Development of a boundary layer control device for tip clearence

advertisement

Ni-.

^.f

.'

MOKTE:.:

SGHOQTj

.;:A9394S-500S

J

NAVAL POSTGRADUATE SCHOOL

Monterey, California

THESIS

DEVELOPMENT OF A BOUNDARY LAYER

CONTROL DEVICE FOR TIP CLEARANCE EXPERIMENTS

IN AN AXIAL COMPRESSOR

1

by

Muliukur Tarigan

March 1988

Thesis Advisor

Approved for public release;

R

P.

Shreeve

distribution is unlimited.

T239283

REPORT DOCUMENTATION PAGE

RESTRICTIVE

MARKINGS

UNCLASSIFIED

'

c\ A^'-o=t

-

DISTRIBUTION AVAILABILITY OF REPORT

3

Approved for public release;

distribution is unlimited.

30.V\GRAD \G 5C-ED^.E

'

CNi

^E^CR' \^V3ER(S)

MONITORING ORGANIZATION REPORT NUMBER(S)

5

7a

Naval Postgraduate School

C

-2i;-E55

sraZPCoae)

Stare

ty

Monterey, California

7b

93943-5000

ADDRESS (Cfy

dude

andZlPCoae)

Stare

Security

'ERSC\A, A.--C=

State,

(C/fy,

and ZIP Code)

93943-5000

PROCUREMENT INSTRUMENT IDENTIFICATION NUMBER

TO

dassitication)

ADDRESS

Monterey, California

9

3c

NAME OF MONITORING ORGANIZATION

Naval Postgraduate School

SOURCE OF FUNDING NUMBERS

DEVELOPMENT OF A BOUNDARY LAYER CONTROL DEVICE FOR TIP

CLEARANCE EXPERIMENTS IN AN AXIAL COMPRESSOR.

S

TARIGAN, MULIUKUR

DATE OF REPORT

4

{Year,

Month, Day)

15

PAGE COUNT

Master's Thesis

3^ = = -£VE\*A3' \G'A'o\ The views expressed in this thesis are those of the author and do not

reflect the official policy or position of the Department of Defense or the United States

Government.

"8

SuBjECT TERMS {Continue on reverse

if

necessary

and

identify by block

number)

Boundary Layer Spires, Axial Compressor, Case-Wall

Boundary Layer Control

i

-3S" = AC"

Cornrue on reverse

if

necessary

and

identify by block

number)

boundA boundary layer control device was designed to change significantly the case-wall

The device was

ary layer thickness entering a large-scale, multistage axial compressor.

intended to double the boundary layer thickness in order to evaluate the influence of the

inlet boundary layer in controlled tip clearance experiments being conducted on the

compressor.

The boundary layer characteristics expected to be produced by the control

Kiel, cobra,

device were predicted empirically and experimental verification was required.

and impact probes were used in the experiments and pressures were recorded manually using

water manometers. The geometry of the boundary layer control device, an annular array of

spires, was derived from shapes developed for simulating the atmospheric boundary layer in

A significantly thicker boundary layer was measured

large rectangular section wind tunnels.

However, the results were interpreted and recommendain the compressor than was intended.

tions were made for geometry changes necessary to achieve the intended control for the tip

clearance investigation.

S-= 3.'

ON AvA ,AS

.\C.ASS- ED

-^N. V:"

OF ABSTRACT

SAME AS RP

21

n

D DTIC

22b TELEPHONE f/nc/ude Area Code)

/E O- 3ESP0NS BlE

1473,

:2c

a

1

ton may be used

until

exhausted

OFFICE

SYMBOL

67Sf

408/646-2593

SHREEVE

DDFORM

ABSTRACT SECURITY CLASSIFICATION

UNCLASSIFIED

USERS

SECURITY CLASSIFICATION OF THIS PAGE

otner editions are obsolete

UNCLASSIFIED

Approved for Public Pele^.se;

Development of

a

list ribut ion

is

unli-riite'i

noundarv T^aver Control Pevice

in an Axial Conpressor

tor Tip Clearance experiments

B.S.,

''luli'.ikur Tariqan

Major, Indonesian Mr Force

Indonesian Air Force Acade^iy,

1966

Subrnitted

in partial fultill^ient of the

requirements for the deqree of

MASTE]R OF SCIENCR

IT.'

AE^ONAfJTIC A L FNCU MFF PI ^IG

NAVAL POSTGPADUATF SCF^OOL

iMarch

1988

boundary

A

layer control device was designed

significantly the case-wall boundary layer

ina

was

a

to change

thickness enter-

large-scale, nultistaae axial compressor.

The device

intended to double the boundary layer thickness in order

to evaluate

the

influence of

the

inlet

boundary

layer in

controlled tin clearance exoer iments being conducted

coniDressor. The

boundary layer characteristics

on

the

expected to

be oroduced by the control device were nredicted empirically

and experimental

verification was

and impact probes were used

in

reguired.

were recorded manually using water manometers.

of

the boundary

layer control

Kiel,

cobra,

the experiments and pressures

The geometry

device, an annular

array of

soires, was derived from shapes developed for simulating the

atmospheric boundary layer in large rectangular section wind

tunnels. A significantly thicker boundary layer was measured

in

the compressor than was

intended.

However,

were interpreted and recommendations were made

changes necessary

tin clearance

to achieve

investigation.

the results

for geometry

the intended control

for the

r

r^'TRODUCTinM

.

I

CO'^^PPES^OR A^tD OPrpATTpM

IT.

^.

rx

ITT

.

B.

IV.

r-;M[->nj^c,.,.^p

p-qpoi

p.oriMpapY

A.

>^

r«ip;N'T'xTT^'^:

^

aH

r^

nA^^

r^..-^ r

,-_

p r-y j

n ^f

LAVFP CO^TPOL nrviCF

r^Fqrc-i

i^:tfnt

i.

Re'7;.'

2.

Oesiqn

ir^nent.s

s<

Aporoach

CONSTRUCTTO^

TEST PROGRAM!

1

2]^

22

26

28

28

B.

STATIC PRESSURE DISTRIBUTION MEASUREMENTS

31

C.

BOUNDARY LAYER flEASUPEflENTS

31

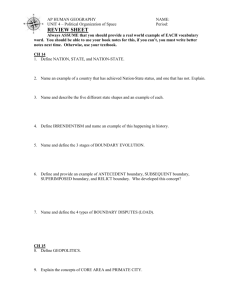

ANALYSIS AND DISCUSSION

3g

A.

