Manuscript Title in Title Case

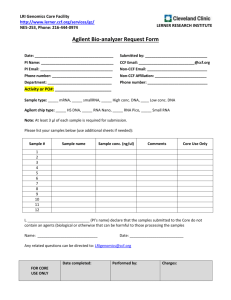

advertisement

Common Cause Failures: Extended Alpha Factor method and its Implementation Alexandra Sitdikova Reactor Engineering Division, Jožef Stefan Institute Jamova 39, SI-1000 Ljubljana, Slovenia Institute of Physics and Technology, National Research Tomsk Polytechnic University, 30, Lenin Avenue, 634050 Tomsk, Russia Alexandra.Sitdikova@gmail.com Marko Čepin Faculty of Electrical Engineering, University of Ljubljana Tržaška 25, SI-1000 Ljubljana, Slovenia marko.cepin@fe.uni-lj.si ABSTRACT Contribution of the common cause failures (CCFs) has been recognized as the dominant, within the results of a safety system reliability analysis and a probabilistic safety assessment (PSA) when analyzing nuclear safety. The purpose of this paper is to present a new method for explicit modeling of multiple components failure event within multiple common cause failure groups simultaneously. The method is based on Alpha Factor model with few modifications because of the developed expansion. The assessment for simultaneous assignment of single or multiple failure events to multiple common cause failure groups is performed. A standard standby safety system was selected as a case study and a comparison of results with standard Alpha Factor and Beta Factor methods was made. The results show that consideration of one failure event in several common cause failure groups gives a larger failure probability of considered systems. 1 INTRODUCTION Nuclear power plants are designed with redundant safety systems, redundant trains and redundant equipment for improved reliability and safety. However, very high reliability theoretically achievable through the use of redundancy is often compromised by single events that can individually render redundant components unavailable [1]. Such events are known under the term common cause failure (CCF) events or common cause failures. CCF events have been recognized as the dominant contributors to the results of the system reliability analysis and the probabilistic safety assessment (PSA). They are defined as a subset of dependent failures in which two or more component fault states exist at the same time, or in short time interval, and thus they represent failures resulting from a shared cause [2]. For example, environmental CCFs include orbital debris strikes and exposure to excessively high humidity, temperature or vibration. Neglecting contribution of common caused failures can result a significant underestimation of risk. [3] CCFs are being acknowledged as one of the most challenging issues in the PSA, especially within PSA fault tree (FT) modeling of safety systems within nuclear power plants. 520.1 520.2 This paper presents the method based on Alpha Factor method, but applying for explicit modeling of single and multiple components failure events simultaneously within number of several different Common Cause Failure Groups (CCFGs) – sets. Each CCFG is defined on the basis of specific coupling mechanism. All sets could be sorted by the group size – k (number of elements in it) and by the number of common elements in each CCFG, – x (if it is single than x = 1 or multiple x ≥ 1; but in any case x ≥ k). The presented method that accommodates components failure events to be simultaneously assigned to different CCFGs given different coupling mechanisms is based on a modification of the well-known Alpha Factor model. The motivation for this study is the incapability of one of the most widespread PSA software for fault tree (FT) and event tree (ET) modeling, [5], for simultaneous assignment of neither one single component failure event, nor multiple components failure event in more than one CCFG within the fault tree analysis technique. Namely, the software package provides with a CCF modeling feature based on manual assignment of arbitrary failure events, i.e. basic events (BEs), to specific CCFG upon selection of proper parametric CCF model. In the process of this assignment of BE to CCFG, the software does not accommodate the option for one to assign one BE to several different CCFGs, a scenario quite probable in practice since given component can experience failure due to different causes, which if seen as shared causes couple the specific component with other components in different CCFGs simultaneously. The method was applied on a selected case study system. The application of the method enables improved PSA models. The improved models consequently implicate better results. 