it difficult to recall anything about Bridge 9053, even after driving under it many times in daily I-35W commutes to and from work or a local mall. Simple as it is, the bridge exhibits features typical for its role in the Interstate Highway System, allowing the freeway to run under a local street. It has two main spans of 60 feet each, each crossing a pair of I-35W traffic lanes—northbound and southbound—and a 40-foot approach span on each side of the freeway. Although all four spans look alike, the different lengths point to engineering differences. The longer center spans have 17 prestressed beams, each weighing 12 tons, while the shorter end spans have only nine 7.5-ton prestressed beams. Despite having the newest beam technology circa 1957, the rest of the bridge uses earlier architectural elements. The ornamental metal railing continues a design of the 1940s, soon to be replaced by the familiar streamlined freeway styles of the 1960s. The large, three-part concrete blocks at each railing-end also reflect styles of the 1930s. *Dave Dahlberg et al., “Spanning the Land of 10,000 Lakes— Minnesota’s Concrete Bridges,” Aspire, Winter 2007, 41. Installing a prestressed-concrete beam, 1957 (Minnesota Commissioner of Highways, Biennial Report 1956–58, 4) W I N T E R 20 1 4 –1 5 165 1950s quickly moved into prestressed concrete. Bailey consulted with Charles Zollman, who advised the company in the technology of large tensioning beds. Cretex’s Elk River plant produced the prestressed beams for many of the earliest highway bridges still standing in Minnesota. Working as a subcontractor, Zollman prepared calculations for at least one of them.24 A lthough initial experimentation and testing of prestressed concrete focused on bridges and bridge beams that would satisfy state and federal safety regulations, the material soon found other places in the new suburban world. Beginning in the 1950s and escalating in the 1960s and afterward, companies produced the major structural components for a wide array of new buildings dotting the suburban landscape. Hoping to attract architects and builders to their products, the new manufacturers promoted their projects in advertisements demonstrating their capability to provide what the market demanded.25 PCI announced that its Roseville plant would serve Minnesota, North and South Dakota, Iowa, and western Wisconsin, offering prestressed channel slabs for floors and roofs, prestressed girders, and prestressed bridge members, along with precast columns, walls, manholes, and custom products. The firm’s first non-bridge projects included two quintessential types of suburban structure: Westwood, a small, early shopping center in St. Louis Park, and a high-school sports stadium in Ad promoting Westwood mall’s safety, thanks to Prestressed Concrete, Inc. (Northwest Architect, May–June, 1955, 7). The St. Louis Park Dispatch claimed the fireproof building was the area’s first. 166 M I N N E S OTA H I S TO RY Bloomington. The latter, part of the multimillion-dollar Bloomington High School construction project in 1956, was the first prestressed, precast-concrete stadium grandstand in the Twin Cities area. News accounts and PCI advertising emphasized that the prestressed channel slabs were “precast inside, under ideal factory control” and “trucked 18 miles to the job site,” promoting the advantages of manufacturing off-site, unaffected by the unpredictable weather that hampered typical outdoor concrete construction. The stadium continues in use at Ninetieth Street and Queen Avenue South.26 Prestressed-concrete slabs or planks emerged as an early modular building product. Cast in long rectangles, several feet wide and several inches thick and arranged side-by- side, they formed thin, flat roofs and floors. To reduce weight, multiple Westwood in 1957, panorama assembled by Emory Anderson from three photos, courtesy St. Louis Park Historical Society WESTWOOD SHOPPING CENTER When small shopping centers, only a block or two long, began appearing in the new 1950s suburban-edge residential developments, they offered an instant market for easily assembled precast, prestressed beams and panels. Among Prestressed Concrete Inc.’s first projects was Westwood Shopping Center in St. Louis Park, which opened in October 1954. Announcing the grand opening, the St. Louis Park Dispatch stated that it was “designed in California style” and that “Pre-stressed concrete roof channels carried on a steel girder make a fireproof building, first of its kind in the area.” PCI’s prestressed-concrete “channel slab” was one of its early modular units, able to span the length or