CALCULATION OF DISPLACEMENT THICKNESS

36

B.

COMPARISON WITH DESIGN INTENT

39

C.

VI.

]_

9

21

PRELiniMAPY TEST

V.

ji

1.

Poundary Layer Thickness

2.

Profile Shape

3.

Other Considerations

ACHIEVING THE REQUIRED CONTROL

CONCLUSIONS AND RECOMMENDATIONS

39

4-7

47

48

5O

LIST OF REFERENCES

BIBLIOGRAPHY

INITIAL DISTRIBUTION LIST

54

jj ,

r-

-

'

'

:

r.CHOOL

LIST OF TAPLRS

I.

Dimensions of Standard Hal^-ridth Snires

24

II.

Throttle Element ^rranqenents

29

III.

Test Proqraf^ Sui^nary

30

IV.

Pressure Dist r i^^ut ion Data for

Conf ioura t ion 1

33

V.

Pressure Distribution Data for

Configuration 2

34

VI.

Intenrated Velocity Profile Parameters

for Conf iourat ion 1

40

VII.

Integrated Velocity Profile ParaTieters

for Configuration 2

41

LIST OF FIGHRES

1.

Compressor Test Rio

2.

View of the Inlet Belli^outh Without

With (b) a Protective Mesh Screen

3.

(a)

and

Conoressor Bladinq

a.

Flow Path View

7

b.

Stage Tip Section

8

4.

Velocity Oiaqrar^

10

5.

View of the Compressor Test Riq

11

6.

Flectric Motor Drive

12

7.

Throttle Showing Removable Elements

13

8.

Arrangement of the Instrumentation

15

9

Probes

10.

11.

12.

a.

Probe Tip Geometries

16

b.

Views of Probe Tips and Actuators

17

Meriam VJater Micromanometers

a.

Connections to the Probes

19

b.

View of the Instruments

20

Compressor Throttle Section

a.

Element Positions

23

b.

Spire and Plate Elements

23

Spire Element

a.

Circular Arrangement as Built

25

b.

Linear Arrangement as Designed

25

13.

Soire Geometry

a.

As Oesianed

27

t:..

As Built

27

Static Pressure Distribution Ahead of the TGV's

- P-.^ = 7.25 Inches of ^^ater

at =,-

32

15.

Boundary Laver Profiles with Screens

Configuration 1) and Spires (Configuration

35

16.

Deter-ninat ion of the Displacement Thickness

For Configuration 1

14.

17.

2)

42

Determination of the Displacement Thickness

For Configuration

7

43

18.

Comparison of Boundary Layers With and

w'ithout Spires

44

19.

Streamline Location for Uniform Inviscid Flow

45

LIST OF SYMBOLS

p

Cj_^

-

Density

-

Center line

-

Static oressure

-

Static oressure at the case-wall

p^

-

Total pressure

P^

-

Total pressure at the center line

P

-

Radius of the pipe

Local radial displacement

Pg

i

PcV]

r

-

D

-

Diameter

V

-

Velocity

-

Absolute velocity into the rotor blade

-

Absolute velocity out of the rotor blade

~

Reference velocity derived from measurements

-

Velocity at the center line

VI

V2

Voo

(Eq.(2))

V^

-

Local velocity

Wi

-

Relative velocity into the rotor

W2

~

Relative velocity out of the rotor

U

-

Wheel speed

s

-

Spire height

h

-

Compressor annulus height

A

-

Displacement of uniform-flow, inviscid streamline

passing through the spire tip, from the case-wall at

the compressor inlet

V-[

LIST OF SY"POL?

(continueri

)

Boundary layer t^'ijckness

'boundary layer disnlace^ent

~

i -^

: 1

>^

a ra

Value of V/Voo

"'.adial

Pot'^r

thickness

nce

^-t

t*~.e

di snlacer-ent

edne of the boundary layer

in'.;ards

fron the case-wall

inlet relative airflow anqle wit*^ respect to

the axis

Potor outl'^t relative airflow anole

the axis

v/ith

resnect to

"Jotor inlet absolute airflcDw anqle with respect to

the axis

xOtor outlet absolute airflow anqle with respect to

the axis

ACKr'Ov.'LFnC'fi^IT

The

1.

aijt>nr wnuld

nrnfv-.c;snr

R.

i^

li>e to

sion Laboratory,

California and

iJav/al

hi?=

assistance

and

Postoraduate School, "onterey,

staff,

guidance

for their

director of the Turboproou 1-

^^^r^ove,

.

in

Tan Moyle and Thaddeus ^est,

project.

this

benefit

the

fnllov/inM neo^l-:

the

t}-\3n\<

of

VJithout

their

their experience,

T

could not have completed this thesis.

2.

The NTS Photo Division for

their effort

tion on the photoqranhs repaired for

3.

My wife,

and

-ny

Enny Sitepu;

dauphters,

"iy

Mena

sons,

and

rny

and coopera-

thesis.

Suranta and Ferianta;

Sabarina,

sunported ny spirit durinq ny studies.

who

alwavs

P2TP0D^CTT0^'

I.

Axial connressors in aircraft engines are

nearly unifor"^ inlet

boundary layers, but

ranoe of

t'">.at

flow/

nenerally ie-

condition

^/it'-^

are reauired to ooer=ite stablv

inlet flow distortion.

thin

over

a

found in

oractice

-'ulti-staoe core connressors, once develooed,

are tv^en

upry sensitive

anv change

to

the tio-cao result

In view of

in

the

in

rotor blades and the case-wall.

ciency and

It

tin-qap

in

to develop

the need

changes in

compressor effi-

the

loss of stability narqin in

a

betv;een the

In particular,

re'-'uction

a

is

distorted inflov/.

military

aircraft enaines

with improved thrust-to-weiaht ratio and increased tolerance

to distortion,

attention

understand ina the

flow

in.

has been liven in recent

effects of

axial compressors.

tip clearance

A

years to

chanqe

on

the

larqe scale, multistaae axial

conoressor facility, which would allow experimental investigations

to be

made under well-controlled

test conditions,

was installed and prepared for that purpose.

(Re^^.

