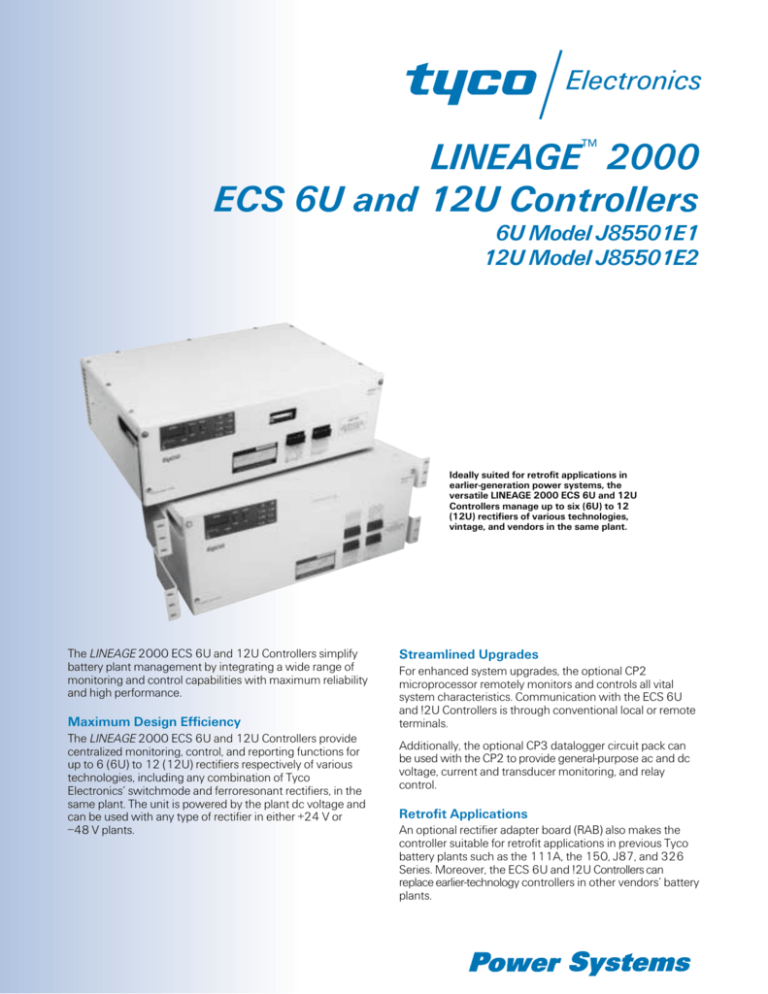

LINEAGE™ 2000

ECS 6U and 12U Controllers

6U Model J85501E1

12U Model J85501E2

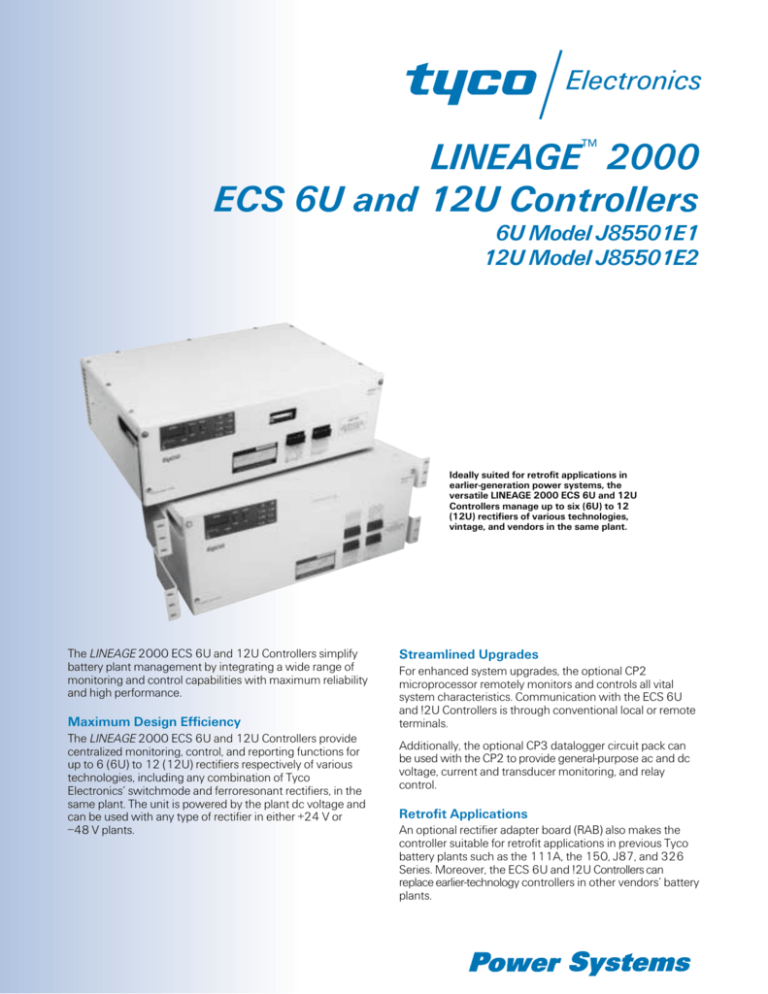

Ideally suited for retrofit applications in

earlier-generation power systems, the

versatile LINEAGE 2000 ECS 6U and 12U

Controllers manage up to six (6U) to 12

(12U) rectifiers of various technologies,

vintage, and vendors in the same plant.

The LINEAGE 2000 ECS 6U and 12U Controllers simplify

battery plant management by integrating a wide range of

monitoring and control capabilities with maximum reliability

and high performance.

Maximum Design Efficiency

The LINEAGE 2000 ECS 6U and 12U Controllers provide

centralized monitoring, control, and reporting functions for

up to 6 (6U) to 12 (12U) rectifiers respectively of various

technologies, including any combination of Tyco

Electronics’ switchmode and ferroresonant rectifiers, in the

same plant. The unit is powered by the plant dc voltage and

can be used with any type of rectifier in either +24 V or

–48 V plants.

Streamlined Upgrades

For enhanced system upgrades, the optional CP2

microprocessor remotely monitors and controls all vital

system characteristics. Communication with the ECS 6U

and !2U Controllers is through conventional local or remote

terminals.

Additionally, the optional CP3 datalogger circuit pack can

be used with the CP2 to provide general-purpose ac and dc

voltage, current and transducer monitoring, and relay

control.

Retrofit Applications

An optional rectifier adapter board (RAB) also makes the

controller suitable for retrofit applications in previous Tyco

