mySTEM™ Project Board

for NI myDAQ™

Copyright © 2013 Studica, Inc. All Rights Reserved

Tom White & Associates

mySTEM Project Board

2

mySTEM Project Board

Table of Contents

Introduction to the mySTEM™ Board ...................................................................................................................... 5

Power Connections ............................................................................................................................................ 5

myDAQ Connections .......................................................................................................................................... 7

Breadboard ........................................................................................................................................................ 8

Output connections............................................................................................................................................ 9

Connecting Signals to the Outputs ........................................................................................................................ 10

Computer Control of Outputs ............................................................................................................................... 11

Launch the NI ELVISmx Instrument ................................................................................................................... 12

Setting Up the Labview Interface .......................................................................................................................... 14

Beginning Labview Programming .......................................................................................................................... 18

Introduction to Sensors- Voltage Divider............................................................................................................... 23

Switches............................................................................................................................................................... 27

Digital Input: Express VI ........................................................................................................................................ 31

The Circuit........................................................................................................................................................ 31

Writing the simple program.............................................................................................................................. 32

Introduction to Programming Structures: ............................................................................................................. 43

Digital Outputs: Sending Signals to Devices: .......................................................................................................... 52

Wiring in the Motor ......................................................................................................................................... 55

Adding Reverse Direction ................................................................................................................................. 64

Designing Programs.............................................................................................................................................. 69

Flow Charts ...................................................................................................................................................... 69

State Machines..................................................................................................................................................... 71

Open Loop Programming:..................................................................................................................................... 74

Closed Loop Programming: ................................................................................................................................... 85

Creating Enum Constants ..................................................................................................................................... 93

Hand Dryer with a Photo Transistor .................................................................................................................... 102

Counter Utilizing a Photo Transistor.................................................................................................................... 112

Programming Structures: Conveyor Belt ............................................................................................................. 125

Parallel Programming: Elevator........................................................................................................................... 142

Introduction to Sensors- Voltage Divider for Analog Sensors ............................................................................... 155

Analog Input: Express VI ..................................................................................................................................... 158

The Circuit...................................................................................................................................................... 159

Writing the simple program............................................................................................................................ 160

Making Analog Decisions: ................................................................................................................................... 169

Introduction to Logic Gates................................................................................................................................. 175

The NOT Gate................................................................................................................................................. 175

Truth Table: ............................................................................................................................................... 176

Boolean Expression: ....................................................................................................................................... 176

AND and OR Gates: ........................................................................................................................................ 176

AND Gate Truth Table: ............................................................................................................................... 178

Boolean Expression: ....................................................................................................................................... 178

OR Gate ......................................................................................................................................................... 178

NOR Gate ....................................................................................................................................................... 179

NAND Gate .................................................................................................................................................... 179

Conclusion ..................................................................................................................................................... 179

3

mySTEM Project Board

mySTEM Project Board

4

mySTEM Project Board

Programming with the mySTEM™ Project Board

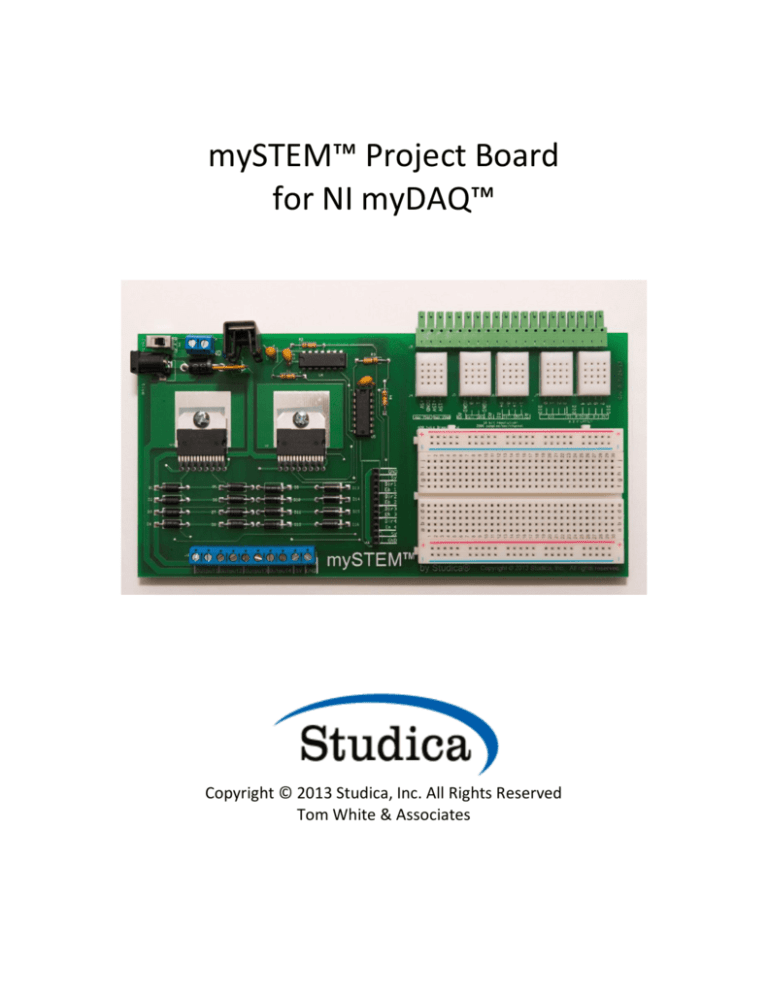

Introduction to the mySTEM™ Board

This activity will introduce you to the various aspects of the mySTEM™ Project Board. The mySTEM™

Project Board is designed to allow you to incorporate all manner of sensors with easily configurable

outputs. This and the following exercises will allow you to become familiar with reading sensors,

configuring Labview to process the information and create desired outputs. The mySTEM™ board plugs

into the side of the myDAQ™ or the myRIO™ turning them into compact affordable programmable

action controllers.

Power Connections

The mySTEM™ Project Board needs to be powered. You can supply any voltage between six and twenty

six volts Direct Current. There is an onboard regulator that produces the required 5 volts for the logic

circuits. You should select a power supply that can supply the voltage and current your output devices

need. The board ships with a Fischertechnik’s Motor. This motor requires 9V to operate.

The first method is to connect a wall transformer to supply the desired DC voltage. The connection is

done through a standard plug 2.1 mm x 5.5 center positive. It is recommended that your power supply

be a switching power supply that will protect the power supply in the event of over current or short

circuit.

5

mySTEM Project Board

For higher voltages, (26 Volts Max), and currents, (4 Amps max), you should use the Screw Terminals to

supply power and use a separate DC power supply as shown below.

The alternate power supply connections are labeled GND and SV+. The SV+ (Supply Voltage) is

connected to the Positive (red) terminal of the power supply connector which is the closest terminal to

the switch, while the GND terminal is connected to the Ground (black) terminal of the power supply

connector. AC adapters, and voltage transformers, are critical safety components.

mySTEM Project Board

6

mySTEM Project Board

IMPORTANT! Damage may be caused by use of improper rated or incompatible devices which can

result in damage or destruction of the mySTEM™ Project Board, and/or powered equipment, as well

as the risk of electrical shock or electrocution in certain cases. Studica will not be held responsible for

damage to equipment, blown electronic parts, or personal injury that may result from the use of this

material.

