Thermodynamics

advertisement

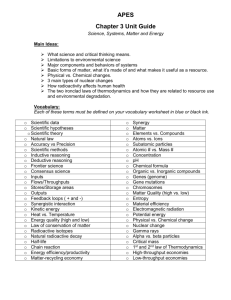

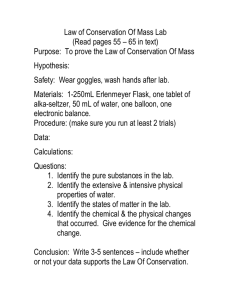

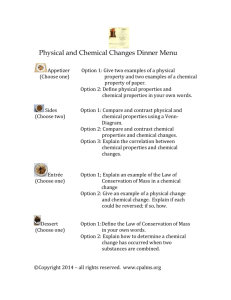

Inter American University of Puerto Rico Bayamon Campus Mechanical Engineering Department MECN 4201 THERMODYNAMICS Fall - 2011 Professor: Dr. Rafael Salgado Thermodynamics Design Project Rolando Santiago, Erik Rosado 12/13/2011 Inter American University of Puerto Rico Bayamon Campus Mechanical Engineering Department Course Number and Name: MECN 4201 THERMODYNAMICS Semester and Year: AUG-DEC 2011 Title of Design: Design a scalding unit for chicken to loosen their feathers. Names of Group Members: Erik T. Rosado Gonzales Y00-22-4943 Rolando Santiago Y00-23-2734 Date of Report Submitted: December 13, 2011 Instructor Comments: Grade: 2 Table of Contents Chapter 1 Objective and Introduction ............................................................................................. 6 Chapter 2 Theory ............................................................................................................................ 7 Conservation of mass .................................................................................................................. 7 Mass Balance .............................................................................................................................. 8 First Law of Thermodynamics .................................................................................................... 9 Heat exchanger.......................................................................................................................... 10 Heat Capacity “Cp”................................................................................................................... 11 Chapter 3 Results and Discussion ................................................................................................. 13 Chapter 4 Conclusions .................................................................................................................. 17 Chapter 5 Appendix ...................................................................................................................... 18 Appendix A-1 (scalding unit design) ........................................................................................ 18 Appendix A-2 (other calculus).................................................................................................. 19 Heating volume sizes: ........................................................................................................... 19 Specific volume @53°C ........................................................................................................ 19 Mass of water in heating size:............................................................................................... 20 Outlet temperature of the heat exchanger ............................................................................. 20 Outlet temperature of the mixing chamber ........................................................................... 21 Appendix A-3 (specific heat chicken) ...................................................................................... 22 Appendix A-4 (specific heat water) .......................................................................................... 25 Appendix A-5 (saturate water temperature table) ..................................................................... 29 Appendix A-6 (design problem 5-218) ..................................................................................... 31 Chapter 6 Works Cited ....................................................................Error! Bookmark not defined. 3 Table of Figure Figure 2-1 Conservation of mass .................................................................................................... 8 Figure 2-2 Mass Balance ................................................................................................................ 9 Figure 2-3 First law of Thermodynamics ..................................................................................... 