battery plants such as the 111A, the 150, J87, and 326

Series. Moreover, the ECS 6U and !2U Controllers can

replace earlier-technology controllers in other vendors’ battery

plants.

Benefits

■

■

■

Simplified System Management

— Efficiently handles plant control,

monitoring, power alarm, and

status and reporting functions

through a centralized point of

operation.

■

Dip-switch settings for battery-ondischarge alarm, float/equalize highvoltage shutdown, and meter scaling

■

Automatic rectifier restart and reserve

ac engine transfer capability

Easy Installation and Maintenance

— Simplifies system setup and

servicing with modular and frontaccess design, connectorized

rectifier interface, and plug-in circuit

boards.

■

High-voltage shutdown testing

■

System normal and alarm LEDs,

major and minor fuse alarms, alarm

interface (form-C)

Fail-Safe Alarm System

— Responds instantly with alarms for

overcurrent, under/overvoltage,

open battery strings and battery on

discharge, minor/major fuse, and

ac and rectifier failure.

— Interfaces with standard office

alarms.

— LEDs indicate both normal status

and alarm status.

For plants requiring even more

sophisticated management capabilities,

the Controllers can be upgraded with

optional microprocessor and

datalogger circuit packs for enhanced

system features.

■

High Reliability

— Compatible with Bellcore technical

requirements and advisories.

■

Continuous Operation

— Loss of controller power, circuit

board removal/upgrade, or other

field maintenance will not disrupt

service to plant loads.