You should also be cautious when using higher currents as significant heating will occur in the controller

output chips U1 and U2.

To reduce the risk of fire, electrical shock, or damage to the unit, do not expose this unit to rain or

moisture or immerse in water. Short circuits on the outputs will cause excessive heating of the output

chips. Be sure you have wired your outputs correctly before turning on the power to the board.

The On/Off switch on the corner of the board controls power to the logic circuits and will not disconnect

the DC power. When making circuit changes the power should be disconnected from the board.

myDAQ Connections

Signals are passed to the myDAQ through the five Quad Point Contact Blocks. These blocks behave

similar to the breadboard. There are four interconnected holes that make up a node. The five blocks are

from left to right: Voltage sources, Analog Output, Analog Input, and two blocks of Digital Input/Output.

For a full discussion of these see the manual for the myDAQ found at

http://www.ni.com/pdf/manuals/373060e.pdf.

7

mySTEM Project Board

Breadboard

The 400 pin breadboard on the face of the mySTEM™ is utilized to build and configure temporary

circuits. A frequent use is for sensor connections. The picture below shows the surface of the

breadboard. Some of the pins are connected under the board by metal strips to make connections

between components convenient. These strips connect the holes on the top to form nodes. In the

picture below you can see the matrix of holes. ABCDE and FGHIJ describe five holes that line up in each

column. The columns are numbered. Circled are the two nodes found on Column 4. ABCDE in Column 4

are connected to each other. FGHIJ in Column 4 are connected to each other. The plastic grove running

down the center of the board separates the two nodes and prevents electrical conduction. On this board

there are 60 nodes. Each node is separate from all the other nodes.

On the outside of the board are two power rows. While the electrons do not care what the color of each

row is, general convention calls for the red rows to be used for the + or positive voltage on the board,

with the blue rows be used for the common ground row. If you learn to stay with color conventions

others will understand your wiring scheme and it will help you eliminate errors.

mySTEM Project Board

8

mySTEM Project Board

Output connections

The output screw blocks are labeled according to channel.

The blocks are labeled Output1-Output4. The polarity can be reversed if so desired to allow for reversing

the current through the output device.

At the end of the output blocks is a connection where the supply voltage (SV) and ground (GND) are

available for testing output devices.

9

mySTEM Project Board

Connecting Signals to the Outputs

There is a 12 pin connector next to the 400 pin breadboard for making connections to the output

channels. Output1 is controlled by the two pins En1 (Enable 1) and Dir1 (Direction 1). Output2 is

controlled by the two pins En2 (Enable 2) and Dir2 (Direction2) … and so on.

Output control signals on the mySTEM Project

Board.

Printout of the Output

Control Signals

To power an output channel you need to provide a digital high (3.3 to 5V) to the enable pin of the

channel. In the picture below a motor connected to output 1 is turned on by providing a jumper wire

from 5 V to En1. When the board is powered and turned on this jumper wire will turn the current on to

the output 1. The direction has a default setting so if you do not need to control direction you only need

to provide the digital high to the Enable of channel 1.

If you desire the motor to change direction you need to provide a second signal. Since the motor is

defaulted high on the direction you need to provide a digital low to the direction pin to have the output

channel reverse polarity. In the picture below the white jumper wire is added from the GND pin to the

Dir1 pin. The motor should spin the other way.

mySTEM Project Board

10

mySTEM Project Board

Try hooking up a motor to Output 1 and running a jumper wire from 5V to En1. When the board is

turned on the motor will spin. Add the jumper wire from GND to Dir1 and the motor will instantly switch

directions.

Computer Control of Outputs

NI Labview is a graphical programming environment that has been built specifically for engineers and

scientists with the intent of making them more productive and ensuring that they have all the tools they

need to prototype, design and build their applications. You can develop sophisticated measurement,

test, and control systems using intuitive graphical icons and wires that resemble a flowchart. LabVIEW

offers unrivaled integration with thousands of hardware devices and provides hundreds of built-in

libraries for advanced analysis and data visualization – all for creating virtual instrumentation. LabVIEW

relies on graphical symbols rather than textual language to describe programming actions.

Labview programs are called Virtual Instruments because their appearance and operation imitate actual

instruments, however they are analogous to main program, functions and subroutines from popular

computer languages such as C.

Connect your mySTEM™ Project Board to the myDAQ and connect the USB cable to your computer.

Now disconnect the input wires from 5V and GND and move them to the Digital Input and Output

section (DIO). Use DIO 0 for En1 and DIO 1 for Dir1. See the connections in the pictures below.

11

mySTEM Project Board

Launch the NI ELVISmx Instrument

On your computer launch the NI ELVISmx Instrument Launcher. It is found in the Start Menu>>All

Programs>>National Instruments>>NI ELVISmx for NI ELVIS & NI myDAQ>>NI ELVISmx Instrument

Launcher.

This brings up the instrument launcher. From the menu select the DigOut icon.

This launches the Digital Writer. You can set the “Lines to Write” to 0-3. Select run at the bottom of the

window. When you push the switch to HI for DIO 0 you will see the motor turn on and an LED on the

screen to let you know that DIO 0 is on. You can now change direction by taking the DIO 1 switch and

move it to the HI setting. You will see the motor reverse direction. Be sure that the DIO 0 is returned to

the LO position before stopping the VI with the stop button. If it is not turned off before you stop

running the program the motor will keep running. If you accidently stop the program with the motor

mySTEM Project Board

12

mySTEM Project Board

running you can select run button again and then stop the motor moving the switches to LO before

stopping the Digital Writer.

In the following exercises you will learn how to plan programming, program structure, analog and digital

inputs, configuring sensors, programming structures and charting data. It is hoped that you will be able

to create your own systems that can monitor inputs and control outputs to create complex cybermechanical systems.

13

mySTEM Project Board

Setting Up the Labview Interface

Open Labview and start a new VI.

From the Window pull down menu select Tile Left and Right. This toggles the two screens, the Front

Panel and the Block Diagram, so they are side by side. Another way to do this is with a keyboard

shortcut. On your computer keyboard hold the Ctrl key down while striking the T key

On the Front Panel select the Controls Palette the View Menu.

This launches the controls palette which provides you with a method of placing various controls and

indicators on the front panel. Everyone’s tastes are a little different so once you are familiar with the

commands and where to find them you will find yourself customizing the Palette. Until then you will

need to see certain ones as you work through the exercises.

mySTEM Project Board

14

mySTEM Project Board

Select the down arrows at the bottom of the Controls pallet.

Once everything is visible you will see the Customize icon at the top of the Controls Pallet. To turn the

palettes on and off you will need to select Customize at the top of the Controls Palette.

Select the option for “Change Visible Palettes.

15

mySTEM Project Board

Select at least the Modern and Express. Select OK. These palettes will then always show when you right

click on the front panel.

Once you have finished setting up the Front Panel move to the Block Diagram Window and select the

Functions Pallet from the View Pull down menu.

This launches the Functions palette which provides you with a method of placing various controls and

functions on the Block Diagram. Everyone’s tastes are a little different so once you are familiar with the

commands and where to find them you will find yourself customizing the Palette. Until then you will

mySTEM Project Board

16

mySTEM Project Board

need to see certain ones as you work through these exercises. Select the down arrows at the bottom of

the Functions pallet.