10 Figure 2-4 A water heater in steady operation .............................................................................. 10 Figure 2-5 Specific heat ................................................................................................................ 11 Figure 2-6 Heat Transfer ............................................................................................................... 12 Figure 5-1 Scalding unit design .................................................................................................... 18 Table of Symbols 4 ABSTRACT In this project a design problem is presented in which a chicken preparation industry needed a scalding unit to prepare chickens to be de-feathered. You’ll see all the analysis involved on the process to build a successful scalding unit. Several equations were used to calculate the exact volume needed of water to have the exact temperature exchange between the system, the chickens and the gas furnace. Also, we have calculated the speed that the conveyor needs to have in order to have each chicken 1.5 min underwater. At the end we proved why the chosen volume is the correct one to make all that process a reality, and calculate the cost of that scalding unit. 5 Chapter 1 Objective and Introduction We were presented with a situation that a chicken preparation industry had a situation, and it was that they needed a scalding unit for slaughtered chickens to loosen their feathers before they were routed to the feather-picking machine. That machine had a capacity of 1200 chicken per hour and these conditions were given: The unit will be of an immersion type filled with hot water at an average temperature of 53°C at all times. Chicken with an average mass of 2.2 kg and an average temperature of 36°C will be dipped into the tank, held in the water for 1.5 min, and taken out by a slow-moving conveyor. The chicken is expected to leave the tank 15 percent heavier as a result of the water that sticks to its surface. The center to center distance between chickens in any direction will be at least 30 cm. The tank can be as wide as 3 m and as high as 60 cm. The water is to be circulated through and heated by a natural gas furnace, but the temperature rise of water will not exceed 5°C as it passes through the furnace. The water loss is to be made up by the city water at an average temperature of 16°C. The walls and the floor of the tank are well-insulated. The unit operates 24 h a day and 6 days a week. We were asked for the following unknowns: a) b) c) d) The mass flow of the rate of the makeup water that must be supplied to the tank. The rate of heat transfer from the water to the chicken. The size of the heating system. The operating cost of the scalding unit per month for a unit cost of $1.12/therm of natural gas. 6 Chapter 2 Theory Conservation of mass The law of conservation of mass, also known as the principle of mass/matter conservation, states that the mass of an isolated system (closed to all matter and energy) will remain constant over time. This principle is equivalent to the conservation of energy, in the sense when energy or mass is enclosed in a system and none is allowed in or out, its quantity cannot otherwise change (hence, its quantity is "conserved"). The mass of an isolated system cannot be changed as a result of processes acting inside the system. The law implies that mass cannot be created or destroyed, although it may be rearranged in space and changed into different types of particles; and that for any chemical process in a closed system, the mass of the reactants must equal the mass of the products. The concepts of both matter and mass conservation are widely used in many fields such as chemistry, mechanics, and fluid dynamics. Historically, the principle of mass conservation, discovered by Antoine Lavoisier in the late 18th century, was of crucial importance in changing alchemy into the modern natural science of chemistry. In special relativity, the mass-energy equivalence theorem states that mass conservation is equivalent to