Borehole Imaging Tools - Principles and

advertisement

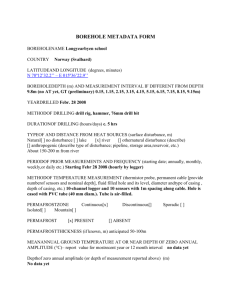

Technical Developments Borehole Imaging Tools - Principles and Applications by Philippe Gaillot, Tim Brewer, Philippe Pezard, and En-Chao Yeh doi:10.2204/iodp.sd.5.07S1.2007 Industry standard wireline imaging tools: Industry-standard wireline image tools, top-combinable with open-hole wireline tools commonly used in the framework of IODP-ICDP, measure either the electrical conductivity of the borehole wall or the sonic travel time and amplitude of ����������������� the reflected acoustic signal��. ��������������������������������������������� The wireline resistivity image tools are pad tools that measure the formation micro conductivity directly through an array of resistivity buttons mounted on pads that are pressed against the borehole wall (Fig. 1a; Ekstrom et al., 1987). Such tools normally provide the best high-resolution borehole images in conductive (water-based) muds. Examples are the Schlumberger Formation MicroScanner (FMS) and Fullbore Formation MicroImager (FMI) with azimuthal resolution of 64 (FMS) vs 192 (FMI), and capable of radial microresistivity measurements (vertical resolution 0.2”, vertical sampling: 0.1”, depth of investigation: 30”; These tools can be used in a wide variety of geological and drilling environments, providing borehole images of rock 4DIMVNCFSHFS'.*QBE 1BEBTTFNCMZ CVUUPOT 1BE Y CVUUPOT )JOHFEGMBQ Y CVUUPOT '.4'.*TFOTPSBSSBZEFUBJM 3PX 3PX 4FOTPSCVUUPOEFUBJM 4DIMVNCFSHFSQBET'.4 NJDSPSFTJTUJWJUZ Schlumberger, Ltd., 1994). The wireline acoustic tools (or acoustic televiewer, ATV) send sound pulses out to the formation and measure both the amplitude and the travel time of the returning signals (Fig. 1B). Because ATVs rely on sound pulses, they can work in resistive (oil based) muds, where electrical conductivity is very poor. Their disadvantages when compared to electrical images are a heightened sensitivity to borehole roughness or washouts and a generally poorer quality image overall in part or all of some holes. One example is the Schlumberger Ultra Sonic Borehole Imager (UBI): azimuthal resolution: ~2°; vertical resolution from 0.2” to 1.0” depending on pulse frequency (500 to 250 kHz); depth of investigation: borehole wall). *OTVMBUJPO "GUFSEFQUITIJGUJOH &MFDUSPEFCVUUPO )JOHF " $PNQFOTBUJOHEFWJDF .PUPSBTTFNCMZ (FBSCPYBTTFNCMZ 3PUBSZFMFDUSJDBMDPOOFDUJPO "DPVTUJDFOFSHZ 'JSFQVMTF $FOUSBMJ[FS 'PSNBUJPO $ 5SBOTEVDFS # &DIP "NQMJUVEF 3PUBSZTFBM 5SBWFMUJNF 5SBOTEVDFS SQT 0SJFOUBUJPO TZTUFN "DPVTUJD USBOTEVDFS 3PUBUJOH NJSSPS .PUPS $$% DBNFSB 3FGMFDUPS 3JOHPG MJHIUT Figure 1. Schematic of electrical, acoustic and optical imaging tools. [A] Schlumberger Formation MicroScanner (FMS) with four pads, 16 buttons each pad, covering 25%-40% of hole diameter and Schlumberger Fullbore Formation MicroImager (FMI) with four pads and four hinged flap and 24 buttons on each pad and flap. The hinged flap is able to increase coverage of up to 80% (Modified from Ekstrom et al., 1987; Schlumberger, 1994). The individual buttons are aligned in two rows; processes for depth corrections shift the recorded resistivity to one row. Each button consists of an electrode surrounded by an insulation. [B] The Ultrasonic Borehole Imager features a high-resolution transducer that provides acoustic images of the borehole wall. The transducer emits ultrasonic pulses at a frequency of 250 or 500 kHz (low and high resolution, respectively), which are reflected by the borehole wall and then received by the same transducer. Amplitude and traveltime of the reflected signal are then determined. [C] Optical televiewers generate a continuous oriented 360° image of the borehole wall unwrapped using an optical imaging system (downhole CCD camera which views a reflection of the borehole wall in a conic mirror-sketch of advanced logic technology ALT OB140). Like electrical imaging tools and acoustic televiewers, the optical televiewers include a full orientation device consisting of a precision 3 axis magnetometer and 2 accelerometers thus allowing for both accurate borehole deviation data to be obtained during the same logging run, and for