width of a shop. The Dispatch’s full-page spread included a personal note and photo for each of the new shop owners. The “shiny new center” tube-like openings extended the length of each plank, suggesting their generic name: hollow core. These openings easily carried electric lines and other utilities. Prestressed steel strands along the bottom of each panel or plank enabled the longer, thinner shapes without compromising strength. Entrepreneurs offered several patented systems for mass-producing these hollow-core slabs, which used a smaller casting system with less intense stressing than did large bridge beams. Each system typically included a machine and a license to produce and sell the hollow-core product. Running on beds up to 500 or 600 feet long with taut wire strands for prestressing, the machine extruded lengths of hollow-core con resembled a small town’s main street: supermarket; apparel, hardware, variety, and drug stores; dry cleaner, barber, and beauty shops; and physicians’ and dentists’ offices, along with 150 “ample well-lighted” parking spaces. At the grand opening, the Giant Food Store held a giveaway, including a “‘Broil Quick’ electric fryer,” Hopalong Cassidy cowboy outfits, and outdoor barbeque table and grill sets. Westwood itself offered the grand prize: “This newest marvel of the electronic age—a new RCA Color Television . . . installed free in the winner’s home.” The Dispatch concluded that Westwood “is truly a NEIGHBORHOOD shopping center where friendly, personal service is the order of the day.” crete slabs in a continuous process. A saw cut the long slab into the shorter units specified by the architect or contractor. In the 1950s at least three more Twin Cities companies entered the market for prestressed, non-bridge building components. Two more operated in the region: Zenith Concrete Products Company in Duluth, and Gage Brothers in Sioux Falls, South Dakota.27 But costs for transporting large components limited the market access for distant firms, favoring those closest to the areas of concentrated new construction. Whether newly established or not, all companies entered the prestressed concrete field at about the same time and all manufactured both prestressed and precast components. Late in the decade, Paul and Bill Radichel of Mankato created Spancrete Midwest Company and set up a plant in Osseo (or Maple Grove, as the successor company identifies its location today). The brothers had purchased the second machine made by Milwaukee manufacturer Henry Nagy, who had bought the rights to a German machine for hollow-core slabs. After reworking the device and process for two years, he named his system Spancrete, establishing the first use of hollow-core slabs in the U.S. in 1954. Four years later he established Spancrete Machinery Corporation.28 By summer 1960 the Radichels’ 600-foot casting bed was completed and their machine began operating. Spancrete Midwest’s operation was W I N T E R 20 1 4 –1 5 167 Original Spancrete Midwest plant, Osseo (Northwest Architect, July–Aug. 1961, 7). in some ways similar to PCI: its prestressed products formed the walls of the long, narrow building enclosing the machine that extruded 600-foot prestressed planks that were subsequently cut into the desired lengths. And, the new Osseo plant stood alone in a future suburban industrial park, with its own railroad spur.29 In St. Paul, Molin Concrete Products Company, operating since 1905, decided to get into the prestressed- concrete business for buildings, too. They acquired the rights to the Flexicore Hollow Core manufacturing process from its Ohio originator, along with its concrete-extruder machine. In 1951 Molin advertised its Flexicore product, a “long span precast prestressed concrete slab.”30 Wells Concrete Products Company in Wells, Faribault County, was established in 1951 by Frank 168 M I N N E S OTA H I S TO RY Balcerzak, who owned the Guaranteed Gravel and Sand Company of Mankato. Although Balcerzak showed some early interest in producing beams for Bridge 9053 (he was adding prestressing capability to the Wells plant), he instead turned his attention to the new prestressed “double-tee” beam. This form quickly became a primary structural member, useful for longer spans where hollow-core slabs were too short or too light.31 Wells recommended its slabs for “schools—churches—factories— warehouses—stores” and promoted the double-tee for “shopping centers, super markets, dormitories.” A 1962 advertisement noted the double-tee’s fire-retardant rating, and fire safety became a selling point for prestressed concrete building components.32 Architects