energy conservation, which is the first law of thermodynamics. In special relativity, mass cannot be converted to energy, since energy always retains its equivalent amount of mass within any isolated system. However, certain types of matter may be converted to energy, so long as the mass of the system is unchanged in the process. When this energy is removed from systems (they are opened), they lose mass. In general relativity, mass (and energy) conservation in expanding volumes of space becomes a complicated concept, subject to different definitions, and neither mass nor energy is as strictly and simply conserved as is the case in special relativity and in Minkowski space. (1) Equation 2-1 7 (2) Figure 2-1 Conservation of mass Mass Balance A mass balance (also called a material balance) is an application of conservation of mass to the analysis of physical systems. By accounting for material entering and leaving a system, mass flows can be identified which might have been unknown, or difficult to measure without this technique. The exact conservation law used in the analysis of the system depends on the context of the problem but all revolve around mass conservation, i.e. that matter cannot disappear or be created spontaneously. Therefore, mass balances are used widely in engineering and environmental analyses. For example mass balance theory is used to design chemical reactors, analyse alternative processes to produce chemicals as well as in pollution dispersion models and other models of physical systems. Closely related and complementary analysis techniques include the population balance, energy balance and the somewhat more complex entropy balance. These techniques are required for thorough design and analysis of systems such as the refrigeration cycle. In environmental monitoring the term budget calculations is used to describe mass balance equations where they are used to evaluate the monitoring data (comparing input and output, etc.) In biology the dynamic energy budget theory for metabolic organisation makes explicit use of time, mass and energy balances. (3) 8 (4) Figure 2-2 Mass Balance Steady Flow: Equation 2-2 First Law of Thermodynamics The first law of thermodynamics is an expression of the principle of conservation of work. The law states that energy can be transformed, i.e. changed from one form to another, but cannot be created nor destroyed. It is usually formulated by stating that the change in the internal energy of a system is equal to the amount of heat supplied to the system, minus the amount of work performed by the system on its surroundings. (5) Equation 2-3 Equation 2-4 9 (2) Figure 2-3 First law of Thermodynamics Heat exchanger A heat exchanger is a piece of equipment built for efficient heat transfer from one medium to another. The media may be separated by a solid wall, so that they never mix, or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power plants, chemical plants, petrochemical plants, petroleum refineries, natural gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. (6) (4) Figure 2-4 A water heater in steady operation 10 Heat Capacity “Cp” Heat capacity (usually denoted by a capital C, often with subscripts), or thermal capacity, is the measurable physical quantity that characterizes the amount of heat required to change a substance's temperature by a given amount. In the International System of Units (SI), heat capacity is expressed in units of joule(s) (J) per Kelvin (K). Derived quantities that specify heat capacity as an intensive property, independent of the size of a sample, are the molar heat capacity, which is the heat capacity per mole of a pure substance, and the specific heat capacity, often simply called specific heat, which is the heat capacity per unit mass of a material. Temperature reflects the average kinetic energy of particles in matter. Heat is the transfer of thermal energy; it flows from regions of high temperature to regions of low temperature. Thermal energy is stored as kinetic energy in the random modes of translation in monatomic substances, and