Once everything is visible you will see the Change Visible Palettes icon at the bottom of the Functions

Pallet. To turn the palettes on and off you will need to select Change Visible Palettes at the bottom of

the Functions Palette list.

You will need to check Programming and Express to follow the commands in the following exercises.

Select OK when you are done.

17

mySTEM Project Board

Beginning Labview Programming

Right click on the Front panel and select the Boolean pallet from the Modern pallet. On the Boolean

pallet select the Round LED and drag it to the Front panel.

You will see the LED on the front panel. Hover over the led and you should see some blue grip points on

the LED.

Left click and hold on one of those points and drag the corner to resize the LED.

This process will work on many of the components you place on the front panel.

mySTEM Project Board

18

mySTEM Project Board

For labels of the components you need to left click to select the text.

Once it is selected you can double click to select the text.

You can now rename the indicator to something that makes sense.

Once you are happy with the name you can resize the text by highlighting the text box again and

selecting the Font menu from the top of the screen.

19

mySTEM Project Board

From the dropdown menu select the size of the text you want.

When you are done you might only have some of the word showing.

Hover over the text and grab one of the blue points and stretch the box to show all the contents.

mySTEM Project Board

20

mySTEM Project Board

Return to the Boolean pallet found in the controls pallet. Select a Vertical Slide Switch and drag it to the

front panel.

Resize the switch and lettering to make it easy to find.

You should now have a switch and an indicator on the front panel.

Depress your ctrl key and the letter T at the same time. This is a shortcut to toggle the Front Panel and

Block Diagram so they are both visible. The front panel is where the user interacts with the program.

The Block Diagram controls the program flow. On the Block Diagram you should see the output and

21

mySTEM Project Board

switch showing. When you renamed them on the Front Panel the naming carried over to the Block

Diagram.

We need to connect the switch to the output. You can accomplish this by hovering over the output of

the switch and you will see what looks like a spool of wire. Click on the output of Switch 1 and then click

on the input terminal of Output.

It should look like the picture below when you are done.

We can now see if this simple program works.

On the front panel select the Run Continuously.

mySTEM Project Board

22

mySTEM Project Board

Once the program is running you can click on the switch and it will toggle and you should see the output

change with the position of the switch. The Boolean logic of the switch is passed to the LED.

Select the Stop button (Abort Execution) to shut the program down.

Introduction to Sensors- Voltage Divider

Sensor is the generic name given to group of devices that can monitor either the absolute value or a

change in the physical quantity and translates the value or change into a useful signal. A sensing system

is comprised by the sensor, data gathering and signal processing components. It is used to monitor,

make decisions and issue feedback to programs that control automated machinery. There are almost

countless varieties of sensors available that can measure anything. In short anything that can gather

information can be called a sensor.

Digital sensors are those transducers that provide an output that is one of two states: high or low, open

or closed, Logic 1 or Logic 0. Digital inputs are the easiest to deal with in programming. There are two

23

mySTEM Project Board

types of sensors you can utilize. They are loosely called active and passive. Passive sensors such as

switches cause a change in state when pushed or excited. No additional power is required. Active

sensors need their own power supplies and a common ground with your data acquisition device.

For the myDAQ to utilize a digital input you need to understand what the myDAQ sees as a high or low.

Electronic equipment utilizes threshold values to determine what is high and what is low. National

Instruments reports that to be read as a low the value must be below .8V. The High must be at least

2.0V. Values in between might be read as either high or low and should be avoided. To have the myDAQ

recognize a signal as a high or low we must be sure that it has the correct voltage input. Free floating

inputs are not recommended as they might be read as either high or low.

To utilize the digital inputs you need to understand the basics of a voltage divider circuit. This exercise

will help you see how to configure a switch to be read by the myDAQ and provide you with the correct

logic level. A voltage divider is a simple linear circuit that produces an output voltage that is some

fraction to the input voltage.

Begin with setting up the following circuit.

Using the basics of Ohm’s Law we know that current in the circuit can be calculated by dividing the

voltage potential by the resistance. Even resistors of the same resistance will have slightly different

resistances so you can double check the circuit by measuring the resistance of the 10K resistor. If you

are in doubt how to measure voltage, resistance and current see http://www.ni.com/whitepaper/11432/en/.

mySTEM Project Board

24

mySTEM Project Board

The 5 V power supply can come from the pin header on the board. You can use the 5V and GND

connections from either end of the pin header.

Place the 10 K resistor so it is inserted into 2 nodes on the breadboard. Bring the wires from the supply

voltage and place 5V at one end of the resistor and the GND at the other end. Turn on the power to the

board and then measure the voltage drop across the resistor. The Voltage dropped across the resistor in

a series circuit is called an IR Drop. The circuit below only has one resistor so the entire voltage is

dropped across the resistor. Measure the voltage across the resistor.

25

mySTEM Project Board

Now add a second resistor. The resistors will join by placing an end in the same node as shown in the

picture below. The GND wire has been moved to the end. There are now two places for an IR Drop.

Measure the voltage from end to end similar to the picture below.

Measure the voltage across the first resistor, similar to the photo below. What relationship does it have

to the total voltage?

Measure the voltage drop across the second resistor. How does it compare to the first? If you had used

different value resistors how would that have affected the voltage drops?

A good explanation of the mathematics and theory involved is found on the All About Circuits site.

http://www.allaboutcircuits.com/vol_1/chpt_5/2.html

mySTEM Project Board

26

mySTEM Project Board

Switches

Switches are installed in circuits to control the flow of electrons through the circuit. They are categorized

by the way they are actuated, by the number of poles and throws they have and their normal position.

The actuator is the mechanical method that causes the switch to open and close. Common types include

momentary, toggle, slide, rocker etc. A normally open switch is one where the circuit is open in its

normal position and the actuator has to be triggered in order to close the circuit and allow current to

flow. A normally closed switch is one where the current can flow unless the actuator causes the switch

to open blocking the current flow.

Poles provide the path for electrons. Throws control the circuits. The schematic below represents a

single pole single throw switch (SPST). It provides a single path for electrons and controls one circuit.

The basic fischertechnik switch is a Single pole double throw switch. It has a single pole for electrons but

two different paths. The schematic is shown below.

The picture below shows the actual Fischertechnik switch. It is a momentary switch which means

depressing the actuator causes a temporary changing of the path. As soon as you let go it reverts to its

original position.

With the cover removed the internal components are visible. The number 1 connection is the middle

contact. You can see that it is in contact with the contact with the number 2 connection making the 1 &

2 normally closed and the 1 &3 normally open. When the button is pushed the connection between 1

27

mySTEM Project Board

and 2 is opened and the connection between 1 and 3 is closed. This is a temporary connection as the

spring will return the switch to its normal position as soon as the pressure is released.

To see how the switch is used in the voltage divider we can replace one of the resistors with a switch. In

the picture below red and green flat plugs are attached to the ends of the jumper wires. This will allow

them to be easily attached to the Fischertechnik switch. The switch is a single pole double throw

momentary switch. Momentary means as soon as you take the pressure off the switch it returns to its

original position. The switch can be used in the normally open or normally closed mode.