accurate and precise orientation of the image. Scientific Drilling, No. 5, September 2007 Table 1. Tectonic, sedimentary and diagenetic features usually recognized on borehole images. Tectonic Sedimentary Diagenetic Self-evident Structural dip Natural Fractures Drilling induced fracture/ breakout Folds Stylotites (high amplitude peaks) Ambiguous Faults Bedding surfaces Laminations Cross-bedding Grading Erosional surfaces Deformation features Lithology changes Cobbles, pebbles, Breccia Detrial shales, ripples Cherts Bioturbation Grain size/texture Bioturbation Thin lamination Limestone textures Vugs Needs Core Small fractures Horizontal fractures and fluid properties in formations ranging from fractured / karstic carbonates to soft, thinly laminated sand/shale sequences. High resolution and often nearly complete borehole coverage images are interpreted at an interactive graphics workstation. When the image is “unrolled” and displayed from 0° to 360°, linear features intersecting the borehole appear as sinusoids (Rider, 1996). Assuming that the images are properly oriented to geographic north, the amplitude and minimum of the sinusoids can be related to the dip and azimuth of the associated feature, respectively, and consequently provide fundamental information regarding the encountered formation (Fig. 2). Bedding, fracture features, faults, stratigraphic features, and many other features can often be manually or (semi-) automatically identified and quantified (Ye and Rabiller, 1998). In addition to identifying fractures and faults, borehole imaging tools are routinely used in support of detailed core analysis for a variety of other applications such as sequence stratigraphy, facies reconstruction, stratigraphy, and diagenetic analysis (Table 1). E 0 90 180 270 Stylotites (low amplitude peaks) In a general manner, electrical images appear to be sensitive to variations in mineralogy, porosity, and fluid content that highlight both natural fractures and rock fabrics. Acoustic image logs reveal a similar natural fracture population, but generally image slightly fewer fractures and do not reveal rock fabric due to their lower resolution. However, due to their full coverage, acoustic images can reveal drillinginduced borehole wall tensile fractures, breakouts, and petalcenterline fractures (Fig. 3). Both images can record textural properties of deformed materials within fractures; these textures can be related to variations in mineralogy, alteration, or porosity using the electrical log and can be used to infer slip history. Drilling-induced fractures, breakouts, and petal-centerline fractures that are thought to form just ahead of the drill bit then provide additional constraints on the orientation of the minimum horizontal regional stress (Zoback et al., 1985). MN N Nodular concretions Amplitude A�V �wo-way MN �raveltime FMS �N Paired tensile cracks 360 Image log 5 ft h d N E S W N Figure 2. Projection of a planar intersection with a cylindrical borehole. Dip direction of the planar feature is given by the orientation of the sinusoid minimum; dip angle = arctan (h/d) where h = height of sinusoid and d = borehole diameter. Paired breakouts Figure 3. Borehole wall tensile fracture and breakouts in acoustic televiewer (AT V). [A] amplitude, [B] travel time images, and [C] Formation MicroScanner (FMS) electrical images The ATV and FMS logs are oriented with respect to magnetic North (MN) and true (TN), respectively (Modified from Zoback et al., 1985). Scientific Drilling, No. 5, September 2007 Rate (m/H) 0 to 40 Pullback pressure (bar) 0 to 40 Torque (bar) 0 to 100 Core Core Depth (m) Technical Developments 65 66 67 68 Figure 4. Integration of optical and acoustic image logs with drilling parameters and digital line scan image of cores from IODP Expedition 310 (Tahiti sea level) Hole M0005D. Example of repositioning core to its correct position in relation to the log-drill datasets. If no attempt if made to position core data accurately, errors are in proportion to the percentage of recovery per length of core drilled. Thus potential errors increase around voids where recovery is lower, especially as core may be collected by subsequent