The first experiment to be conducted in the

one in

which

the tip

clearance will

be

1)

facility

is

increased syste-

m.atically and data will be obtained from instrumentation de-

signed to

flov/

be

field.

limited

resolve

the

important changes

However, the

to the

in

the

internal

results of this experiment would

particular

compressor-face

inlet

flow

conditions which the test installation qenerated.

a

priori,

is

case-wall boundary

importance of the inlet

the

layer profile,

and thickness,

in

ly

The purpose

nap.

Thus,

the boundary layer as

important to chanqe

of

the physical

relation to

gao between the rotor and the case-wall.

clearance

fJnknown,

equal-

is

it

channe the

to

oresent study was

the

to

control the

develop an experimental technique to be used to

boundary layer thickness entering the compressor.

The approach was

removable element

as a

in

a

installed

"spires"

throttle housing in

and design

The presence,

duct.

use an array of

to

the

the throttle,

of

inlet

and the

difficulty of alternate approaches such as providing suction

on the scale

reguired,

that is reported here,

and

a

suggested this solution.

Tn the work

the design of

is

the spires

reviewed

program of measurements to evaluate the effect

spires on the compressor inlet case-wall boundary

reported.

The m.easurements

of

layer,

the

is

showed that the boundary layer

with the spires was thicker than was intended, and

that the

velocity profile was unacceptably distorted.

It was concluded

that compromises which were made

manufacture of the spires, which involved

slender

Also,

cusped shapes with linear cuts,

the installation

within

a

round

qeometry within

data on

of

duct was

a

which the

the

design was

spires as

approximating the

circular array

a

from

tunnel that had

based.

the

were unacceptable.

quite different

larqe wind

in

the linear

provided the

Recommendations were

made for

changes to be

nade to

the soires

goal of doublinq the inlet boundarv layer

changing the shane of the velocity profile.

to

achieve the

thickness without

II

COMPRESSOR AND QPIJRATIOH

.

The compressor

and details of

test facility,

collection method,

data

instrumentation used are '^iscussed

the

in

the

fnllowina sections.

\.

COMPRESSOR

compressor

three-staqe axial

The

with

assembled

desiqned

a

new

to serve

as

a

research

tool for

bladinq, was

variety

a

The facility is shown in Fiqure

experiments.

presently

facility,

synnetrical

desiqn of

of

1.

Two (iifferent sizes of inlet bellmouths were orovided in

measure flow

adjust the pressure differential and

order to

rate to the com.pressor satisfactorily for various staqe con-

fiqurations and operatinq speeds.

larqer bellmouth was used (Ref.

with and without

a

protective

are shown in Fiqure 2.

enters the

throuqh

(Ref.

20-foot lonq

a

1)

3.

mesh screen over

in

the

the

duct containinq

a

inlet,

the airflow

the fiqure,

outside the buildinq

and flows

throttle device

bladinq

the test

inlet quide vanes

first staqe

is

shown

in

the

two

The bladinq is removable and adjustable.

present experiments,

row of

the present work,

Views of the bellmouth,

to the compressor test section.

The compressor

Fiqure

As seen

compressor from

In

2).

in

Fiaure

3

(IGV),

section was bladed

two symmetrical

was removed),

parts of

For the

with one

staqes (the

and one row

of exit

SCO

>=>!

tl=^;

V

J)

u o

^

CJ

u

a

iV

view ne thp Inlet Rellnouth Without (a)

and I'ith (b) 3 Protective riesh Screen

XvXvXv

^ioure

3.

(Continued) Conore!=;sor Tlaciim

(b)

Stane Tin Section

vanes

aui'ie

(EGV).

Each staqe consisted of 30 rotor blades

and 32 stator blades.

The function of the TGV

the radial distribution

of

piaure

is

4,

sv^metrical

the

3,

belt drive

is

radius

(Both the

oroduce

equal to the

an

driven by

ria

a

150

ninimum loss

two-dimensional compressor

to the compressor

is

shown

Figure

in

a

The speed of the

(Fiaure 6).

RP^I

The low speed drive

by

(1610

was used in the present experiment.

The throttle,

located approximately mid-way

inlet bellmouth and the compressor face

spaces

(8

useable)

throttle plates.

7.

The

5.

HP electric motor coupled by

ch?,nqind the belt drive pulleys.

10

At

incidence

compressor can be chanoed nominally from 1600 to 2200

PPM)

in

axial

and 5).

conpressor test

compressor

is

vary with radius.)

designed to

rotor blade

4,

radii.

all

for the correspondinc

cascade (Refs.

The

at

by the

stage design

shown at one

flow angles

TGV is

with resnect to the

incidence

sypnetric

^

velocity diaaran,

velocity comnonent and

each radius,

turn the flow to produce

flow anole renuired

the

rotor in the svr^^retric staqe.

one in which the

to

is

s

The

compressor

throttle

be

the

throttle

chanqed only

is

by

between the

1),

for inserting different

A view of

can

(Fiq.

contained

screens and

shown

in

Figure

stoppinq

the

Symmetric Blading Requires a^=62 & ot2=6l at All Radial Stations.

Figure 4.

Velocity niaqran

10

11

12

13

the connections between

All

the

inlet bell'^outh and the

comnressor were sealed to eli'ninate leaks that niqht effect

the experimental

B.

results.

TNSTRUMF:MTATIO^] AND DATA C0LLF:CT I ^)ri

tlany

The arrangement of

conoressor case.

the present experiments

of

the

is

IGV

8.

pressure distributions

In

Cobra probe were

airflow.

The Kiel probe was

surveys

always

probe was

that the

centerline of the duct.

and the

facing the

installed and held fixed on the

Pressure distributions in the probe

were referenced

to corresponding

values

pressure on the centerline and static pressure at

wall.

9a and

pressure ports on each side of the

connected to the U-tube manometer

such

static

same location (Figure

in the

the latter case,

probe rotated

travers-

a

used similarly to mea-

A cobra probe was

pressure and, by prior calibration,

sure stagnation

b).

the com-

Stagnation pressure

pressor periphery shown in the figure.

impact probe.

inches in

were located 1.0

distributions from tip to hub were m.easured using

ing

in

static

VJali

the selected stations around

at

s

instrumentation used

shown in Figure

survey stations

taps and probe

frorit

along the

oorts for probes are orovided around and

of

total

the case-

The differences between probe total pressure and wall

static pressure

and between

probe

were

pressure

adjusting

twr

'^eriam

probe total pressure

recorded

manually

micromanometers

.

after

and Kiel

carefully

The connections

to

Traverse Probe (Impact Probe)

Center Line Probe (Kiel)

Case-Wall

Static Pressure Tap

Figure

8.