The picture below has the jumper wires connecting pin 1 and pin 3. This is the normally open position of

the switch.

mySTEM Project Board

28

mySTEM Project Board

The switch replaces the second 10K resistor.

Measure the voltage across the resistor and switch. You should see the 5V applied. While measuring the

voltage depress the red switch toggle. Does this change the voltage?

Now measure the voltage across the resistor. Depress the switch again. Does this change the voltage?

29

mySTEM Project Board

We are interested to see the voltage on the Signal Out pin. In the picture below you will see the voltage

being measured across the switch. Depress the switch. Does the voltage change?

When the switch is open you have the equivalent of an infinite value resistor. The 10K in series with the

infinite value resistor hardly has an effect on the voltage drop across the entire circuit so you are seeing

the equivalent of the logic Hi. When the switch is depressed you have a resistor of almost no resistance.

At that point the majority of the voltage drop occurs across the 10K resistor so it provides the equivalent

of a logic low.

There is a special name for a resistor utilized in this manner. Because the resistor is attached to the plus

voltage and is used to hold the input at a logic high it is a called a pull up resistor. Its function is to pull

the input to a high state. When the switch is closed it causes the input to see a logic low. If the wiring is

reversed with the resistor between the switch and ground then it becomes a pull down resistor as it

holds the input at a low until the switch closes and allows the 5V to be seen as a logic high.

Now that you can wire a switch to be read by the myDAQ you should learn how to configure an input to

read the value. See the exercise on the Digital Input Express VI.

mySTEM Project Board

30

mySTEM Project Board

Digital Input: Express VI

Before beginning this exercise, be sure you understand how a pull up resistor is utilized with a switch or

other sensor to allow for logic voltage to be seen at an input. This is covered in the exercise on the

Voltage Divider for Digital Circuits.

Digital sensors are those transducers that provide an output that is one of two states: high or low, open

or closed, Logic 1 or Logic 0. Digital inputs are the easiest to deal with in programming. There are two

types of sensors you can utilize. They are loosely called active and passive. Passive sensors such as

switches cause a change in state when pushed or excited. No additional power is required. Active

sensors need their own power supplies and a common ground with your data acquisition device. The

program you are writing will need to import the data you are sensing from the outside world. To

accomplish this, the program has a special function to read from the Digital Input/Output (DIO) pins.

The Circuit

Wire the following circuit using a pull up resistor and a switch to provide input to DIO 0

When you are done it will probably look something like the picture below. The five volts is coming from

the pin header. You can use either of the 5V outputs. The 5V is connected to a 10K resistor and the 10K

resistor is connected to pin one of the fischertechnik switch. Pin 3 of the switch is connected to either of

the GND connections on the pin header.

31

mySTEM Project Board

In the picture a yellow wire is used to connect the junction of the 10K resistor and the switch to the DIO

0 pin header. The end of the resistor and both wires are in the same node on the breadboard.

Writing the simple program

Now that the screen is set up we can build a simple program to read an input. You must have the

myDAQ connected to your computer with the USB cable for this to work.

On the block diagram right click to bring up the Functions pallet. Select the Express option to bring up

the Express pallet.

mySTEM Project Board

32

mySTEM Project Board

From the Express pallet select Input.

From the Input pallet select the option for DAQ Assist.

Place the block on the block diagram. The hand will allow you to move it anyplace on the screen. When

you are happy with the placement click to release the block.

33

mySTEM Project Board

This block is an Express VI. This means that much of the configuration is already done for us and we

need to provide some information to complete the action. When the “Create New…” screen comes up

expand the Acquire Signals menu and then the Digital Input menus so you can select the Line Input

option.

This will bring up the Supported Physical Channels dialog box. Since we connected our input to DIO 0 we

will select that one from the list.

mySTEM Project Board

34

mySTEM Project Board

Once you select the option for port0/line0 you will see the Finish button be enabled. Select Finish. Be

patient as it will take a while for it to finish building.

Once it has finished building the DAQ Assistant will show you the channel. To test your input select Run

at the top of the DAQ Assistant.

35

mySTEM Project Board

With the mySTEM™ Project Board powered on you will be able to read the input as you toggle the

switch. The DigitalIn LED will light when it detects a Logic High and be off when it sees a logic low. Once

you are sure it is working you can select Stop from the menu at the top of the DAQ Assistant.

Look for the OK button at the bottom right corner of the dialog box. It sometimes hides off screen and

needs to be dragged onto the screen so you can see it.

mySTEM Project Board

36

mySTEM Project Board

Once you say OK it will take a while to build the Block, be patient one more time.

You will know it is done when you see the DAQ Assistant block diagram with the Data port showing. This

port is where the information from the sensor is showing.

We want an indicator on the Front panel to show us the status of our push button switch.

Right click on the Front panel and select the Boolean pallet from the Modern pallet. On the Boolean

pallet select the Round LED and drag it to the Front panel.

37

mySTEM Project Board

You will see the LED on the front panel. Hover over the led and you should see some blue grip points on

the LED.

Left click and hold on one of those points and drag the corner to resize the LED.

This process will work on many of the components you place on the front panel.

For labels of the components you need to left click to select the text.

Once it is selected you can double click to select the text.

You can now rename the indicator to something that makes sense.

mySTEM Project Board

38

mySTEM Project Board

Once you are happy with the name you can resize the text by highlighting the text box again and

selecting the Font menu from the top of the screen.

From the dropdown menu select the size of the text you want.

39

mySTEM Project Board

When you are done you might only have some of the word showing.

Hover over the text and grab one of the blue points and stretch the box to show all the contents.

You should now see the LED show up on the Block diagram.

If you try to connect the data pin to the output you will see the program give you a visual clue that you

cannot connect these two terminals.

This is the most common of errors in the Labview programming environment. There is an additional step

we need to do before we can see the output on the screen. The DAQ Assistant builds an array of data

mySTEM Project Board

40

mySTEM Project Board

that it provides the rest of the program. The LED only wants a Boolean input. It cannot decide what to

do with the data. For a complete explanation see the exercise Introduction to Arrays.

For now we will add one block so we can pick the information we wish from the DAQ Assistant.

From the Functions pallet select the Array pallet from the Programming pallet. On the Array pallet

select the Index Array block.

Place the block on your screen. Hover your cursor over the lower left hand corner and you will see the

Index window show.

Right click and select the option to Create and then select Constant.

41

mySTEM Project Board

Once you select the constant it will appear on your screen with a 0 in the box. This is what we need.

Now wire the blocks together so they resemble the picture below.

The information is passed from the DAQ Assistant to the Index Array block. The Index Array block is

selecting the first block of information and passing the output to our output LED.

Test the program by selecting the Run Continuously button.

If you have set this up correctly you will see the LED on the front panel react to the switch to show you

the logic level being delivered.

Stop the program. Rewire the Fischertechnik switch so your wires are connected to terminals 1 and 2.

This is using the switch as a normally closed switch. Run the program continuously again. How does the

output of the LED differ from your first wiring?

Save your program as we will use that again when we learn to configure outputs.

mySTEM Project Board

42

mySTEM Project Board

Introduction to Programming Structures:

The mySTEM™ Project Board needs to talk to the Labview program you write to know when to turn on

and off an output. Before we learn to turn on an output it is important to learn how to turn it off first.