developed aesthetic interest by revealing parts of the double-tee beam, first exposing beam ends for a repetitive roofline or cornice detail and then turning beams from the horizontal to the vertical as wall panels, transforming the functional tee- stems into linear exterior features.33 Northwest Architect, May–June, 1951, 43 COLUMBIA PARK PICNIC SHELTER By midcentury, parks founded 50 years earlier faced pressures to expand and modernize for a growing population with new recreational interests. One response was the Columbia Park Picnic Shelter in northeast Minneapolis, constructed entirely of precast and prestressed members, all fully visible in a hilltop setting. The University of Minnesota’s School of Architecture held a design competition in 1955, sponsored by the Northeast Lions Club, which funded part of the shelter’s construction as a gift to the city. Out of 40 entries, John R. Miller’s student design won. He drew the final plans, which were signed by Walter K. Vivrett, a professor and registered architect. Completed in 1955, the shelter employs paired, precast-concrete, rigid-frame bents, each incorporating a column and cantilever roof support for half the span. Prestressed-concrete planks extend from bent to bent, comprising the roof and interior ceiling. The rear wall included a recess for vending facilities, while the front, under the shelter, provided modern, coin-operated “automatic electric burners”—10 cents for 20 minutes and 25 cents for 50 minutes.* No need for smoky outdoor fireplaces in this fireproof concrete pavilion. Today, the Minneapolis Park Board considers the shelter’s unaltered, elegant, state-of-the-art design and construction a “classic modern composition.” It will be carefully restored to meet current accessibility standards in 2015. Designer John Miller went on to a distinguished career and founded the Minneapolis architectural firm of Miller, Hanson, Westerbeck, Bell (today, Miller Hanson Partners). He died in 2003. *Minneapolis Board of Park Commissioners, Seventy-Third Annual Report (1955). PCI advertisement, Northwest Architect, January–February 1958, and the well-used shelter with its simple, box-shaped brick support building housing restrooms, 2014 W I N T E R 20 1 4 –1 5 169 Double-tee beam, an aesthetic element in advertising and construction (Northwest Architect, Jan.–Feb., 1965, 33). Zollman found, “Above all, it gave engineers the power and freedom to control the internal ‘stresses and strains’ produced by the application of exterior design loads.” Looking to the horizon, the eminent historian of engineering, David P. Billington, who studied under Magnel, called prestressing “the single most significant new direction in structural engineering of any period in history. . . . Moreover, the idea of prestressing opened up new possibilities for form and aesthetics.”34 Prestressed concrete continues today as a widely used building material, with additional forms and shapes added in subsequent decades. The technology is central to nationally recognized Twin Cities landmarks— some no longer standing—spanning more than a half-century, including the Metropolitan Sports Center in Bloomington (erected 1967–68), Hubert H. Humphrey Metrodome (1980), Minnesota Timberwolves Arena (1989), the parking ramps at the Mall of America, the largest in the world when they were built (1992), and the new I-35W bridge over the Mississippi River (2008). B y the middle of the 1960s, the prestressed-concrete industry had established itself in Minnesota, and the firms that would dominate the state’s industry for subsequent decades were up and running. Despite the ubiquitous nature of prestressed concrete, few Minnesotans realized they were surrounded by a radically new technology: working, worshiping, or studying in prestressed concrete buildings, shop170 M I N N E S OTA H I S TO RY ping in prestressed-concrete malls, parking in prestressed-concrete ramps, and driving on and under prestressed-concrete bridges. Even fewer knew how this technological innovation worked and how it had transformed the world around them in the decades after World War II. Two knowledgeable observers identified the larger contributions of prestressed concrete. Addressing its engineering significance, Charles Notes The authors wish to thank Kristen Zschomler, MnDOT Cultural Resources Unit, and Keith Molnau, PE, MnDOT Bridge Office, for their historical and technical reviews. Andrea Weber, PLA, Minneapolis Park & Recreation Board, provided detailed information on the Columbia Park Picnic Shelter. Bill Soukup discussed the background of the Soukup family and Prestressed Concrete, Inc. Gary Pooley, Wells Concrete, Maple Grove, provided historical materials on Spancrete Midwest. Mike Johnsrud, PCI Midwest, and Prof. Cathy French, University of Minnesota Center for Transportation Studies, offered insights into the prestressed concrete industry. Secret world of the Metrodome, revealed in Corporate Report: precast and prestressed concrete. Vomitories? Those are openings onto the seating area from passageways below. 