translations and rotations of polyatomic molecules in gases. Additionally, some thermal energy may be stored as the potential energy associated with higher-energy modes of vibration, whenever they occur in interatomic bonds in any substance. Translation, rotation, and a combination of the two types of energy in vibration (kinetic and potential) represent the degrees of freedom of motion which classically contribute to the heat capacity of a thermodynamic system. On a microscopic scale, each particle in a system absorbs heat energy among the few degrees of freedom available to it, and this absorption contributes to a specific heat capacity which classically approaches a maximum per mole of particles that is set by the Dulong-Petit law. The limit is achieved by many kinds of solids at room temperature. For quantum mechanical reasons, at any given temperature, some of these degrees of freedom may be unavailable, or only partially available, to store thermal energy. In such cases, the specific heat capacity will be a fraction of the maximum. As the temperature approaches absolute zero, the specific heat capacity of a system also approaches zero, due to loss of available degrees of freedom. Quantum theory can be used to quantitatively predict specific heat capacities in simple systems. (7) (4) Figure 2-5 Specific heat 11 (2) Figure 2-6 Heat Transfer 12 Chapter 3 Results and Discussion A. The mass flow rate of the makeup water that must be supplied to the tank. 13 B. The rate of heat transfer from the water to the chicken, in kW. Equation 3-1 14 C. The size of the heating system in kJ/h. Equation 3-2 15 D. The operating cost of scalding unit per month for a unit cost of $1.12/therm of natural gas. 16 Chapter 4 Conclusions This project was useful to be exposed to a real life problem, something that can be used at the industry. The scalding unit was easy saw as a heat interchanger to solve the equations. Once we figured out the right volume of the scalding unit we could then assume the temperatures of the water so it could maintain the desired 53°C and have a perfect balance between the energy leaving with each chicken and the energy entering because of the furnace. That allowed us prevented the scalding unit to overheat and evaporate the water or loose the temperature because of the 16°C entering to the unit. 17 Chapter 5 Appendix Appendix A-1 (scalding unit design) Figure 5-1 Scalding unit design 18 Appendix A-2 (other calculus) Heating volume sizes: Specific volume @53°C 53° ------------------ 19 Mass of water in heating size: Outlet temperature of the heat exchanger Equation 5-1 20 Outlet temperature of the mixing chamber Equation 5-2 216.2889 y 21 Appendix A-3 (specific heat chicken) Specific Heat above Freezing Specific Heat below Freezing Food (Btu/lboF) (KJ/kgoC) (Kcal/kgoC) (Btu/lboF) (KJ/kgoC) (Kcal/kgoC) Apples 0.87 3.64 0.87 0.42 1.76 0.42 Apricots. fresh 0.88 3.68 0.88 0.43 1.8 0.43 Artichokes 0.87 3.64 0.87 0.42 1.76 0.42 Asparagus 0.94 3.94 0.94 0.45 1.88 0.45 Asparagus beans 0.88 3.68 0.88 0.43 1.8 0.43 Avocados 0.72 3.01 0.72 0.37 1.55 0.37 Bananas 0.8 3.35 0.8 0.4 1.67 0.4 Barracuda 0.8 3.35 0.8 0.4 1.67 0.4 Bass 0.82 3.43 0.82 0.41 1.72 0.41 Beef, carcass 0.68 2.85 0.68 0.48 2.01 0.48 Beef, flank 0.56 2.34 0.56 0.32 1.34 0.32 Beef, loin 0.66 2.76 0.66 0.35 1.47 0.35 Beef, rib 0.67 2.81 0.67 0.36 1.51 0.36 Beef, round 0.74 3.1 0.74 0.38 1.59 0.38 Beef, rump 0.62 2.6 0.62 0.34 1.42 0.34 22 Specific Heat above Freezing Specific Heat below Freezing Food (Btu/lboF) (KJ/kgoC) (Kcal/kgoC) (Btu/lboF) (KJ/kgoC) (Kcal/kgoC) Beef, shanks 0.76 3.18 0.76 0.39 1.63 0.39 Beef, corned 0.63 2.64 0.63 0.34 1.42 0.34 Beets 0.9 3.77 0.9 0.43 1.8 0.43 Blackberries 0.87 3.64 0.87 0.42 1.76 0.42 Blueberries 0.87 3.64 0.87 0.42 1.76 0.42 Brains 0.84 3.52 0.84 0.41 1.72 0.41 Broccoli 0.92 3.85 0.92 0.44 1.84 0.44 Brussels sprouts 0.88 3.68 0.88 0.43 1.8 0.43 Butter 0.3 1.26 0.3 0.24 1 0.24 Butterfish 0.77 3.22 0.77 0.39 1.63 0.39 Cabbage 0.94 3.94 0.94 0.45 1.88 0.45 Candy 0.93 3.89 0.93 0.93 3.89 0.93 Carp 0.82 3.43 0.82 0.41 1.72 0.41 Carrots 