There are two programming structures you need to learn so you can be sure your output is turned off

before exiting your program. In this exercise you will learn those structures and see how they operate.

Once you have mastered the structures you can then learn how to configure an output to run larger

current devices. In a previous exercise you learned how to configure an input and hooked a switch up to

DIO 0. Open the saved file from that exercise. It should look similar to the one below.

Hook up your myDAQ to the computer and connect the mySTEM™ board.

When you ran this program after you wrote it you selected the run continuously button to launch it.

While this works on very simple programs it is very limiting. The first structure we will explore is called a

While Loop. This forces a program to repeat an instruction until some condition is met. The first step is

to place a while loop on the Block Diagram.

Right click on your block diagram to access the functions pallet. From the Programming pallet you will

select the Structures pallet. On the Structures pallet you will select the While Loop.

43

mySTEM Project Board

Instead of a block you will get a strange looking icon where your mouse is. Start above and to the left of

the program structure and then click and drag until you are below and to the right of the program blocks

you already have.

You will have traced a dotted box around your program.

Once you click on the screen below and to the right of the last programming block you will see the

structure appear.

In the lower right hand corner you will see the conditional terminal. In the picture above the conditional

terminal is the “Stop if True” condition. The condition behavior can be changed by right clicking on it and

mySTEM Project Board

44

mySTEM Project Board

selecting another option. The default condition is acceptable. We need to create a condition for the loop

to stop. Right click on the front panel and select the Boolean Pallet from the Modern Pallet.

From the Boolean pallet select the Stop button and place it next to your output LED.

Once placed select the button and drag it to the desired size.

45

mySTEM Project Board

Once you have the button resized you can then resize the text.

Back on the Block Diagram you will find the stop button. Drag it close and then wire it to the conditional

terminal.

mySTEM Project Board

46

mySTEM Project Board

Now the program is run by selecting just the Run button.

You can toggle your switch to see the output change. After you see it work select the stop button. The

program should end. As long as we only have the LED on the front panel as our output it doesn’t really

matter what state it is in when the program ends.

Run the program again and try to stop the program with the LED in the on status. In the picture above

you see the LED was on when the program stopped. If this had been a motor it would stay running

when you select stop. This could be a dangerous situation.

To be sure we always are turning off the output we need to provide a structure that allows us to run a

program and make decisions but when we hit the stop button everything stops. When you think about

this there are really two cases for behavior. One case when the stop button is not pressed and gives us

a false Boolean output, and the other when we press the stop button and it gives us a true output. The

structure we will use is called a Case Structure.

47

mySTEM Project Board

Create some room inside the While Loop by clicking on the loop and using the blue drag boxes.

Unwire the output by clicking on the wire and then selecting the delete button on your keyboard.

Right click on the block diagram and select the Structures pallet from the Programming pallet. On the

Structures pallet select Case Structure.

mySTEM Project Board

48

mySTEM Project Board

Drag the structure around the DAQ Assistant and Index array blocks.

When you let go you will see the structure in place.

The top case is true and that is where your blocks appear. If you think about the stop button, the

program should stop completely when it is pushed and the Boolean is true. We need to move the DAQ

Assistant and Index Array blocks to the False case. The easiest way to do that is to right click on the case

outline and select the option for “Make This Case False”.

Once the case is false we will wire the Index Array Block to the output through the wall of the case

structure.

49

mySTEM Project Board

Now switch to the True case by selecting the down arrow next to false and selecting the true option.

You will see that the True case is empty and there is a wiring tunnel in the side of the True case. Right

click on the block and select The Boolean pallet from the Programming pallet. Select a False Constant

from the Boolean pallet.

mySTEM Project Board

50

mySTEM Project Board

Place this in the True Case structure and wire it to the tunnel connection.

The case structure needs an input on the left side so it knows whether to run the True case or the False

case. Wire this input from the stop button.

Once this is wired run the program again by selecting the run button. Now try to stop the program with

the LED in the on state. You will notice no matter what position your switch is in, when you click on the

stop button the LED shuts off. Using these two programming structures together will allow you to safely

control motors and other output devices and know they will be turned off when you hit the stop button.

Save this program and we will adapt it to run a motor.

Once you are comfortable with the structures you can move on to the exercise on Creating a Digital

output.

51

mySTEM Project Board

Digital Outputs: Sending Signals to Devices:

The mySTEM™ Project Board needs to talk to the Labview program you write to know when to turn on

and off an output. Before we learn to turn on an output it is important to learn how to turn it off first.

There are two programming structures you need to learn so you can be sure your output is turned off

before exiting your program. Once you have mastered the structures you can then learn how to

configure an output to run larger current devices. If you have not completed the exercise on the

Introduction to Basic Structures you should complete that before attempting to configure an output.

Make another set of jumper wires with the red and green flat plugs connected to one end. Connect the

Fischertechnik motor to Output1 on the mySTEM™ Project Board.

The Fischertechnik motor included with the board is a DC motor inserted into a case with slots and

electrical connections built in. This allows the motor to be connected to hundreds of different

components used in the design of cyber-mechanical devices.

mySTEM Project Board

52

mySTEM Project Board

The picture below shows the motor both in and outside of the case.

The motor itself consists of two permanent magnets in a case which establishes a magnetic field

between them.

Inside the magnetic field we place a shaft wound with wire that is free to Rotate. This shaft is called an

armature. Current passing through the wire of the armature causes a creation of a magnetic field. The

wire is wound around a series of segmented plates of silicon steel to concentrate the magnetic fields.

53

mySTEM Project Board

mySTEM Project Board

54

mySTEM Project Board

The current passes through brushes which are the two pieces in the red circle on the left. These brushes

contact the commutators on the armature allowing the armature to rotate in the magnetic field.

This setup allows a motor to run in two directions depending on the polarity of the connections. The

mySTEM™ Project Board allows for the control of the direction of the current allowing the user to select

the direction of the motor spin when desired.

Wiring in the Motor

Run a jumper wire from DIO 1 to the EN1 on the Pin Header.

55

mySTEM Project Board

Setup the voltage divider using the 10K resistor and switch from the Digital Input activity. Wire the signal

to the DIO 0 pin.

Open the program you saved after completing the Introduction to Structures activity.

The block diagram should resemble the one pictured here with both the While and Case Structures

Loops.

mySTEM Project Board

56

mySTEM Project Board

57

mySTEM Project Board

Create a little more room by extending the right side of the While Loop.

Right click on the block diagram and select Express from the Functions pallet. Select the Output pallet

from the Express pallet. Select the DAQ Assist from the Output pallet.

Place the DAQ Assistant inside the While Loop similar to the picture below.

mySTEM Project Board

58

mySTEM Project Board

In the Create New dialog box Expand the Generate Signals and then Digital Output sections to find the

Line Output.

In the Supported Physical Channels select port0/Line1 option and select Finish.

59

mySTEM Project Board

This will bring up the DAQ Assistant dialog box. With the board plugged in and turned on select the Run

at the top of the DAQ Assistant.

Once the DAQ Assistant is running click on the radio button above the DigitalOut label. If you are

hooked up properly the motor should turn on.

