Additional file 1 - Earth, Planets and Space

advertisement

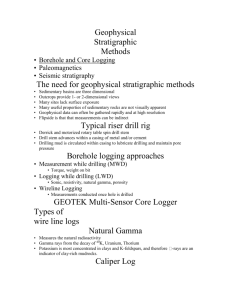

1 (“Additional file 1”): The Nobeoka Thrust Drilling Project Coring and Logging 2 Operation-Methodology for Core-log Integration 3 4 Drilling and coring down to 255 m depth across the Nobeoka Thrust was conducted 5 from 27 July to 15 September 2011 by Sumiko Resources Exploration & Development, 6 Co., Ltd (SRED). Prior to coring, the S-wave velocity structure of the study area was 7 investigated using a micro-tremor survey to determine the depth of the fault zones and 8 to select casing programs and coring techniques. Cores with a diameter of 86 mm were 9 retrieved with 99.81% recovery. The azimuths of the cores were measured during 10 drilling, and reference lines were marked on every core. Cores were then scanned with a 11 digital camera and set out for visual observation at the drilling site. Lithological 12 descriptions and structural analyses of cleavage, fractures, faults, mineral veins, bedding, 13 and folding were conducted for every 1-m core. Image fitting of the cores and the 14 borehole wall was carried out to better determine core orientation, eliminating the effect 15 of rotation due to drilling. 16 Geophysical wireline logs were acquired continuously across the Nobeoka Thrust 17 along the borehole at a depth of 11.5–254.5 m during 17–18 September 2011 by SRED 18 and Raax Co., Ltd. The logging recorded neutron porosity, resistivity, acoustic wave 19 velocity (Vp, Vs), natural gamma rays, density, caliper, spontaneous potential, and 20 temperature for every 10 cm. Acoustic and optical images were obtained along the 21 borehole to evaluate the presence of bedding, fractures, and faults. 22 The neutron logging tool (SYSTEM VI, CNL-9073) measures neutron porosity 23 values, in which neutrons are emitted into the formation from a source (AmBe241; 16 24 Cu, ~5 MeV), and detectors at short and long distances from the neutron source (32.4 25 cm and 61 cm, respectively) measure the attenuation of the neutrons [Ellis and Singer, 26 2007]. Neutrons emitted from a source collide with various atoms and become 27 attenuated, losing energy by releasing gamma rays. Since neutrons lose the most energy 28 when they collide with hydrogen, which is nearly the same weight as the neutrons (i.e., 29 the billiard effect), the measured energy loss may be caused by pores filled with 30 hydrogen compounds such as water, oil, and gas. Thus, porosity is calculated from the 31 measured attenuation by neutron signals. The sensor that measures the intensity of total 32 natural gamma rays (NGR) from the formation is combined with the neutron porosity 33 logging tool. When radioactive materials such as 34 gamma radiation with a unique energy spectrum is emitted. The NGR detector consists 35 of a sodium iodide (NaI) scintillator through which the gamma rays pass to be detected. 36 Energy windows measure each spectrum, and applications such as the indication of 238 U, 232 Th, and 40 K isotopes decay, 37 shaliness and the classification of lithology are possible. 38 The resistivity log (ELM-204, SCM-304) was obtained from the electrical survey, 39 which consists of two electrodes (>150 V, 0–50 mA) lowered down the borehole, from 40 which currents (>20~300 Hz, shortwaves) travel through the stratum. The two 41 electrodes are connected to an ammeter and voltmeter on the ground, respectively, 42 detecting the current and voltage. The equipotential surface around the ammeter would 43 ideally be a sphere, and resistivity is obtained from Ohm’s Law. The measurement depth 44 can be controlled by changing the distance L between the two electrodes and the radius 45 of the equipotential sphere. In this measurement, two types of resistivity (long normal 46 [LN] resistivity and short normal [SN] resistivity) were obtained, corresponding to L = 47 100 cm and L = 25 cm, respectively, in which the electric current travels a longer 48 distance (LN) and shorter distance (SN). Although LN measurements can measure 49 greater depths, the vertical resolution is relatively lower compared to SN measurements. 50 The acoustic log (MATRIX Logger, FWS 50) calculates acoustic wave velocity by 51 the travel time difference between first arrivals of primary waves from three receiver 52 points; 80, 120, and 160 cm from a single transmitter. Here, an electric monopole source 53 generates a pressure wave (>25 kHz) that impinges on the borehole wall and causes a 54 flexural wave to propagate through the wall. Since shear waves cannot be transmitted in 55 water, the S-wave velocity can be detected only when its velocity is above the acoustic 56 velocity through water (~1.5 km s-1) where rocks do not have major voids and fractures. 57 Four sets of arrival points of the same phase were picked for each depth, and an 58 approximated line was fitted using a least-squares method to obtain wave slowness and 59 velocity. 60 The density log tool (SYSTEM VI, CDL-9139) consists of a gamma ray transmitter 61 for a Cs137 (1.7 Cu, 662 keV) source, which shoots gamma rays into the formation and 62 far-field and near-field detectors (30.9 cm and 14.9 cm from the transmitter, 63 respectively) that measure the attenuation of the gamma rays as counts per second in the 64 region near the borehole at each depth. Gamma rays shot into a material will lose energy 65 due to collisions with electrons (known as “Compton scattering”). The coefficient of 66 attenuation is linear with the density of the electrons. The coefficient corresponds to the 67 formation density, and thus density is obtained from the log-linear relationship with the 68 counts measured in the two detectors (near, far). The transmitter and detectors are 69 attached directly to the borehole to minimize the effect of mud water, and a caliper arm 70 of the tool extends to the other end of the borehole, measuring the caliper at the same 71 time. An electrode that measures another type of resistivity called guard resistivity (GD) 72 is also included in the density log tool. 73 Optical and ultrasonic wave images were scanned through the BIP-V system 74 operated by SRED and Raax. The optical scanner digitally recorded 360° borehole 75 images with measured azimuth using an optical camera and a specialized mirror 76 included in the probe. A beam of ultrasonic waves helically scans the borehole wall at a 77 frequency of 1 MHz, recording the reflectance time and strength along the borehole wall. 78 The optical images were then analyzed using the imaging tool “BIPS Image Viewer” 79 and the structural analysis tool “StereoWin” (trademarked by Raax) to measure the dip 80 directions and dip angles of fractures, faults, mineral veins, cleavage, bedding, and 81 breccia seen within the image. 82 Core images were laid out side-by-side with logs and borehole images to produce a 83 visual correlation between core and log data. Thus, better determination of in situ or 84 drilling-induced structures and calibration of depth and core orientation eliminating the 85 effect of rotation due to drilling are possible. The precise location of the fault core (the 86 boundary between the hanging wall and footwall) was recognized at ~41 m below the 87 ground surface by comparing the lithology and structures observed in surface outcrops 88 and cores, and is also shown clearly by the contrasts in geophysical logs (Hamahashi et 89 al., 2013).