1. For a visual comparison of panel lengths (roof and floor) with prestressed and reinforced concrete, see Charles C. Zollman, “The End of the ‘Beginnings,’” in Reflections on the Beginnings of Prestressed Concrete in America (Chicago: Prestressed Concrete Institute, 1981), pt. 9, p. 310, showing the maximum practical length of a prestressed-concrete panel to be about 2.5-to-3 times that of reinforced concrete. The maximum length for prestressed-concrete components was limited, in part, by the availability of new trucks to transport them and new cranes to lift them; see 317. 2. David P. Billington, “Historical Perspective on Prestressed Concrete,” PCI Journal 49 (Jan.–Feb. 2004): 16–17, 20. 3. Shri Bhide et. al., “The Interstate Highway System and the Development of Prestressed Concrete Bridges,” in 50 Years of Interstate Structures: Past, Present, and Future, Transportation Research Board, Transportation Research Circular E-C104, Sept. 2006, 52. 4. Wire strands were fundamental to the success of prestressed-concrete components. See Kenneth Dunker and Basile Rabbat, “Performance of Prestressed Concrete Highway Bridges in the United States—The First 40 Years,” PCI Journal 37 (May–June 1992): 49; Zollman, “End of the ‘Beginnings,’” 298–307. For the Art Jury evaluation, see Billington, “Historical Perspective on Prestressed Concrete,” 21–22; Tyson Dinges, “The History of Prestressed Concrete: 1888 to 1963” (MS thesis, Kansas State University, 2009), 47. 5. Historic American Engineering Record, Walnut Lane Bridge, Spanning Lincoln Drive & Monoshone Creek at Walnut Lane, Philadelphia, Philadelphia County, PA, “HAER PA, 51-PHILA, 731-” (1988); Charles C. Zollman, “Magnel’s Impact on the Advent of Prestressed Concrete,” Reflections, pt. 1, p. 7; Bhide et al., “Interstate Highway System,” 53–54. See also George D. Nasser, “The Legacy of the Walnut Lane Memorial Bridge,” Structure Magazine, Oct. 2008, 27–31, noting that after cracks were observed in 1989, the city replaced the entire original. 6. John J. Hogan, “Cost Comparisons of Prestressed Concrete vs Conventional-Type Highway Bridges,” in Some Cost Data on Prestressed Concrete Bridges, National Research Council, Highway Research Board Bulletin 144 (1956), 25. For the differences between European and American approaches, see Zollman, “End of the ‘Beginnings,’” 288–89; Dinges, “History of Prestressed Concrete,” 49–50. The Minnesota Highway Dept. confirmed, “Construction of prestressed concrete bridges in Minnesota, begun on a trial basis, was expanded to offset a shortage of steel”; “Concrete is ‘Squeezed’ to Extend Its Use,” Minnesota Highways, Apr. 1960, 6. 7. “Milestones of Events and Developments in North American Prestressed Concrete Industry (1939–1958),” Reflections, pt. 9, p. 361–65. See also Billington, “Historical Perspective on Prestressed Concrete,” 24. 8. L. H. Corning, “Remarks,” in Second Annual Concrete Conference, Dec. 12 and 13, 1952, University of Minnesota, Center for Continuation Study, Minneapolis, 42–43, copy in Minnesota Historical Society (MNHS) library. The document includes the program, list of registrants, and full or partial transcripts of presentations and remarks. 9. Carl W. Condit, American Building Art: The Twentieth Century (New York: Oxford University Press, 1961), 191. 10. Leonard N. Thompson, “Sort Water for St. Paul,” Engineering News-Record, June 8, 1939, 793. The domes are described in “Principle of Pre-Stressed Reinforcement in Design of Dome,” Concrete 47 (Feb. 1939): 3–4. 11. Thomas W. Balcom, “A Tale of Two Towers: Washburn Park and Its Water Supply,” Minnesota History 49 (Spring 1984): 25–26. “The Hewett System of Reinforced Concrete Construction as Applied to Reservoirs, Tanks and Domes,” Bulletin A, four-page pamphlet (Chicago: William S. Hewett System, n.d.), n.p., includes Minnesota examples and photographs, copy in personal collection of Fredric L. Quivik, Michigan Technological University. A possible, as yet unexplored, relationship of Hewett to the pioneers of prestressed-concrete bridge development is found in Hewett’s 1943 Patent No. 2,329,719 for a concrete tank. Hewett assigned the patent to The Preload Co., which was instrumental in the construction of the Walnut Lane Bridge. This bridge, Zollman wrote, was W I N T E R 20 1 4 –1 5 171 the first major linear prestressed-concrete structure in the U.S., as opposed to the earlier circular tanks and domes; Zollman, “Magnel’s Impact,” 6. 