drill runs (Figure courtesy of Jenny Inwood). Wireline slim-hole imaging tools: In the framework of fractured-rock and karstic aquifer studies, slim borehole-wall imaging has undergone significant advancements since Paillet et al. (1990) provided a state-of-the-art overview. Due to their small diameter and advanced �������������������������������� focusing system (acoustic reflector and rotating mirror), s������������������������� limhole ATVs and optical televiewers (OTVs) offer incredibly high azimuthal and vertical resolution (e.g. Advanced Logging Technology televiewers: acoustic borehole imager (ABI40) and optical borehole imager (OBI40); azimuthal resolution: 1° or less, vertical resolution: 1 mm). �������������������������������������� ATV slim-hole tools use an ultrasonic pulse-echo configuration with a 0.5–1.5 MHz transducer (Fig. 1B). The transit time and amplitude of the reflected Scientific Drilling, No. 5, September 2007 acoustic signal are recorded as photograph-like images, and the transit-time data can be used to generate high-resolution caliper logs.�������������������������������������������������� OTV tools use a ring of lights to illuminate the borehole, a CCD (charge-coupled device) camera, and a conical or hyperbolic reflector housed in a transparent cylindrical window (Fig. 1C). The CCD camera measures the intensity of the color spectrum in red, green, and blue. If the medium is transparent (air or clean water), the reflector focuses a 360° slice of the borehole wall in the camera’s lens. Like industry-standard wireline imaging tools, slim-hole� OTV and ATV provide high-resolution, continuous, and oriented 360° views of the borehole wall from which the character, relation, and orientation of lithologic and structural planar features can be defined. The combined application of optical and acoustic imaging provides critical information for water-supply development and source-water protection, as well as characterization and remediation of contamination of water reservoirs (Cunningham et al., 2004). Such types of televiewers have been successfully used in IODP Expedition 310 to image Tahiti Pleistocene-Holocene reefs (Camoin et al., 2005). There, imaging of the borehole wall using acoustic and optical geophysical methods complimented the sedimentological work and allowed an unambiguous correlation of cores (coral assemblages), core logs (Multi-Sensors Core Loggers), downhole logs, and drilling parameters resulting in a more precise depth assignation of core sections (Fig. 4) and proper identification of macro-porosity regions and estimation of true core recovery. Logging While Drilling (LWD) imaging tools: Back to oilbusiness industry standards, a major step in downhole geology includes logging while drilling, or LWD, where the formation properties are measured just after they have been drilled. Electrodes on a rotating LWD collar produce 360° images of the formation resistivity. These images can be analyzed in real time by geologists and the driller to make timely decisions about difficult drilling operations (unstable hole conditions). The Resistivity at Bit (Schlumberger RAB) tool is one of the LWD tools that can provide azimuthal-oriented images of the borehole. Connected directly to the drilling bit, this tool uses its lower portion and the bit as a measuring electrode. Button electrodes provide shallow, medium, and deep resistivity measurements as well as azimuthally oriented images acquired as the RAB rotates, with a ~6º resolution. Low resolution (16 azimuthal sectors, with one-foot axial resolution) density images can also be measured by the rotating LWD collar. Such LWD resistivity and density images were used to estimate the concentration of gas hydrate in several boreholes drilled in the vicinity of Hydrate Ridge during ODP Leg 204 (Tréhu et al., 2003). Density at azimuthal positions and formation resistivity around each borehole as a function of depth were used to compute porosity and water (Sw) and hydrate (1-Sw) saturation, respectively, at each azimuthal position in these holes. The results allow for delineation of the shape, geometrical distribution, and azimuthal orientation of the porous