<

Arrangement of the Instrumentation

15

VIEW

A - A

VIEW

B

c=;'^-,

-

,032'*

B

•

A

I

A.

Cobra Probe

VT'

VIEW

C.

Fiqure

(a)

Kiel Probe

9.

Probes

Probe Tip Geometries

16

A - A

^i

Figure

(b)

9.

(Continued)

Probes

Views of Probe Tins and Actuators

and

a

view of the nicromanoneters are shown in Fiaure 10. (a)

and Fiqure 10. (b),

The scales

respectively.

of

the

rieria-ii

manometers were adjusted to zero jefore each experiment.

meter to measure

the

counter and timing

the compressor.

ture

were

resi^ec

t i

vely

total temperature

inlet

using

barometer

a

located insid

gible and no correction

tions

-he

not

and

a

oulse

speed of

building.

required

thermometer

and

Ourina each test

jre was observed to

for change

in

watermanometers was required.

v/ere

digital thermo-

wheel to record the rotational

the change in ambient tempe.

Meriam

a

The local atmospheric pressure and temoera-

measured

,

included

instrumentation

Auxiliary

due to

Air density

the use

velocity derived from the centerline probe.

18

be

water density

of

a

negliin

the

correc-

reference

Kiel Prohe

Static Pressure Tap

Figure 10,

(a)

rieriam V/ater Micromanorneters

Connections to the Probes

19

'^iaure

10.

(Continued)

(b)

Heriam Water iMicromanoneters

View of the Instruments

20

Ill

QOUNDARY LAYE^ CONTROL DEVICE

,

The boun^'^arv

layer control

device

described

is

followinq section and the desi-in intent, actual

in

the

desiqn,

and

construction are discussed.

DESITAT

A.

1

INTE\'T

Requirements and Anoroach

.

boundary

''lor^al

layer conditions at

known to be

5

=

1.1

inches

dary layer thickness

and

5*

=

.13

layer control device.

Either by

could be reduced.

In

the

screens, were

inches.

The boun-

addim

could be chanqed by

wall, or by coolinq the case-wall,

ness

the compressor

from earlier experiments with uniform

inlet,

suckinq air

laver thick-

planned experiment,

required, to increase the boundary laver thickness

factor of two and obtain measurements with

of

the

tip clearance

in

the case-

at

the boundary

boundary

a

it

(5*)

was

by a

different values

the compressor.

Thus,

it

would be

possible to obtain data at two values of tip clearance while

holding

the

ratio

of

boundary to

clearance

tip

[6*/t]

constant.

To increase

elements

reiected.

readily

6*

by a factor of

and graduated

The

for

rouqhness

tests

with

case-wall rouqhness

two,

screens were

elements

both

could

thin boundary

21

considered, but

not be

layers.

removed

Previous

experience with

suqqested that

graded screens

to produce axi-symmet

difficult

(graduated screen

uniformity with

r ic

2

installed

blank throttle elements as shov/n in Fiaure

the

one

in

11.

Pes iqn

.

The system

produce

spires

of

boundary

thickened

particularly

tunnels,

in

has been

layers

experiments

previously to

used

rectangular

in

simulation of the atmospheric boundary

7).

In

Reference

Table

I

produced

were given for

a

used in the

for the

a

to account

configuration and annular

The spire

flow con-

geometry and total number

spires were selected using the information in Reference

for experiments carried out

in

a

wind tunnel.

spire configuration was chosen for the

to avoid possible

in

These data were

but were corrected

present design,

traction (Figure 12).

the data

non-dimensional spire qeometry that

known boundary layer thickness.

circular duct

the

layer (Ref.

based on many experiments,

7,

wind

required

which

careful

of

larqe

a

located so far from the compressor face.

The approach taken was to use "spires"

of

would be

it

A

7

29-element

circular arrangement

resonance due to the wakes from the spires

interacting with the

30

blades of the rotor.

1.5"

1

2

3

A

3.

^le-^ent Positions

b.

Fioure 11.

5

6

7

9

10

Spire and Plate Eler^ents

Conpressor Throttle Section

23

TAT

DI^E^ISIONS OF stan:.

HEIGHT

:

-^.D

I,

HALF--WIDTH SPIRES

SPIRE WIDTH

0.5000

0.0016

0.3750

0.0111

0.3100

0.0167

0.29 3 3

0.0250

0.2733

0.04 17

0.2483

0.0833

0.2100

0.12 50

0.1850

0.1667

0.1650

0.2500

0.1350

0.3333

0.1117

0.4167

0.0917

0.5000

0.0750

0.5833

0.0600

0.6667

0.0450

0.7500

0.0333

0.8333

0.0217

0.9167

0.0117

1.0000

0.0

a.

Circular ^rranaenent as Built

)

Linear Arranqer-ent as Designed

.

FIGUPF 12.

Spire Elenent

25

B.

CONSTRUCTION

qeometry (Fiqure 13(a) could not

The spire

and therefore,

locally,

linear cuts

as

from aluminum

in

Figure 13(h).

alloy,

.25

inches thick,

were arranged uniformly in

attached

tav

three flush,

the

of

the

rim

the screws were

throttle

screen was

ring

rina.

a

aooroxinated

was

the j^hape

shown

he nachine^

The shane

and

the

with

was cut

29-elements

Fach snire was

circular ring.

countersunk Phillips-head screws to

Mo locking

wire was necessary since

prevented from backing out hy

installed in

the throttle

positioned dov/nstrean

of

housing,

the spires

any possibility of dam.aae to the compressor.

the adjacent

and

a

to prevent

(a)

As Desiqned

Piqure 13.

(b)

Spire Geometry

27

As

Built

Tf^ST

IV.

program consisted

test

The

PROGRAM

exploratory flow

of

field neasure^ents

detailed boundary layer surveys to

the snires on

the effect of

the compressor

A.

nunber

a

initial,

of

and then

series of

a

establish quantitatively

the boundary

thickness at

layer

face.

PRELIMI^TARY TEST

conductinq

^^efore

establish an

conducted to

elements

detailed flow

the throttle

in

one which

open throttle

stall and

It was

was

and spire

by

selected

a

The desired through-

removed

was well

boundaries on the

from both

compressor map.

found during this procedure that the position

spire element in

were

similar average

a

that produced

combination of screens only (Ref. 8).

flow condition

tests

arrangement of screen

which produced

through-flow to

mass rate of

surveys,

the throttle housing was

of

important.

the

Less

stable compressor operation was found when the spire element

was the

tests,

most downstream

the

element.

two arrangements

As

a

summarized in

Table

selected, and the test program summarized in Table

carried out.