0.91 3.81 0.91 0.44 1.84 0.44 Cauliflower 0.93 3.89 0.93 0.44 1.84 0.44 Celery 0.94 3.94 0.94 0.45 1.88 0.45 23 Specific Heat above Freezing Specific Heat below Freezing Food (Btu/lboF) (KJ/kgoC) (Kcal/kgoC) (Btu/lboF) (KJ/kgoC) (Kcal/kgoC) Chard 0.93 3.89 0.93 0.43 1.8 0.43 Cherries, sour 0.88 3.68 0.88 0.41 1.72 0.41 Cherries, sweet 0.84 3.52 0.84 0.4 1.67 0.4 Chicken, squab 0.8 3.35 0.8 0.39 1.63 0.39 Chicken, broilers 0.77 3.22 0.77 0.38 1.59 0.38 Chicken, fryers 0.74 3.1 0.74 0.35 1.47 0.35 Chicken, hens 0.65 2.72 0.65 0.44 1.84 0.44 Chicken, capons 0.88 3.68 0.88 0.41 1.72 0.41 Clams, meat only 0.84 3.52 0.84 0.36 1.51 0.36 (8) 24 Appendix A-4 (specific heat water) -t- Absolute pressure -p- Density -ρ- Specific volume -v- Specific Heat - cp - Specific entropy -e- (oC) (kN/m2) (kg/m3) 10-3 (m3/kg) (kJ/kgK) (kJ/kgK) 1.00 4.210 0 0 (Ice) 916.8 0.01 0.6 999.8 4 (maximum density) 0.9 1000.0 5 0.9 1000.0 1.00 4.204 0.075 10 1.2 999.8 1.00 4.193 0.150 15 1.7 999.2 1.00 4.186 0.223 20 2.3 998.3 1.00 4.183 0.296 25 3.2 997.1 1.00 4.181 0.367 30 4.3 995.7 1.00 4.179 0.438 35 5.6 994.1 1.01 4.178 0.505 40 7.7 992.3 1.01 4.179 0.581 45 9.6 990.2 1.01 4.181 0.637 50 12.5 988 1.01 4.182 0.707 55 15.7 986 1.01 4.183 0.767 25 -t- Absolute pressure -p- Density -ρ- Specific volume -v- Specific Heat - cp - Specific entropy -e- (oC) (kN/m2) (kg/m3) 10-3 (m3/kg) (kJ/kgK) (kJ/kgK) 60 20.0 983 1.02 4.185 0.832 65 25.0 980 1.02 4.188 0.893 70 31.3 978 1.02 4.191 0.966 75 38.6 975 1.03 4.194 1.016 80 47.5 972 1.03 4.198 1.076 85 57.8 968 1.03 4.203 1.134 90 70.0 965 1.04 4.208 1.192 95 84.5 962 1.04 4.213 1.250 100 101.33 958 1.04 4.219 1.307 105 121 954 1.05 4.226 1.382 110 143 951 1.05 4.233 1.418 115 169 947 1.06 4.240 1.473 120 199 943 1.06 4.248 1.527 125 228 939 1.06 4.26 1.565 130 270 935 1.07 4.27 1.635 135 313 931 1.07 4.28 1.687 26 -t- Absolute pressure -p- Density -ρ- Specific volume -v- Specific Heat - cp - Specific entropy -e- (oC) (kN/m2) (kg/m3) 10-3 (m3/kg) (kJ/kgK) (kJ/kgK) 140 361 926 1.08 4.29 1.739 145 416 922 1.08 4.30 1.790 150 477 918 1.09 4.32 1.842 155 543 912 1.10 4.34 1.892 160 618 907 1.10 4.35 1.942 165 701 902 1.11 4.36 1.992 170 792 897 1.11 4.38 2.041 175 890 893 1.12 4.39 2.090 180 1000 887 1.13 4.42 2.138 185 1120 882 1.13 4.45 2.187 190 1260 876 1.14 4.46 2.236 195 1400 870 1.15 200 1550 864 1.16 220 225 240 840 2550 834 814 2.282 4.51 2.329 4.63 1.20 4.65 2.569 4.78 27 -t- Absolute pressure -p- Density -ρ- Specific volume -v- Specific Heat - cp - Specific entropy -e- (oC) (kN/m2) (kg/m3) 10-3 (m3/kg) (kJ/kgK) (kJ/kgK) 250 3990 799 125 4.87 2.797 260 784 4.98 275 5950 756 1.32 5.20 3.022 300 8600 714 1.40 5.65 3.256 325 12130 654 1.53 6.86 3.501 350 16540 575 1.74 10.1 3.781 360 18680 528 1.90 14.6 3.921 (9) 28 Appendix A-5 (saturate water temperature table) 29 (4) 30 Appendix A-6 (design problem 5-218) 31 Chapter 6 Bibliography 1. contributors, Wikipedia. Conservation of mass. Wikipedia . [Online] November 23, 2011. [Cited: December 3, 2011.] http://en.wikipedia.org/wiki/Conservation_of_mass. 2. NASA. NASA. NASA. [Online] http://www.grc.nasa.gov/WWW/k12/airplane/Images/mass.gif. 3. contributors, Wikipedia. Mass balance. Wikipedia . [Online] November 30, 2011. [Cited: December 3, 2011.] http://en.wikipedia.org/wiki/Mass_balance. 4. Yunus A. Cengel, Michael Boles. Thetmodynamics. 5. Wikipedia. First law of thermodynamics. Wikipedia . [Online] November 27, 2011. [Cited: Dcenber 3, 2011.] http://en.wikipedia.org/wiki/First_law_of_thermodynamics. 6. —. Heat exchanger. Wikipedia . [Online] November 28, 2011. [Cited: December 3, 2011.] http://en.wikipedia.org/wiki/Heat_exchanger. 7. Heat capacity. Wikipedia . [Online] Wikipedia , December 2, 2011. [Cited: December 3, 2011.] http://en.wikipedia.org/wiki/Heat_capacity. 8. Engineeringtoolbox. Food and Foodstuff - Specific Heats. Engineeringtoolbox. [Online] http://www.engineeringtoolbox.com/specific-heat-capacity-food-d_295.html. 9. —. Water - Thermal Properties. Engineeringtoolbox. [Online] 2011. http://www.engineeringtoolbox.com/water-thermal-properties-d_162.html. 32