2 COMMON CAUSE FAILURE METHODS Three most known CCF methods include the Beta Factor, the Multi-Greek Letter (MGL) and the Alpha Factor method. The Beta Factor method is a single parameter method and assumes that whenever a CCF occurs, all components within a CCFG fail. Although historical nuclear industry data indicates that common caused events do not always fail all redundant components, the Beta Factor method does not allow consideration of intermediate failure criteria (e.g., 2 of 3 failures leading to a specific failure). The MGL and Alpha Factor methods are more detailed and allow consideration of intermediate failure criteria. That is for large number of redundant components, many possible failure scenarios exist and extensive modeling efforts are required in order to depict all possible failure combinations. Practicality necessitates some simplification, especially for large CCFG sizes and components with high degrees of redundancy [2]. 2.1 Alpha Factor Method Several guidelines for modeling CCFs in PSA have been published [1, 2, 3]. Some give the sources of generic common caused data. This data is presented in the form of Alpha Factor fractions of the total frequency (αn) in tables for use with CCFG size up to eight. For a given component group size k, an individual is the probability that when a CCF occurs, it involves failure of exactly n of k components. The sum of these fractions for a single CCFG is equal to one. The probability of CCF event involving 'n' specific components (1 ≤ n ≤ k) in CCFG of size 'k' for non-staggered testing scheme , is calculated by using the following equation: (1) (2) Proceedings of the International Conference Nuclear Energy for New Europe, Bovec, Slovenia, Sept. 12-15, 2011 520.3 By equation (2) the normalizing factor is calculated. Then, is the probability of an independent failure of a single component. is the total probability of failure for a given component. Therefore, represents a CCF multiplier, often shown as a percentage, intended to be multiplied by the component failure rate for PSA fault tree CCF basic event data entry. These CCF multipliers are calculated for each CCF criteria in a CCFG. The system failure probability is also calculated. Analyzing a system S made of three components A, B, C, where system failure probability of two-out-of-three components, with Alpha factor method is given by Eq. (3): (3) where P(S) – failure probability system S; P(A), P(B), P(C) - failure probability of component A, B and C respectively; P(CAB) - failure probability of two component failures: A and B, common cause; P(CABC) - failure probability of three component failures: A, B and C, common cause. The failure probability of a system S depends on failure probability of its components and on the contribution of common cause failures, which are modeled as one common cause group consisting of components A, B and C, which may fail due to common cause. Alpha facto method considers cases where two of three components fail due to common mechanism or all three components fail due to common mechanism. It is assumed that failure probabilities of similar components are the same. (4) (5) (6) The probability of occurrence of any basic event within a given common cause component group is assumed to depend only on the number and not on the specific components in that basic event. Using the above notation, the system failure probability can be written as: (7) This method was developed for system with three components considering one CCFG. For cases of multiple CCFG simultaneously, the modified Alpha Factor method is proposed. 2.2 Modified Alpha Factor Method The method is based on traditional Alpha Factor Method with few modifications because of expansion for multiple CCFGs defined for a system. The extension goes by number of groups in every set and number of common elements. In parallel system of four trains, the function of one is enough for the system success, so all trains should fail for the system failure, i.e. the failure criteria is n out of n. In order to present briefly how the modified Alpha Factor model works, let us assume an example system with four trains as presented on the Figure 1. The success criteria is 1/4, the failure criteria is 4/4. A1 A2 A3 B1 B2 B3 C1 C2 C3 D1 D2 D3 Figure 1: Example system with four trains