28

these

result of

II

Illf

were

was

THROTTLE ELEMENT

LOCATIOM

UPSTREAM

co^'^^iGijRArrox

(1)

screen: o^:ly

SC^EE\

C0>:

FIGURATION

(2)

SCRFEM

&

il

SCREEN *3

SCREEN #5

SCREEN ^1

29

|

I

S^IRE

TARLR iir

1

TEST PROGRz\M S(U1MARY

1

TFIPOTTLE ELEMENT

TEST

CONFIGURATION

SURVEYS

1

1

COBRA PROBE

2

1

IMPACT PROBE

&

KIEL PROBE

3

2

IMPACT PROBE

&

KIEL PROBE

KIEL PROBE

&

STATIC PRESSURE DISTRISUTION flEASURETlEMTS

B.

In Test

tion

a

1,

establish

with the throttle elements

1,

survey

was conducted

outer to inner case-wall.

The procedure

confiquraorobe to

cobra

oressure

distribution of static

the radial

was to measure

using the

in

in

fror^

this experiment

"indicated" static pressure trom the side

the

holes of the cobra

orobe as

step-by-step from

was moved

it

the outer wall to the inner.

The relationship of the cobra

probe "indicated" static pressure was established

usinq the

case-wall static pressure and cobra orobe measurements adjaThe survey measurements were individually

cent to the wall.

referenced to

total

pressure from

probe

the Kiel

at

the

center of the axial line A-A (Figure 8).

so obtained

The static pressure

It

is

seen

to decrease linearly

is

from,

shown in Figure 14.

the wall

(Pc

)

to

the

hub surface.

C.

BOUNDARY LAYER MEASUREMENTS

In

Tests

2

and

3,

surveys

were made using

orobe from the outer case wall to where the

became

constant.

almost

(configuration

configuration

in

15,

of

1)

2

and test

(Table II).

Test

3

2

was

with

was with the spire

The results

the impact

impact pressure

screens only

element

in

are shown plotted

Pigure 15 and listed in Table IV and Table V.

In

Figure

the value of the velocity measured on the center line of

the annulus has been used to normalize the profiles.

s^j

Figure 14.

(Inches of VJater)

Static Pressure Distribution Ahead of the Inlet

at P^

-Psw = 7.25 inches of \Jater

Gui(ie Vanes

TABLE IV.

PRESSURE DISTRIBUTION DATA FOR CONFIGURATION

Ri = RADIAL DISPL. INWARDS FROM CASE-WALL,

PRESSURES ARE IN INCHES WATER

V/Vp

^L

-^1

1

V/Voo

0.01

7.100

-.060

7.040

-.0902

.0923

0.02

7.092

-.318

7.058

-.0656

.0671

0.1

3.410

3.6466

7.075

.7018

.7179

0.2

2.3195

4.9920

7.197

.8142

.8328

0.3

1.539

5.5672

7.073

.8673

.8872

0.4

1.078

6.0044

7.038

.9030

.9237

.9264

.9467

.9814

0.5

.755

6.3286

7.048

0.7

.38 8

6.7828

7.043

.Q594

0.9

.185

6.9750

7.060

.9717

.9948

1.1

.010

7.1472

7.125

.9792

1.0016

1.5

-.010

7.3271

7.065

.9798

1.0018

2.0

-.0465

7.2882

7.061

.9980

1.0184

2.5

.0

7.3402

7.6500

.9987

1.0187

3.0

.065

7.3518

7.0835

.9991

1.0188

3.4

.071

7.3967

7.1890

.9915

1.0143

3.6

.070

7.4400

7.110

1.0000

1.0299

3.8

.101

7.4702

7.149

1

.0002

1.0225

4.2

.009

7.5859

7.1590

1.0068

1.0293

4.5

.006

7.6200

7.126

1.0109

1.0340

5.8

.091

7.7524

7.199

1.0015

1.0337

6.0

.012

7.6776

7.117

1.0153

1.0386

•

1

1

PRESSURE DISTRIBUTION DATA FOR CONFIGURATION

R^ = PADIAL DISPL. INV7ARDS FROfl CASE-WALL,

PRESSURES ARE IN INCHES WATER

V/Vc^

^c,

Ri

0.01

7.009

.02

-.2179

--w

7.216

v/v»

-.1710

-.1737

6.690

.4292

7.1170

.2419

.2456

0.1

3.800

3.2621

7.051

.6698

.6802

0.2

2.634

4.4082

7.0850

.7768

.7887

0.3

2.090

5.0133

7.07

.8292

.8421

0.4

1.848

5.4029

7.207

.8529

.8658

0.5

1

.84

5.3526

7.191

.8495

.8627

0.7

1.733

5.5393

7.195

.8614

.8748

0.9

1.497

5.7915

7.189

.8839

.8976

1.1

1.397

5.7872

7.062

.8915

.9053

1.5

1.373

6.1133

7.193

.9078

.9219

2.0

1.000

6.36 3 2

7.141

.9295

.9439

2.5

.915

6.3938

7.123

.9308

.9474

3.0

.484

6.7183

7.136

.9555

.9703

3.4

.032

6.8056

7.157

.9891

.9799

3.6

.156

7.4020

7.178

1.0000

1.0155

3.8

-.117

7.5492

7.264

1.0000

1.0194

4.2

-.227

7.9146

7.221

1.0310

1.0469

4.5

-.911

8.1556

7.098

1.0556

1.0719

5.8

-.411

8.1954

7.143

1

.0550

1.0771

6.0

-.337

8.1086

7.105

1.0520

1.0654

34

BOUNDARY LAYER

.

.

-«^0.1 0.0

.

0.1

M

OJ

l

I

0.9 0.4 0.5 0.6 0.7 0.8 0.9 1.0

1.1

IJ

1.9

V/V(1NF)

Screens

Figure 15. Boundary Layer Profiles With (Conf iqurat ion

(Confinuration 1) and Spires

^

35

2)

ANALYSIS AND DISCUSS lOM

V.

report describes

section of the

This

to

the neasurenents

results of

in

the method

thickness,

boundary layer

calculate the

used

discusses the

cornparison with

the desiqn

expectation, and sunimarizes the results.