sediment structures that are saturated with gas hydrate as a function of depth. This 360° approach contrasts with conventional methods that use wireline logs or core data and produces a single saturation value at each measurement depth. In addition, LWD data are acquired only minutes after the formation is drilled, limiting the extent of hydrate dissociation on the measured in situ properties resulting into a significant increase of the understanding of the original spatial distribution of hydrate in these formations (Janik et al., 2003). References Camoin, G.F., Iryu, Y., McInroy, D.B., and the Expedition 310 Scientists, 2005. Expedition 310 of the mission-specific drilling platform from and to Papeete, Tahiti, French Polynesia - Sites M0005–M0026 ; Proc. IODP 310, ISSN WWW 1930-1014 (http://publications.iodp.org/ proceedings/310/310toc.htm). Cunningham, K.J., Carlson, J.I, and Hurley, N.F, 2004. New method for quantification of vuggy porosity from digital optical borehole images as applied to the karstic Pleistocene limestone of the Biscayne aquifer, southeastern Florida. J. Appl. Geophys., 55:77–99, doi:10.1016/j.jappgeo.2003.06.006. Ekstrom, M.P., Dahan, C., Chen, M.-Y., Lloyd, P., and Rossi, D.J., 1987. Formation imaging with microelectrical scanning arrays. Log Analyst, 28:294-306. Haggas, S., Brewer, T.S., Harvey, P.K., and Iturrino, G., 2001. Relocating and orienting cores by the integration of electrical and optical images: a case study from Ocean Drilling Program Hole 735B. J. Geol. Soc. (London, U.K.), 158:615–623. Janik, A., Goldberg, D., and Collett, T., 2003. Azimuthal variability in gas hydrate concentration using LWD resistivity and density images. EOS Trans. AGU Suppl., 84(46) abstract #OS51C–0875. Paillet, F.L., Barton, C., Luthi, S., Rambow, F., and Zemanek, J.R., 1990. Borehole imaging and its application in well logging— an overview. In Paillet, F.L., Barton, C., Luthi, S., Rambow, F., and Zemanek, J.R. (Eds.), Borehole Imaging, Houston, Ye, S.-J., and Rabiller, P., 1998. Automated fracture detection on high resolution resistivity borehole imagery, SPE-49300, in 1998 SPE annual technical conference and exhibition proceedings, v. pi, Production operations and engineering/general: Society of Petroleum Engineers, p. 777–784. Zoback, M.D., Moos, D., Mastin, L., and Anderson, R.N., 1985. Well bore breakouts and in situ stress, J. Geophys. Res., 90(B7): 5523–5530. Authors Philippe Gaillot, CDEX (Center for Deep Earth Exploration)—IFREE (Institute for Research on Earth Evolution), JAMSTEC (Japan Agency for Marine-Earth Science and Technology), Yokohama Institute for Earth Science, 3173-25 Showa-machi, Kanazawa-ku, Yokohama, Kanagawa, 236-0001 Japan, e-mail: gaillotp@jamstec.go.jp. Tim Brewer, Department of Geology – Geophysics and Borehole Research, University of Leicester, University Road, Leicester, LE1 7RH, U.K. Philippe Pezard, LGHF (Laboratoire de Géophysique et d’Hydrodynamique en Forage) – Geosciences Montpellier, University of Montpellier 2, France. En-Chao Yeh, Department of Geosciences, National Taiwan University, No.1, Sec. 4, Roosevelt Road., Taipei 106, Taiwan. Related Web Links http://publications.iodp.org/proceedings/310/310toc.htm http://www-odp.tamu.edu/publications/176_IR/176TOC. HTM http://www.scec.org/instanet/01news/es_abstracts/Iturrino_et_al.pdf Texas, (Scociety of Professional Well Log Analylsts), pp. 3–23. Rider, M.H., 1996. The Geological Interpretation of Well Logs, (Second Edition): Cambridge, England (Rider-French Consulting,Ltd). Schlumberger, Ltd., 1994. FMI Fullbore Formation MicroImager: Houston, Texas (Schlumberger Educational Services). Tréhu, A.M., Bohrmann, G., Rack, F.R., Torres, M.E., Bangs, N.L., Barr, S.R., Borowski, W.S., Claypool, G.E., Collett, T.S., Delwiche, M.E., Dickens, G.R., Goldberg, D.S., Gràcia, E., Guèrin, G., Holland, M., Johnson, J.E., Lee, Y.-J., Liu, C.-S., Long, P.-E., Milkov, A.V., Riedel, M., Schultheiss, P., Su, X.., Teichert, B., Tomaru, H., Vanneste, M., Watanabe, M., Weinberger, J.L., 2003. Proc. ODP, Init. Repts., 204: College Station, Texas (OCean Drilling Program), doi:10.2973/odp. proc.ir.204.2003. Scientific Drilling, No. 5, September 2007