12. Ross Bryan, “Prestressed Block Beam Units,” in Concrete Conference, 15–16. For a personal account of the bridge, see Ross H. Bryan, “Prestressed Concrete Innovations in Tennessee,” Reflections, pt. 4, p. 122–39. 13. “Registrants,” Concrete Conference, iii–vi. 14. “Minnesota’s First Prestressed Concrete Bridge, Near Lake City,” Construction Bulletin, Aug. 6, 1953, 68–69. Identified only as Bridge No. L-0619, Lake City, Goodhue Co., it was replaced in 2000. The Portland Cement Association actively promoted prestressed concrete and was instrumental in Bryan & Dozier’s Tennessee bridge. PCA representatives’ presence in Lake City indicates national interest in the Minnesota project. 15. A search of Minneapolis city directories, 1952–57, found no mention of Northern States Prestressed Concrete. Leonard Soukup was listed in 1952 as a cement contractor and in 1957 as “plant mgr Prestressed Concrete”; Robert Soukup, another founder, was a block layer for Soukup Construction in 1953. For the company’s incorporation, see Minnesota Secretary of State, Incorporation Records, filed June 30, 1952, accessed online. 16. L. W. Murray, “Iowa’s First Prestressed Structure,” Construction Bulletin, Dec. 3, 1953, 52–53, 98; Robert W. Randall, “Pre-stressed Concrete in North Dakota,” Construction Bulletin, Nov. 5, 1953, 52–53; Vince Bovitz, “A Preview— Bridges of the Future,” Minnesota Highways, Sept. 1953, 3–4. 17. Richard F. Weingroff, “Federal Aid Highway Act of 1956: Creating the Interstate System,” Public Roads 60 (Summer 1996), www.fhwa.dot .gov/publications/publicroads/96summer/index .cfm; “Network Routes Will Have Big Impact,” Minnesota Highways, Feb. 1957, 6. 18. “Network Routes Will Have Big Impact,” 5. The final number of new bridges built during the entire period of interstate construction is uncertain but may have been slightly less than estimated. 19. Mead & Hunt, Inc., Final Evaluation Report and Historic Context, Minnesota Bridges, 1955–1970, prepared for the Minnesota Department of Transportation, Mar. 2011, 11–12, 41–42; Don Stoltz, Cretex Times (Edina, MN: Beaver’s Pond Press, 1997), 104. 20. E. L. Gardner, “Cost Estimate, Bridge No. 9053, 94th St./T.H. 65 for State of Minnesota. . .,” Ellerbe and Co., Jan. 4, 1957, copy in Correspondence File for Bridge No. 9053, Records Storage, Minnesota Department of Transportation, St. Paul (MnDOT). For the cost advantage of prestressed concrete over steel, see Billington, “Historical Perspective on Prestressed Concrete,” 24. 21. On 9053’s status as the state’s first prestressed-concrete bridge, see Commissioner of Highways of Minnesota, Biennial Report, July 1, 1956 to June 30, 1958, 25. A. E. LaBonte, Bridge Engineer, Minnesota Department of Highways, 172 M I N N E S OTA H I S TO RY to P. H. Schultz, Assistant Bridge Engineer, South Dakota Highway Department, Mar. 18, 1957: “This bridge is our first prestressed concrete structure;” copy in Correspondence File for Bridge No. 9053, MnDOT. See also “Pre-stressed Beams Introduced,” Minnesota Highways, Sept. 1957, 7. 22. “Pretensioned Concrete Girders Erected,” Construction Bulletin, Oct. 3, 1957, 35, identifying PCI as the beam producer. See also 1957 documents in Correspondence File for Bridge No. 9053, MnDOT. 23. “Prestressed Concrete: They Use Their Own Product,” Construction Bulletin, Jan. 6, 1955, 52–53. The claim is unconfirmed. 24. Stoltz, Cretex Times, 51–55, 103–05; for The Cretex Companies, Inc. 1920s incorporation in Delaware, see 42. Elk River Concrete Products Co. fabricated the prestressed-concrete beams for Bridge 6580, which carries Rice St. over I-694/Hwy 10 north of St. Paul. Charles Zollman and Associates, Newtown Square, PA, prepared the detailed prestressed calculations in 1957–58; see plan sheet No. 7, Elk River Concrete Products Co., “Prestressed Concrete Girder Details,” approved Mar. 11, 1958 (with associated correspondence), and Zollman’s 20-page document (Dec. 1957–Jan. 1958), Correspondence File for Bridge 6580, MnDOT. 25. Kenneth T. Jackson, Crabgrass Frontier: The Suburbanization of the United States (New York: Oxford University Press, 1985), particularly chapter 14, “The Drive-in Culture of Contemporary America,” 246–71, on the role of the Interstate Highway System. State and local highway departments and engineers were largely aware of the new technology, but the non-bridge market of architects and contractors was more diverse and required wider promotions. 