A.

DISP LACEP1ENT THICKNESS

CALCrjLA.TK^M OF

The displacenent

the present v/ork was

Pgs.

=

+

1/2

(Pt-

)

9)

configuration

and for conf iqura t ion

1

in

The nethod was as follows:

qives, at any

rad ial stat ion

.

(1)

based on total pressure

Va,f

static pressure at the wall,

and

2

P^i2

The reference velocity,

centerline

.13

inches.

.53

Bernoulli's equation (Ref.

Ptt.

obtained for

thicl-'ness

from earlier experiments waS

the

at

(P^

)

is

^'..^

^Cl

given by

Pt

=

Cr,

Ps

^Cr

+

1/2

Using the results given

static pressure

pVco

-

Pc

=

7.25

(2)

Figure 14, which shows

in

dropped linearly

from the tip to the hub at

P,.

^

a

to -0,8

distance of

inches of water,

36

h =

inches

7.2

that the

of water

inches,

at

—

0.11

=

]

(7-4] =

n.ni53Ri

(3)

^Cl

Usinq

equations (1),

each ooint

(R^)

and

(2)

the

(3),

for configuration

(2)

is

ratio of velocitv at

given,

in

the static pressure distribution for configuration

+

terms of

1,

by

0.0153Ri

(4)

"sw

^tc,

and the centerline velocity by

VCL

=

Using

/

Equation

1

+

(4)

(5)

0.0153Ri

and

Equation (5),

the

ratio

of

velocity at the centerline

velocity at each point to the

the

is

given by

(6)

37

From experiment

-

P»-

and

P^

P^ ^i

W

^Cl

i

The

Location from the case-wall to the hub.

configuration

profiles for

shown

and

(

Figure

in

6

)

boundary layer

conf iaurat ion

and

1

are known at each

P_

which are

2

were obtained using Eguations

15

(5),

(4),

.

The boundary layer displacement thickness was deternined

from boundary

layer profile data before normalising

passane centerline

displacement

(y)

of

Referring

velocity.

to

the

the following

and area A-2 were calculated

the area A-1

sketch,

to

for each

the probe from the case-wall using

-

if

A-1

=

A-2

then y

v/v„

x-y

-J^d

-

At - /^(i -

where

X

total area

is

T7^) dy

^)

^y

(6)

=

^-1

the "free-stream" value of

under the

boundary

38

layer

(7)

V/V„

and A^ is the

profile.

The

areas

described by equations

tion of

y

to

were plotted as

a

funcThe

(7)

results for configuration

data listed

and

determine the dispacement thickness (6*).

1

Table VI.

in

(8)

are shown

Fiqure 16, with the

in

The results

for conf iqurat ion

2

are shown in Fiqure 17, with the data listed in Table VII.

R.

CO^'lPARISO^I

1

.

WITH DESIGN INTENT

Boundary Layer Thickness

The

effect

layer thickness

illustrates the

boundary

of

the

spire element

clearly to increase

is

effect

of

layer profile

on

and

5

6*

spire element

the

and the

boundary

the boundary

layer thickness.

the

layer can

qeometry of

a

combined

However,

chanqinq the shape of the

results

shown in

Fiqure 18,

layer thickness

with the

spire element

the

with

the qoal

by

the

is

doubling of the overall and displacement thick-

nesses without

in

inches.

to 0.53

clearly be controlled

the spire,

selection and position of the screens.

to produce

4.5

thickness was increased from 0.13

The boundary

inches.

selecting

18

both the

on

The overall thickness was increased from 1.1 to

The displacem.ent

Figure

.

the

profile. Clearly,

overall boundary

exceeds

the half-

heiqht of the compressor annulus.

We first examine how far the effect of the

be expected to extend when the

compressor annulus.

the

streamline

from

spire should

flow from the duct enters the

Referring to Figure 19, the position of

the

tip

of

the

spire,

when

it

TABLE VI.

1

1

INTEGRATED VELOCITY PROFILE PARAMETERS EOR

CONFIGURATION 1

|

y

Ri

/

(1-V/V„)dy

0.0

1

x-y-J (1-V/V„)dy

o

o

A^-/ (1-V/V<„)dy

o

.1473

0.0

0.0

0.1

.0461

.0539

.1012

0.2

.0703

0.3

'

.1297

.0770

2

.2138

.0611

7

.3023

.0483

0.5

:

.39 38

.0411

0.7

.1177

.5823

.0296

0.9

.1246

.7754

.0227

1.1

.1295

.8705

.0178

1.5

'"7

...._

""7

0.4

.

2.0

/

/

/

/

2.5

/

/

3.0

/

/

/

/

/

3.4

1

1

1

3.6

.1473

3.4527

0.0

3.8

.1473

3.6527

0.0

4.2

.1473

4.0527

0.0

4.5

.1473

4.3577

0.0

5.8

.1473

5.6527

0.0

6.0

.1473

5.8537

0.0

1

1

TABLE VII.

1

1

1

INTEGRATED VELOCITY PROFILE PARAMETERS FOR

CO^JFIGURATION

Y

Ri

/

y

(l-V/V„)dY

o

0.0

2

Y

x-y-J (1-V/V„)dy

0.0

A^-/ (1-V/V„)dv

o

o

1

.5716

0.0

0.1

.0536

.0470

.5130

0.2

.0901

.1210

.4815

0.3

.1140

.20 27

.4576

0.4

.1343

.3880

.4473

0.5

.1537

.4741

.4179

0.7

.1933

.5456

.3783

0.9

.2262

.7238

.3454

1.1

.2580

.9032

.3136

_____

""1

1.5

2.0

1

/

/

1

/

2.5

/

1

/

/

3.0

1

/

/

3.4

I

/

/

1

1

3.6

/

3.8

/

/

1

/

1

1

1

4.2

/_

/

1

4.5

.5716

4.1786

0.0

5.8

.5716

5.5501

0.0

6.0

.5716

5.7620

0.0

1

41

LEGEND

XY-lNT(l-V/y(INF))pY

0.6

o.e

X

Fiqure 16.

Determination of the Disolacement

Thickness for Configuration 1

42

Fiqure 17.

Determination of the Displacement

Thickness for Conf iqurat ion 2

43

•

o

1

3-

•

!

