Occupational Health and Safety Management Systems

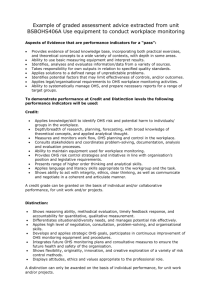

advertisement