Be sure the motor is turned off before you hit the Stop button. If you accidently hit the stop button

without unchecking the DigitalOut radio button you will have to run the DAQ Assistant again to shut off

the output.

mySTEM Project Board

60

mySTEM Project Board

In the Settings area in the DAQ Assistant there is a check box for Invert Line. Place a check in the box.

Run the DAQ Assistant again. Click on the radio button on the DigitalOut again. How does this behavior

differ from the when the box was not checked. Be sure the motor is off before stopping the DAQ

Assistant.

Once the DAQ Assistant is off uncheck the Invert Line check box to unselect the Invert Line option and

click the DigitalOut radio button to clear the input.

When you are done Select the OK button at the bottom right hand corner of the DAQ Assistant dialog

box.

You will see the notification that it is building the VI.

61

mySTEM Project Board

Once the VI is complete arrange it so your program looks like the picture below.

We can Rename the DAQ Assistant2 by clicking on the words and removing them. Enter a descriptive

name. The example below has named the DAQ Assistant2 to OUTPUT.

We need to connect the data to OUTPUT. Since this is a DAQ Assistant and can handle many outputs at

once the data has to be in an array format. If we try to wire without creating an array we will see the

wiring error.

To allow us to connect we need to change the Boolean information to an Array of Boolean information.

mySTEM Project Board

62

mySTEM Project Board

From the Functions pallet select the Programming Pallet. On the Programming Pallet select the Array

pallet. On the Array pallet select the Build Array block and place it on the block diagram.

Once placed it will look like the picture below.

You can now wire in the information to the data input of the OUTPUT block.

63

mySTEM Project Board

If we look very closely at the data flow from the input to the output we will see subtle differences in the

sizes of the wire. In the labeled diagram below you can follow the data. The data in the array is in the

thicker green lines. The Boolean Data is in the narrow green lines.

Now it is time to see if our program will run. With the myDAQ connected to your computer and the

mySTEM™ Project Board connected and powered, select run at the top of the window. As you toggle

the switch the motor should run and shut off.

When you hit the Stop button the motor and the program should shut down.

Save your program.

Adding Reverse Direction

We are going to add a second output to our program so you can see how the build array works.

Double click on the OUTPUT Block. This will bring up the DAQ Assistant dialog box again. Select the blue

+ sign on the Configuration Tab.

mySTEM Project Board

64

mySTEM Project Board

This will bring up the Supported Physical Channels box again. Add port0/line2 to the task and select OK.

You now see two tasks in the list. It will be confusing unless we name them something that means

something to us.

Right click on the DigitalOut_0 and select Rename from the options.

65

mySTEM Project Board

In the dialog box type a distinct name for what the task is. In the example below the channel name has

become Direction1. Select OK.

Repeat the process renaming the DigitalOut to Enable1 and select OK. Now the two tasks have unique

names that relate to what we want them to do.

Select OK from the bottom right hand corner of the DAQ Assistant window and allow it time to rebuild.

On your front panel select the Modern pallet from the Controls pallet. From the Modern pallet select

the Boolean pallet. From the Boolean pallet select the Vertical Slide switch and place it on your screen.

mySTEM Project Board

66

mySTEM Project Board

Resize and rename the switch. In the picture below it was named Direction.

On the block diagram find the Direction block and arrange it to resemble the picture below. You might

have to do some rearranging to make it fit.

Hover over the Build Array block and drag the blue grip point downward.

67

mySTEM Project Board

Pull slowly and stop when you have a second section on your Build Array block. The enable data is going

into the first block. We can feed the Direction data into the second data entry point on the Build Array

block.

The OUTPUT knows that DIO 1 will be connected to the first element in the array and the DIO 2 will be

connected to the second element in the array. Wire the Direction block to the second element in the

Build Array block.

Run a jumper wire from DIO 2 to Dir1 on the pin header.

mySTEM Project Board

68

mySTEM Project Board

You now have an onscreen switch on your front panel that will allow you to control the direction of the

motor. To enable the motor you must press the Fischertechnik switch. Connect the board to power and

run the program. Hold the fischertechnik switch so the motor is running. Slide the direction switch to

the other position. What happens to the motor?

Save your program.

Designing Programs

There are a number of ways to design programs. We present two different ways here. It should be

noted there is no one correct or perfect way to solve these problems. The following exercises are

presented in order to help you organize your thinking.

Flow Charts

Flowcharts are a graphic representation of an algorithm, often used in the design phase of programming

to work out the logical flow of a program. Flowcharts use simple geometric symbols and arrows to

define relationships between elements. This visual representation of the flow of a process helps

organize thinking. The program designer knows where decisions need to be made and can identify what

processes are conducted and in what order. Flowcharts are also used in other design work to explain

complex processes and as an aid in quality control. This activity will introduce you to flowchart symbols.

While there are numerous symbols used by professional programmers this exercise will concentrate on

the ones used most often. You should familiarize yourself with the basic shapes and what they

represent.

The Terminator block is used to indicate the Start or End of a program.

The process block represents a Process that occurs. This might be turning a motor or lamp on, getting

the value of a variable or setting input or output pins.

69

mySTEM Project Board

The Decision block is used to branch the program after comparing variables or checking the position of

switches.

Data blocks are used to assign variables and allow us to set parameters. This shape is also used for

assigning inputs and outputs to variables as well as defining delays.

Blocks are connected by arrows called Flow Lines which show how the blocks connect together.

Review the flow chart that follows. Step through it to follow the logic it is mapping out.

mySTEM Project Board

70

mySTEM Project Board

What is the eventual course of action if it is the weekend?

If it is not the weekend and you missed the bus what is your next action.

Conclusion:

Using the information from the flowchart section above prepare a flow chart for each of the following

problems and attach them to this sheet.

1. Create a flow chart for placing toothpaste on a toothbrush and then brushing your teeth for 45

seconds.

2. Create a flowchart for creating a peanut butter and jelly sandwich.

3. Create a flowchart for helping a three-year-old child put on their jacket.

State Machines

State Diagrams are graphical representations of how systems sequentially behave. They depict the flow

of control using states and transitions. State Diagrams describe a system as a series of States which

perform an activity or wait for an event to occur. The system can only exist in one state at a time. The

system executes the current state until a change is initiated by a triggering event or condition that will

cause a transition to another state. State machines are used to design programs and sequential logic

circuits. Understanding how to draw state machines will help solve more complex programming

problems. Since there are many ways to approach any problem state machines can define a system and

71

mySTEM Project Board

allow the programmer to focus on transitions and guarding actions. This exercise will help you

understand and create state machines to help you design programs to control models, robotics, and

experiments.

There is a graphical language used in state diagrams. Below are the simple graphics and what they

represent:

mySTEM Project Board

72

mySTEM Project Board

A simple example of what you might create to explain a motion sensing light with a photoelectric eye.

This would turn the lights on when it was dark and motion detected. It would recheck every 15 minutes.

You can clean up complicated diagrams like the one below by nesting them, creating separate state

diagrams for each section. This makes them easier to read.

Before and After images of the same diagram. The nested one below allows for better organization.

73

mySTEM Project Board

Conclusion:

Translating diagrams into Labview programming is fairly easy. For example a case structure used to shut

down all the motors found in the Introduction to Programming Structures allows for a switch to change

between one state and another. When the Boolean signal goes from low to high you change states.

Before attempting a difficult program you should get some experience creating state diagrams.