Features

■

Front-access design

■

The ECS 6U Controller monitors and

controls up to six rectifiers, and the

ECS 12U Controller monitors and

controls up to 12 rectifiers

■

Connectorized rectifier interface

■

Operate with or without batteries

(depending on rectifier capabilities)

■

Illuminated digital metering (±0.05%

voltmeter and ±0.5% ammeter

accuracy

■

Local initiated equalize charging

■

Extensive Statistical/Historical

Recording

— In-depth historical information,

including up to 128 plant and 50

rectifier alarm events, 12 equalize

charging events, and 16 control

relay status changes (sorted by

alarm type or date)

— Plant-load current statistics, hourly,

weekly, and monthly

— Plant voltage and current during

battery discharge

— Hourly average load currents over

any user-programmable 24-hour

period

— Datalogger channels statistics

— Historical data on installed power

equipment

■

Comprehensive Communications

— RS-232 port for local terminal or

printer

— Modem (300 bits per

second/1200 bits per second) and

RJ11 phone jack for remote

communications

— Pass-through communications to

the Microprocessor Control System

controller, the Remote Access

system, the OMNIpulse® system,

and the Intelligent Reserve Unit

— Periodic dial-out automatically

delivers plant statistics and

histories and datalogger readings

and statistics

— Automatic dial-out on occurrence

or retirement of alarms

— User-assigned alarms, delays, and

telephone numbers (compatible

with beepers)

— Note pad for message exchange by

maintenance personnel

Options

The additional capabilities can include

remote control, voice-response options,

system diagnostics and statistics,

general-purpose voltage and current

monitoring, and programmable control

relays.

Shunt isolator circuits and order wire

boards are available for use with certain

application-specific configurations.

Microprocessor (CP2)

■

Advanced System Management

— User-friendly, menu-driven software

— Multiple security levels: callback,

user, and superuser

— Remote rectifier surveill

capabilities (ON/STANDBY/

FAILURE modes)

— Remote rectifier ON/STAN

control*

— Remote equalizer control or b

charge initiation*

— Programmable for autom

maintenance reminders

— Rectifier sequence co

(facilitates transfer to an ac engine

alternator and allows userselectable delay times to sequence

ON/OFF states for individual

rectifiers or groups of rectifiers)

* These features can be hardware enabled/

disabled.

Datalogger (CP3)

■

General-Purpose Monitoring/Control

— Sixteen analog data-monitoring

channels with multiple range

(150 mV, 6 V, 60 V, and 150 V),

polarity, voltage selections (+dc,

–dc, and ac), and userprogrammable scale factors and

alarm thresholds

— Extensive alarm history and

statistical history on alarm

channels

— Eight form-C relay contacts with

programmable control logic for use

when generating alarms or

activating/deactivating other

equipment

— On/off control relay history (up to

16 events recorded per relay)

AKC1 Shunt Isolator Circuit

Pack

■

The AKC1 is required when the plant

shunt is located in the hot lead of the

discharge bus. Early Tyco plants and

some commercial plants have the

plant shunt in the hot lead. All Tyco

plants have the shunt in the ground

lead and do not require the AKC1

shunt isolator circuit pack.

The modular, front-access ECS 6U and 12U Controllers simplify

installation and maintenance and allow for convenient circuit-board

upgrades without interrupting service.

248A Order Wire Board

■

The 248A provides ringing to the

modem in the J85501E2 Controller.

It provides the ringing when a

contact closure is sent to the 248A

board from the order wire or an

equivalent system and eliminates the

need for a dedicated phone line.

This option should be ordered only

when the controller will be monitored

over the FT-Series G or a similar

embedded maintenance system.

