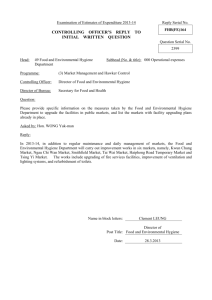

English full version (PDF format)

advertisement