3-

1

•

3-

•i

P

51

*3

i

LEGEND

lO

•i-

M-

9

3-

i t

O

5* (Config. 2)

p

C[_/

3-

6* (Config.

o

-0^0.1 0.0

0.1

ojt o.a 0.4 o.s o.a 0.7 o.a o.o 1.0

1.1

u

i.a

1.4

1.9

V/V(INF)

Fic]urtj

la.

Comparison of Boundary Layers

With and Without Spires

44

1)

the conpressor

approaches

blading can be

calculated

usin-i

the continuity' equation,

pAV

constant

=

assumino the airflow

(

unizorm and axial at

is

Then the streamline displacement

is

both stations.

compressor face

the

at

(A)

9

niven by

Ptt(r2

-

(P.-s)^)

^

pTT(p2

-

(R

-

A)^)

pTr(R2

_

(r

_

h) 2)

defined

in

Figure 19.

(10)

PTT

r2

where the notation

the

spire,

=

S

8

is

inches,

height at station

2,

eguation (10),

4.56

iment

in

Figure

from the

inches

results given

of spires

in

Ref.

the airflow extends

7,

height.

The difference

tunnel results

layer in

to approximately

comparison,

In

the effect of a

the

of

applied in

may be

spire height from

between the

the

the

in

linear arrangement

the test section

arriving at

due to

data in

the circular

of

six spire heights downstream,

approximately only 0.8

This factor was

the annulus

and

Using these

the effect

case-wall.

on the boundary

large wind tunnel,

inches,

The height

The results from the expp^-

inches.

show that

18

18

inches.

7.2

h =

arrangement on

spire

4.5

A =

R =

the

of a

extended to

the wall.

present spire

present and the

wind

significantly different

blockage presented by the spires to the pipe flow, or may

result from the bluntness of the present shapes.

46

2

.

Profile Shane

conoaring

In

the two

sir-nificant difference

noted.

Pirst,

departure

away

fron the wall,

sinnle power-law profile.

There

dient in the velocity deficit

dary layer.

This

is

the soire shape used

to

enphasize

Fiqure

in

noticeable

there is

sioniFicant

a

seen to be

one

are

from a

2

a

sharp gra-

out to the edpe of

the boun-

is

nrobably the result of the bluntness of

in

the experinients

the necessity

cusped profile shown

13,

sinilarity

orofile shape for conf iqurat ion

the

in

profiles

and one

to achieve

Fiqure

in

The results appear

.

very slender,

the

rather

13(a)

than

use the

blunt approximation shown in Fiqure 13(b).

Second,

profile close

the

affected by the spires.

of

turbulence

in

seems

wall

little

This may be the result of the level

inherent

the pipe-flov;

in

rouqhness, but suggests that

a

to the

and

thicker boundary layer using spires which

is

pipe-

the

nay be difficult

it

to produce

also similar

profile shape both near to and far from the wall.

3

.

Other Considerations

The

degree

of

axi-symmetry

briefly

examined

was

during the experiments by rotating the spire element

throttle

housing.

detected, however, the data

reasonably representative

The degree

of

Fiqure

in

of

unsteadiness

the

in

47

in

non-uniformity

peripheral

Some

18

are believed

average

the flow,

the

was

to be

radial behavior.

which

made

it

difficult

during probe surveys,

stable readings

to obtain

did not measurably affect the accuracy of the nean velocityprof i les

C.

REQUIRED CONTROL

-'XCHievING THE

The velocitv nrofile shown for configuration

18

can be characterized

as

nearly uniform

a

1

in

Fiqure

with

flow

well-defined turbulent boundary layer at the case-wall.

velocity profile shown for conf iaurat ion

ized as

a

a

The

can be character-

2

irregular case-wall boundary layer, or

very thick,

alternately described as

wholly distorted velocity profile

a

across more than half the compressor blade height.

Since

compressor investiga-

the purpose of the overall

tion is to examine the effects of tip gap on

and performance

flow field

tip clearance gap size

blade height,

than the

radial

of

distortions

in

which

investigation.

boundary layer must

small

compared

This

a

range of

very much

always

smaller

make sense to introduce

is

not within the scope of

Any variation in the case-wall

be confined

to the

in

the flow field which extend over much

the span of the blading.

the proposed

is

does not

it

the compressor

characteristics,

to a

blade height

which remains

scale

or

the

investigation

becomes one of investigating inlet flow distortion.

spire

Thus,

if

necessary

to

order

recover

to

elements

use the

the

are to

be used,

original, sharply

asymptotic

outer

cusped

it

is

very

spires in

boundary

layer

profile Shane.

5

of

A

reduction

in

the spire heiqht

inches, nay be necessary to achieve no more

the natural

boundary lavor thickness.

to

(^

or even

than doublino

CONCLUSIONS AND RECOMMENDATIONS

VI.

this study,

In

exoer imental ly

two was intended,

experinent

a

spires

^irst,

approximated

the present

circular pipe, with

turbulence

levels

control

to

the present arranqement was based,

slender cusped

the

the

in

The

present

the

in

on which

are thought

shape of the

present case

thicker profile which could be nachined with

Second,

factor of

a

large rectangular wind tunnels,

in

understood.

spires was

between results

obtained usinq

and results

boundary layers

the design of

nhile an increase

factor close to four was measured.

differences

quantitative

and shown

the case-wall

the thickness of

and disolacenent thicknesses by

the overall

to be

spires was designed

of

increase

layer at the connressor inlet.

boundary

in

rim

a

to

by

a

blunt,

straight cuts.

installation of the spires was

within

much laraer area blockage

and higher

a

present in

than were

wind

the

a

tunnel

anpl icat ion

It was

found

installed in the

element in

order

that the

ring-element of

throttle upstream

to reduce

of at

oscillations

spires

least

in

the

must be

one screen

flow and

vibrations in the compressor to acceptable levels.

The

following

recommendations

are made

achieve the intended boundary layer control:

50

in

order

to

1.

The

orioinallv

specified

neomet rica 1

spire elenents should he nachined,

for

reasons of

exoense.

should be reduced to

2.

The inlet

"^

or

oipe iunctions

The

5

shane of

without conpromise

heiqht

of

the

spire

inches.

should he

snoothed and all

flanged connections should he tiqhtlv sealed.

51

the

REFERENCES

Evaluation of the PerforT^ance and Flow

i-Jaddell, J. L.

S

Thesis, Naval Postgraduate

in an Axial Coripressor

School, Monterey, California, October 1932.