1. Create a state diagram for the process of buying lunch.

2. Create a nested state diagram for the systems in a car. You might include the starter,

transmission, acceleration and breaking.

Open Loop Programming:

Basic systems consist of an input, a process and an output. These simple systems are called open loop

systems because the system cannot interact with the world. For example the clothes washer has no idea

if the clothes are clean or not. The cycle runs for a time and then stops. Understanding how open loops

control actions is the first step in learning programming.

This exercise utilizes parts found in the Do Engineering Basic Kit available from Studica. The components

are listed below.

Rack and Pinion 60

(3)

Building block 15 with 2 pins

(2)

Base Plate

(1)

Motor Rack Gearbox

(1)

Building Block 30

(7)

S Motor

(1)

Flat Plug Red

(6)

Flat Plug Green

(6)

Cable Clamp

(5)

The components are assembled as shown below. There are seven of the building block 30s that allow

the rack gears to be aligned in a row. The two 15 mm blocks with the two pins hold the assembly up in

the air. Electrical wiring should be organized in any model you construct. The cable clamps allow the

wire to be supported and out of the path of the motor. Be sure you leave enough wire so the motor and

gear box can travel from end to end of the rack gear.

mySTEM Project Board

74

mySTEM Project Board

The gear box will lock upon the rack gear when the motor is engaged. Pull the motor up slightly to

release the gear before moving the assembly by hand. The picture below shows the motor in both

positions. On the left you can see the worm gear on the motor as it is not engaged with the gears. On

the right the motor worm is all the way down and the assembly should not move unless you power the

motor. Damage will result when the motor and gearbox are forced.

75

mySTEM Project Board

Wiring this exercise is fairly simple. The picture below shows the wiring necessary.

The motor wires are connected to Output1 on the board.

mySTEM Project Board

76

mySTEM Project Board

The motor is controlled by two signals. Enable 1 turns the motor on and is connected to DIO1. Direction

is controlled by DIO0. The picture below shows the jumper wires going from the DIO section to the pin

header for the output channels.

The Program

Below is the state diagram for the Open Loop programming.

77

mySTEM Project Board

In the state diagram the first decision that needs to be made is the state of the stop button. If it is not

pressed then the first nested diagram is run. if it is then the program should shut down the output to

the motor and close the program. The program should run except for that one condition. If it is not

pressed we then look at the nested states. This program will use time to control the motor. The

program will not know where the motor is on the rack gear and it will run off the track if you are not

careful. Be sure there is enough wire to run off each end of the rack gear so you have time to shut the

motor down if you need to.

You should complete the exercises on Programming Structures and Digital Outputs before attempting

this exercise.

Begin a new Labview Virtual Instrument (VI).

Place a While Loop on the screen from the Structures pallet. This will continuously run the various

states placed inside it until a true condition is fed to the conditional terminal. Wire a stop button to the

conditional terminal.

Place a case structure from the Structures pallet inside the while loop to create the structure needed to

control the motor. Wire the All Stop button to the case selector. This will select state True when the All

Stop button is pressed.

When the All Stop button is pushed we want the motor to stop. Since the motor has both an enable

signal and a direction signal being used (DIO 0 and DIO 1) both of these pins should be set to provide a

mySTEM Project Board

78

mySTEM Project Board

digital 0 when the All Stop button is pressed. In the True case place an Output DAQ Assistant. In the

dialog box select Generate Signals, Digital Output and select Digital Output, Line Output, and select

port0/line0 and port0/line1. Do this by holding your control or shift key down while you select them

one at a time. When both are highlighted select the finish button at the bottom of the dialog box. Select

OK at the bottom of the dialog box and it will create the Assistant. Once Created rename it so you will

remember what it is for.

We have to add two signals to control the motor. One false constant to be sure the direction is canceled

and a second false constant to switch the enable signal to the motor to the off position which will stop

the motor. Select the false constant from the Boolean pallet on the block diagram. Place them on the

True case.

Remember that the DAQ assistants like information in the form of an array. From the Array Pallet select

the block for “Build Array”

Once you place that block hover over it until you see the arrows. Drag slowly down until you have a two

input Build Array block.

79

mySTEM Project Board

Finish wiring the build array block.

Change the case to false by selecting the down arrow next to True at the top of the case structure.

When the Stop Button is not pressed we are directed to the false case by the logic of the switch. As long

as the stop button is not pressed we want the motor to travel back and forth on the rack. In reality there

are two cases that we want to occur here and we have to tell the program what state we want to have.

Inside the False case place another case structure.

Leave room around the area to work.

For this example we will keep the naming of the states simple. Since there are two states to deal with

we will select 0 and 1 for our state names. If state 0 is moving the motor right, then state 1 will be

moving the motor left.

mySTEM Project Board

80

mySTEM Project Board

Inside the true state place a DBL Numeric Constant block from the Numeric pallet.

Wire the DBL numeric constant to the edge of the case structure. By clicking on the structure you are

creating a tunnel.

Once that is accomplished you can wire the tunnel around to the conditional terminal on the other side

of the case structure. This should automatically place a feedback node in the line.

81

mySTEM Project Board

If you do not see the node you will probably see the error on the proposed wire.

If you see that error right click on the wire and select the insert feedback node to insert one.

To select which of these cases go first we need to move our cursor over the * on the Feedback node.

You will see that it is the Initializer Terminal. Right click and select Create>>Constant.

mySTEM Project Board

82

mySTEM Project Board

Make the constant a 0. This will force the 0 case to go first.

You will see that the name of the case has changed. It is now 1. Change to the 0 case and add a DBL

numeric constant there. Click on it until it highlights and change the value to 1.

Wire it to the tunnel. This wiring will cause the next state after 0 to be 1. Looking at the 1 case the next

case after 1 will be 0. This will continue this pattern until the stop button is pressed.

We can now define what we want for the programming in each case.

Return to the initial true case. Stretch a capture box around the blocks there to select them all.

83

mySTEM Project Board

Once they are all highlighted select the CTRL key and the C key at the same time to copy the blocks. You

can also go to the edit menu and select the Copy function.

Return to the False case. Paste the blocks into the 1 case. Change the false constants to true constants

by clicking on them.

Change to the 0 case. Paste the blocks again. This time change only the lower false constant to true.

Leave the top false constant as a false.

The program doesn’t know when to change states yet. If you were to run the program it would try to

change states as fast as possible. We need to give this time to work so a wait block is needed.

mySTEM Project Board

84

mySTEM Project Board

Place a wait block from the Timing Pallet. Right click on the Wait Block and select create constant. Set a

value of 1000 for 1000 milliseconds. This will allow the motor to travel for one second and then switch

direction. Place a wait block in the other state so each one will wait for 1000 milliseconds.

Run the program and see how far the motor will travel in each direction. Does the motor run farther in

one direction than the other?

Conclusion:

Stop the program and adjust the wait time until you are covering almost all the rack gear with the motor

travel. Save your program.

Closed Loop Programming:

Basic systems consist of an input, a process and an output. These simple systems are called open loop

systems because the system cannot interact with the world. For example the clothes washer has no idea

if the clothes are clean or not. The cycle runs for a time and then stops. For most of our needs simple

systems are not enough or are energy wasters. Closed loop systems add feedback to the system from

sensors to continuously monitor and regulate the system. Street lights have a sensor to turn themselves

on when it gets dark and off again when it becomes light. In programming we design loops to monitor

sensors to allow control of systems.