Proceedings of the International Conference Nuclear Energy for New Europe, Bovec, Slovenia, Sept. 12-15, 2011 520.4 The fault tree without implementation of CCF is shown on Figure 2 and the one with CCF implementation on Figure 3. TOP A A1 B A2 A3 B1 B2 C B3 C1 D C2 C3 D1 D2 D3 Figure 2: Fault tree without CCF implementation TOP CCF CCFG 4 elements Indep. Component A Fails CCFG 2 elements A_ind A1_ ind A2_ ind A3_ ind Component B Fails CCFG 3 elements B1_ ind CCFG 2 elements B_ind B2_ ind B3_ ind Component D Fails Component C Fails CCFG 3 elements CCFG 2 elements C_ind C1_ ind C2_ ind CCFG 3 elements C3_ ind D1_ ind CCFG 2 elements D_ind D2_ ind CCFG 3 elements D3_ ind Figure 3: Fault tree with CCF implementation One common mechanism is found for components A1, B1, C1 and D1, which is modeled in one CCFG. The other common mechanism is found for components: A1, B2, C2 and D2, which is modeled in other CCFG. The size k = 4 (Figure 4) means the number of components in a group. The probability of a set failure, concerning Boolean logic, could be calculated as a sum of all combinations of two, three and four element failures and independent failure of element A1: 12 – A1B1, A1C1, A1D1, B1C1, B1D1, C1D1, A1B2, A1C2, A1D2, B2C2, B2D2, C2D2; 8 – A1B1C1, A1B1D1, A1C1D1, B1C1D1, A1B2C2, A1B2D2, A1C2D2, B2C2D2; Proceedings of the International Conference Nuclear Energy for New Europe, Bovec, Slovenia, Sept. 12-15, 2011 520.5 2 – A1B1C1D1, A1B2C2D2; Summarizing, the probability of failure for given set could be defined as: , or (8) (9) where - number of combinations n of k, . Pind – independent failure probability of a component; P2CF - failure probability of two component failures due to common cause; P3CF - failure probability of three component failures due to common cause; P4CF - failure probability of four component failures due to common cause. Figure 4: Example system with two CCFGs: A1B1C1D1, A1B2C2D2 Thus, the probability of failure for m-set Ps with single common component in it is calculated as follows. (10) One more way of applying modified Alpha Factor method is to use the sets with more than one common element in CCFGs. The probability of multiple failure events in multiple common cause failure groups is calculated in this case. The probability of failure of a set with x common components in it (size k > x) could be described with the following equation: (11) where – the probability of independent failures, sum of probabilities of each common component (A1, B1, C1, etc.). The main difference in comparison with usual Alpha factor method is the way of calculation probabilities of the basic events involving n specific components in a CCFG of size k (1 ≤ n ≤ k), or : (12) This method is proposed for cases, where the set contains the groups with similar types of components in one train (i.e. diesel generators, check valves, motor pumps), where all component failure probabilities are equal. For component groups of different types of components, where several failure probabilities are used, the mean value of normalizing factor and failure frequency of each component are calculated as follows. , , (13) (14) (15) Proceedings of the International Conference Nuclear Energy for New Europe, Bovec, Slovenia, Sept. 12-15, 2011 520.6 So the probability of common cause failure involving n specific components in CCFG can now be written as: (16) 3 CASE STUDY A simplified model of an auxiliary feedwater system (AFWS) of a light-water PWR second generation NPP was used for a case study (Figure 5). The AFWS provides a backup supply of feedwater to the secondary side of the steam generators when the main feedwater pumps cease to operate that makes the normal main feedwater unavailable [4], [5]. SG 1 MIV 7 CV 7 CV 4 FCV 1 MIV 9 CV 1 MIV 1 MIV 4 MDP 1 CV 9 MIV_CS 1 MIV 12 CST 1 POIV 2 FCV 3 MIV 5 CV 5 TDP CV 2 MIV 2 FCV 4 POIV 1 MIV_CS 2 CST 2 MIV 11 SG 2 CV 10 FCV 2 MIV 10 MIV 8 CV 8 MIV 6 CV 6 MDP 2 CV 3 MIV 3 Figure 5: Auxiliary Feedwater System (AFWS) The corresponding FT top event is defined as system failure. AFWS is nonoperational if either one of the two steam generators does not receive cooling water. The presented method for assigning single component failure within different CCFGs simultaneously was applied. Two categories of AFWS components were encompassed by the method, i.e. check valves (CVs) and isolation valves (MIVs). These components were combined, first, into