26. “Prestressed Concrete: They Use Their Own Product,” 52–53; Northwest Architect, May– June 1955, 7 (Westwood ad); “Prestressed, Precast Concrete Grandstand—First in Twin City Area,” Construction Bulletin, Jan. 17, 1957, 33; Northwest Architect, Nov.–Dec. 1956, 42 (PCI ad). Bloomington High School was renamed Abraham Lincoln Senior High School in 1965 when Bloomington Kennedy High School opened. Lincoln was closed in 1982 but the stadium, on the west side of the athletic field, continued in use for the Bloomington schools. 27. For Zenith, see “Form Concrete Products Firm,” Construction Bulletin, July 1, 1954, 78; Northwest Architect, Jan.–Feb., 1955, 29 (ad). A Zenith representative attended (with Norbert Soukup and others) a 1954 course at the University of Minnesota; “To Hold Short Course on Quality Concrete,” Construction Bulletin, Dec. 30, 1954, 3. For the history of Gage Brothers and their early years in prestressed concrete, see www.gagebrothers.com. 28. “The History of Spancrete,” PCI Historical-Technical Series, Jan.–Feb. 2005, 17–18, viewed online. For the machine at Spancrete Midwest, see “Spancrete: Strength in Numbers,” Concrete Products, Sept. 1988, n.p. Harry Edwards, “The Innovators of Prestressed Concrete in Florida,” Reflections, pt. 3, p. 98 (footnote) attributes the first use of hollow-core slab in the U.S. to Nagy and Spancrete. 29. “Paul W. Radichel,” obituary, Lake Region Times, Oct. 28, 2009; “New Spancrete Plant Operates in Osseo” and Spancrete Midwest ad, Northwest Architect, July–Aug. 1961, 78–79, and 7, respectively; “Registrants,” Concrete Conference, iii–vi. 30. Northwest Architect, July–Aug., 1951, 27 (ad); PCI Manual for the Design of Hollow Core Slabs, 2nd ed. (Chicago: Precast/Prestressed Concrete Institute, 1998), 1-1–1-3; Molin history, www.molin.com. 31. Letters between Frank Balcerzak and A. E. LaBonte, Jan. 27–30, 1957, Correspondence File for Bridge 9053, MnDOT; “Frank Balcerzak,” in Val Bjornson, History of Minnesota (West Palm Beach, FL: Lewis Historical Publishing Company, 1969), 4: 598–99. 32. Balcerzak and LaBonte letters; Northwest Architect, Sept.–Oct. 1962, 10 (ad); “About Us: History,” wellsconcrete.com/about-us/history/. 33. For the development of early prestressed structural members and shapes, see Edwards, “Innovators of Prestressed Concrete in Florida,” 89–99. Although discussed in a Florida context, the early development of several basic components applies universally. 34. Zollman, “End of the ‘Beginnings,’” 354; Billington, “Historical Perspective on Prestressed Concrete,” 14, 29. The photos on p. 165 (top two) and 169 (bottom) are courtesy Robert Frame III; p. 171, courtesy Wells Concrete, Maple Grove. All others, including the magazine images and p. 159 (Metropolitan Airports Commission audio-visual files, State Archives) are in MNHS collections. Copyright of Minnesota History is the property of the Minnesota Historical Society, and its content may not be copied or emailed to multiple sites or users or posted to a listserv without the copyright holder’s express written permission: contact us. Individuals may print or download articles for personal use. To request permission for educational or commercial use, contact us. Include the author’s name and article title in the body of your message. But first-If you think you may need permission, here are some guidelines: Students and researchers • You do not need permission to quote or paraphrase portions of an article, as long as your work falls within the fair use provision of copyright law. Using information from an article to develop an argument is fair use. Quoting brief pieces of text in an unpublished paper or thesis is fair use. Even quoting in a work to be published can be fair use, depending on the amount quoted. Read about fair use here: http://www.copyright.gov/fls/fl102.html • You should, however, always credit the article as a source for your work. Teachers • You do not need permission to incorporate parts of an article into a lesson. • You do need permission to assign an article, either by downloading multiple copies or by sending students to the online pdf. There is a small per-copy use fee for assigned reading. Contact us for more information. About Illustrations • Minnesota History credits the sources for illustrations at the end of each article. Minnesota History itself does not hold copyright on images and therefore cannot grant permission to reproduce them. • For information on using illustrations owned by the Minnesota Historical Society, see MHS Library FAQ. www.mnhs.org/mnhistory