LINEAGE 2000 ECS 6U and 12U Controllers, Model J85501E1 and J85501E2 Specifications

Battery Plant Alarm Voltage Ranges

High-Voltage Shutdown Thresholds

(adjustable to 0.5 V increments)

Equalize High-Voltage Shutdown

Thresholds (adjustable to

0.5 V increments)

Battery-On-Discharge Thresholds

(adjustable to 0.5 V increments)

Electrical and Thermal Specifications

Float Voltage Range

Operating Voltage Range

Input Power Range

Display Meter (four-digit, backlit LCD)

Range:

Voltmeter

Ammeter

Accuracy:

Voltmeter

Ammeter

Resolution

Plant Shunt

Alarm Contact Rating

Temperature

Physical Specifications

Height

Width

Depth

Weight

Frame Mounting Requirements,

Standard 23 in. and 26 in. Relay Rack:

Vertical Mounting Centers

Horizontal Mounting Centers

Environmental Specifications

Altitude

48 V Plant

Range

Accuracy

49.0 V to 60.0 V

±0.5 V

24 V Plant

Range

Accuracy

24.7 V to 29.75 V

±0.25 V

51.0 V to 60.0 V

±0.5 V

25.75 V to 30.75 V

±0.25 V

46.0 V to 57.5 V

±0.5 V

23.0 V to 28.50 V

±0.25 V

47.0 Vdc to 58.5 Vdc (48 Vdc nominal)

23.5 Vdc to 29.0 Vdc (24 Vdc nominal)

40.0 Vdc to 60.0 Vdc (48 Vdc nominal)

20.0 Vdc to 30.0 Vdc (24 Vdc nominal)

8 W to 16 W (depending on options)

0.00 V to ±60.00 V

0.0 A to 8000.0 A

±0.05% of full-scale reading

±0.5% of full-scale reading

±0.1 A for <1000 A

±1.0 A for >1000 A

50 mV at 300 A, 600 A, 1200 A, 2000 A, 2600 A,

4000 A, 6000 A, or 8000 A

60 Vdc, 1.0 A, form-C

0 °C to 50 °C (32 °F to 122 °F)

12U

9.0 in. (229 mm)

21.5 in. (546 mm)

15 in. (381 mm)

38 lb. (17.3 kg)

6U

7.0 in. (178 mm)

21.5 in. (546 mm)

15 in. (381 mm)

14 lb. (6.4 kg)

1.0 in. (25 mm)

22.32 in. (567 mm) for 23 in. (584 mm) rack mount

24.32 in. (618 mm) for alternate 26 in. (660 mm) rack mount

Humidity

–200 ft. to +13,000 ft. (–61 m to +3962 m)

For altitudes of 5000 ft.—13,000 ft., derate maximum temperature by

3.6 °F per 1000 ft. above 5000 ft.

For altitudes of 1524 m—3962 m, derate maximum temperature by

0.656 °C per 100 m above 1524 m

10% to 95% noncondensing

Safety/Standards Compliance

Electrostatic Discharge

Radiated and Conducted Emissions

Electromagnetic Immunity

IEC 801-2 Level 5 (15 kV) at 20% relative humidity

FCC Level A

10 V/m over the range of 20 MHz—2000 MHz

Outline Drawings

15 in.

(381 mm)

21.5 in.

(546 mm)

7 in.

(178 mm)

LINEAGE 2000 ECS 6U Controller Model J85501E1

15 in.

(381 mm)

21.5 in.

(546 mm)

9 in.

(229 mm)

LINEAGE 2000 ECS 12U Controller Model J85501E2

Ordering Information

For ordering information or assistance, please contact your Tyco Electronics Energy Solutions sales representative.

Tyco Electronics Power Systems, Inc.

3000 Skyline Drive, Mesquite, TX 75149, USA

+1-8

800-5

526-7

7819 FAX: +1-888-315-5182

972-2

284-2

2626, FAX: +1-972-284-2900)

(Outside U.S.A.: +1-9

http://power.tycoelectronics.com

Tyco Electronics Corporation reserves the right to make changes to the product(s) or information contained herein without notice. No liability is assumed as a result of

their use or application. No rights under any patent accompany the sale of any such product(s) or information.

©2001 Tyco Electronics Corporation, Harrisburg, PA. All International Rights Reserved.

Printed in U.S.A.

DS00-034LIN (Replaces DS97-461LIN and DS98-173LIN)

Printed on

Recycled Paper