groups and then to several sets by size. For calculation the probability of sets failure were used Modified Alpha Factor method, Alpha Factor method and Beta Factor method. The following Table 1 and Table 2 present the value of probabilities of a CCF involving n components in CCFG size k. Notation CV# means failure of check valve #. Notation MIV# means failure of isolation valve #. Table 1: Value of PnCF for Modified Alpha Factor method Proceedings of the International Conference Nuclear Energy for New Europe, Bovec, Slovenia, Sept. 12-15, 2011 520.7 CVs Sets CV1CV6, CV1CV8 CV1CV4CV7,CV1CV2CV3 CV1CV5CV9CV10 MIVs Sets MIV4, MIV10; MIV4, MIV9 MIV4, MIV5, MIV6; MIV4, MIV1, MIV7; MIV4, MIV11, MIV12 PIND 8,79E-05 8,40E-05 8,13E-05 PIND P2CF 1,21E-05 2,33E-05 2,18E-05 P2CF P3CF P4CF PS 1,00E-04 5,51E-06 1,13E-04 5,39E-06 1,85E-06 1,09E-04 P3CF PSUM 9,55E-05 2,27E-06 9,77E-05 9,33E-05 1,51E-05 3,29E-06 1,12E-04 Table 2: Value of PnCF for Alpha Factor method CVs Sets CV1CV6, CV1CV8 CV1CV4CV7, CV1CV2CV3 CV1CV5CV9CV10 MIVs Sets MIV4, MIV10; MIV4, MIV9 MIV4, MIV5, MIV6; MIV4, MIV1, MIV7; MIV4, MIV11, MIV12 PIND 1,76E-04 2,52E-04 3,25E-04 PIND 1,91E-04 P2CF 2,42E-05 7,76E-06 2,43E-06 P2CF 9,07E-06 P3CF P4CF PS 2,00E-04 1,65E-05 2,76E-04 1,35E-06 7,40E-06 3,36E-04 P3CF PSUM 2,00E-04 2,80E-04 5,05E-06 9,86E-06 2,95E-04 Table 3: Results comparison for applied CCF methods PCV1 PMIV4 PTOP2 Modified Alpha factor Alpha factor Method Method 3,21E-04 8,12E-04 2,09E-04 4,95E-04 2,45E-04 2,69E-04 Beta factor Method 1,00E-04 1,00E-04 2,88E-04 Table 3 comprises the comparison of results for applied methods of calculation CCF, considering TOP event and two categories of AFWS components check valves and isolation valves. Due to the fact that Alpha Factor modeling techniques more failure combinations, the meaning of failure probability could be two to three orders higher than for Beta Factor method. The modified Alpha Factor method gives good results, what can let use it for CCF analysis. 4 CONCLUSION The modified Alpha Factor method for CCF analysis and prevention has been examined to show that it is useful for assessment the potential CCF at nuclear power plants. This method will help calculate probabilities of single and multiple events components failure events simultaneously within number of several different CCFGs, combined in set. Proposed method has several differences from standard Alpha Factor method. It can be seen as its upgrade. The main advantage of the discussed model is fact that implementation of such CCF approach could be especially useful for CCFG within several numbers of Proceedings of the International Conference Nuclear Energy for New Europe, Bovec, Slovenia, Sept. 12-15, 2011 520.8 different types of components. Examples include number of system trains with components placed in one room or on the same floor, the number of similar components of the same producer with the same physical and technological characteristics. The proposed method presents the explicit modeling of CCF. The disadvantage is associated with the fact that it requires more specific calculations for several parameters which is connected with more efforts and more data, which may lead to a higher uncertainty. ACKNOWLEDGMENTS The Slovenian Research Agency supported this research (project J2-2182). REFERENCES [1] Mosleh A., Parry G.W., Paula H.M., Worledge D. H., Rasmuson D. M. Procedures for treating common cause failures in safety and reliability studies. NUREG/CR-4780, Vol.1. US NRC, 1981; Washington, DC. [2] Mosleh A., Parry G.W., Paula H.M., Worledge D. H., Rasmuson D. M. Procedures for treating common cause failures in safety and reliability studies. NUREG/CR-4780, Vol.2. US NRC, 1989; Washington, DC. [3] Mosleh A., Rasmuson D.M., Marshall F.M. Guidelines on modelling common-cause failures in PRA. NUREG/CR-5485. US NRC, 1998; Washington, DC. [4] Čepin M. Optimization of safety equipment improves safety. Reliability Engineering and System Safety 2002; pp 71-80. [5] Kančev D., Čepin M. Common Cause Failures: Explicit modelling of single failure event within different common cause groups, Proceedings of NENE201, NSS, 2011. [6] Čepin M., Application of common cause analysis for assessment of reliability of power systems, Proc. of 2010 IEEE PMAPS Conf., Singapore, June 14-17, 2010, pp. 575-580. Proceedings of the International Conference Nuclear Energy for New Europe, Bovec, Slovenia, Sept. 12-15, 2011