85

mySTEM Project Board

This exercise utilizes parts found in the Do Engineering Basic Kit available from Studica. The components

are listed below in addition to wires and two 10K resistors.

Rack and Pinion 60

(3)

Building block 15 with 2 pins

(2)

Mini-Switch

(2)

Motor Rack Gearbox

(1)

Building Block 30

(8)

S Motor

(1)

Flat Plug Red

(6)

Flat Plug Green

(6)

Cable Clamp

(5)

Base Plate

(1)

The components are assembled as shown below. There are seven of the building block 30s that allow

the rack gears to be aligned in a row. The two 15 mm blocks with the two pins hold the assembly up in

the air. Electrical wiring should be organized in any model you construct. The cable clamps allow the

wire to be supported and out of the path of the motor. Be sure you leave enough wire so the motor and

gear box can travel from end to end of the rack gear. In the picture below you can see the switches set

up at each end of the rack gear.

mySTEM Project Board

86

mySTEM Project Board

The gear box will lock upon the rack gear when the motor is engaged. Pull the motor up slightly to

release the gear before moving the assembly by hand. The picture below shows the motor in both

positions. On the left you can see the worm gear on the motor as it is not engaged with the gears. On

the right the motor worm is all the way down and the assembly should not move unless you power the

motor. Damage will result when the motor and gearbox are forced.

Wiring this exercise is fairly simple. The picture below shows the wiring necessary. The two switches are

connected to a pull up resistor to provide the appropriate logic to the circuit.

Wiring the Motor:

The motor wires are connected to Output1 on the board.

87

mySTEM Project Board

The motor is controlled by two signals. Enable 1 turns the motor on and is connected to DIO1. Direction

is controlled by DIO0. The picture below shows the jumper wires going from the DIO section to the pin

header for the output channels.

Wiring the Switches

In the picture below you will see the wiring for the switches.

mySTEM Project Board

88

mySTEM Project Board

To utilize these switches as digital sensors we create a voltage divider circuit by applying power.

The 5 V power supply can come from the pin header on the board. You can use the 5V and GND

connections from either end of the pin header.

We use the power from the pin header and then utilize the common hot and ground nodes on the

breadboard. In the picture below the 5V is connected to one end of each of the 10K resistors. The

orange wires carry the signal out to the switches. The Yellow wires connect to DIO2 and DIO3.

89

mySTEM Project Board

The orange wires have the red fischertechnik connectors attached so wiring the switch is easier. The

Green ground wires are connected to the common ground on the breadboard.

The Program

This program will use switches to control the transition to the next state. The program will not know

which switch is at which end of the rack gear. You should use the DigIn program from the NI ELVIS

mySTEM Project Board

90

mySTEM Project Board

instrument launcher to determine which switch is which. Since the first time running the program it is

likely that the motor will run off the track if you are not careful so be sure there is enough wire to run

off each end of the rack gear so you have time to shut the motor down if you need to.

You should complete the exercises on Programming Structures, Digital Outputs, Digital Inputs and Open

Loop Programming before attempting this exercise.

Begin a new Labview Virtual Instrument (VI).

Place a While Loop on the screen from the Structures pallet. This will continuously run the various

states placed inside it until a true condition is fed to the conditional terminal. Wire a stop button to the

conditional terminal.

Place a case structure from the Structures pallet inside the while loop to create the structure needed to

control the motor. Wire the All Stop button to the case selector. This will select state True when the All

Stop button is pressed.

When the All Stop button is pushed we want the motor to stop. Since the motor has both an enable

signal and a direction signal being used (DIO 0 and DIO 1) both of these pins should be set to provide a

digital 0 when the All Stop button is pressed. In the True case place an Output DAQ Assistant. In the

dialog box select Generate Signals, Digital Output and select Digital Output, Line Output, and select

port0/line0 and port0/line1. Do this by holding your control or shift key down while you select them

one at a time. When both are highlighted select the finish button at the bottom of the dialog box. Select

91

mySTEM Project Board

OK at the bottom of the dialog box and it will create the Assistant. Once Created rename it so you will

remember what it is for.

We have to add two signals to control the motor. One false constant to be sure the direction is canceled

and a second false constant to switch the enable signal to the motor to the off position which will stop

the motor. Select the false constant from the Boolean pallet on the block diagram. Place them on the

True case.

Remember that the DAQ assistants like information in the form of an array. From the Array Pallet select

the block for “Build Array”

Once you place that block hover over it until you see the arrows. Drag slowly down until you have a two

input Build Array block.

mySTEM Project Board

92

mySTEM Project Board

Finish wiring the build array block.

Change the case to false by selecting the down arrow next to True at the top of the case structure.

When the Stop Button is not pressed we are directed to the false case by the logic of the switch. As long

as the stop button is not pressed we want the motor to travel back and forth on the rack. In reality there

are two cases that we want to occur here and we have to tell the program what state we want to have.

Inside the False case place another case structure.

Leave room around the area to work.

Creating Enum Constants

As our programs become more complex with many more states naming the various states becomes

much more important. In this example we want to have the motor travel forward, then pause, then

travel in the reverse direction and then pause again. For naming we can call these states Forward,

Reverse, Pause1 and Pause2. To name the various states we utilize enumerated type controls (Enum for

short). These allow the programmer to set up names that explain what function they wish the states to

utilize and then apply them to move from state to state. This helps keep confusion to a minimum during

programming.

93

mySTEM Project Board

Right click and select Enum Constant from the Numerical pallet.

Place the block on the diagram close to the right hand side of the case structure.

Right click on the Enum Constant and select Edit.

mySTEM Project Board

94

mySTEM Project Board

Select Insert and type Forward into the box.

Continue selecting the insert button on the Enum Constant Properties and adding items called Pause1,

Reverse and Pause2.

95

mySTEM Project Board

If you want you can reorder the list to make sense to what you are doing by selecting the move up or

move down buttons. In complicated programs the order becomes more important.

Now that you have the enum constants created begin by left clicking in the middle of the enum

constant. This will give you the choice of all the possibilities. Select forward.

Once Forward is selected wire it to the case structure by selecting the wiring tool and clicking on the

edge of the case structure.

The Enum constant is not wired to the case structure.

Wire from the tunnel to the case selector on the other side of the case structure terminal.

If you do this you will see a feedback node automatically created on the wire.

mySTEM Project Board

96

mySTEM Project Board

If you wire the structure and you do not see the feedback node you will see an error on the wire. If you

see that error, right click on the wire and select the insert feedback node to insert one.

To select which of these cases go first we need to move our cursor over the * on the Feedback node.

You will see that it is the Initializer Terminal. Right click and select Create>>Constant.

Make the constant Forward from the choices. This will force the Forward case to go first.

To add all the cases necessary right click on the edge of the case structure and select Add Case for Every

Value. This will add all the necessary cases automatically.

We can now define what we want for the programming in each case.

97

mySTEM Project Board

The first step is to add the enum constants to each case. In the forward case we will add the Pause1

enum. In the Pause1 case we add the Reverse enum. In the Reverse case we add the Pause2 enum and