,

^

""I

.

.

Pressure

Distribution

The

in

a

Tobiason, E. A.,

Naval

M.S. Thesis,

Postgraduate School,

Bel l^outh

Monterey, California, June 1973.

,

AT-i.erican Institute of Aeronautics and Astronautics,

Turbine and Rocket

^eroth.ernodynanics

of

Gas

Inc.,

Propulsion Gates, G. C, Editor, 1984.

,

Design of

Staff of Lewis Research Center,

Aerodyna^iic

Axial-Flow

Co^^nressors

NASA SP-36,

reproduced by

National Technical

Information Service,

Washington,

D.C., 1965.

,

Vavra, M. H.,

Aerothermodynanics

machines Uiley, New York, 1974.

Flow

and

in

Turbo-

,

Zucker, R. D.,

Aeronautics,

California.

Aerodynamic Analysis

Department of

Naval

Postgraduate School,

Monterey,

,

Standen, N., M.,

A Spire Array

for Engineering

Thick

Turbulent Shear Layers for Natural wjnd Simulation in

tJind Tunnels

Ottawa, Canada, 1972.

,

TPL Technical Note 82-01,

Waddell, J. L.,

Multistage

Compressor - Flow Losses in Throttle Screens and ^lates,

Feburary 1982.

Zucker, R.

Publishers,

D.

,

Inc.,

Schlichting, H.,

Inc.,

1979.

Fundamental

of

Gas

Dynamics,

Matrix

1977

Poundary-Layer

Theory

,

M.cGraw-Hill

BI3LrOGRAPHY

^.

I

A

,\

Fduca t ion

Con'^onep ts

,

Series, Aerot'iernodvnanics of Aircraft. Fnnine

(jorrion

C.

^

Cat-^-,

"^

i

:^ r

,

l-jr, 3

.-^/-inos u"^ on r'lov/ Research on '^laiin':],

c'-.e

"^low Research on Bla>iim

Brown, '^overi

Co"^^a^y Limited,

Baden, Switzerland, 1969.

'rnc^-^i,-

: i -v :.M

•>»:

L

,

Sc

'J.

H. and La^

S. ^., Principles of ^luid "'echanics

\ddison l/esley Publishing Conoany, 1964

Li,

,

Goldstein, p. J., Fluid 'Mechanics Measurements

Pub 11 shim Cor nor at ion, 1933.

,

,

Hemisphere

Moyle, I., Progress Report - Multistage Axial Conoressor

Progran on Tip Clearance Effects \PS Contractor Reoort

(MPS67-31-01CR)

"'ay 1979 - August 1981.

,

,

Dearock

Peviev^

,

,

R.E., Blaie Tin Gap Effects in Turbo^ach i nes Final Report No MPS67-8 1-0 16

October 198U.

\'PS

\

,

McKligot, Cant. D.M., Uniform inlet Conditions for the MPS

Subsonic Cascade Wind Tunnel Project Report, NPS No.

NPS67-31-019PR, January 1981.

,

I. and Zebner, H., Multistage Compressor Installation of Cast-Enoxy Blades TPL Technical rJote 80-05,

October 1980.

Moyle,

,

Mcyle, I. \'., Multistage Compressor - Initial Measurement

One Stage of Symmetrical Blading TPL Technical Note

80-09, October 1980.

;;ith

,

Neuhoff, F., Calibration and Application of a Combination

Temperature-Pneumatic Probe for Velocity and Rotor Loss

Distribution '^leasurements in a Compressor NPS Contractor

Report No: NPS-67-81-03CR, December 1981.

,

53

IMITI/\L

DISTRIBUTION LIST

No.

of Copies

Defense Technical Information Center

Caneron Station

Alexandria, Virginia 22304-6145

2

Super inten jent

Library, Code 0142

Attn:

Naval Postgraduate School

Monterey, California 93943-5000

2

Chair-^an

1

Department of Aeronautics and Astronautics, Code 67

Naval Postgraduate School

Monterey, California 93943-5000

Professor R. P. Shreeve, Thesis Advisor

Director, Turbooropuls ion Laboratory, Code 67Sf

Department of Aeronautics and Astronautics

r]aval Postgraduate School

Monterey, California 93943-5000

4

Naval Air Systems Command

(Attn:

AIR 931E)

Washington, D.C. 20361

1

Naval Air Propulsion Center

(Attn: Vernon Lubosky)

P.O. Box 7176

Trenton, New Jersey 08628

1

Professor G. J. Walker

Department of Civil and Mechanical Engineering

University of Tasmania

GPO Box 252C

Hobart, Tasmania 7001

Austral ia

1

Dirpers, Mabes TNI-AU

1

Jl Gatot Subroto 72

Jakarta,

INDONESIA

Dirdik, flabes TNI-AU

Jl Gatot Subroto 72

Jakarta, INDONESIA

Komandan Koharmatau

Lanuma Husein Sastanegara

Bandung, INDONESIA

.

1

2

INITIAL DISTRIBUTION LIST (CONTINUED)

No.

11.

Perpustakaan PT Dirgantara

Lanuma Husein Sastaneqara

Banduna, INDONESIA

12.

Muliukur Tarigan

Komplek Kartanegara D-5

Singosari-Malang

INDONESIA

13.

Director S. M. A. Negeri

Kaban jahe

Sumatera Utara

INDONESIA

14.

of Copies

.

1

4

1

Wing Pesbang 30

Lanunia Abd

Saleh

1

.

Malang

INDONESIA

15.

Perpustakaan

Lanuma Abd. Saleh

Malang

INDONESIA

16.

Wing Pesbang 10

Lanuna Husein Sastraneqara

Bandung

INDONESIA

17.

Perpustakaan I.T.B.

Bandung

INDONESIA

18.

Perpustkaan Universitas U.S.U.

Medan, Sumatera Utara

INDONESIA

1

19.

Perpustakaan Universitas Dirgantara

Lanuma Halim P.

Jakarta

INDONESIA

1

20.

Marie Hashimoto

Department of Aeronautics and Astronautics, Code 67

Naval Postgraduate School

Monterey, California 93943-5000

1

1

1

1

55

jThesis

T13835

c.l

Thesis

T13835

c.l

Tarigan

ww^^m

Development of a

boundary layer

control device

for tip clearence

explrj!

-ents in an axial

coT

pressor.

Tarigan

Development of a boundary layer control device

for tip clearence experiments in an axial compressor.